Exhibit 10.5

Vendor

Agreement

Section 1 of 3: Legal

Revised: Aug 2023

| ||

| 1 |

Contents

| A. | Introduction | 3 |

| Definitions | 3 | |

| B. | Terms and Conditions | 4 |

| C. | Representations and Warranties | 4 |

| D. | Ethical Conduct Policy | 6 |

| E. | Conflict Minerals | 6 |

| F. | Insurance | 7 |

| G. | Product Recall Policy | 8 |

| H. | Disposition of Rejected Goods | 9 |

| Appendix A | A-1 | |

| Appendix B | B-1 | |

| Appendix C | C-1 | |

| ||

| 2 |

A. Introduction

Five Below is committed to processing merchandise efficiently, safely, and in compliance with all applicable federal, state and local laws, rules and regulations. By doing so, we are able to offer our customers exciting merchandise at a great value.

We have made significant investments within our Supply Chain network to speed the delivery of product to our stores. This includes highly automated distribution centers that are capable of conveying, sorting, and cross-docking product. To leverage these investments, it is required that all vendors ship product in case pack quantities that are packed in corrugated cartons that are shippable and conveyable, unless otherwise agreed to in writing by Five Below. This will allow us to serve our customers by accelerating the flow of merchandise and leveraging every cost dollar along the way.

We appreciate your support in helping us ensure that every order is shipped to arrive in a safe, timely and efficient manner.

Definitions

As used herein, capitalized terms shall have the meanings assigned to them in Five Below’s then current Purchase Order Terms and Conditions (the current version of which is attached here as Appendix A). Appendix C is a list of all states in which Five Below currently operates. In addition, the following capitalized terms are defined as follows:

“Applicable Law” means all applicable laws, ordinances, rules, regulations and orders of all foreign nations (or governmental subdivision thereof) and all applicable domestic (United States of America) federal, state, and local laws, ordinances, rules, regulations and orders pertaining to the production, sale and shipment of the goods.

“Buyer” means Five Below.

“Factory” or “manufacturing plant” means a building or group of buildings where goods are manufactured or assembled.

“Goods” or “goods” means the items of merchandise (including components and related packaging, labeling, instructions, product descriptions, printed matter and visual and digital information) that are the subject of any Purchase Order.

“Preferred Compliance Auditor” means Five Below’s preferred firm for factory audit and shipment inspections in China or in any other countries from which Goods are manufactured or sourced. Five Below’s current Preferred Compliance Auditor(s) can be found in the Compliance section of the Vendor Agreement.

“Preferred Specialized Testing Lab” means Five Below’s preferred laboratory for microbiological, TRA, USP 51, USP 61, and 62 testing of Goods in China (or in any other countries from which Goods are manufactured or sourced) and for all product testing, shipment inspection and factory audit services in India. Five Below’s current Preferred Specialized Testing Lab, which may be changed at any time by Five Below, can be found in the Compliance section of the Vendor Agreement.

| ||

| 3 |

“Preferred Standard Testing Lab” means Five Below’s preferred laboratory for standard testing of Goods. Five Below’s current Preferred Standard Testing Lab, which may be changed at any time by Five Below, is Bay Area Compliance Labs (“BACL”).

“Merchandise Buyer” means an employee of Five Below who is authorized to purchase goods from Vendor.

“Purchase Order Terms and Conditions” means Five Below’s then current Purchase Order Terms and Conditions (the current version of which is attached here as Appendix A).

“Vendor Agreement” means the Company’s Routing, Packaging and Vendor Compliance Guide then in effect and as modified from time to time by the Buyer (current versions with updates will be available upon request by Vendor).

B. Terms and Conditions

By signing the Five Below Vendor Agreement Vendor Acknowledgment, and in consideration of the right to sell Goods to Five Below to be offered for sale by Five Below in its stores and online, and for other good and valuable consideration, the receipt and sufficiency of which is hereby acknowledged, Vendor agrees to comply with all of the terms, conditions, and requirements set forth in this Vendor Agreement, including but not limited to the Purchase Order Terms and Conditions attached hereto as Appendix A. This Vendor Agreement together with the Purchase Order, Purchase Order Terms and Conditions, the terms contained in Five Below’s online system (or any successor system thereto), any other written and signed agreement(s) entered into between Five Below and Vendor (including any agreements entered into through Five Below’s online systems), and any attachments, instructions, or requirements furnished to Vendor by Five Below are considered one integrated agreement governing all aspects of the relationship between Five Below and Vendor. All representation, warranties, covenants and terms applicable to Vendor contained in any of the foregoing shall be considered cumulative obligations of Vendor.

NO ORDERS ARE GIVEN BY BUYER VERBALLY OR IN WRITING EXCEPT BY AN OFFICIAL PURCHASE ORDER. PROJECTIONS OR ESTIMATES ARE NOT ORDERS NOR DO THEY CONSTITUTE ANY OBLIGATION OF BUYER. PRODUCTION COMMITMENTS OR RAW MATERIAL REQUIREMENTS (INCLUDING BUT NOT LIMITED TO RESERVATION OF PRODUCTION SPACE AND/OR OF RAW MATERIALS BY VENDOR) ARE FOR PROJECTION AND PLANNING PURPOSES ONLY AND IN NO WAY FORM OR CONSTITUTE AN OBLIGATION ON THE PART OF BUYER.

C. Representations and Warranties

In addition to, and not in limitation of, the representations and warranties in the Purchase Order Terms and Conditions, Vendor further represents and warrants to Five Below as follows:

| (1) | In obtaining, selling and delivering Goods to Five Below neither Vendor nor anyone affiliated with or representing Vendor has or will breach any agreement with or commitment or representation to any third party and there is no impediment or restriction, legal or otherwise, that limits, prohibits or prevents Five Below from reselling the product to its customers; |

| ||

| 4 |

| (2) | The Goods shipped, as of the date of shipment, comply with, and are not adulterated or misbranded within the meaning of the Federal Food, Drug and Cosmetic Act, as amended (“FDCA”), including, without limitation, the Food Additives Amendment as further amended and also comply with, and are not adulterated or misbranded within the meaning of, any state’s food and drug law; |

| (3) | The Goods shipped, as of the date of shipment, are not articles that may not be introduced into interstate commerce pursuant to Sections 404 or 405 of the FDCA, or otherwise, and conform to all rules, bans, standards or regulations of or under the Consumer Product Safety Act (“CPSA”) and the Consumer Product Safety Improvement Act of 2008 (“CPSIA”) and will include a Certificate of Compliance for children’s products or a General Compliancy Certificate for other CPSA regulated products as required under the CPSIA; |

| (4) | Each shipment or other delivery of Goods is not misbranded or mislabeled under the Federal Hazardous Substance Act (“FHSA”) or any other Applicable Law, and if applicable, has been tested and approved by any approved third party, including the Underwriters Laboratory, Inc. or the ETL, and the National Sanitation Foundation. |

| (5) | Each shipment or other delivery of Goods will comply in all material respects with all Applicable Laws (including those enforced by the CPSC) governing product safety, product content and labeling, and shall include a Certificate of Compliance supplied by Vendor or maintained on Vendor’s internet accessible electronic platform to comply with applicable requirements of CPSIA §14(a); |

| (6) | Each shipment or other delivery of Goods will, if constituting or containing an economic poison as defined in the Federal Insecticide, Fungicide, and Rodenticide Act, be registered pursuant to said Act and comply with all other provisions of such Act; |

| (7) | Each shipment or other delivery of Goods will conform to the applicable flammability standards and other requirements under the Federal Flammable Fabrics Act and any other Applicable Law applicable to textiles, fabric, bedding and/or furniture and all Goods that contain textile fiber products shall be properly branded and invoiced in accordance with the Textile Fiber Products Identification Act and any other all Applicable Laws with respect to such products; |

| (8) | The Goods meet all applicable Occupational Safety and Health Administration Standards; |

| (9) | Each shipment or other delivery of Goods containing electric appliances, component parts and wiring shall be listed by either the Underwriters Laboratories, Inc. or the ETL and be in compliance with applicable electrical codes or other Applicable Laws; |

| ||

| 5 |

| (10) | Each shipment or other delivery of Goods does not require a warning under California Proposition 65 or, if it requires a warning, a warning in a form which complies with the requirements of California Code of Regulations Title 27, Division 4, Article 6 is provided on the product or product labeling for the Goods. Vendor must notify Five Below that Goods require Proposition 65 warning at the time of item set up. Five Below has the right to reject or cancel orders for Goods where a Proposition 65 warning is required; and |

| (11) | As required by Applicable Law, Vendor will maintain copies of all Safety Data Sheets and like documentation for any Goods and will, upon request by Five Below, provide Five Below with copies of such documentation promptly. |

D. Ethical Conduct Policy

Vendor represents and warrants to Five Below that it will obey and conform to all Applicable Laws, and is in full compliance with all Applicable Laws, including, without limitation, those relating to anti-bribery and anti-corruption (including without limitation, the US Foreign Corrupt Practices Act, the US Travel Act, the UK Bribery Act 2010, and any and all similar provisions in the jurisdiction(s) in which it operates). Vendor represents and warrants that it has not and will not engage in any activity, practice or conduct which would constitute an offense under those requirements, and that it has in place its own policies and procedures adequate to ensure compliance with these anti-bribery and anti-corruption provisions by its officers, employees, agents and any other third party or person associated with Vendor in the performance of services or shipment of goods to Five Below.

