B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.1 C O M PA N Y O V E R V I E W August 2025

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.2 Babcock & Wilcox Enterprises, Inc. (“B&W Enterprises” or “B&W”) cautions that this presentation contains forward-looking statements within the meaning of federal securities laws. All statements other than statements of historical or current fact included in this presentation are forward-looking statements, including, without limitation, statements relating to the company's business outlook and expected financial performance expectations regarding future growth, expansion and profitability, outlook and expectations regarding B&W’s BrightLoop technology and statements about our support of net-zero, decarbonization and sustainable power ambitions and key technologies, data centers and electric demand, as well as statements about B&W’s future pipeline of new projects and business within its Renewable, Environmental and Thermal operating segments and their impact on future shareholder value. These forward-looking statements are based on management’s current expectations and involve a number of risks and uncertainties, including, among other things: our financial condition and ability to continue as a going concern and that we have entered into a number of amendments and waivers to our Debt Facilities (as defined in our Annual Report on Form 10-K for the year ended December 31, 2024); our need of additional financing to continue as a going concern; any negative reactions to the substantial doubt about our ability to continue as a going concern by our customers, suppliers, vendors, employees and other third parties; risks associated with contractual pricing in our industry; our relationships with customers, subcontractors and other third parties; our ability to comply with our contractual obligations; disruptions at our manufacturing facilities or a third-party manufacturing facility that we have engaged; the actions or failures of our co-venturers; our ability to implement our growth strategy, including through strategic acquisitions, which we may not successfully consummate or integrate; our evaluation of strategic alternatives for certain businesses and non-core assets which may not result in successful transactions; the risks of unexpected adjustments and cancellations in our backlog; professional liability, product liability, warranty and other claims; our ability to compete successfully against current and future competitors; our ability to develop and successfully market new products; the impacts of industry conditions and public health crises; the cyclical nature of the industries in which we operate; changes in the legislative and regulatory environment in which we operate; supply chain issues, including shortages of adequate components; failure to properly estimate customer demand; our ability to comply with the covenants in our debt agreements; our ability to refinance any of our debt in the future on commercially reasonable terms or at all; our ability to maintain adequate bonding and letter of credit capacity; impairment of goodwill or other indefinite-lived intangible assets; credit risk; disruptions in, or failures of, our information systems; our ability to comply with privacy and information security laws; our ability to protect our intellectual property and use the intellectual property that we license from third parties; risks related to our international operations, including fluctuations in the value of foreign currencies, current and future changes to global tariffs, sanctions and export controls that could harm our profitability; volatility in the price of our common stock; B. Riley’s significant influence over us; changes in tax rates or tax law; our ability to use net operating loss and certain tax credits; our ability to maintain effective internal control over financial reporting; our ability to attract and retain skilled personnel and senior management; labor problems, including negotiations with labor unions and possible work stoppages; risks associated with our retirement benefit plans; natural disasters or other events beyond our control, such as war, armed conflicts or terrorist attacks; and the other factors specified and set forth under "Risk Factors" in our periodic reports filed with the Securities and Exchange Commission, including, without limitation, the risks described in the Company's Annual Report on Form 10-K for the year ended December 31, 2024 under the captions "Risk Factors" and "Management's Discussion and Analysis of Financial Condition and Results of Operations" (as applicable). These factors should be considered carefully, and B&W Enterprises cautions you not to place undue reliance on these forward-looking statements, which speak only as of the date of this presentation, and undertakes no obligation to update or revise any forward-looking statement, except to the extent required by applicable law. SAFE HARBOR STATEMENT

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.3 Providing high quality and innovative technologies since 1867 From our first patent for a more efficient boiler to more than 17,000 patents since, we continue to drive innovation and change Today, we are a globally recognized technology leader and innovator at the forefront of the energy transition WE’RE A GLOBAL ENERGY LEADER CREATING A BRIGHTER FUTURE Ensuring energy security for customers and the world Helping utility and industrial customers with the technical challenges of moving from current to future energy sources Delivering systems, parts and field services to help utility and industrial plants operate more effectively and efficiently Advancing solutions for the clean energy landscape Our hydrogen production, carbon capture, renewable energy and environmental technologies support the reduction of greenhouse gases, including CO2 and methane, in an environmentally friendly way

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.4 WE’RE HELPING CUSTOMERS CREATE CLEAN AND RELIABLE ENERGY SUPPORTING A CIRCULAR ECONOMY Providing ecologically sound ways of using and recycling resources like biomass and municipal waste to create clean, renewable baseload power while reducing greenhouse gas emissions. REDUCING THE IMPACT OF GREENHOUSE GAS EMISSIONS Providing hydrogen production, carbon capture, ash handling, energy recovery and storage, and advanced emissions control solutions to help preserve the world’s natural resources. CREATING RELIABLE AND EFFICIENT STEAM GENERATION Providing boilers and related equipment, aftermarket parts, service and upgrades to help utilities and industries generate reliable thermal energy from a wide range of fuels and bridge the gap during the global transition to new energy sources.

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.5 THE FOUNDATION OF OUR COMPANY VISION: Advancing energy and environmental solutions that bring power and progress to our world. MISSION: B&W delivers environmentally conscious, technology- driven solutions and services to energy and industrial customers worldwide – safely, ethically and as promised. CORE VALUES: Safety • Integrity Quality • Respect • Agility

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.6 Increase focus on large thermal growth projects and higher-margin aftermarket parts and services and continue to expand geographical presence in support of these markets Leverage our advanced thermal technologies to support fuel switching projects Convert anticipated global pipeline of more than $7.6 billion of identified project opportunities into bookings, including over $2.6 billion in BrightLoop and ClimateBright opportunities Continue to implement up to $30 million in cost reductions associated with strategic realignment Strengthen balance sheet including evaluating alternatives for non-strategic assets and potential refinancing to reduce current and long-term debt Utilize state and federal project-level financing to accelerate deployment of BrightLoop technology Execute paid front-end engineering and design studies to further drive BrightLoop and ClimateBright technology bookings WE’RE STRENGTHENING OUR BUSINESS TO ACHIEVE PROFITABLE GROWTH

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.7 WE'RE LEVERAGING A VAST INSTALLED BASE AND PROVEN TECHNOLOGIES More than 300 operating utility and industrial boiler units in the U.S. and nearly 200 operating utility and industrial boiler units across 40 countries around the world More than 5,000 industrial water- tube package boilers and other waste heat recovery products installed in a variety of facilities Average of more than 500,000 U.S. Boilermakers’ construction manhours per year over last five years One of the top five Boilermaker employers in the U.S. utility industry More than 300+ renewable energy units at facilities globally (consuming over 61 million tonnes of waste per year) and a leader in plant availability Serving utility, waste management, municipality and investment firm customers Large worldwide installed base of wet and dry scrubbers for SOX reduction, particulate control equipment, NOX reduction technologies, and mercury control systems to meet environmental regulations Flue gas pre-treatment technologies for use with CO2 capture VAST GLOBAL INSTALLATION OF B&W’S CORE TECHNOLOGIES AT UTILITY AND INDUSTRIAL PLANTS CREATES LARGE GROWTH OPPORTUNITIES FOR PARTS, SERVICES AND RETROFITS Ensuring energy security Driving decarbonization Supporting sustainable power

