Class A, Painted Automotive Plastics Parts from 100% Post-Consumer Recycled PP Classification: Public EXHIBIT 99.1

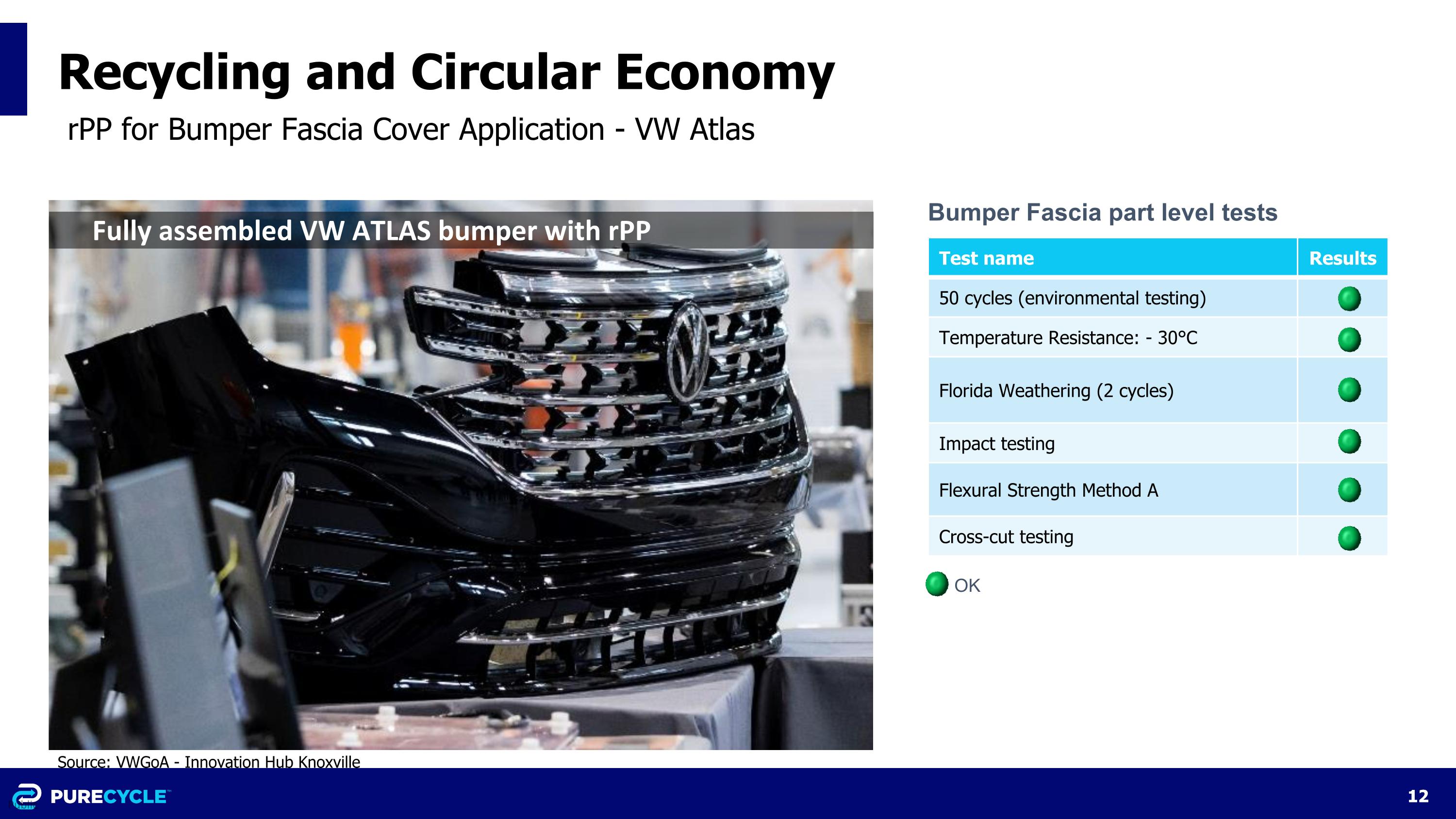

Recycling and Circular Economy rPP for Bumper Facia Cover Application - VW Atlas Fully assembled VW ATLAS bumper with rPP Source: VWGoA - Innovation Hub Knoxville