Five Below’s expectation is that no Vendor producing Goods for Five Below will attempt to circumvent Five Below’s quality process through unethical conduct. We rely on our laboratories to assist Vendors to certify products to be in compliance with Applicable Laws by providing unbiased test reports. Attempts to alter test results, submit samples of Goods to labs that do not accurately represent final production, influence third party inspectors or auditors, or force laboratories to certify non-compliant product through exertion of undue influence is strictly prohibited. No Vendor or factory may circumvent Five Below’s requirements through modification, substitution, alteration or withholding information in test reports, factory audits, shipment inspections, etc.

E. Conflict Minerals

The SEC adopted the Conflict Minerals Provision, Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act (Dodd-Frank Act), to require publicly-held companies to publicly disclose their use of conflict minerals that originated in Covered Countries. At this time, Covered Countries include the Democratic Republic of Congo and its adjoining countries, including: Angola; Burundi; Central African Republic; the Republic of Congo; Rwanda; South Sudan; Tanzania; Uganda; and Zambia. The rule applies to all products manufactured on or after January 31, 2013, and according to the legislation, columbite-tantalite, cassiterite, wolframite and gold ore – which are refined into tantalum, tungsten, and gold, are considered Conflict Minerals.

| ||

| 6 |

Five Below does not directly purchase raw conflict materials for products we sell and is committed to complying with the reporting requirements under the conflict minerals rule.

Vendor understands that Five Below does not require, mandate or control the materials used on Goods ordered by Five Below from Vendor. Vendor represents and warrants that it shall not utilize, nor allow any other third party to utilize, any Conflict Minerals which are sourced from Covered Countries in any goods or components of goods, or in the production of such goods or components of goods, manufactured or produced by Vendor for Buyer under a Purchase Order or otherwise. This representation and warranty by Vendor is based on personal knowledge and/or written guarantees provided by Vendor’s suppliers. Five Below may require Vendor to provide due diligence documentation relating to Conflict Minerals, including formal certifications and policies and Vendor shall promptly comply with any such requests.

F. Insurance

Vendor shall, at its own cost, obtain and maintain insurance as required by Five Below’s then current Purchase Order Terms and Conditions.

INSURANCE. Vendor shall maintain and require its subcontractors to maintain:

| (a) | Commercial General Liability (CGL): Covering CGL on an “occurrence” basis, including products and completed operations, property damage, bodily injury and personal & advertising injury with limits no less than $5,000,000 per occurrence. Claims made policies are not accepted; |

| (b) | Automobile Liability, including owned, hired and non-owned vehicles (Employers’ Non-Ownership Liability), at a limit not less than $1,000,000; |

| (c) | Statutory Workers’ Compensation in compliance with state laws and Employers’ Liability with limit of no less than $500,000 per accident for bodily injury or disease; |

| (d) | Property Insurance on all materials that are part of this Purchase Order until such time as the materials are accepted by Buyer. In addition, Vendor is required to provide its own Property Insurance for its own equipment, materials and tools that are used by Vendor which are not part of this Purchase Order; and |

| (e) | any other insurance, as may be required by law. |

If Vendor maintains broader coverage and/or higher limits than the minimums shown above, Buyer requires and shall be entitled to the broader coverage and/or higher limits maintained by Vendor.

Vendor must submit a Certificate of Insurance (Accord 25-S) to Buyer in compliance with the above requirements. The certificate should:

| (a) | Designate Buyer, its affiliates, subsidiaries, and their respective successors, assigns, customers, and users of its products as additional insured with respect to liability arising out of goods or services hereby ordered from Vendor on a primary and non-contributory basis (even for Buyer’s sole negligence) on both your general liability and automobile liability insurance policies. It is specifically agreed by Vendor that Buyer’s policies of insurance are in excess of any coverage to be provided by Vendor to Buyer as Additional Insured. |

| ||

| 7 |

| (b) | Include a waiver of subrogation in favor of Buyer, its affiliates, subsidiaries, and their respective successors, assigns, customers and users of its products on Vendor’s property, general liability, automobile liability and workers’ compensation insurance policies. Vendor agrees to obtain any endorsement that may be necessary to affect this waiver of subrogation, but this provision applies regardless of whether or not Buyer has received a waiver of subrogation endorsement from Vendor or Vendor’s insurer. |

Vendor waives all rights of recovery or subrogation against Buyer for damage caused by fire or other perils to the extent covered by Property Insurance required pursuant to this Vendor Agreement and/or Five Below’s then current Purchase Order, whether or not such damage was caused by the negligence, strict liability or other actions or in-actions of Buyer, general contractor/construction manager or Buyer, or not.

| (c) | Contain a provision for notice of cancellation, non-renewal, or material change to Buyer of not less than thirty days. | |

| (d) | Be addressed to Certificate Holder and Additional Insured as follows: |

Five Below, Inc.

1616 Holdings, Inc.

701 Market Street

Suite 200

Philadelphia, PA 19106

All coverage must be underwritten by licensed insurance companies rated no less than A- VII by A.M. Best.

Self-Insured retentions of $50,000 or more must be declared and approved by Buyer.

Vendor shall require and verify that all subcontractors maintain insurance meeting all the requirements stated herein, and Vendor shall ensure that Buyer is an additional insured on insurance required from subcontractors.

Buyer reserves the right to modify these requirements, including limits, based on the nature of the risk, prior experience, insurer, coverage, or other circumstances.

G. Product Recall Policy

In the event of any and all product recalls that are either (i) agreed upon between Vendor and Five Below, or (ii) that are required (either by law or in the commercially reasonable judgment of Five Below) because Five Below has reason to believe the Goods are defective, dangerous, incomplete, infringe upon intellectual property rights or are not in compliance with applicable laws or regulations, the Goods will be returned to Vendor at Vendor’s expense, or otherwise disposed of by Five Below, at Five Below’s discretion. This expense will include (a) a 12% product handling fee; (b) incoming and return freight charges; (c) reasonable attorneys’ fees of Five Below; and (d) any and all other expenses, fees, or costs incurred by Five Below in connection with such recall.

| ||

| 8 |

In the event of a recall, Vendor shall immediately provide to Five Below any information requested by Five Below, including, without limitation, the following:

| ● | List of all affected items by Five Below SKU, UPC, Description and Vendor Style # |

| ● | Specific production lots/batches, if applicable, (including instructions and photos on how to locate the batch information) |

| ● | Detailed description of the issue/reason for recall |

| ● | List of governmental agencies involved, if any |

| ● | RTV information |

| ● | Recall poster PDF for posting in stores and on Five Below’s website, including UPC information |

Any consumer-level recalls must be provided to the Five Below Merchandise Buyer and QA-Compliance department in advance of public release. In no event shall Five Below be named in a recall unless specifically agreed in writing by Five Below prior to issuance of such release.

For additional detail on the Five Below product recall process, see Five Below’s current Policies and Principles Governing Product Recalls, the current version of which is attached here as Appendix B.

H. Disposition of Rejected Goods

With respect to Goods that Five Below has rejected (or revoked acceptance of), Five Below will return Goods to Vendor, except Five Below may elect not to return Goods in the following circumstances: (i) in the event Vendor and Five Below have agreed that Goods will not be returned to Vendor, (ii) in the event Vendor fails to authorize the return of Goods within 20 days after Five Below’s notice of rejection or revocation, (iii) in the event the return of Goods is precluded by act of any government agency, regulatory authority or third party, (iv) in the event Five Below has reasonable cause to believe that Goods contain defect or hazards that could create a substantial risk of injury to any person or property. Goods not returned by Five Below may be disposed of by Five Below in its sole discretion. With respect to any Goods disposed of or returned by Five Below, Vendor will be liable for all costs and expenses related to the disposition or return, including any standard processing fees charged by Five Below, any freight, store, and disposal or destruction costs.