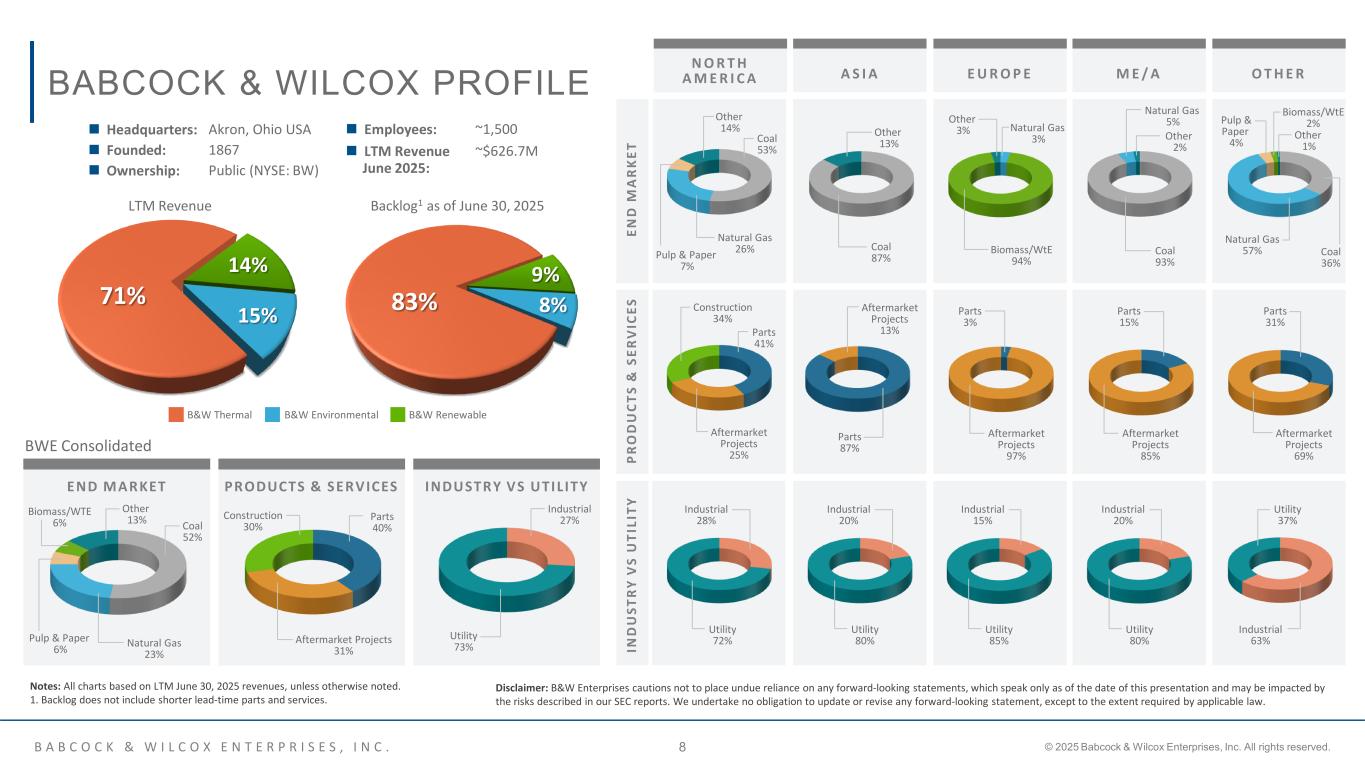

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.8 N O R T H A M E R I C A A S I A E U R O P E M E / A O T H E R EN D M A R K ET P R O D U C TS & S ER V IC ES IN D U ST R Y V S U TI LI TY 14% 15% 71% 9% 8%83% END MARKET Other 13% Coal 52% Natural Gas 23% Pulp & Paper 6% Biomass/WTE 6% PRODUCTS & SERVICES Parts 40% Construction 30% INDUSTRY VS UTILITY Industrial 27% BABCOCK & WILCOX PROFILE Backlog1 as of June 30, 2025LTM Revenue Employees: ~1,500 LTM Revenue June 2025: ~$626.7M Headquarters: Akron, Ohio USA Founded: 1867 Ownership: Public (NYSE: BW) Notes: All charts based on LTM June 30, 2025 revenues, unless otherwise noted. 1. Backlog does not include shorter lead-time parts and services. Disclaimer: B&W Enterprises cautions not to place undue reliance on any forward-looking statements, which speak only as of the date of this presentation and may be impacted by the risks described in our SEC reports. We undertake no obligation to update or revise any forward-looking statement, except to the extent required by applicable law. B&W RenewableB&W EnvironmentalB&W Thermal BWE Consolidated Aftermarket Projects 31% Utility 73% Other 14% Coal 53% Natural Gas 26%Pulp & Paper 7% Parts 41% Construction 34% Aftermarket Projects 25% Industrial 28% Utility 72% Other 13% Coal 87% Parts 87% Aftermarket Projects 13% Industrial 20% Utility 80% Natural Gas 3% Other 3% Biomass/WtE 94% Parts 3% Aftermarket Projects 97% Industrial 15% Utility 85% Coal 93% Natural Gas 5% Other 2% Parts 15% Aftermarket Projects 85% Industrial 20% Utility 80% Other 1% Coal 36% Natural Gas 57% Pulp & Paper 4% Biomass/WtE 2% Parts 31% Aftermarket Projects 69% Industrial 63% Utility 37%

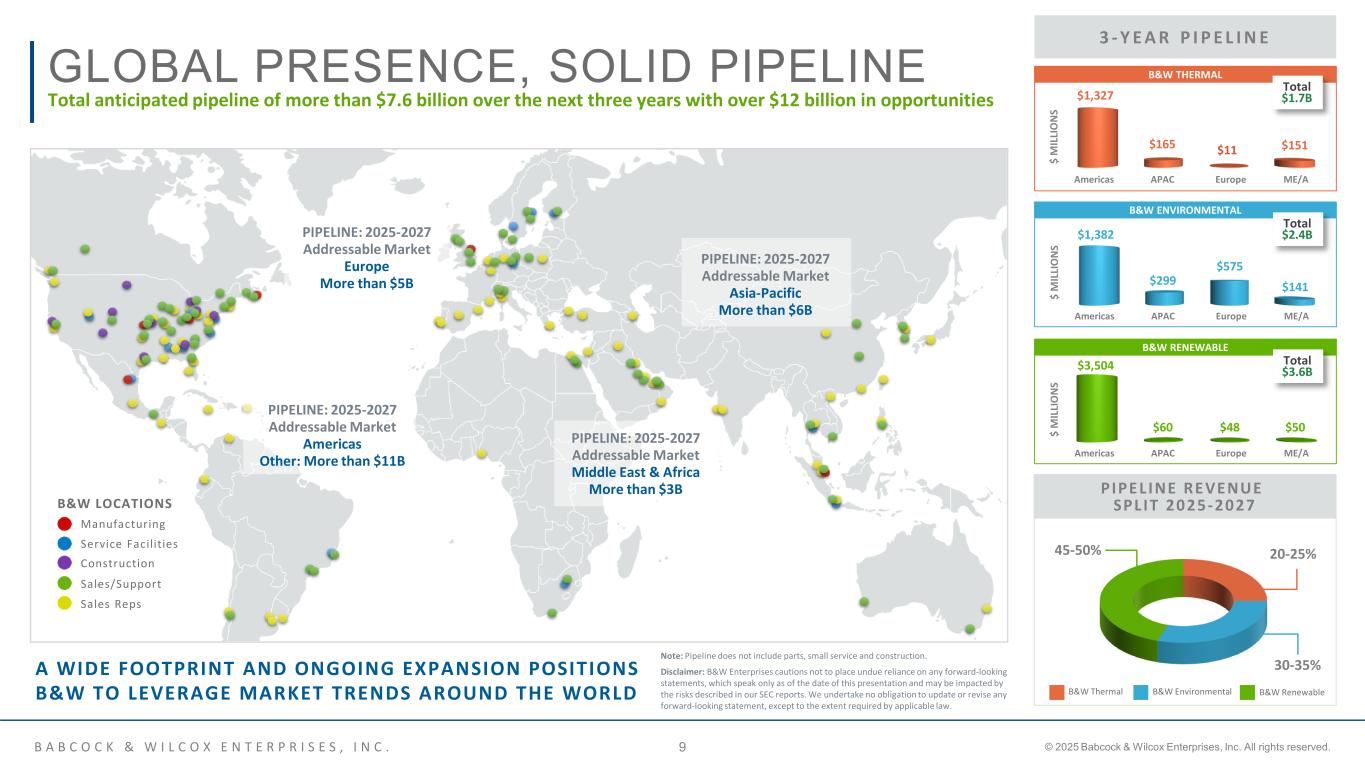

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.9 PIPEL INE REVENUE SPLIT 2025-2027 GLOBAL PRESENCE, SOLID PIPELINE Manufacturing Service Facilities Construction Sales/Support Sales Reps Total anticipated pipeline of more than $7.6 billion over the next three years with over $12 billion in opportunities Note: Pipeline does not include parts, small service and construction. Disclaimer: B&W Enterprises cautions not to place undue reliance on any forward-looking statements, which speak only as of the date of this presentation and may be impacted by the risks described in our SEC reports. We undertake no obligation to update or revise any forward-looking statement, except to the extent required by applicable law. PIPELINE: 2025-2027 Addressable Market Europe More than $5B PIPELINE: 2025-2027 Addressable Market Americas Other: More than $11B PIPELINE: 2025-2027 Addressable Market Asia-Pacific More than $6B A WIDE FOOTPRINT AND ONGOING EXPANSION POSITIONS B&W TO LEVERAGE MARKET TRENDS AROUND THE WORLD PIPELINE: 2025-2027 Addressable Market Middle East & Africa More than $3B 20-25%45-50% 30-35% 3 - Y E A R P I P E L I N E B&W RENEWABLE B&W ENVIRONMENTAL $1,327 $165 $11 $151 $ M IL LI O N S B&W THERMAL Total $1.7B B&W RenewableB&W EnvironmentalB&W Thermal Americas APAC Europe ME/A $1,382 $299 $575 $141 $ M IL LI O N S Total $2.4B Americas APAC Europe ME/A $3,504 $60 $48 $50$ M IL LI O N S Total $3.6B Americas APAC Europe ME/A B&W LOCATIONS