EU Commission's proposal on ‘End of Life Vehicles’ Regulation (ELV) Published 13th of July 2023 To enhance the circularity of the automotive sector, covering the design, production and End of Life treatment of vehicles Applies mainly to passenger cars and SUVs Ensure that at least 25%1 of plastic used to build a vehicle comes from recycling (of which 25% from recycled ELVs)2 Circularity Requirements Design for Circularity End of Life Vehicle Management Extended Producer Responsibility Recycled Content Target for new vehicles. (Source: PlasticsEurope3) Challenge: high-quality PCR materials “The recycled content target shall enter into force … 2030” Motivation * Proposal draft may reduce to 20 % EU Parliament Revises End-of-Life Vehicle Rules, Lowers Recycled Plastic Targets End-of-Life Vehicles - Environment - European Commission 2024.11.14-Plastics-Europe-position-ELVR.pdf Government Response: EU ELV Directive Proposal

Plastic Bumper Recycling “Recycling Plastic car bumpers could prevent over a million pounds of waste from landfills annually”1 Today the average new car bumper is made from multiple types of plastic and may have integrated lights, turn signals, reflectors, wiring harnesses, mounting brackets and sensors Removing and separating the parts to get to the bumper core is time-consuming and costly 1. Recycling Plastic Car Bumpers Could Prevent Over A Million Pounds Of Waste - Auto Recycling World March 4, 2021