With respect to Goods designated as ‘Fail’ by Five Below’s designated third party shipment inspection partner at the Vendor’s overseas factory, Five Below’s QA-Compliance and Merchandising departments will determine disposition of failed Goods (rework, re-inspection or accept as it is, or provide other specific directions), at their sole discretion.

| ||

| 9 |

Appendix A

Five Below Purchase Order Terms and Conditions

| ||

| A-1 |

Five Below

Purchase Order Terms and Conditions

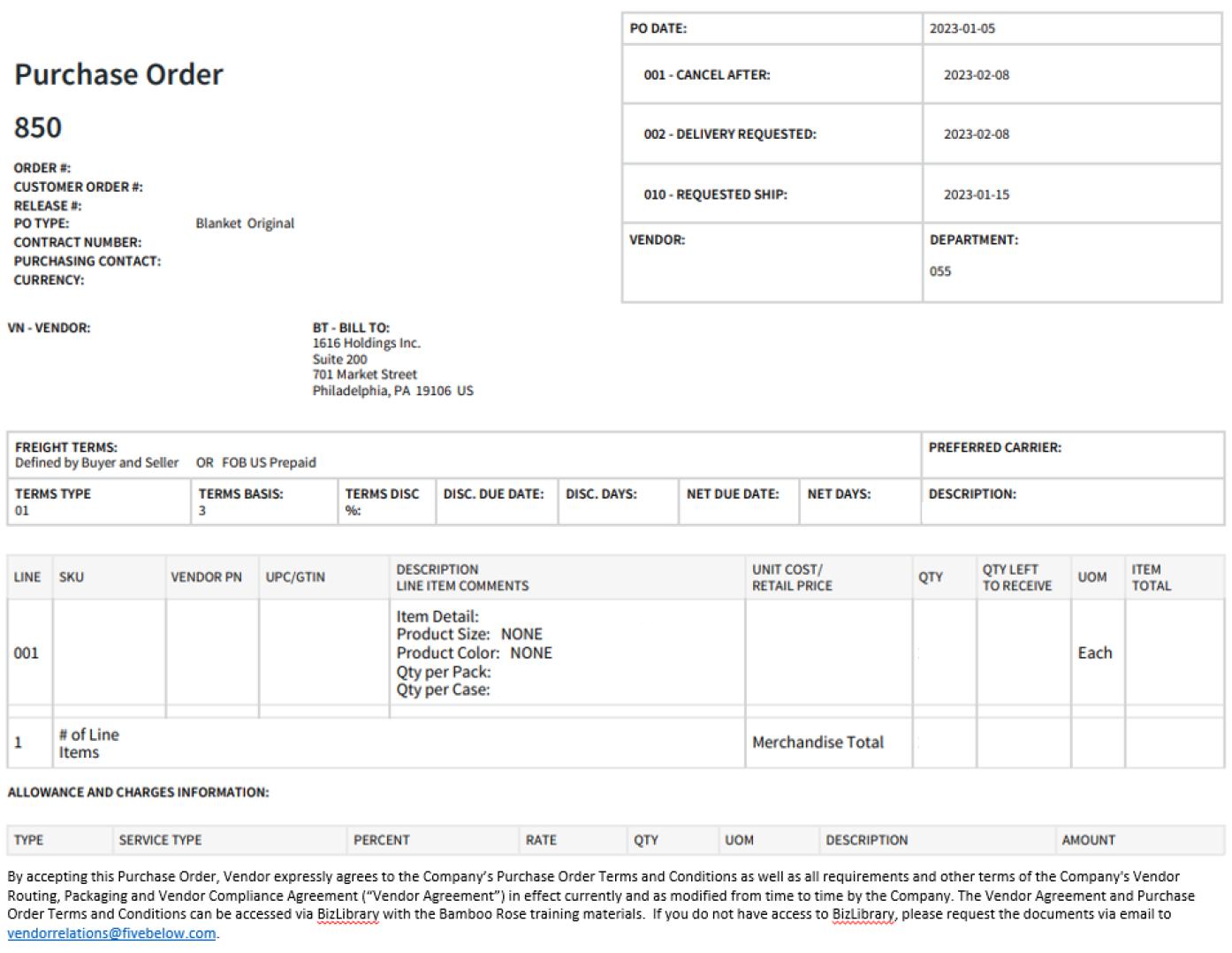

The following terms and conditions shall apply to transaction(s) between the parties, including those described in applicable purchase order(s) between Five Below, Inc., 1616 Holdings, Inc. and/or one of more of their respective subsidiaries or affiliates (as designated on the Purchase Order, the “Buyer”) and the entity shown as the Vendor thereon. Whenever a term defined by the Pennsylvania Uniform Commercial Code (“UCC”) is used herein, the definition contained in the UCC shall control. As used herein, the term “Purchase Order” or “PO” shall mean these Purchase Order Terms and Conditions together with a document entitled “Purchase Order” issued by Buyer to Vendor with a Purchase Order Number and detailing specific order details and other information.

NO ORDERS ARE GIVEN BY BUYER VERBALLY OR IN WRITING EXCEPT BY AN OFFICIAL PURCHASE ORDER. PROJECTIONS OR ESTIMATES ARE NOT ORDERS NOR DO THEY CONSTITUTE ANY OBLIGATION OF BUYER. PRODUCTION COMMITMENTS OR RAW MATERIAL REQUIREMENTS (INCLUDING BUT NOT LIMITED TO RESERVATION OF PRODUCTION SPACE AND/OR OF RAW MATERIALS BY VENDOR) ARE FOR PROJECTION AND PLANNING PURPOSES ONLY AND IN NO WAY FORM OR CONSTITUTE AN OBLIGATION ON THE PART OF BUYER.

| 1. | ACCEPTANCE. A Purchase Order is not an acceptance of any offer to sell but is an offer to purchase. A Purchase Order shall constitute no more than Buyer’s offer to purchase goods from Vendor in accordance with these Purchase Order Terms and Conditions and any additional terms and conditions expressly set forth or incorporated by express reference on the Purchase Order or herein, including, without limitation, the Company’s Routing, Packaging and Vendor Compliance Guide (the “Vendor Agreement”) in effect and as modified from time to time by the Buyer (current versions with updates will be available upon request by Vendor) (collectively, “terms and conditions”). When Vendor accepts a Purchase Order, the Purchase Order (together with these terms and conditions) collectively constitutes a binding contract between the parties. Acceptance of this Purchase Order is expressly limited to these terms and conditions. Any terms and conditions proposed by the Vendor in the Vendor’s quotation, invitation, acceptance, acknowledgement, invoice, transmittal or any other document which is different from, conflict with or add to these terms and conditions shall be deemed to materially alter the terms and conditions and are hereby objected to and rejected by Buyer. Acceptance of this Purchase Order, including acceptance of these terms and conditions shall occur upon the earliest occurrence of any of the following events: (i) receipt by Buyer of written acknowledgement that Vendor has accepted this Purchase Order, or (ii) receipt by Buyer of notification that Vendor has commenced performance hereunder, or (iii) tender or purported tender by Vendor of conforming goods and/or services. All dollar amounts on Purchase Orders and as used herein are in United States Dollars unless explicitly stated otherwise. |

| 2. | CHANGES. No change shall be undertaken except upon express written authorization of Buyer. Buyer may at any time, by written notice, make changes within the general scope of this Purchase Order in the packaging, methods of shipment, quantities, place of delivery or delivery schedules. If any such change causes an increase or decrease in the costs of, or the time required for Vendor’s performance, an equitable adjustment shall be made in the price or delivery schedule, or both, provided a written request for such an adjustment shall be made to Buyer within ten business days from the date of Vendor’s receipt of notice making the change and this Purchase Order shall be modified accordingly by written change order. Nothing contained herein shall relieve the Vendor from proceeding, without delay, to perform this Purchase Order, as changed. |

| 3. | QUALITY, PACKING, TICKETING AND DELIVERY. Goods must be of the appropriate quality, packed, ticketed and shipped in accordance with the terms and conditions contained in the Vendor Agreement. The time of delivery is of the essence, however, Buyer has the right to request Vendor to delay or accelerate any particular shipment, and Vendor shall use commercially reasonable best efforts to accommodate any such request. If a tender of conforming goods is not made by the scheduled delivery date, Vendor shall have no right to make a later conforming tender. Vendor shall bear the risk of loss to the goods purchased hereunder until received and accepted by Buyer. Unless designated otherwise on the face of this Purchase Order by Buyer, all goods ordered hereunder must be shipped FOB Point of Destination as designated on the face of this Purchase Order by Buyer. |

| ||

| A-2 |

| 4. | WARRANTIES. Vendor warrants that all goods or services furnished hereunder (i) will conform to applicable specifications, including those specified in the then current Vendor Agreement, and samples, (ii) will be merchantable, (iii) will be of good material and workmanship and free from defects, (iv) will be fit and sufficient for the purposes intended, if such intent is known to Vendor, (v) will be free from all liens and other, encumbrances, and (vi) will not be designed, manufactured or otherwise produced in violation of any patent, trademark, copyright, trade secret or other intellectual property right existing anywhere in the world. In addition, Vendor represents and warrants that it shall not utilize, nor allow any other third party to utilize, any so called “Conflict Minerals” (such as gold, columbite-tantalite, cassiterite, and wolframite (and their respective metal derivatives, Gold, Tantalum, Tin, and Tungsten), as defined in Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act (as amended from time to time and including rules and regulations thereunder, “Dodd-Frank”), which are sourced from “Covered Countries” (such as, without limitation, the Democratic Republic of Congo), also as defined in Dodd-Frank) in any goods or components of goods, or in the production of such goods or components of goods, manufactured or produced by Vendor for Buyer under the Purchase Order or otherwise. These warranties are in addition to all other warranties, expressed or implied, and survive acceptance of and payment for any and all goods or services ordered, and the warranties run to Buyer, its successors, assigns, customers and users of its products. |