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.10 Electric demand forecast • Total data center power demand, including non-AI data centers, is anticipated to soar to 176 GW by 2035, up from 33 GW in 2024. AI alone is expected to reach 123 GW by 2035 compared to 4 GW in 2024.* Who are Data Center Hyperscalers: • Enterprise services: data management, cloud storage, computing - Amazon, IBM, Microsoft, Google, Oracle, Apple, Meta • Crypto mining: bitcoin use could diminish over the next five years, and 20% of datacenters could be converted to AI • Artificial intelligence (AI): AI represents approximately 10-20% of total data center demand. AI power demand will grow to about 40% of total data center demand Constraints: • Power and grid capacities, supply chain constraints, grid construction timelines, unplanned natural gas and new nuclear power availability prior to 2030-2035 Solutions: • Increased use of existing available, reliable power, such as coal plants • 46% of surveyed* said hydrogen use will increase as part of their solution to meet parallel renewable goals – CCS and alternate fuels, fuel for GTs • Onsite or co-located power supply to eliminate grid issues DATA CENTERS – ELECTRIC POWER DEMAND Capital expenditure is expected to exceed $1 trillion within the next five years for electric and gas utilities, and reach $1 trillion within the next three years for data centers Deloitte - April 2025 * https://www.deloitte.com/us/en/insights/industry/power-and-utilities/data-center-infrastructure-artificial-intelligence.html

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.11 LEADERSHIP TEAM Executive Vice President and Chief Financial Officer Cameron Frymyer Executive Vice President, General Counsel and Corporate Secretary John J. Dziewisz Chief Technology Officer Brandy Johnson Chairman and Chief Executive Officer Kenneth Young Executive Vice President and Chief Commercial Officer Jimmy B. Morgan Senior Vice President, Corporate Operations Gillianne Hetrick Vice President, Corporate Development Sarah Serafin Non-Executive Advisor Dr. Homaira Akbari

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.12 CORPORATE GOVERNANCE B O A R D O F D I R E C T O R S Chairman and Chief Executive Officer Kenneth Young Joseph TatoRebecca StahlHenry Bartoli Alan Howe Philip Moeller Naomi Boness

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.13 FINANCIAL INFORMATION

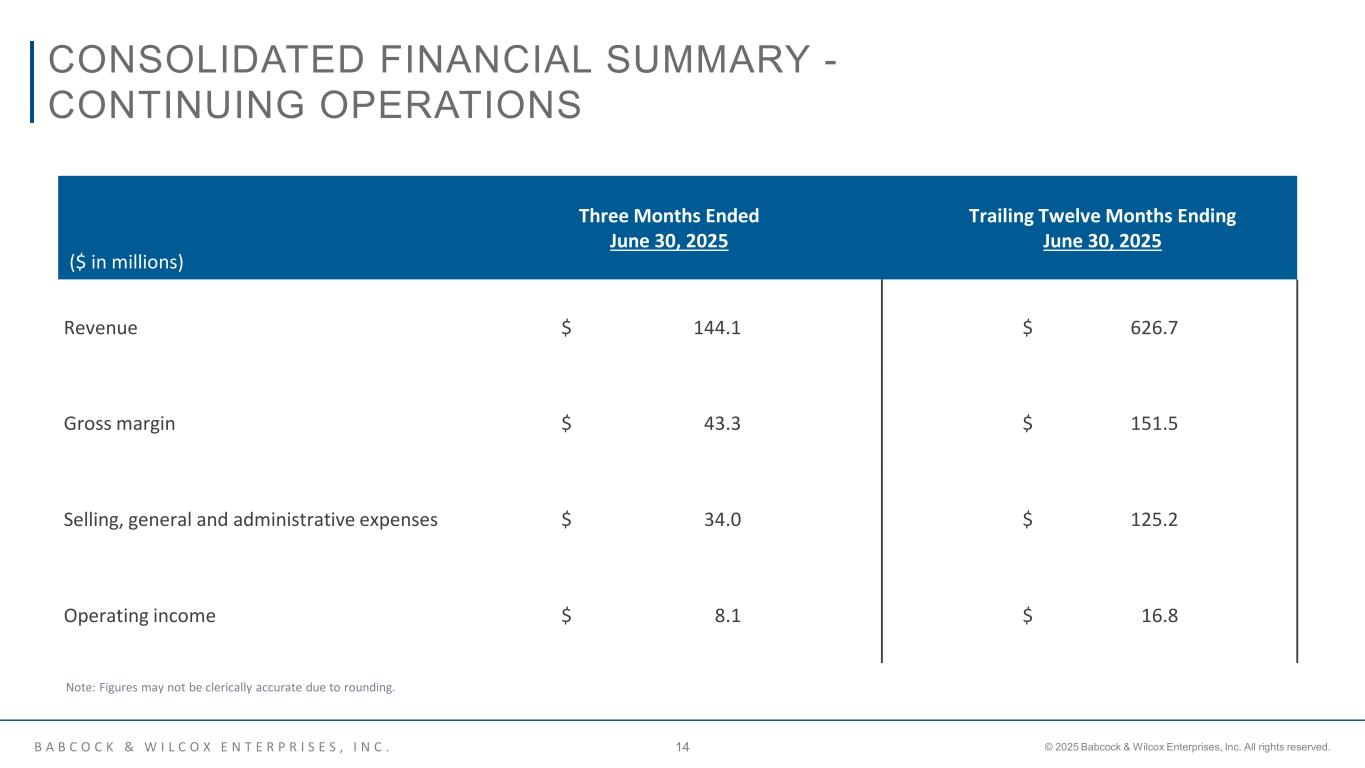

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.14 CONSOLIDATED FINANCIAL SUMMARY - CONTINUING OPERATIONS ($ in millions) Three Months Ended June 30, 2025 Trailing Twelve Months Ending June 30, 2025 Revenue $ 144.1 $ 626.7 Gross margin $ 43.3 $ 151.5 Selling, general and administrative expenses $ 34.0 $ 125.2 Operating income $ 8.1 $ 16.8 Note: Figures may not be clerically accurate due to rounding.