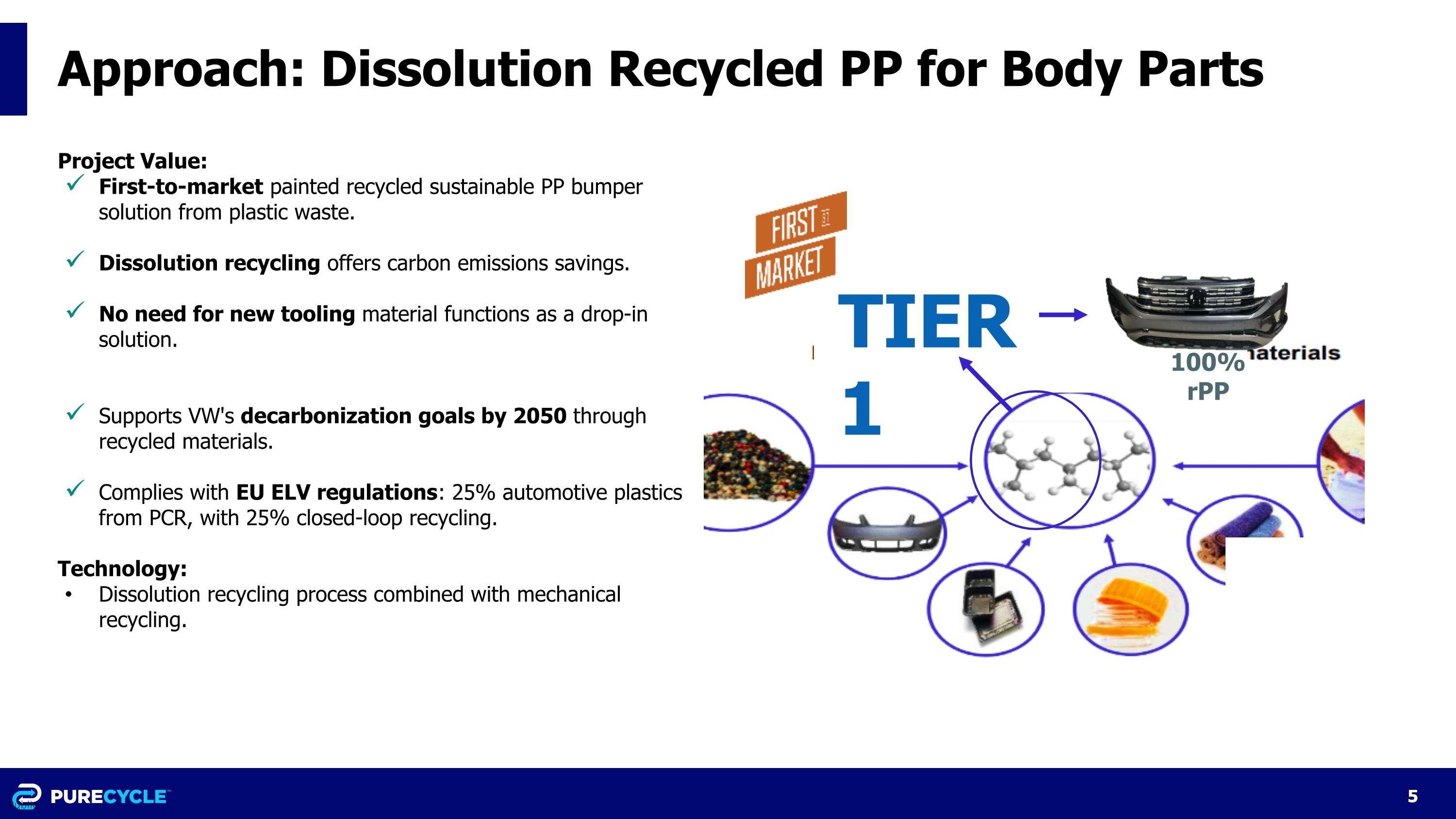

Approach: Dissolution Recycled PP for Body Parts Project Value: First-to-market painted recycled sustainable PP bumper solution from plastic waste. Dissolution recycling offers carbon emissions savings. No need for new tooling material functions as a drop-in solution. Supports VW's decarbonization goals by 2050 through recycled materials. Complies with EU ELV regulations: 25% automotive plastics from PCR, with 25% closed-loop recycling. Technology: Dissolution recycling process combined with mechanical recycling. 100% rPP TIER 1