| 5. | INSPECTION AND TESTS. All goods ordered hereunder and Vendor processes will be subject to inspection and testing by Buyer at all reasonable times and places, including Vendor’s facilities. It is expressly agreed that inspections and/or payments prior to, at the time of or after delivery do not constitute a final acceptance of the goods or services. Buyer’s inspection, discovery of any breach of warranty, failure to make an inspection or failure to discover any breach of warranty does not constitute a waiver of any of Buyer’s rights or remedies whatsoever. |

| 6. | CONFIDENTIALITY. All know-how, methods, marketing strategies, specifications, prices, costs, business plans, purchasing data, research and development data, customer lists and/or information, and other data, whether written or oral, (collectively, “Confidential Information”) furnished by Buyer to Vendor, or otherwise learned by Vendor as a result of its vendor relationship with Buyer, is proprietary to Buyer, and Vendor agrees to keep all such Confidential Information confidential and use such Confidential Information only as necessary in order to fulfill Vendor’s obligations to Buyer under Purchase Orders placed by Buyer with Vendor. Vendor further agrees to return to Buyer all Confidential Information, including all copies thereof made by or for Vendor, upon Buyer’s request. Excess inventory of goods ordered hereunder made by or for Vendor (and not purchased by Buyer) with the use of Confidential Information, or including Buyer’s trademarks or trade names, or trademarks and trade names of Buyer’s customers, shall be destroyed by Vendor at Vendor’s expense. Vendor shall not in any manner advertise or publish the fact that it has furnished or contracted to furnish to Buyer the goods or services herein mentioned without prior written consent of Buyer. Vendor agrees that all information furnished or disclosed to Buyer by Vendor in connection with this Purchase Order is furnished or disclosed as part of the consideration for this Purchase Order. Notwithstanding the foregoing, if Vendor clearly identifies, in writing, information that Vendor considers to be confidential or proprietary, Buyer will protect and not disclose such information, except for information: (a) which is already known to Buyer; or (b) which is or becomes generally available to the public through no fault of Buyer; or (c) which is properly obtained from a third party who has the right to make such disclosure; or (d) which is independently developed by Buyer. |

| 7. | EQUIPMENT, BUYER’S PROPERTY. All equipment, tools, material, vehicles and/or other articles required for Vendor’s performance of this Purchase Order shall be furnished by Vendor, maintained in good condition, and replaced when necessary at Vendor’s expense. Title to and a right of immediate possession of any property of any nature whatsoever furnished or paid for by Buyer shall remain in Buyer. |

| 8. | FORCE MAJEURE. Buyer shall have the right to suspend shipments from Vendor hereunder without penalty or liability to Buyer in the event of war, riot, flood, pandemic or other public health emergency, acts of God, fire, court order, strike, work stoppage, act of governmental authority, or other causes beyond Buyer’s control. Buyer shall not be liable to Vendor for its failure to accept delivery of goods purchased hereunder, provided such failure arises from any of such above-mentioned causes. |

| 9. | TERMINATION AND DAMAGES. Buyer may terminate performance of the work under this Purchase Order, in whole or in part, by written notice to Vendor without incurring any liability to Vendor other than as specifically set forth in this Section. Upon receipt of such notice, Vendor shall immediately discontinue all work and the placing of all orders for material, facilities, and supplies pursuant to this Purchase Order. Upon termination by Buyer under this paragraph for reasons other than force majeure (as set forth above), Buyer shall negotiate payment to Vendor based on Vendor’s nonrecoverable, reasonable and actual documented costs and expenses; in no event, however, shall Buyer be obligated to pay Vendor an amount in excess of the aggregate price stated in this Purchase Order, less payments otherwise made or to be made. Nothing contained in this paragraph shall be construed to limit or affect any remedies which Buyer may have under this Purchase Order or under applicable law. In no event shall Buyer be liable for incidental, consequential, punitive or special damages. Buyer’s liability arising out of or relating to this Purchase Order shall not exceed the reasonable value of goods and services provided for hereunder. |

| ||

| A-3 |

| 10. | DEFAULT AND CANCELLATION BY BUYER. Buyer may cancel any Purchase Order, without incurring any liability to Vendor, for any failure to comply with the terms of this Purchase Order, including, without limitation, the following reasons as determined by Buyer in its reasonable discretion: |

| (a) | the failure or inability of Vendor to complete product development activities on a timetable supporting on-time deliveries; | |

| (b) | the failure or inability of Vendor to meet the quality and other requirements of the Purchase Order and/or the Vendor Agreement; | |

| (c) | the failure or inability of Vendor to timely deliver (i) samples (which meet specifications, testing standards or aesthetic criteria provided) or (ii) raw materials or finished products; | |

| (d) | the failure or inability of Vendor to comply fully with the Buyer’s terms of engagement governing treatment of workers, safety of facilities, conduct of the Vendor and compliance with all applicable laws, rules and regulations; | |

| (e) | if Vendor’s financial condition, based on criteria determined by Buyer, is found to be or becomes unsatisfactory to Buyer during the term of the Purchase Order; or | |

| (f) | the failure or inability of Vendor to comply with any other of the terms of this Purchase Order or of the Vendor Agreement, or any breach by Vendor of any term or condition of this Purchase Order, including, without limitation, the terms relating to shipping point, Country of Origin, delivery, and order quantity. |

Upon cancellation Vendor will refund any deposits, down payments or other advance payments to Buyer (except that for goods or services already delivered). After cancellation, Buyer also reserves the right to similarly terminate all other contracts covering purchases by Buyer of Vendor’s products or services whether or not Vendor may otherwise be in default, and no rights shall accrue to Vendor against Buyer on account of such termination. If Vendor fails to perform as specified in this Purchase Order or breaches any of these terms and conditions hereof or in the Vendor Agreement, Buyer also reserves the right, without incurring any liability, to: (a) cancel this Purchase Order in whole or part; (b) obtain the goods or services ordered herein from another source; (c) setoff or reduce all claims for money due or to become due from Buyer to Vendor; or (d) exercise any other right or remedy permitted by applicable law. These rights and remedies are cumulative and in addition to any other remedies provided at law or in equity. Buyer’s failure to insist on performance of any of these terms and conditions herein or to exercise any right or privilege, or Buyer’s waiver of any breach hereunder, shall not thereafter waive any other terms, conditions or privileges, whether of the same or similar type.

| 11. | CANCELLATION BY VENDOR. Vendor may not cancel a Purchase Order within sixty (60) days of the FOB/FCA date, for an FOB/FCA order, or ninety (90) days of the in warehouse date, for an LDP order. Vendor cancellation within this time period, without the prior written authorization of Buyer, will result in a chargeback to the vendor of 50% of the FOB/FCA/LDP (depending on order terms) value of the order. Buyer may permit Vendor, at its sole discretion and on a case by case basis, to short or over ship an order by five percent 5% of quantity (10% for yarn/fiber dye orders). Any overages not reported will not be paid. In the case of a short shipment (shipping less than the shortage allowance, if such a shortage allowance is provided), Vendor will be charged back 50% of the FOB/FCA/LDP value as stated above. Vendor may cancel unconfirmed Purchase Orders by promptly informing Buyer, in writing, of Vendor’s intent not to confirm the order. |

| ||

| A-4 |

| 12. | COMPLIANCE WITH LAWS. (i) Vendor agrees to comply full with all applicable laws, ordinances, rules, regulations and orders of all foreign nations (or governmental subdivision thereof) and all applicable domestic (United States of America) federal, state, and local laws, ordinances, rules, regulations and orders pertaining to the production, sale and shipment of the goods or services ordered, and, upon request, Vendor shall furnish Buyer certificates or other evidence of compliance. Further, to the extent applicable, such goods were or will be produced in compliance with all provisions of Executive Order 11246 and Sections 6, 7, 12, and 14 of the Fair Labor Standards Act of 1938, as amended, Dodd-Frank, all rules, regulations and orders thereunder, and any successor provisions thereto. (ii) In addition, Vendor is responsible for ensuring that the goods sold to Buyer comply with California Code of Regulations Title 27, Division 4, Article 6 for consumer product warnings (known as “Prop 65”), including, without limitation, all necessary testing and labeling requirements associated therewith. Unless otherwise agreed in writing, Vendor is required to label any goods that require a Prop 65 warning with a warning, the content of which satisfies the requirements of applicable law and has been placed on the goods (either on the product or the product labeling) in a manner that complies with such applicable law. As to specific goods, Buyer reserves the right to reject goods if such goods require a Prop 65 warning. Buyer will not sign, label or otherwise provide warnings in its stores, or online as an alternative to Vendor’s obligations. When submitting sample goods to Buyer, Vendor must indicate whether the item and its packaging meet the safe harbor limits of Prop 65, whether the item or its packaging require a Prop65 warning label, and whether there is any restriction on Buyer’s ability to sell the goods in California. For any goods purchased by Vendor that are not in compliance with Prop 65, Buyer, in addition to any other rights or remedies which it may have at law or in equity, shall have the right to reject, return or dispose of and recover associated costs at the Vendor’s expense. Further, any such goods may not be replaced with substitute goods, without written authorization from Buyer. (iii) Vendor hereby agrees to indemnify, defend (at Buyer’s option) and hold harmless Buyer, its affiliates and their respective successors, assigns, customers and users of its products from any costs, losses, expenses, damages, claims, suits, fines, penalties or any liability whatsoever, including attorneys’ and other professional fees, resulting from the failure of Vendor to comply, in the furnishing of goods or services under this Purchase Order, with all applicable foreign or domestic federal, state, or local laws, ordinances, rules, regulations or orders as set out herein above. |