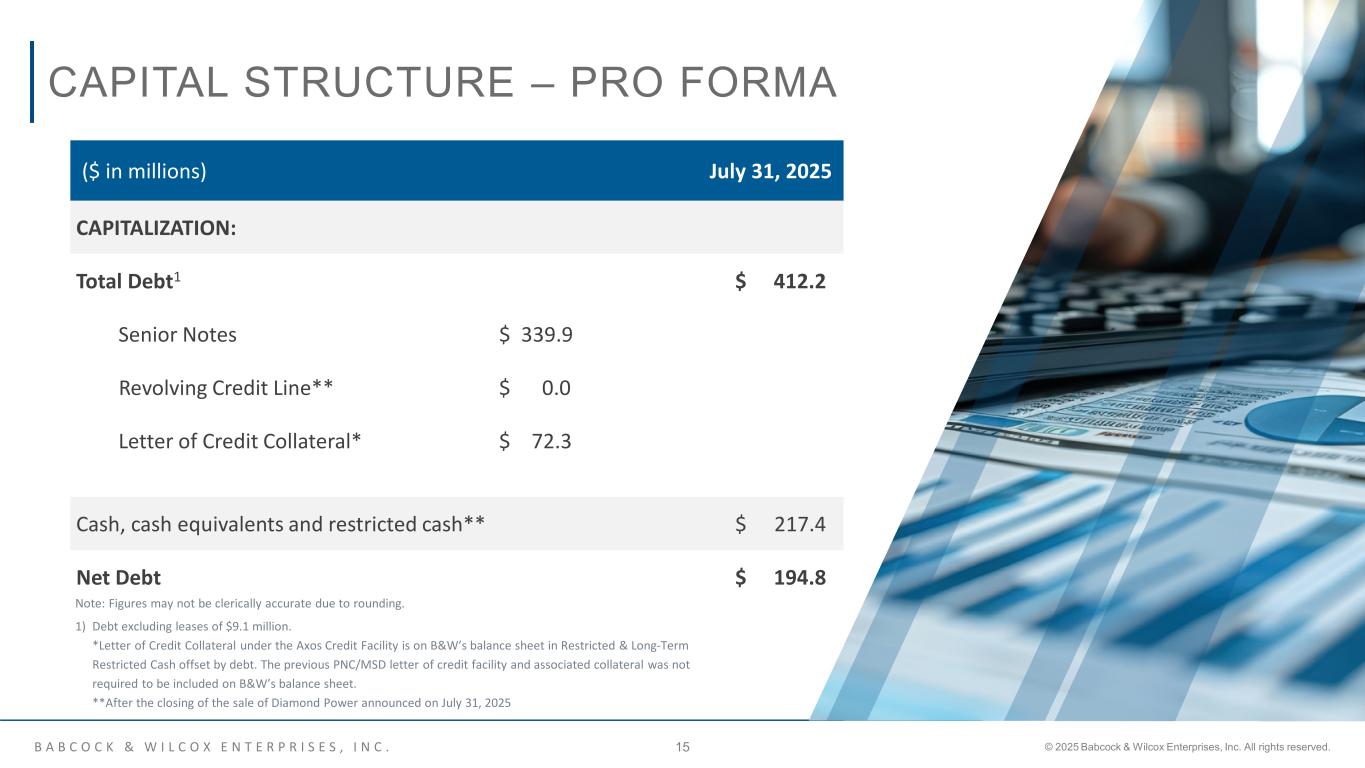

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.15 CAPITAL STRUCTURE – PRO FORMA ($ in millions) July 31, 2025 CAPITALIZATION: Total Debt1 $ 412.2 Senior Notes $ 339.9 Revolving Credit Line** $ 0.0 Letter of Credit Collateral* $ 72.3 Cash, cash equivalents and restricted cash** $ 217.4 Net Debt $ 194.8 Note: Figures may not be clerically accurate due to rounding. 1) Debt excluding leases of $9.1 million. *Letter of Credit Collateral under the Axos Credit Facility is on B&W’s balance sheet in Restricted & Long-Term Restricted Cash offset by debt. The previous PNC/MSD letter of credit facility and associated collateral was not required to be included on B&W’s balance sheet. **After the closing of the sale of Diamond Power announced on July 31, 2025

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.16 KEY TECHNOLOGIES AND CAPABILITIES

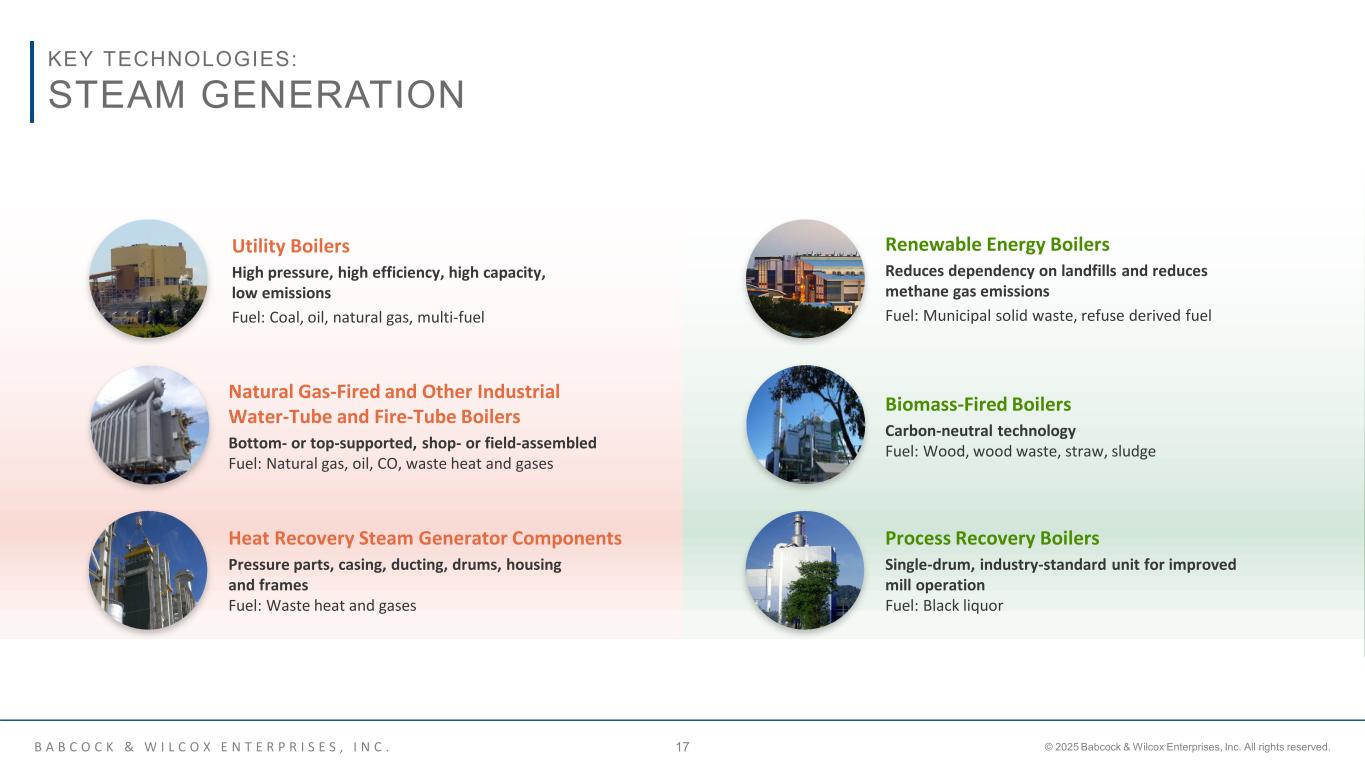

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.17 KEY TECHNOLOGIES: STEAM GENERATION Utility Boilers High pressure, high efficiency, high capacity, low emissions Fuel: Coal, oil, natural gas, multi-fuel Natural Gas-Fired and Other Industrial Water-Tube and Fire-Tube Boilers Bottom- or top-supported, shop- or field-assembled Fuel: Natural gas, oil, CO, waste heat and gases Heat Recovery Steam Generator Components Pressure parts, casing, ducting, drums, housing and frames Fuel: Waste heat and gases Renewable Energy Boilers Reduces dependency on landfills and reduces methane gas emissions Fuel: Municipal solid waste, refuse derived fuel Biomass-Fired Boilers Carbon-neutral technology Fuel: Wood, wood waste, straw, sludge Process Recovery Boilers Single-drum, industry-standard unit for improved mill operation Fuel: Black liquor

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.18 KEY TECHNOLOGIES: IGNITORS, FLAME SCANNERS AND CONTROLS Natural gas conversions from oil- or coal-firing Alternative energy fuels such as hydrogen, biodiesel, methanol and biogas Burner management and controls for complete turnkey system capability Flame scanning capability can be effectively implemented on any industrial application Technologies can be utilized for new construction or retrofit projects Safety standards conforming to National Fire Protection Association (NFPA) classes PROVEN TECHNOLOGIES WITH INSTALLATIONS IN MORE THAN 70 COUNTRIES, INCLUDING MORE THAN 11,000 IGNITORS Designed for safety, reliability and fuel flexibility

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.19 KEY TECHNOLOGIES: BOILER CLEANING EQUIPMENT, SOOTBLOWERS, SYSTEMS AND REPLACEMENT PARTS HIGH-PERFORMANCE BOILER CLEANING PRODUCTS Boiler cleaning Replacement parts and upgrades Cameras and monitoring Port rodders and dampers Titanium® intelligent sootblowing and boiler cleaning controls Gauges and level indicators Reliability, versatility, maximum cleaning performance and low maintenance, backed by experience