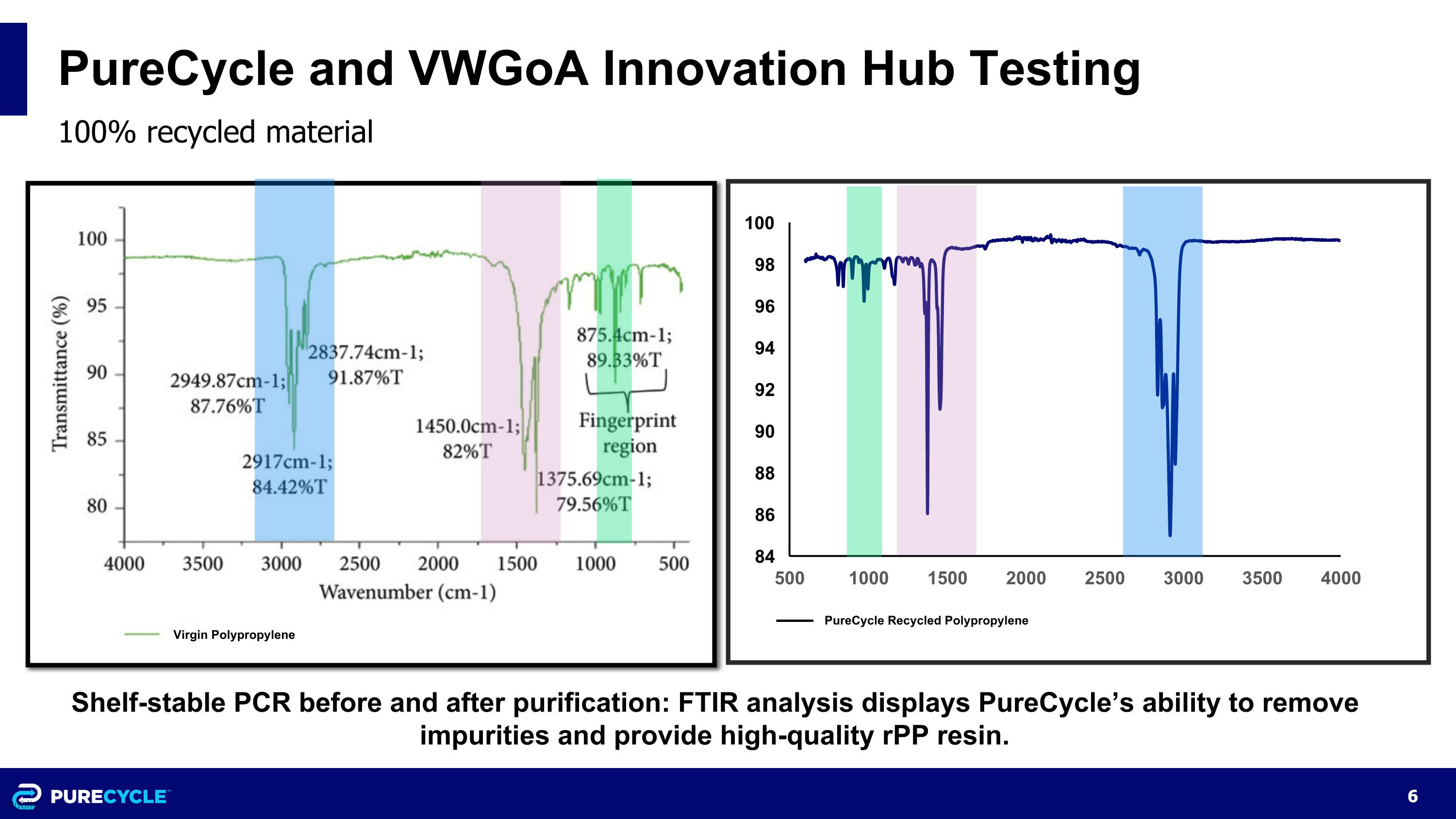

Shelf-stable PCR before and after purification: FTIR analysis displays PureCycle’s ability to remove impurities and provide high-quality rPP resin. Virgin Polypropylene PureCycle Recycled Polypropylene PureCycle and VWGoA Innovation Hub Testing 100% recycled material