| 13. | INDEMNIFICATION. Vendor agrees to indemnify, defend (at Buyer’s option) and hold harmless Buyer, its officers, directors, employees, agents, affiliates and their respective successors, assigns, customers and users of its products against all suits at law or in equity and from all damages, claims, demands and/or liability, including those arising out of, or relating in any way to: (a) the goods sold by Vendor to Buyer, or Vendor’s breach of any of the terms, conditions, requirements, representation or warranties contained in this Purchase Order or the Vendor Agreement, (b) the death of or injury to any person, or damage to any property, alleged to have resulted from the goods or services hereby ordered, (c) any actual or alleged failure by Vendor, or Vendor’s goods, to comply with applicable laws, ordinances, rules, regulations and orders of all foreign nations (or governmental subdivision thereof) and all applicable domestic (United States of America) federal, state, and local laws, ordinances, rules, regulations and orders (including, without limitation, as related to testing, labeling, marketing, content, shipment, or safety of goods); (d) any voluntary or mandatory recalls of goods (either required by law or deemed necessary in the commercially reasonable judgment of Vendor because Vendor has reason to believe the goods are defective, dangerous, incomplete, infringe upon intellectual property rights or are not in compliance with applicable laws, ordinances, rules, regulations or orders), and (e) any claim that the manufacture, importation, marketing, promotion, use, offer for sale, sale or resale of any goods or services supplied under this Purchase Order infringe any patent, copyright, trademark, trade dress, trade name, trade secret or other intellectual property rights. Vendor, when notified shall, at Buyer’s sole option, either defend any action or claim at its own expense, or reimburse Buyer’s expenses, attorneys’ fees, and other costs for defending such action or claim, with Buyer having the right to select and approve counsel to defend the action or claim in both instances. Vendor shall be responsible for all costs, losses, expenses, damages claims, suits, or any liability whatsoever, including attorneys’ fees. The foregoing indemnification shall apply whether the damage, claim or demand, including those for death, injury, or property damage, or relating to an intellectual property claim is caused by the sole or concurrent actions, inaction, or conduct of Vendor. To the extent that Vendor’s employees, or subcontractors enter upon the premises of Buyer, Vendor shall take all necessary precautions to prevent injury or death to any person or damage to property arising out of acts or omissions of such agents, employees or subcontractors, and, except to the extent that any such injury or damage is due solely and directly to Buyer’s gross negligence, shall indemnify, defend (at Buyer’s option) and hold harmless Buyer, its affiliates and their respective officers, employees, and agents, from any and all cost, losses, expenses, damages, claims, suits, or any liability whatsoever, including attorneys’ fees, arising out of any act or omission of Vendor, its agents, employees or subcontractors. If the goods purchased hereunder or any part thereof cannot be imported, promoted, marketed, used, offered for sale, or sold by virtue of any court or administrative order finding them to be infringements, Vendor shall promptly and at its own expense (a) procure for the Buyer the right to continue to import, promote, market, use, offer for sale, and sell the goods purchased hereunder, or (b) replace the goods with noninfringing goods satisfactory to Buyer, or (c) modify such goods in a way satisfactory to Buyer and its counsel so they become noninfringing. |

| 14. | INSURANCE. Vendor shall maintain and require its subcontractors and suppliers to maintain insurance as set forth in the Vendor Agreement. |

| ||

| A-5 |

| 15. | ASSIGNMENT. This Purchase Order may not be assigned by Vendor without the Buyer’s prior written consent. Vendor may delegate its duty to perform hereunder or subcontract the furnishing of any of the completed or substantially completed goods required by this Purchase Order; provided that any such delegation or subcontracting is only permitted if Buyer provides its prior written consent, and further provided that the delegatee or subcontractor agrees in writing to be bound by all of these terms and conditions contained in this Purchase Order and/or in the Vendor Agreement. Vendor acknowledges that such delegation or subcontracting does not relieve Vendor of its duty to perform its obligations hereunder or from any liability it may have as a result of its, or its delegatee’s or subcontractor’s failure to perform any of the terms or conditions contained herein and Vendor shall be liable for the act or neglect of its delegatees or subcontractors. Any assignment by Vendor of its right to payment under this Purchase Order shall be subject to all claims and defenses of Buyer. This Purchase Order may be assigned at any time and from time to time by the Buyer at its sole discretion. |

| 16. | APPLICABLE LAW. The validity, interpretation, and performance of this Purchase Order will be governed by the laws of the Commonwealth of Pennsylvania (except for conflicts of laws rules), except to the extent that the transaction covered by this Purchase Order involves the international sale of goods, in which case the validity, interpretation and performance of these terms and conditions shall be governed and construed by the provisions hereof in accordance with the United Nations Convention on Contracts for the International Sale of Goods, as amended, and all rules, regulations, orders thereunder, and any successor provisions thereto. Buyer and Vendor agree that the exclusive jurisdiction, forum and venue for any disputes arising or related to the Purchase Order or the Vendor Agreement shall be United States District Court for the Eastern District of Pennsylvania, and Buyer and Vendor submit to the personal jurisdiction of that court. If neither subject matter nor diversity jurisdiction exists in that court, then the exclusive jurisdiction, forum and venue for any such action shall be the courts of the Commonwealth of Pennsylvania located in Philadelphia County. |

THE PARTIES HEREBY WAIVE THEIR RIGHT TO A TRIAL BY JURY OF ANY DISPUTES, CLAIMS OR LITIGATION ARISING OUT OF OR RELATED TO THE PURCHASE ORDER OR THE VENDOR AGREEMENT.

| 17. | SEVERABILITY. The terms and conditions of this Purchase Order are severable and if any terms and conditions or portions of any terms and conditions herein are stricken or declared illegal, invalid or unenforceable for any reason whatsoever, the legality, validity or enforceability of the remaining terms and conditions shall not be affected thereby. |

| 18. | ENTIRE AGREEMENT. This Purchase Order, together with the Vendor Agreement, constitutes the entire expression of the parties’ agreement with regard to the Goods identified in this Purchase Order. All prior or contemporaneous negotiations and agreements between the parties with regard to the Goods identified in this Purchase Order are expressly superseded by this Purchase Order and the Vendor Agreement. |

| 19. | MISCELLANEOUS. (a) Vendor shall be bound by any representation or undertaking made by any of its agents or employees with respect to the specifications, quality, packaging, price or conditions of delivery of the goods. By accepting this Purchase Order, Vendor ratifies any such representation or undertaking made by any of its agents or employees. (b) This Purchase Order shall be binding upon and inure to the benefit of the parties hereto and their respective successors and permitted assigns. (c) If importation of the goods results in the assessment of a countervailing duty on Buyer as the importer, Vendor shall reimburse such countervailing duty on the Buyer, provided such reimbursement is permitted under applicable laws and regulations. (d) Vendor shall cooperate fully with the Buyer at Vendor’s expense in obtaining approvals of the goods requested by Buyer from certifying organizations. (e) The captions appearing at the beginning of each paragraph of these terms and conditions are for convenience only and are not to be construed as a substantive part of said terms and conditions. (e) The provisions of each of Sections 3, 4, 6, 12, 13, 15, 16, 17, 18, and 19 shall survive any termination, cancellation, execution, delivery, and/or performance of this Purchase Order. |

| ||

| A-6 |

Appendix B

FIVE BELOW, INC.

POLICIES AND PRINCIPLES GOVERNING PRODUCT RECALLS

March 2019

| ||

| B-1 |

TABLE OF CONTENTS

| I. THE DETERMINATION BY FIVE BELOW AS TO WHETHER A RECALL IS NEEDED | B-3 | |

| II. DIFFERENTIATING A RECALL FROM DISCONTINUANCE OF A PRODUCT OR A PRODUCT LINE | B-4 | |

| III. FIVE BELOW’S PREFERENCE FOR VOLUNTARY ACTION AND FOR COLLABORATION WITH RESPONSIBLE MANUFACTURERS AND REGULATORY AGENCIES | B-5 | |

| IV. MANAGEMENT OF THE RECALL PROCESS, AND CRITICAL ACTION ITEMS | B-6 | |

| A. The Formation Of A Recall Task Force And The Designation Of A Recall Coordinator | B-6 | |

| B. The Evaluation Of Reporting Obligations | B-7 | |

| C. Collection And Preservation Of Records And Data | B-8 | |

| 1. Purchase Records | B-8 | |

| 2. Records On Purchases, Sales, And On Units Removed From Inventory | B-8 | |

| 3. Returns By Consumers | B-8 | |

| 4. Tracking Of Individual Customers | B-8 | |

| D. Methods For Communicating With The Public About Recalls | B-8 | |

| V. CONCLUSION | B-9 |

| ||

| B-2 |

FIVE BELOW, INC.