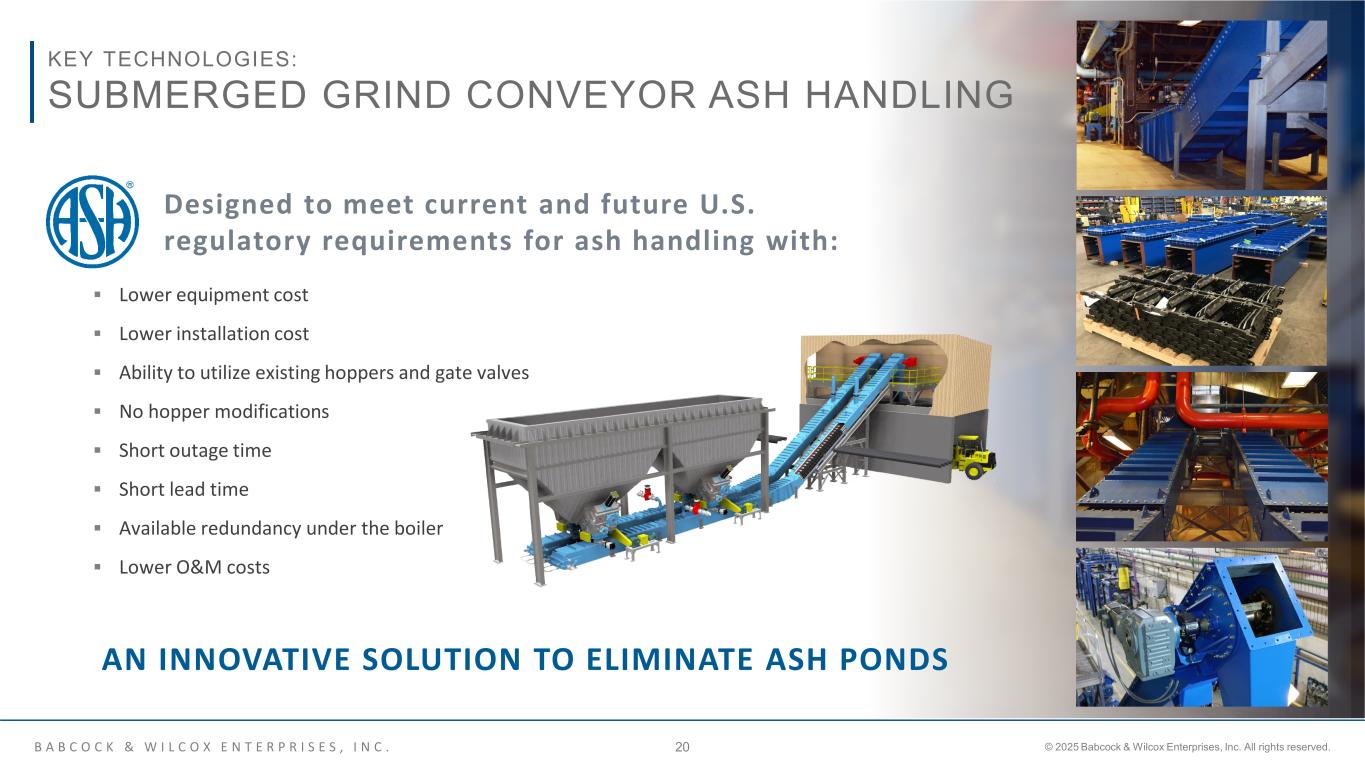

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.20 KEY TECHNOLOGIES: SUBMERGED GRIND CONVEYOR ASH HANDLING Lower equipment cost Lower installation cost Ability to utilize existing hoppers and gate valves No hopper modifications Short outage time Short lead time Available redundancy under the boiler Lower O&M costs AN INNOVATIVE SOLUTION TO ELIMINATE ASH PONDS Designed to meet current and future U.S. regulatory requirements for ash handling with:

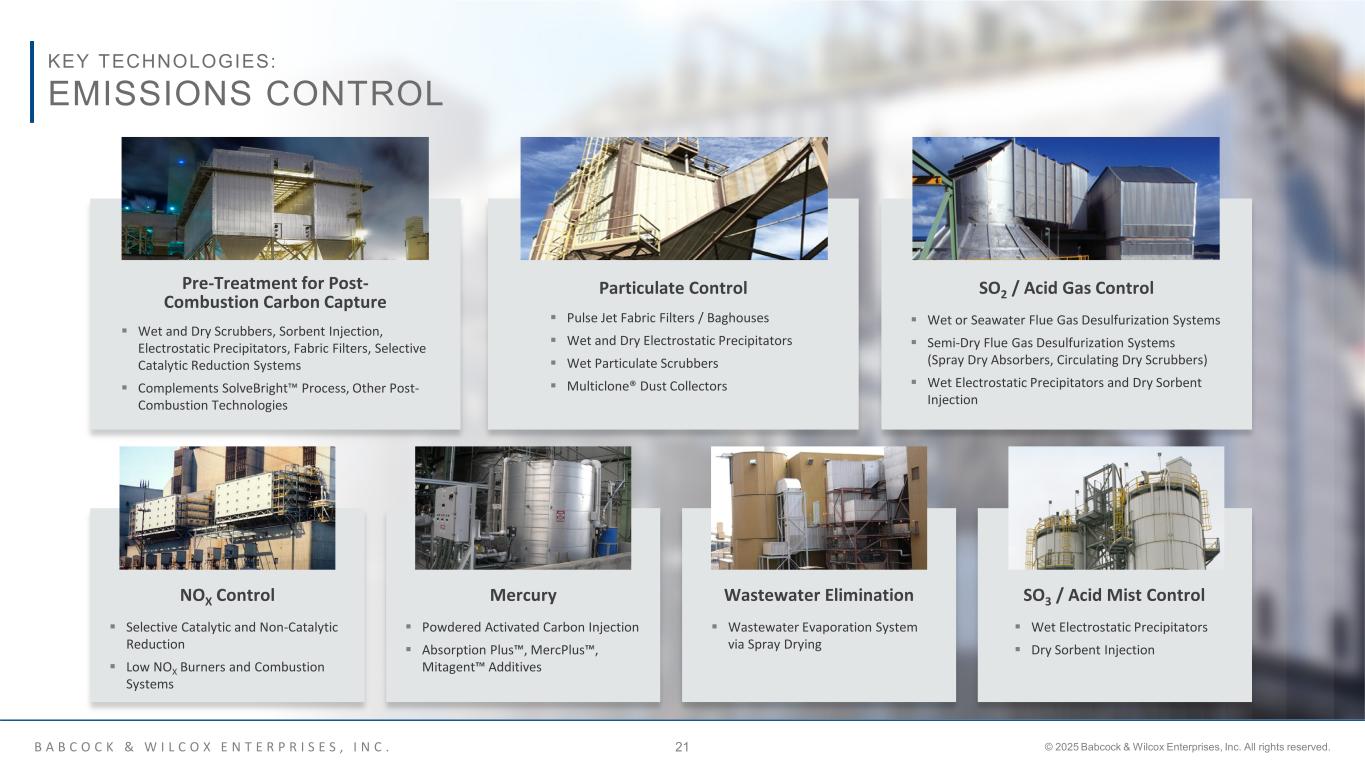

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.21 KEY TECHNOLOGIES: EMISSIONS CONTROL Pre-Treatment for Post- Combustion Carbon Capture Wet and Dry Scrubbers, Sorbent Injection, Electrostatic Precipitators, Fabric Filters, Selective Catalytic Reduction Systems Complements SolveBright Process, Other Post- Combustion Technologies Particulate Control Pulse Jet Fabric Filters / Baghouses Wet and Dry Electrostatic Precipitators Wet Particulate Scrubbers Multiclone® Dust Collectors NOX Control Selective Catalytic and Non-Catalytic Reduction Low NOX Burners and Combustion Systems SO2 / Acid Gas Control Wet or Seawater Flue Gas Desulfurization Systems Semi-Dry Flue Gas Desulfurization Systems (Spray Dry Absorbers, Circulating Dry Scrubbers) Wet Electrostatic Precipitators and Dry Sorbent Injection SO3 / Acid Mist Control Wet Electrostatic Precipitators Dry Sorbent Injection Mercury Powdered Activated Carbon Injection Absorption Plus , MercPlus , Mitagent Additives Wastewater Elimination Wastewater Evaporation System via Spray Drying

