EXHIBIT 96.1

Cover Image Credits

Bear River Zeolite Mine Site (drone image), Processing Plant, Zeolite Crystal Image

(SEM), and Digital Elevation Model (DEM) background.

Images courtesy of Bear River Zeolite Company and GeoGRAFX Consulting.

| Bear River Zeolite Project Franklin County, USA | Page: 3 |

Contents

| 1. Executive Summary |

| 17 |

|

| 1.1 Introduction |

| 17 |

|

| 1.2 Terms of Reference |

| 17 |

|

| 1.3 Property Setting |

| 17 |

|

| 1.4 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements |

| 18 |

|

| 1.5 Geology and Mineralization |

| 19 |

|

| 1.6 History and Exploration |

| 20 |

|

| 1.7 Drilling and Sampling |

| 21 |

|

| 1.8 Data Verification |

| 22 |

|

| 1.9 Mineral Processing and Metallurgical Testing |

| 23 |

|

| 1.9.1 Testing Overview and Methodology |

| 23 |

|

| 1.9.2 Key Findings and Mineralogical Characteristics |

| 23 |

|

| 1.9.3 Qualified Person’s Assessment |

| 23 |

|

| 1.10 Mineral Resource Estimation |

| 24 |

|

| 1.10.1 Estimation Methodology |

| 24 |

|

| 1.10.2 Mineral Resource Statement |

| 24 |

|

| 1.10.3 Factors That May Affect the Mineral Resource Estimate |

| 25 |

|

| 1.11 Mineral Reserve Estimation |

| 25 |

|

| 1.11.1 Estimation Methodology |

| 25 |

|

| 1.11.2 Mineral Reserve Statement |

| 25 |

|

| 1.11.3 Factors That May Affect the Mineral Resource Estimate |

| 26 |

|

| 1.12 Mining Methods |

| 26 |

|

| 1.13 Processing and Recovery Methods |

| 27 |

|

| 1.14 Infrastructure |

| 27 |

|

| 1.14.1 Site Facilities and Layout |

| 27 |

|

| 1.14.2 Power and Communications |

| 28 |

|

| 1.14.3 Water and Fuel Supply |

| 28 |

|

| 1.14.4 Roads, Rail, and Transportation |

| 28 |

|

| 1.14.5 Waste and Reclamation Management |

| 28 |

|

| 1.15 Markets and Contracts |

| 29 |

|

| 1.15.1 Market Overview and Product Positioning |

| 29 |

|

| 1.15.2 Pricing and Sales Strategy |

| 29 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 4 |

| 1.16 Environmental, Permitting and Social Considerations |

| 30 |

|

| 1.16.1 Permitting |

| 30 |

|

| 1.16.2 Environmental Studies and Monitoring |

| 30 |

|

| 1.16.3 Closure and Reclamation Considerations |

| 31 |

|

| 1.16.4 Social Considerations, Plans, Negotiations and Agreements |

| 31 |

|

| 1.17 Capital and Operating Cost Estimates |

| 31 |

|

| 1.18 Economic Analysis |

| 32 |

|

| 1.19 Risks and Opportunities |

| 33 |

|

| 1.19.1 Key Risks |

| 33 |

|

| 1.19.2 Key Opportunities |

| 34 |

|

| 1.20 Conclusions |

| 34 |

|

| 1.21 Recommendations |

| 34 |

|

| 2 Introduction |

| 36 |

|

| 2.1 Registrant |

| 36 |

|

| 2.2 Scope of Report |

| 36 |

|

| 2.2.1 Report Purpose |

| 36 |

|

| 2.2.2 Terms of Reference |

| 36 |

|

| 2.3 Qualified Persons |

| 37 |

|

| 2.4 Site Visits and Scope of Personal Inspection |

| 38 |

|

| 2.5 Report Date |

| 39 |

|

| 2.6 Information Sources and References |

| 39 |

|

| 2.7 Previous Technical Report Summaries |

| 40 |

|

| 3 Property Description |

| 41 |

|

| 3.1 Property Location |

| 41 |

|

| 3.2 Land Tenure and Mineral Titles |

| 43 |

|

| 3.2.1 Federal Lands |

| 45 |

|

| 3.2.2 Private Ground |

| 48 |

|

| 3.3 Property Agreements |

| 51 |

|

| 3.3.1 Zeolite, LLC Amended and Restated Mining Lease |

| 51 |

|

| 3.4 Additional Royalties |

| 51 |

|

| 3.5 Surface Rights |

| 52 |

|

| 3.6 Water Rights |

| 52 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 5 |

| 3.7 Significant Encumbrances |

| 52 |

|

| 3.7.1 Permitting Requirements |

| 52 |

|

| 3.7.2 Permitting Timelines |

| 52 |

|

| 3.7.3 Violations and Fines |

| 52 |

|

| 3.8 Significant Factors and Risks That May Affect Access, Title or Work Programs |