POLICIES AND PRINCIPLES GOVERNING PRODUCT RECALLS

March 2019

This memorandum describes the general principles that will be followed by Five Below, Inc. (“Five Below”) in implementing product recalls. As explained below, in conducting recalls and in supporting recalls initiated by its suppliers, Five Below’s primary objective is to prevent harm to consumers. Another critical objective is to ensure that Five Below complies with all applicable legal requirements.

In furtherance of these objectives, this guidance document initially discusses when recalls are necessary. It explains how recalls differ from decisions to halt sales of specific products. This memorandum then provides guidance on the management of the recall process, focusing on (a) the executives involved in managing recalls, and their responsibilities; (b) the process for evaluating and meeting reporting obligations to regulatory agencies such as the Consumer Product Safety Commission (“CPSC”) and the Food and Drug Administration (“FDA”); (c) the procedures to locate and remove from Five Below’s stores and distribution centers any dangerous, defective, or noncompliant products; (d) the methods for communicating recall information to consumers; and (e) the tools available to encourage consumers to return any products found to be dangerous.

| I. | The determination by Five Below as to whether a recall is needed |

In deciding whether a recall is needed, there are at least two fundamental questions that must be considered. The first question is whether there is credible evidence indicating that a product is defective and/or creates risks of injury, death, or property damage. This question typically will be evaluated by considering many types of data, including injury claims, consumer complaints, data on warranty claims or returns, product testing results, design information, and physical evidence relating to products alleged to be defective or dangerous, along with any other information provided by regulatory authorities. As explained below, Five Below’s Recall Coordinator or its Recall Task Force will evaluate all pertinent information on a rolling basis and may, if necessary, arrange for inspection or testing of products under review.

Certainly, a recall may be necessary if a product is found to have a defect and if the defect creates significant dangers or risks for consumers. Separately, however, a recall may be necessary if a product is found to be non-compliant. For example, the CPSC has adopted labeling, testing, and flammability requirements for children’s sleepwear. (See 16 C.F.R. §§ 1615.1-1615.5 (Sizes 0-6X) and 1161.1-1616.6 (Sizes 7-14).) If Five Below learns that it is selling or has sold children’s sleepwear that does not satisfy these CPSC requirements, it will initiate, or have its supplier initiate, a recall. Similarly, if a chocolate bar sold by Five Below is returned by customers, is tested or inspected, and is found to contain peanuts, and if there is no reference to peanuts on the packaging or label, this chocolate bar would likely be viewed as misbranded by FDA, due to the presence of undeclared allergens. Accordingly, Five Below would have to initiate, or ask its supplier to initiate, a recall on this product.

| ||

| B-3 |

If a recall is necessary, the second question is whether the recall should be initiated by Five Below itself or by the supplier that sold the merchandise to Five Below. Five Below operates solely as a retailer. Irrespective of whether its products are sold as Five Below-branded items or under other brands, all products distributed or sold by Five Below are produced by independent manufacturers. If a product is defective, noncompliant, or dangerous, Five Below’s supplier or the manufacturer generally is the entity responsible for the product’s flaws. For that reason, and in the interest of protecting its public image, Five Below’s strong preference is to have the responsible supplier or manufacturer conduct any necessary recall with appropriate cooperation or support from Five Below.

If Five Below obtains credible information that a product is unsafe or non-compliant, Five Below will promptly contact the manufacturer or supplier and share the information in question. Where appropriate, Five Below simultaneously will evaluate and attempt to meet its own reporting obligations vis-à-vis the CPSC, FDA, or other regulatory agencies and will urge the supplier or manufacturer to conduct any necessary recall.

From time to time, without any prodding or involvement by Five Below, one of the company’s suppliers or manufacturers may independently determine that a recall is required. Five Below generally will request that the supplier or manufacturer provide information on the scope of the recall, on factors driving the recall, and on the programs in place for covering the costs incurred by retailers and consumers. As a matter of corporate policy, however, Five Below will not second-guess the need for a recall being initiated by one of its manufacturers or suppliers. If any of Five Below’s manufacturers or suppliers determines that a product is unsafe or non-compliant and must be recalled, Five Below’s policy is to cooperate fully with that manufacturer or supplier.

Five Below recognizes, however, that there may be instances in which its supplier or manufacturer is unwilling or unable to conduct a recall. In that situation, or whenever it is otherwise necessary, Five Below may be forced to take on this responsibility itself.

| II. | Differentiating a recall from discontinuance of a product or a product line |

For planning purposes, it is necessary to differentiate product eliminations from product recalls. There may be situations where a product or stock-keeping unit (“SKU”) does not live up to expectations and elicits consumer complaints or returns, but poses no safety or non-compliance issue. For example, consumers might complain about the durability of a toy or a shirt, but there might be no questions about the safety of the product. If enough complaints or returns surface, the company generally will evaluate the SKU and may decide to discontinue sales. We refer to this as discontinuance or elimination of a product, not as a recall.

By contrast, a recall involves a situation in which a product is either noncompliant with a regulatory standard or is found to be dangerous. In a recall, Five Below will immediately halt sales, will quickly remove the product from its stores and distribution centers, and will encourage consumers to return the merchandise in question. As an inducement for such returns, consumers will typically be offered a full refund or credit, or will be offered a replacement product that does not have the defect or dangerous element. As a further inducement, Five Below will publicly disclose the known risks associated with the product and, where appropriate, will publicly disclose the harm that may result from continued use of the product.

| ||

| B-4 |

In any product discontinuance or recall, Five Below will promptly instruct all stores and distribution centers to locate and quarantine the affected merchandise. Five Below will also provide instructions on whether the merchandise should be destroyed or should be preserved for inspection. All store personnel will be instructed to end sales of this merchandise. Company personnel also may be asked to keep a running count on the number of items that have been pulled from inventory. This data will be reported back to Five Below’s Recall Coordinator or to another designated executive overseeing the corrective action being taken.

| III. | Five Below’s preference for voluntary action and for collaboration with responsible manufacturers and regulatory agencies |

In planning and implementing product recalls, Five Below strongly prefers to collaborate with responsible manufacturers and distributors and to confer with any regulatory agencies that have authority over the product in question. Likewise, whenever recalls are necessary, whether by a manufacturer or distributor that has supplied products to Five Below or by Five Below itself, Five Below generally prefers to have the recall undertaken on a voluntary basis, without the need for regulatory compulsion.

Five Below’s preference for a collaborative, voluntary approach with regulatory agencies such as the CPSC and FDA stems from several factors. To start with, Five Below recognizes that these agencies have substantial expertise in assessing product hazards and in developing appropriate recall plans. Additionally, regulatory authorities may have access to information on product hazards that is not readily available to Five Below. This information may reach these regulatory agencies through reports filed by manufacturers, consumers, or State public health agencies. Furthermore, many products carried by Five Below are sold by other retailers as well, and regulatory authorities may have knowledge of recent experiences involving these retailers or their customers.

Collaboration with regulatory agencies also may be advisable from a legal standpoint. While each recall needs to be examined individually, Five Below has a long-term interest in maintaining strong relationships with regulatory authorities. Moreover, a forced recall by the CPSC or by any other agency often increases the risks associated with third-party litigation by injured persons or by consumers who have suffered property damage.

| ||

| B-5 |

As explained above, in conducting or participating in recalls, Five Below also prefers to work closely with the manufacturers and independent distributors that supply merchandise to Five Below. In conducting or facilitating recalls, Five Below must take into account its role in the market. Specifically, Five Below is a retailer that operates bricks and mortar stores and separately sells merchandise online. While a portion of the merchandise carried by Five Below is branded as Five Below merchandise, the company does not own or operate any manufacturing facilities. Consequently, all merchandise carried by Five Below is manufactured by third parties. Often, if a product is mislabeled or is defective or is unexpectedly linked to accidents or injuries, Five Below’s supplier will be the entity responsible for creating the defect or hazard. Thus, if possible, when product hazards are identified, Five Below will work closely with the responsible manufacturer or distributor. Where appropriate, Five Below will encourage the manufacturer to interface with responsible regulatory agencies and to conduct any necessary recalls. Five Below recognizes, however, that, depending upon the circumstances, it may have its own reporting obligations. Five Below also recognizes that if a recall is necessary and if the responsible manufacturer or distributor fails to initiate a required recall, Five Below may have no choice but to take action itself.

Conversely, as a matter of corporate policy, if any supplier to Five Below initiates a recall, Five Below will cooperate fully with that supplier. As part of this cooperation, Five Below will promptly remove the affected merchandise from its stores and distribution centers. Where appropriate, Five Below also will publicize the recall online and in stores, and will process returns or exchanges by consumers. Five Below will of course seek reimbursement from the responsible manufacturer or distributor for direct costs incurred in supporting or implementing such recalls.