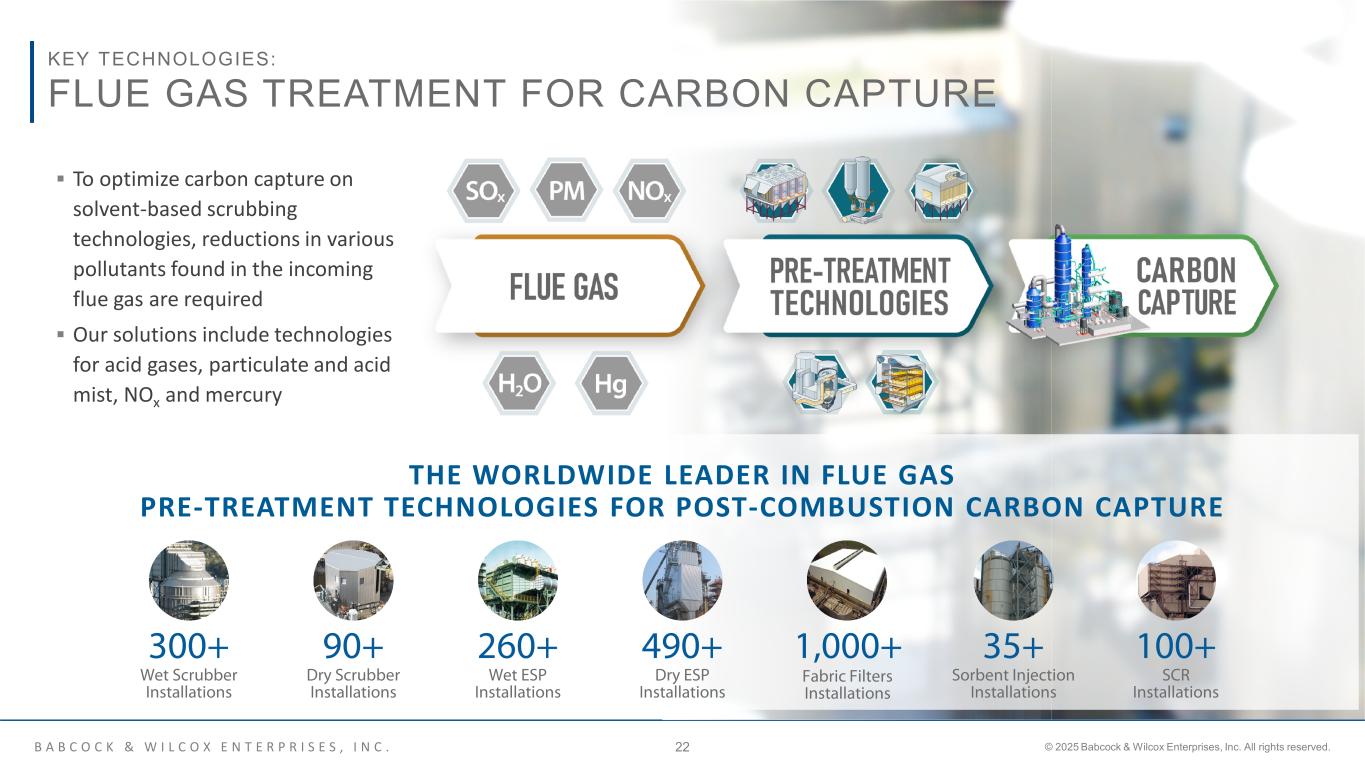

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.22 KEY TECHNOLOGIES: FLUE GAS TREATMENT FOR CARBON CAPTURE THE WORLDWIDE LEADER IN FLUE GAS PRE-TREATMENT TECHNOLOGIES FOR POST-COMBUSTION CARBON CAPTURE To optimize carbon capture on solvent-based scrubbing technologies, reductions in various pollutants found in the incoming flue gas are required Our solutions include technologies for acid gases, particulate and acid mist, NOx and mercury 300+ Wet Scrubber Installations 90+ Dry Scrubber Installations 260+ Wet ESP Installations 490+ Dry ESP Installations 1,000+ Fabric Filters Installations 35+ Sorbent Injection Installations 100+ SCR Installations

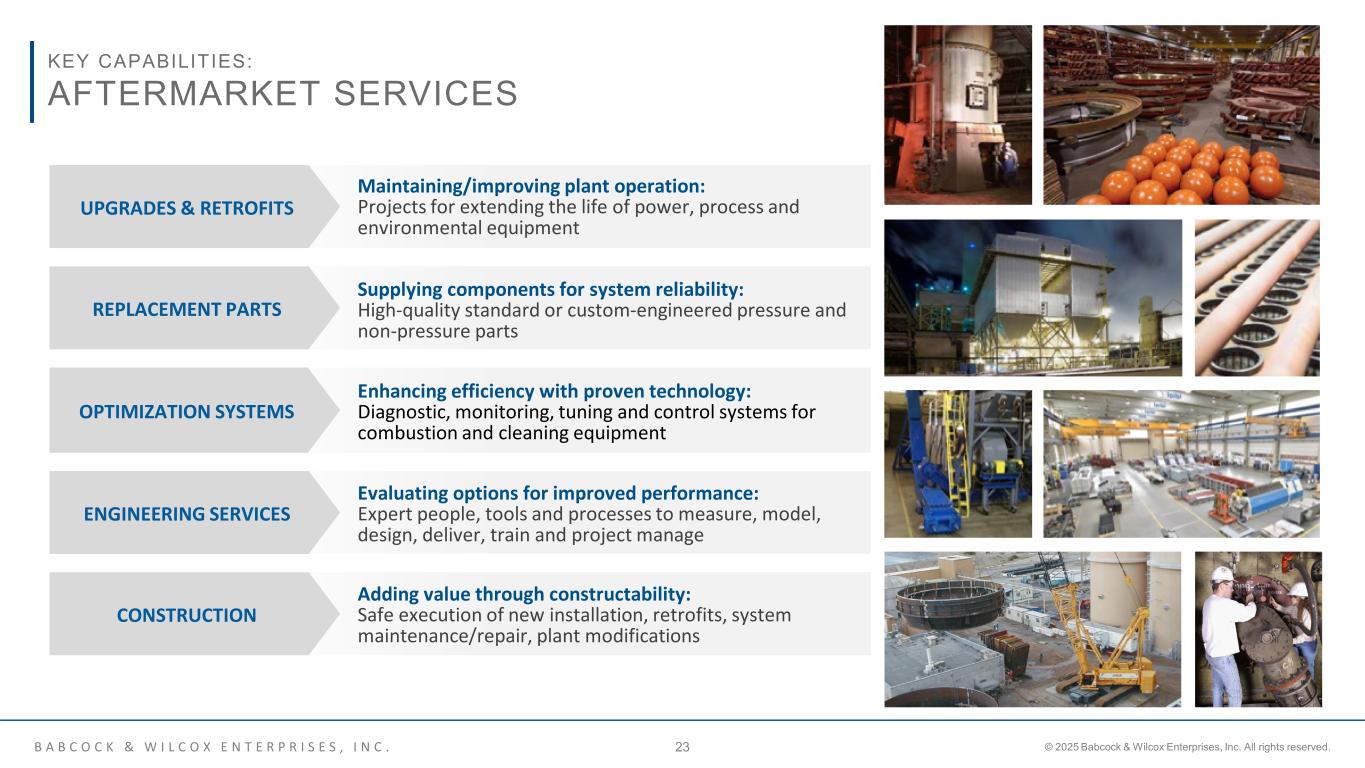

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.23 KEY CAPABILITIES: AFTERMARKET SERVICES Adding value through constructability: Safe execution of new installation, retrofits, system maintenance/repair, plant modifications CONSTRUCTION OPTIMIZATION SYSTEMS Enhancing efficiency with proven technology: Diagnostic, monitoring, tuning and control systems for combustion and cleaning equipment UPGRADES & RETROFITS Maintaining/improving plant operation: Projects for extending the life of power, process and environmental equipment ENGINEERING SERVICES Evaluating options for improved performance: Expert people, tools and processes to measure, model, design, deliver, train and project manage REPLACEMENT PARTS Supplying components for system reliability: High-quality standard or custom-engineered pressure and non-pressure parts

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.24 B&W’S EMERGING TECHNOLOGIES