| 53 |

|

| 3.9 Qualified Person Statement |

| 53 |

|

| 4 Accessibility, Climate, Local Resources, Infrastructure and Physiography |

| 54 |

|

| 4.1 Accessibility |

| 54 |

|

| 4.2 Climate |

| 54 |

|

| 4.3 Local Resources and Infrastructure |

| 54 |

|

| 4.4 Physiography |

| 55 |

|

| 5 History |

| 59 |

|

| 5.1 Overview of Zeolite Development in the United States |

| 59 |

|

| 5.2 Property Discovery and Early Development |

| 59 |

|

| 5.3 Ownership History |

| 59 |

|

| 5.4 Historic Exploration |

| 60 |

|

| 5.5 Initial Mine Development and Plant Construction |

| 60 |

|

| 5.6 Facility and Infrastructure Expansion |

| 62 |

|

| 5.7 Production History |

| 63 |

|

| 6 Geological Setting, Mineralization and Deposit Type |

| 64 |

|

| 6.1 District Geology |

| 66 |

|

| 6.1.1 Lithologies |

| 66 |

|

| 6.1.2 Structure |

| 69 |

|

| 6.1.3 Mineralization |

| 70 |

|

| 6.2 Property Geology |

| 71 |

|

| 6.2.1 Lithology |

| 71 |

|

| 6.2.2 Structure |

| 76 |

|

| 6.3 Bear River Deposit |

| 76 |

|

| 6.3.1 Lithology |

| 76 |

|

| 6.3.2 Genesis and Depositional Environment |

| 79 |

|

| 6.3.3 Structure |

| 80 |

|

| 6.3.4 Mineralization |

| 80 |

|

| 6.3.5 Deposit Dimensions |

| 80 |

|

| 6.4 Geological Model and Deposit Type |

| 81 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 6 |

| 7 Exploration |

| 83 |

|

| 7.1 Exploration (Other Than Drilling) |

| 83 |

|

| 7.1.1 Topographic Surveying |

| 83 |

|

| 7.1.2 Geological Mapping |

| 84 |

|

| 7.1.3 Surface Geochemistry |

| 85 |

|

| 7.1.4 Qualified Person’s Interpretation of the Exploration Information |

| 87 |

|

| 7.2 Drilling |

| 87 |

|

| 7.2.1 Overview |

| 87 |

|

| 7.2.2 Drill Methods |

| 89 |

|

| 7.2.3 Logging |

| 89 |

|

| 7.2.4 Recovery |

| 90 |

|

| 7.2.5 Collar Surveys |

| 90 |

|

| 7.2.6 Down Hole Surveys |

| 90 |

|

| 7.2.7 Drilling Results |

| 90 |

|

| 7.2.8 Comment on Material Results and Interpretation |

| 96 |

|

| 7.3 Hydrogeology |

| 97 |

|

| 7.4 Geotechnical |

| 97 |

|

| 7.5 Exploration Potential |

| 97 |

|

| 7.6 Qualified Person’s Conclusions on Exploration |

| 98 |

|

| 8 Sample Preparation, Analyses, and Security |

| 99 |

|

| 8.1 Sampling Methods |

| 99 |

|

| 8.1.1 Surface Samples |

| 99 |

|

| 8.1.2 Hydraulic Percussion Drill Rig |

| 99 |

|

| 8.2 Sample Security Methods |

| 100 |

|

| 8.3 Density Determinations |

| 100 |

|

| 8.4 Analytical and Test Laboratories |

| 100 |

|

| 8.5 Sample Preparation |

| 101 |

|

| 8.6 Analysis |

| 101 |

|

| 8.6.1 ALS |

| 101 |

|

| 8.6.2 SGS |

| 101 |

|

| 8.7 Quality Assurance and Quality Control |

| 102 |

|

| 8.7.1 Certified Reference Materials (Standards) |

| 103 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 7 |

| 8.7.2 Blank Samples |

| 103 |

|

| 8.7.3 Field Duplicates |

| 105 |

|

| 8.7.4 Laboratory Quality Control |

| 106 |

|

| 8.8 Qualified Person’s Opinion on Sample Preparation, Security, and Analytical Procedures |