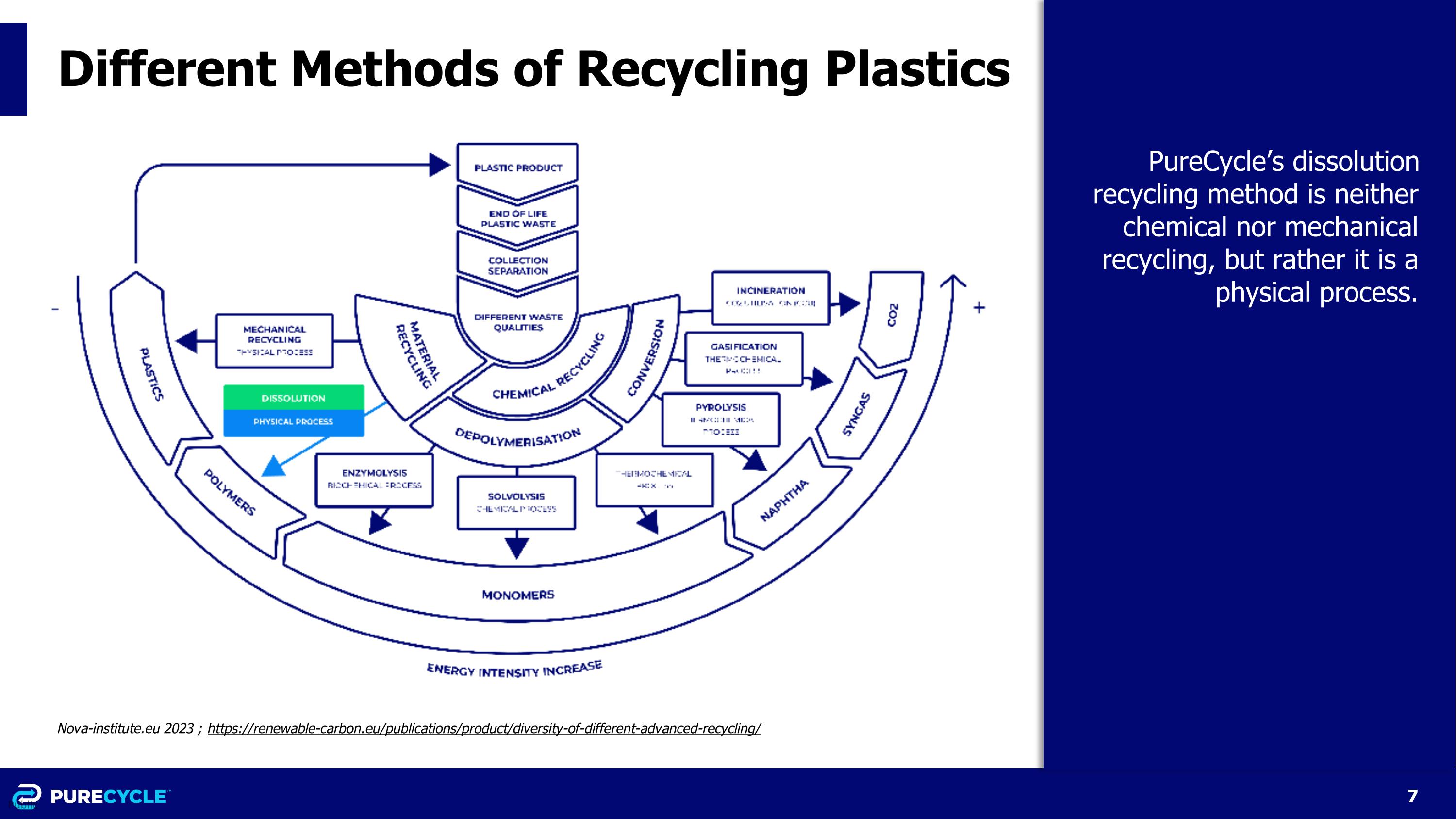

Different Methods of Recycling Plastics PureCycle’s dissolution recycling method is neither chemical nor mechanical recycling, but rather it is a physical process. Nova-institute.eu 2023 ; https://renewable-carbon.eu/publications/product/diversity-of-different-advanced-recycling/