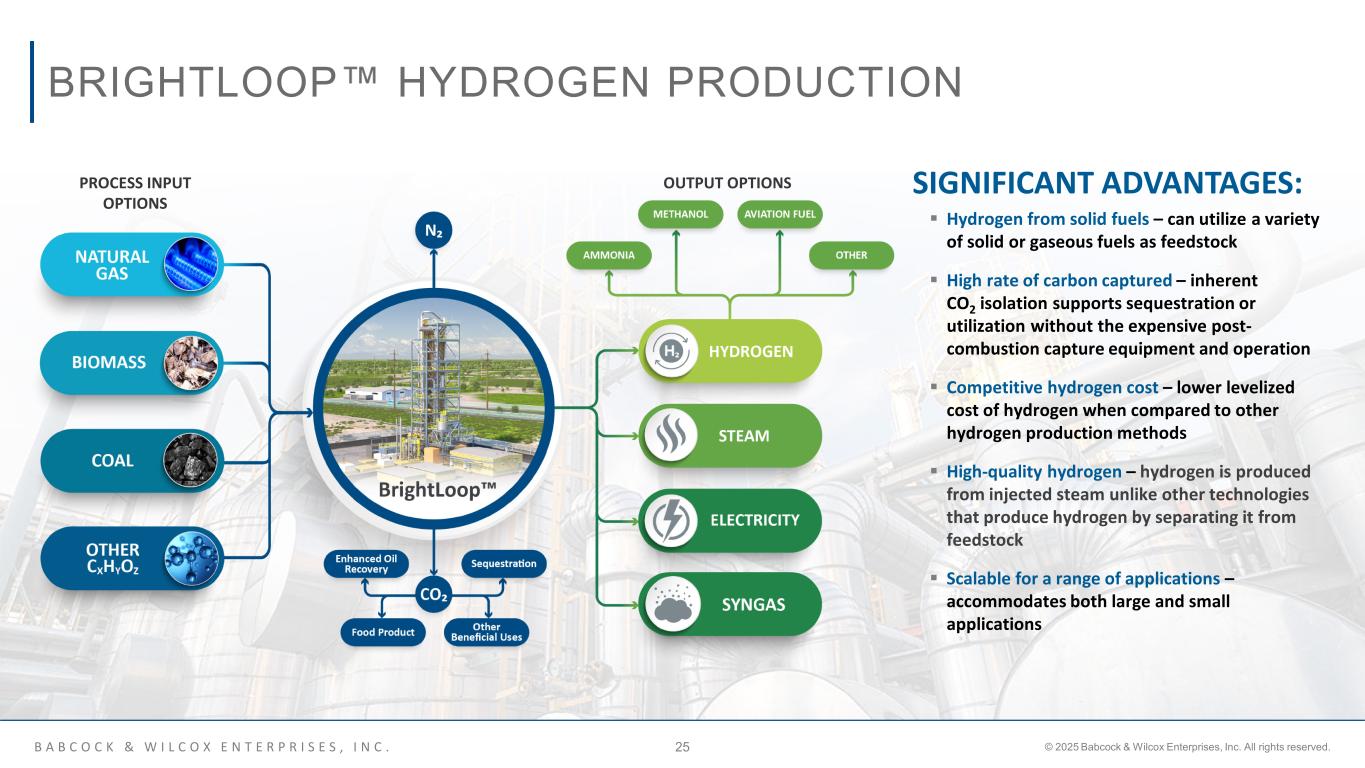

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.25 BRIGHTLOOP HYDROGEN PRODUCTION PROCESS INPUT OPTIONS OUTPUT OPTIONS SIGNIFICANT ADVANTAGES: Hydrogen from solid fuels – can utilize a variety of solid or gaseous fuels as feedstock High rate of carbon captured – inherent CO2 isolation supports sequestration or utilization without the expensive post- combustion capture equipment and operation Competitive hydrogen cost – lower levelized cost of hydrogen when compared to other hydrogen production methods High-quality hydrogen – hydrogen is produced from injected steam unlike other technologies that produce hydrogen by separating it from feedstock Scalable for a range of applications – accommodates both large and small applications

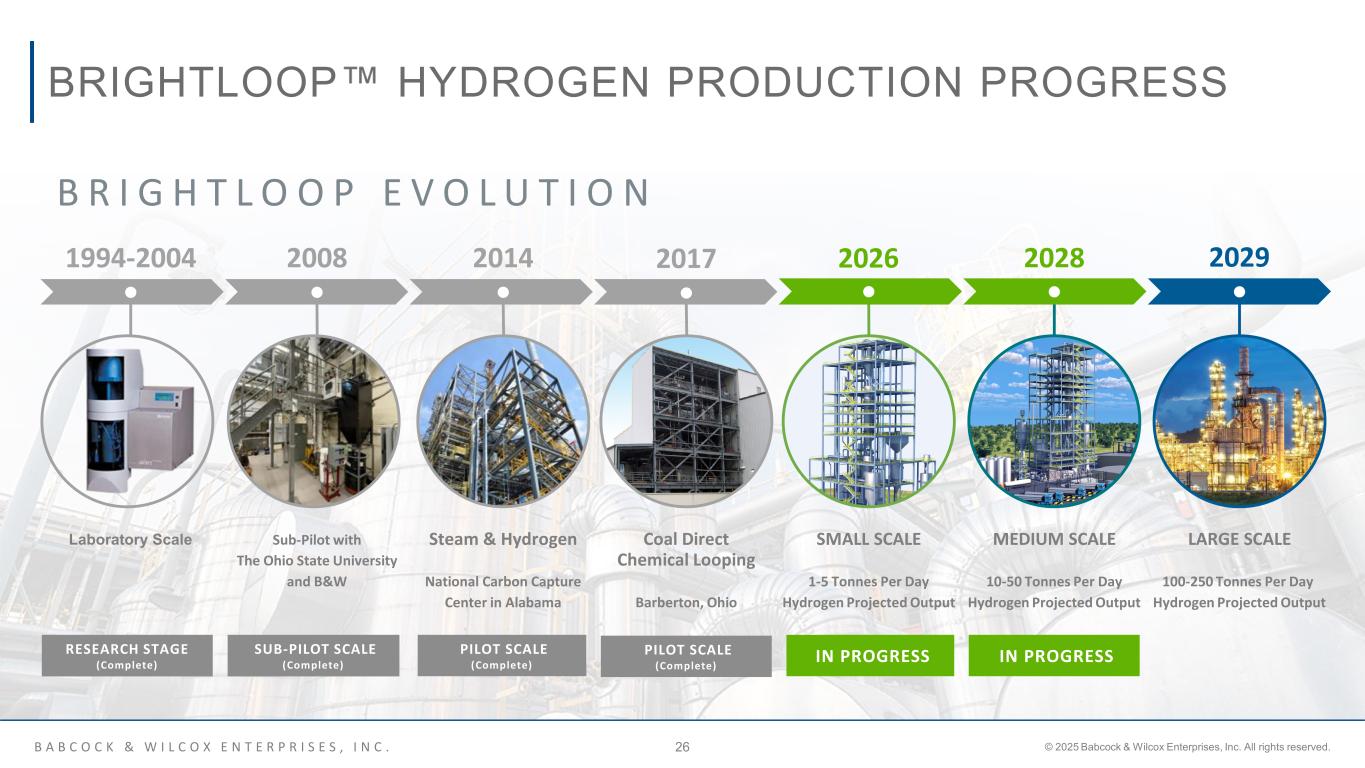

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.26 BRIGHTLOOP HYDROGEN PRODUCTION PROGRESS B R I G H T L O O P E V O L U T I O N Sub-Pilot with The Ohio State University and B&W MEDIUM SCALE 10-50 Tonnes Per Day Hydrogen Projected Output LARGE SCALE 100-250 Tonnes Per Day Hydrogen Projected Output SUB-PILOT SCALE (Complete) 2008 2028 2029 IN PROGRESS Laboratory Scale RESEARCH STAGE (Complete) 1994-2004 PILOT SCALE (Complete) Steam & Hydrogen National Carbon Capture Center in Alabama 2014 SMALL SCALE 1-5 Tonnes Per Day Hydrogen Projected Output IN PROGRESS 2026 PILOT SCALE (Complete) Coal Direct Chemical Looping Barberton, Ohio 2017