While Five Below generally prefers to collaborate with its suppliers and with regulatory authorities, each recall needs to be evaluated, planned, and conducted individually. With particular merchandise, the facts relating to product risks, defects, and potential exposure will vary considerably. These individual factors and any related legal obligations imposed on Five Below will need to be carefully considered in deciding whether a recall is needed and in planning any corrective action. In addition, final decisions relating to product hazards should always be made in consultation with Five Below’s Legal Department. In almost any recall, the company will need to evaluate its compliance obligations vis-à-vis the CPSC or other regulatory agencies, and the company may need to develop a strategy that minimizes risks stemming from third-party claims.

| IV. | Management of the recall process, and critical action items |

The recall process is complex, and recalls may be necessitated or triggered on an emergency basis. In this memorandum, Five Below describes the basic procedures that will be used to manage the recall process. These procedures can be modified or tailored for particular recalls, but should at least provide a starting point for the management team tasked with overseeing or implementing particular recalls.

| A. | The Formation Of A Recall Task Force And The Designation Of A Recall Coordinator |

For each recall, Five Below will designate a Recall Coordinator and a Recall Task Force. Unless otherwise specified, the company’s General Counsel will have full authority to make these appointments. Presumptively, the Recall Coordinator will serve on the Task Force, along with a Five Below attorney designated by the company’s General Counsel.

The Task Force will have broad authority to design and oversee the recall. This group will be empowered to manage communications with the public and with regulatory authorities. Additionally, the Task Force will coordinate with the responsible buyer within Five Below and will decide on how the recall will be implemented. In many instances, consumers will be encouraged to return the affected merchandise and will be offered replacement merchandise or a refund or a credit. In most instances, systems will have to be established for keeping lists of the names of consumers who have returned the merchandise and the dates of such returns. Likewise, systems for tracking claims, consumer complaints, and any other alleged injuries should be established.

| ||

| B-6 |

As the recall progresses, the Task Force will brief Five Below’s Chief Executive Officer, Chief Financial Officer, and General Counsel periodically on the progression of the recall and on information obtained about the safety of particular products and the reliability of particular suppliers. If needed, efforts will be made to suggest improvements to product screening procedures going forward.

Under the guidance of the Task Force, the Recall Coordinator will take the lead in collecting and tracking data on the products in question and on any complaints or allegations relating to deaths, injuries, accidents, or property damage. The Recall Coordinator will collect and preserve quality control records, engineering analyses, test results, and any other pertinent data. Together with the General Counsel or one of the Company’s other attorneys, the Recall Coordinator will ensure that the Company’s insurance companies and suppliers receive appropriate notifications. Additionally, the Legal Department will draft any required submissions to regulatory agencies such as the CPSC. All such submissions shall be subject to review and approval by the Task Force.

| B. | The Evaluation Of Reporting Obligations |

During or prior to the initiation of a recall, it is likely that questions may arise as to whether Five Below has any reporting obligations vis-à-vis the CPSC or other regulatory agencies. For example, as a retailer, if Five Below receives credible information that one of its products has a defect that has caused, or has the potential to cause, significant injuries or deaths, the company may have reporting obligations under Section 15 of the Consumer Product Safety Act.

Under the guidance of the Recall Task Force, the Recall Coordinator will evaluate such reporting obligations. Before making any final decision on the filing of such reports, however, the Recall Coordinator will seek guidance from the Legal Department on the appropriate course of action and on the content of any written submissions.

There may be products, such as food items, that are not within the CPSC’s jurisdiction. Reporting obligations on such products should be examined in the same manner as specified above. Additionally, even if Five Below does not have a mandatory reporting obligation vis-à-vis the FDA, CPSC, or any other agency, the Recall Coordinator or the Task Force should assess whether voluntary consultation with regulatory authorities is advisable. In some circumstances, a voluntary disclosure to regulatory authorities may be appropriate. Again, however, any final decision on such disclosures should be made in consultation with Five Below’s Legal Department.

| ||

| B-7 |

| C. | Collection And Preservation Of Records And Data |

The Recall Coordinator will be tasked with collecting and maintaining records and data relating to any recall. The collection of substantial data is often necessary in order to determine whether a product is defective and whether the recall should be limited to particular batches or production runs. Information also must be collected, as needed, in order to provide progress reports to any regulatory authorities overseeing the recall.

Depending upon the circumstances, the Recall Coordinator should try to collect and maintain the following:

| 1. | Purchase Records |

Five Below should collect purchase orders, supplier agreements, and records showing the volume and timing of its purchases of the product in question. If the manufacturer or distributor has supplied testing data, quality control records, or inspection reports, those documents should be collected and preserved.

| 2. | Records On Purchases, Sales, And On Units Removed From Inventory |

For products subject to recalls, Five Below should preserve records indicating the number of units purchased and the number of units sold to consumers. Likewise, as these products are removed from Five Below’s stores and distribution centers, records should be kept on the number of units that are retrieved or isolated and on the disposition of those items. (Store personnel should be instructed never to sell items that are being recalled.)

| 3. | Returns By Consumers |

To the extent that consumers return affected merchandise for exchanges, credits, or refunds, Five Below should track the volume of such returns. In many instances, the company also should track the disposition or disposal of the returned units.

| 4. | Tracking Of Individual Customers |

To the extent that Five Below has data or documents that could be used to identify the buyers of affected merchandise, such records should be preserved. In some instances, if customer names are available, the company may wish to open communications with such consumers for the purpose of encouraging returns or exchanges.

| D. | Methods For Communicating With The Public About Recalls |

As part of every recall, Five Below will develop a public communications plan. If the recall is undertaken in coordination with the CPSC or another regulatory agency, the communications plan may be developed and implemented jointly. Irrespective of the level of coordination with regulatory authorities, however, the communications plan must be carefully designed and must provide information in an understandable form that will encourage consumers to return the product in question. Typically, Five Below’s communications will identify the product with specificity, will describe any product defect or hazard, and will describe the corrective action being taken by the company.

| ||

| B-8 |

The CPSC and other regulatory agencies have identified many methods for reaching consumers. The CPSC encourages companies conducting recalls to issue joint press releases with the CPSC. This approach is especially appropriate if the recall is being implemented in consultation with the CPSC and under the CPSC’s rules.

In addition to press releases, many other communications tools are available and should be considered. Certainly, recall posters in stores are often useful and should be considered. Likewise, information relating to recalls should be published on Five Below’s website. In particular recalls, the company may also consider release of a video news release (“VNR”). Such VNRs increase the likelihood of television coverage. In addition, in reaching consumers, Five Below may be able to use social media platforms such as Facebook, YouTube, and Twitter. To facilitate interaction with consumers, the CPSC also recommends the use of a toll-free telephone number, a dedicated email address, and a website URL. All of these tools are potentially effective and should be considered in designing the communications plan for a particular recall.

Furthermore, if Five Below is able to identify consumers known to have purchased the product in question, the company should contact these consumers. Telephone calls, regular email, and text messages could potentially be used for this purpose.

| V. | CONCLUSION |

Each recall by Five Below will need to be carefully planned and implemented. This memorandum is intended to guide this decision-making process.

The approach taken on a particular product will depend in part on the level of risk associated with use of that product. As a starting point, whenever a product is found to be dangerous or non-compliant, the company will need to evaluate its reporting obligations. Then, if a recall is necessary, Five Below will have to immediately halt sales of the product, promptly remove the product from inventory, and actively encourage consumers to return the affected merchandise.

In most instances, if products are found to be dangerous or non-compliant, Five Below will work closely with its suppliers and manufacturers to develop a corrective action plan. If suppliers or manufacturers are responsible for the product defect or for any non-compliance, Five Below will encourage those firms to take the lead on any necessary recall. Five Below, however, will actively support their recalls and will conduct its own recall if necessary.