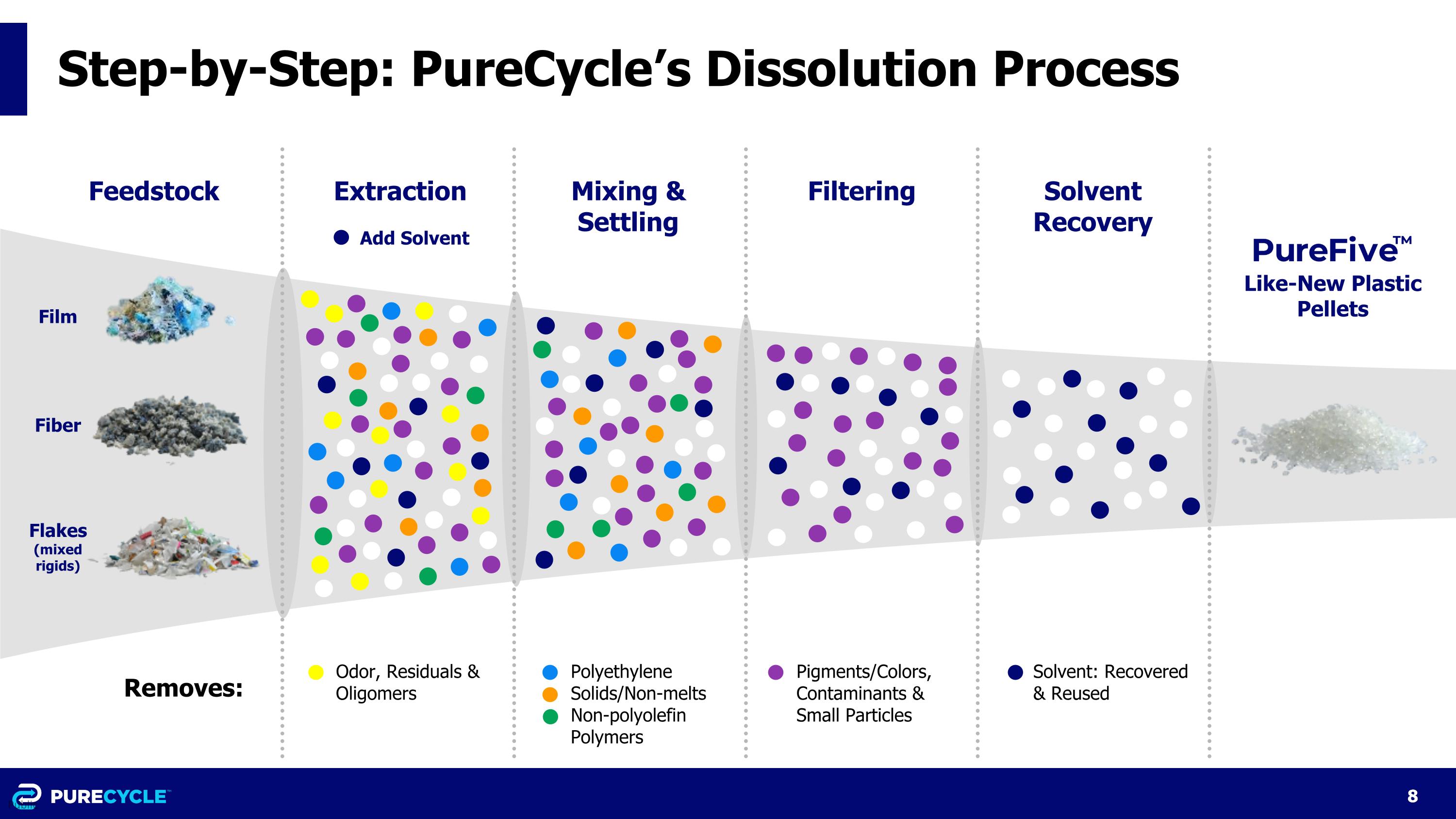

Step-by-Step: PureCycle’s Dissolution Process Extraction Mixing & Settling Filtering Solvent Recovery Film Odor, Residuals & Oligomers Polyethylene Solids/Non-melts Non-polyolefin Polymers Pigments/Colors, Contaminants & Small Particles Solvent: Recovered & Reused Like-New Plastic Pellets Feedstock Flakes (mixed rigids) Fiber Removes: Add Solvent

PureFive™ Resin in Fiber Applications Fiber Made from rPP Fiber Package PureCycle Resin Finished Product - Carpet