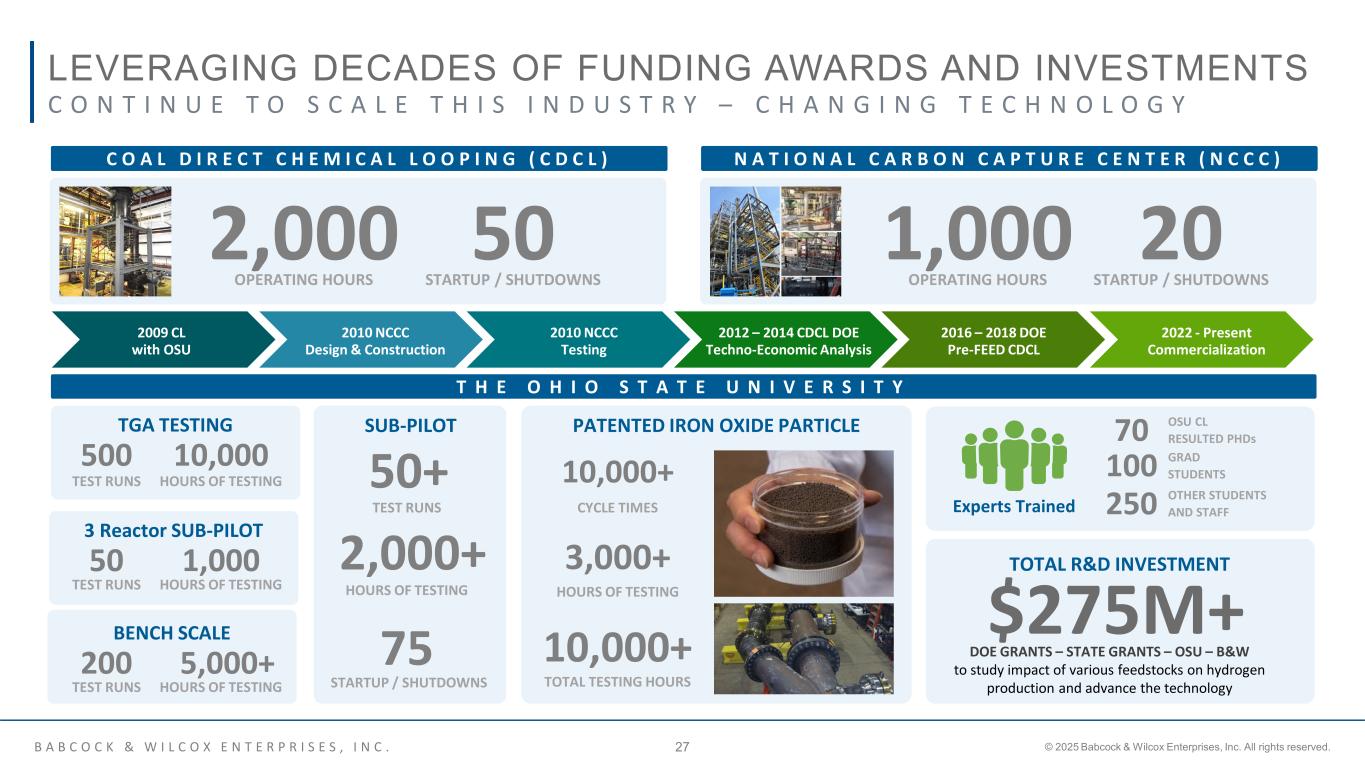

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.27 LEVERAGING DECADES OF FUNDING AWARDS AND INVESTMENTS C O A L D I R E C T C H E M I C A L L O O P I N G ( C D C L ) N A T I O N A L C A R B O N C A P T U R E C E N T E R ( N C C C ) T H E O H I O S T A T E U N I V E R S I T Y OPERATING HOURS 2,000 STARTUP / SHUTDOWNS 50 OPERATING HOURS 1,000 STARTUP / SHUTDOWNS 20 $275M+ PATENTED IRON OXIDE PARTICLETGA TESTING TEST RUNS HOURS OF TESTING 500 10,000 BENCH SCALE TEST RUNS HOURS OF TESTING 200 5,000+ 3 Reactor SUB-PILOT TEST RUNS HOURS OF TESTING 50 1,000 SUB-PILOT TEST RUNS 50+ HOURS OF TESTING 2,000+ STARTUP / SHUTDOWNS 75 TOTAL R&D INVESTMENT CYCLE TIMES 10,000+ HOURS OF TESTING 3,000+ TOTAL TESTING HOURS 10,000+ DOE GRANTS – STATE GRANTS – OSU – B&W to study impact of various feedstocks on hydrogen production and advance the technology OSU CL RESULTED PHDs GRAD STUDENTS 70 100 OTHER STUDENTS AND STAFF250Experts Trained 2016 – 2018 DOE Pre-FEED CDCL 2009 CL with OSU 2010 NCCC Testing 2012 – 2014 CDCL DOE Techno-Economic Analysis 2010 NCCC Design & Construction 2022 - Present Commercialization C O N T I N U E T O S C A L E T H I S I N D U S T R Y – C H A N G I N G T E C H N O L O G Y

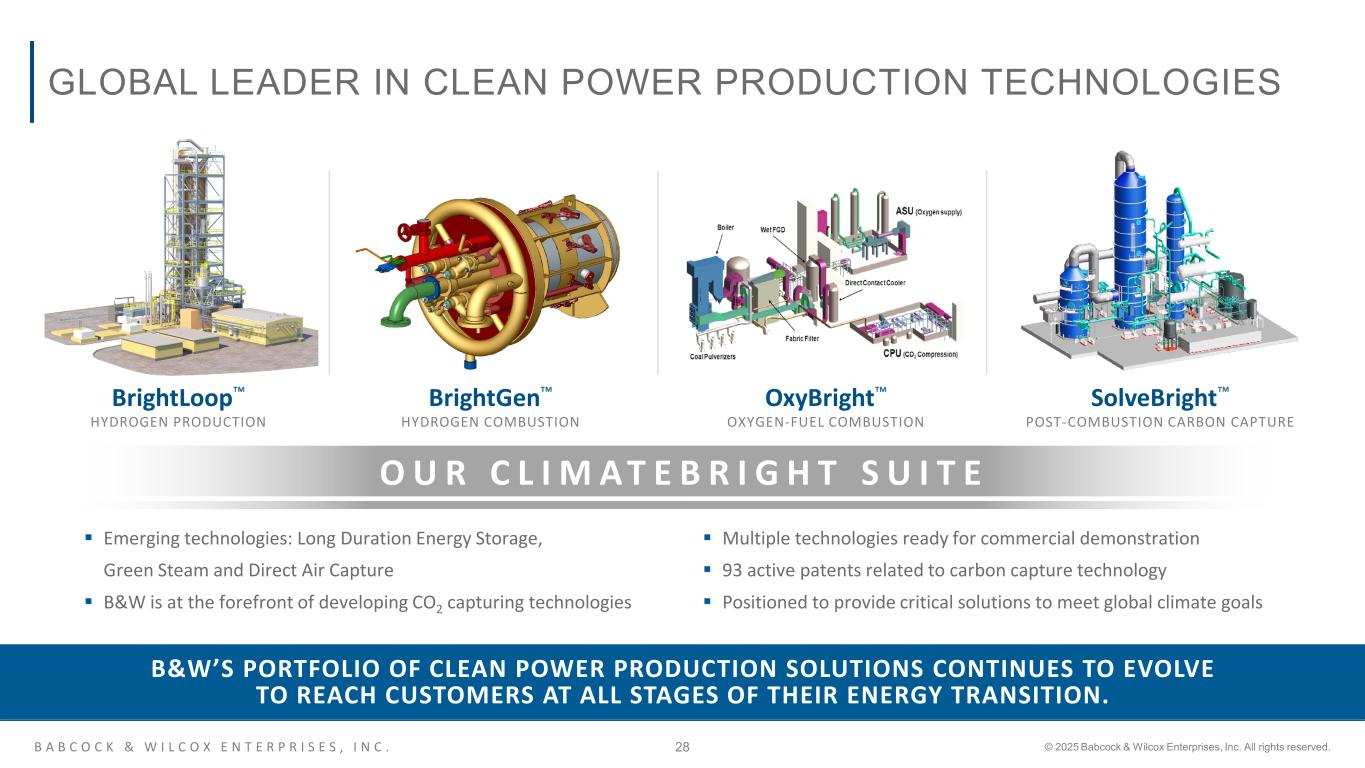

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.28 O U R C L I M A T E B R I G H T S U I T E GLOBAL LEADER IN CLEAN POWER PRODUCTION TECHNOLOGIES Emerging technologies: Long Duration Energy Storage, Green Steam and Direct Air Capture B&W is at the forefront of developing CO2 capturing technologies B&W’S PORTFOLIO OF CLEAN POWER PRODUCTION SOLUTIONS CONTINUES TO EVOLVE TO REACH CUSTOMERS AT ALL STAGES OF THEIR ENERGY TRANSITION. BrightLoop HYDROGEN PRODUCTION OxyBright OXYGEN-FUEL COMBUSTION BrightGen HYDROGEN COMBUSTION SolveBright POST-COMBUSTION CARBON CAPTURE Multiple technologies ready for commercial demonstration 93 active patents related to carbon capture technology Positioned to provide critical solutions to meet global climate goals

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.29 BIOENERGY WITH CARBON CAPTURE AND SEQUESTRATION (BECCS) B&W’s biomass boilers paired with either OxyBright or SolveBright produce carbon-negative energy with a -2,500gCO2e/kWh carbon intensity OxyBright with B&W’s renewable energy solution could produce carbon-negative energy with a -1,000 gCO2e/kWh carbon intensity Our negative carbon intensity (-2,500 gCO2e/kWh) is nearly seven times more negative than the U.S. grid is positive (+373 gCO2e/kWh)

B A B C O C K & W I L C O X E N T E R P R I S E S , I N C . © 2025 Babcock & Wilcox Enterprises, Inc. All rights reserved.30