Lastly, in most recalls, even in voluntary recalls, Five Below will at least consult with regulatory authorities and may elect to conduct a recall under regulatory oversight. The company’s main objectives are to prevent harm to consumers and to meet all legal requirements. In pursuing these objectives, Five Below prefers to work on a collaborative basis with the responsible regulatory agencies whenever possible.

| ||

| B-9 |

Appendix C

States in which Five Below currently operates

| ● | Alabama | |

| ● | Arizona | |

| ● | Arkansas | |

| ● | California | |

| ● | Connecticut | |

| ● | Delaware | |

| ● | Florida | |

| ● | Georgia | |

| ● | Illinois | |

| ● | Indiana | |

| ● | Iowa | |

| ● | Kansas | |

| ● | Kentucky | |

| ● | Louisiana | |

| ● | Maine | |

| ● | Maryland | |

| ● | Massachusetts | |

| ● | Michigan | |

| ● | Minnesota | |

| ● | Missippi | |

| ● | Missouri | |

| ● | Nebraska | |

| ● | New Hampshire | |

| ● | New Jersey | |

| ● | New York | |

| ● | North Carolina | |

| ● | Ohio | |

| ● | Oklahoma | |

| ● | Pennsylvania | |

| ● | Rhode Island | |

| ● | South Carolina | |

| ● | Tennessee | |

| ● | Texas | |

| ● | Virginia | |

| ● | Washington DC | |

| ● | West Virginia | |

| ● | Wisconsin |

| ||

| C-1 |

Vendor Guide

Section 2 of 3: Compliance

Revised: June 2023

| ||

| 1 |

| Contents | ||

| A. | Change Log | 4 |

| B. | Social Compliance Policy | 5 |

| C. | Factory Audits—Import Vendors | 7 |

| D. | Supply Chain Security Guidelines for Vendors, Suppliers, and Service Providers | 9 |

| Overview | 9 | |

| Onboarding New Vendors for Supply Chain Safety and CTPAT: | 10 | |

| Five Below and SCAN | 11 | |

| Five Below Document Requirements at Time of Shipment | 11 | |

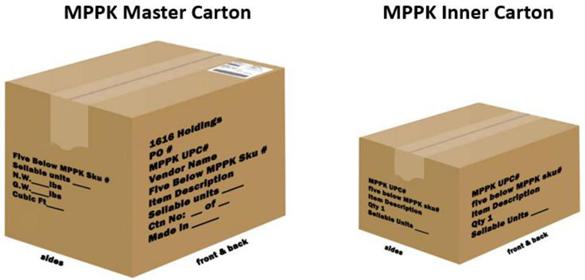

| Carton and Item Markings and Labeling | 11 | |

| Customs Country of Origin Requirements | 12 | |

| E. | CTPAT Minimum Security Criteria | 12 |

| Corporate Security | 12 | |

| Security Vision and Responsibility | 12 | |

| Risk Assessment | 12 | |

| Business Partners | 12 | |

| Cybersecurity | 13 | |

| Transportation Security | 13 | |

| Conveyance and Instruments of International Traffic (ITT) Security | 13 | |

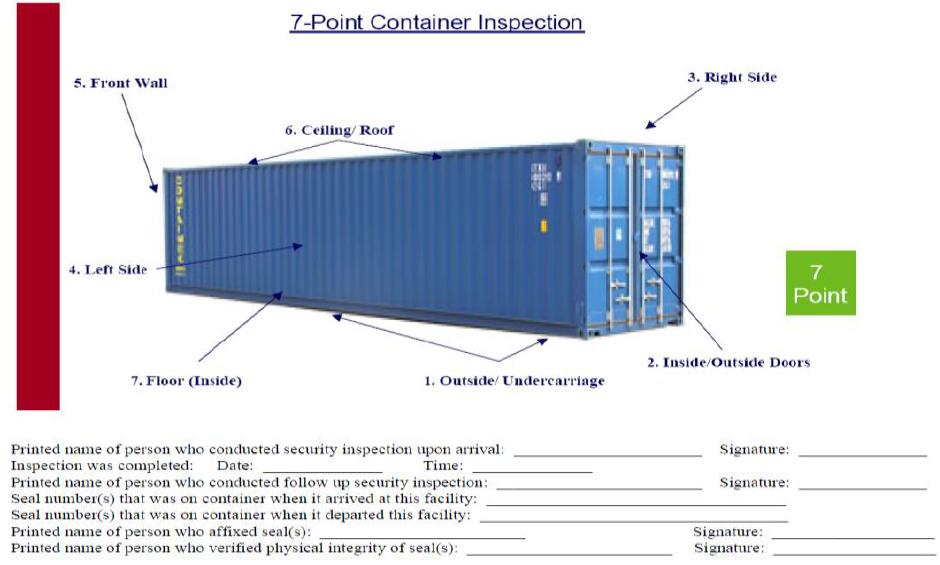

| Container Inspection | 13 | |

| Container Sales | 14 | |

| Procedural Security | 15 | |

| Agricultural Security | 16 | |

| People & Physical Security | 16 | |

| Physical Security | 16 | |

| Physical Access Controls | 17 | |

| Education, Training, and Awareness | 17 | |

| F. | Compliance with Applicable Laws | 18 |

| Consumer Product Safety Improvement Act (CPSIA) | 18 | |

| Toxic Substances Control Act (TSCA) – Title VI for Composite Wood Products | 20 | |

| California Statutes and Regulations Governing Product Content | 21 | |

| ||

| 2 |

| Tracking Labels on Product and Packaging | 25 | |

| Fair Packaging and Label Act Section 500.5 | 25 | |

| Private Brand Packaging Review and Approval | 26 | |

| California Proposition 65 Labeling | 26 | |

| Uniform Label Law for Stuffed Articles | 27 | |

| Textile Fiber Products Identification Act | 27 | |

| Care Labeling Rule | 27 | |

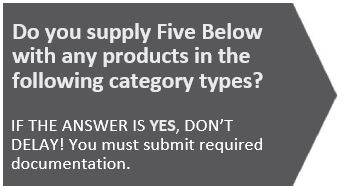

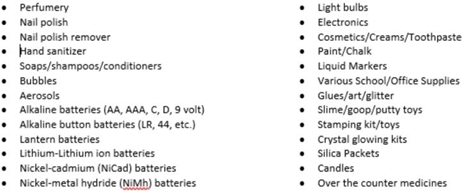

| Safety Data Sheet (SDS) | 28 | |

| G. | Testing Process | 29 |

| General Testing Guidelines | 29 | |

| Testing Guidelines | 30 | |

| Products with the Five Below Name and/or Brands, including 1616 Holdings | 30 | |

| Vendor-Branded Goods for which Five Below is Importer of Record | 30 | |

| Submitting Items to Five Below’s Designated Third Party Lab for Testing | 30 | |

| Lab Testing Process—Riskonnect ESG (formerly ICIX) | 31 | |

| Five Below Test Review Timelines | 31 | |

| H. | Shipment Inspection | 32 |

| I. | Appendix A – Five Below’s Designated 3rd Party Audit, Inspection, and Lab Contacts | 33 |

| Five Below Designated Labs & Audit Firms China | 33 | |

| Five Below Designated Labs & Audit Firms - India | 35 | |

| Five Below Designated Labs & Audit Firms – Vietnam | 37 | |

| Five Below Designated Labs & Audit Firms – United States | 38 |

| ||

| 3 |

A. Change Log

| Update | Page | Date |

| Updated factory audit policy | 8 | August 2023 |

| Updated approved lab and audit partner matrix | 9 | August 2023 |

| Addition of RN number for Five Below branded goods subject to Textile, Wool and Fur Act | 26 | August 2023 |

| California Proposition 65 Policy | 27 | August 2023 |

| Product Testing for Vendor-Branded Good for which Five Below is Importer of Record | 32 | August 2023 |

| ||

| 4 |

B. Social Compliance Policy

Five Below strives to be an example of good human rights and labor practices throughout our business activities. As we do not own our manufacturing facilities, we take care in the selection of our vendors, and our process intends to screen out any that do not share our values.

Five Below requires that each of its Vendors:

| (1) | Complies with all Applicable Laws regarding eradication of forced, indentured, involuntary or compulsory labor in its facilities, and requires its suppliers, including labor brokers and agencies, to do the same; |

| (2) | Ensure that its supply chain and materials incorporated into its products (including Goods supplied to Five Below) comply with all Applicable Laws (including international laws) prohibiting slavery and human trafficking; |

| (3) | Treats its workers with dignity and respect, provides them with a safe work environment, and conducts business in compliance with all Applicable laws (including applicable environmental, labor and employment laws), and refrains from corrupt practices and engaging in human rights violations; |

| (4) | Has and will continue to maintain records that are sufficiently detailed to substantiate that all Goods it supplies to Five Below are produced in compliance with the anti-slavery and human trafficking laws of the country or countries where they are produced and will produce such records to Five Below or its auditors upon request. |

| (5) | Will allow Five Below and its agents access to every facility to conduct schedule and unscheduled inspections for the purpose of ensuring compliance with our social compliance requirements. It will grant Five Below and its Preferred Compliance Auditor the right to review all employee-related books and records maintained by the Vendor and to interview workers. Inspection/audit costs will be paid by the Vendor; |

| (6) | Use of any sub-contracted factories will be communicated to and approved by Five Below, in advance, of outsourcing production of Goods;. |

| (7) | Pays all workers at least the minimum wage and benefits as required by any Applicable Laws and regulations; as well as compensates workers for overtime at the rate enforced by Appliable Laws and regulations; |

| (8) | Respects the rights of all workers to lawfully associate or not associate with groups of their choosing, so long as the groups are permitted by law. Vendors shall not unlawfully prevent or interfere with employee associations and related activities; |

| (9) | Follows all Applicable Laws and regulations, and prohibits discrimination or harassment due to an employee’s sex, race, color, religion, origin, age, disability, marital status, gender identity, gender expression, or sexual orientation. Vendors should maintain a workplace that is free from harassment or discrimination; |

| ||

| 5 |

| (10) | Maintains a working environment free from abuse or harassment. Vendors shall not tolerate forms of physical, sexual, psychological or verbal abuse; and |