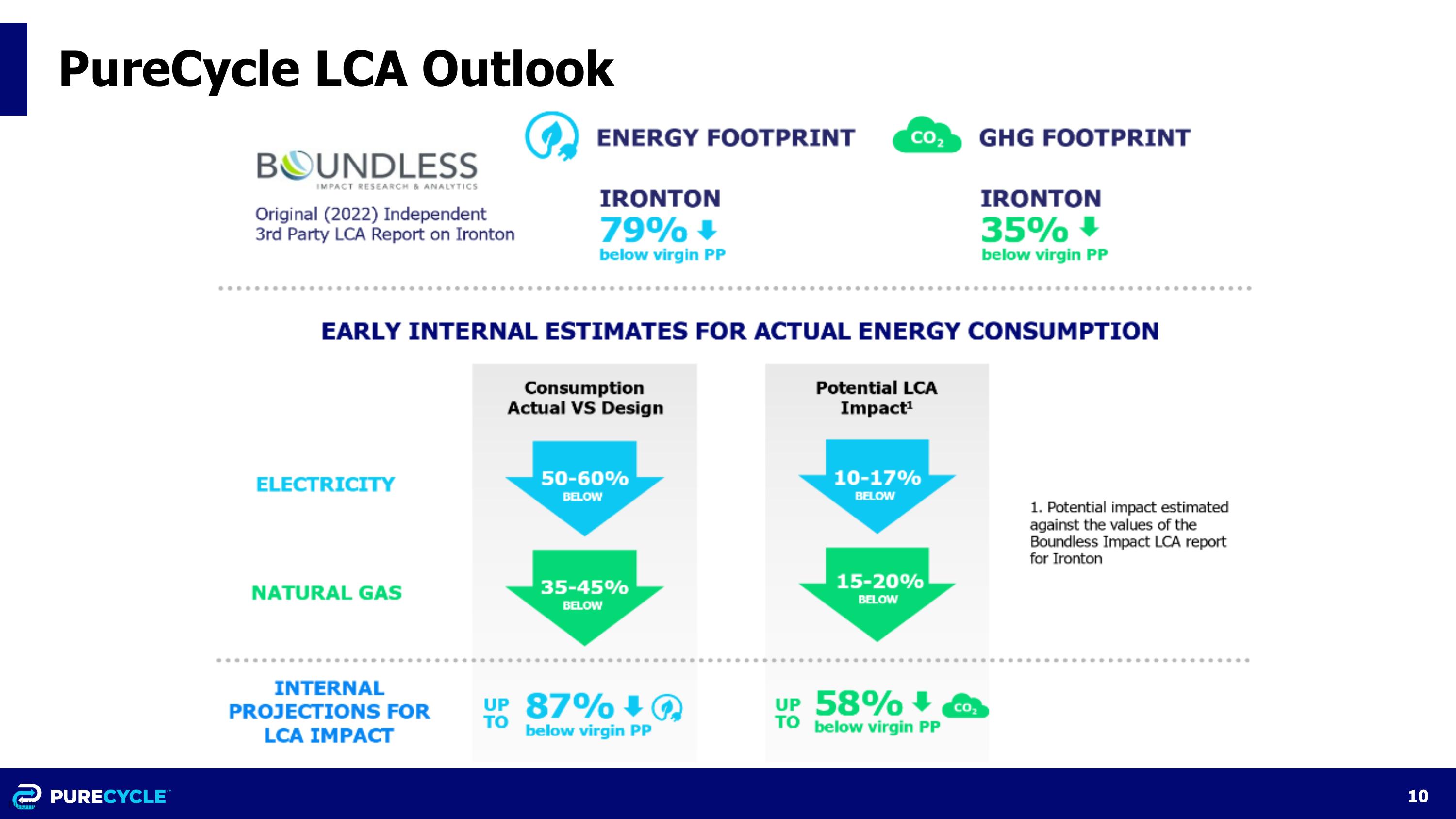

PureCycle LCA Outlook

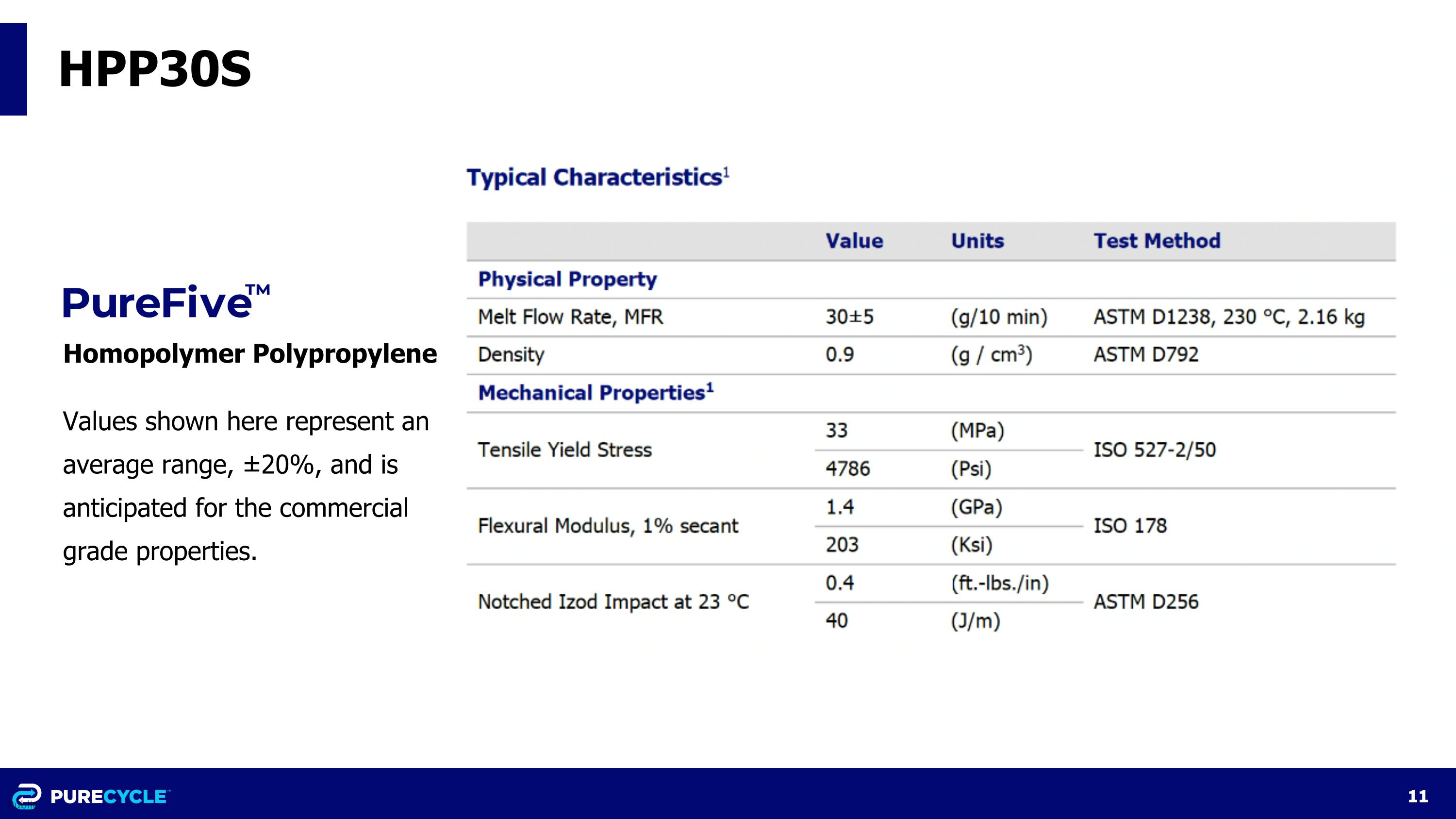

Homopolymer Polypropylene Values shown here represent an average range, ±20%, and is anticipated for the commercial grade properties. HPP30S

Recycling and Circular Economy rPP for Bumper Fascia Cover Application - VW Atlas Bumper Fascia part level tests Test name Results 50 cycles (environmental testing) Temperature Resistance: - 30°C Florida Weathering (2 cycles) Impact testing Flexural Strength Method A Cross-cut testing OK Fully assembled VW ATLAS bumper with rPP Source: VWGoA - Innovation Hub Knoxville

Thank You