| 107 |

|

| 9 Data Verification |

| 108 |

|

| 9.1 Internal Data Verification |

| 108 |

|

| 9.1.1 Drill Hole Database Audit |

| 108 |

|

| 9.2 External Data Verification |

| 108 |

|

| 9.2.1 Independent CEC Analysis |

| 108 |

|

| 9.3 Data Verified by Qualified Person |

| 110 |

|

| 9.3.1 Data and Document Examination |

| 110 |

|

| 9.3.2 Unpatented Claim Status |

| 110 |

|

| 9.3.3 Site Visit |

| 111 |

|

| 9.3.4 Field Collar Verification |

| 112 |

|

| 9.4 Data Adequacy for Mineral Resource and Reserve Estimation |

| 113 |

|

| 10 Mineral Processing and Metallurgical Testing |

| 114 |

|

| 10.1 Physical and Chemical Characteristics of Clinoptilolite Zeolite |

| 114 |

|

| 10.2 Mineralogy |

| 115 |

|

| 10.2.1 Cation Exchange Capacity Analysis |

| 115 |

|

| 10.2.2 XRD Analysis |

| 120 |

|

| 10.2.3 XRD Analysis of Zeo1 lithology |

| 121 |

|

| 10.2.4 Whole Rock Analysis |

| 125 |

|

| 10.2.5 Elemental Analysis |

| 127 |

|

| 10.3 Applications |

| 130 |

|

| 10.3.1 CEC Classification and Potential Uses |

| 130 |

|

| 10.3.2 Classification of Bear River Lithologies |

| 130 |

|

| 10.4 Registrations and Certifications |

| 132 |

|

| 10.5 Qualified Person’s Opinion on Data Adequacy |

| 133 |

|

| 11 Mineral Resource Estimate |

| 134 |

|

| 11.1 Summary of Mineral Resources |

| 134 |

|

| 11.2 Data Used in the Estimate |

| 134 |

|

| 11.3 Exploratory Data Analysis (EDA) |

| 135 |

|

| 11.4 Geological and Mineralization Interpretation |

| 140 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 8 |

| 11.5 Compositing and Capping |

| 152 |

|

| 11.6 Variography and Geostatistics |

| 152 |

|

| 11.7 Block Model Parameters |

| 156 |

|

| 11.8 Classification Criteria |

| 156 |

|

| 11.9 Validation of the Estimate |

| 160 |

|

| 11.10 Mineral Resource Sensitivity Analysis |

| 169 |

|

| 11.11 QP Statement |

| 170 |

|

| 11.12 Mineral Resource Statement |

| 171 |

|

| 11.13 Uncertainties (Factors) That May Affect the Mineral Resource Estimate |

| 172 |

|

| 12 Mineral Reserve Estimate |

| 174 |

|

| 12.1 Introduction |

| 174 |

|

| 12.2 Reserve Classification Confidence |

| 174 |

|

| 12.3 Reserve Estimation Methodology |

| 174 |

|

| 12.4 Modifying Factors |

| 174 |

|

| 12.5 Ore Selection Analysis |

| 175 |

|

| 12.6 Mineral Reserve Estimate |

| 175 |

|

| 12.7 Design Pit |

| 178 |

|

| 12.8 Risk Factors Affecting Reserves |

| 181 |

|

| 12.9 Recommendations |

| 181 |

|

| 12.10 Qualified Person’s Statement |

| 181 |

|

| 13 Mining Methods |

| 182 |

|

| 13.1 Introduction |

| 182 |

|

| 13.2 Geotechnical Considerations |

| 183 |

|

| 13.3 Hydrogeological Considerations |

| 183 |

|

| 13.4 Mine Design |

| 183 |

|

| 13.5 Dilution and Recovery Factors |

| 184 |

|

| 13.6 Mining Method |

| 184 |

|

| 13.7 Stripping and Backfilling |

| 184 |

|

| 13.8 Blasting and Explosives |

| 185 |

|

| 13.9 Explosives Storage and Handling |

| 185 |

|

| 13.10 Grade Control and Production Monitoring |

| 186 |

|

| 13.11 Production Schedule |

| 186 |

|

| 13.12 Mining Fleet |

| 186 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 9 |

| 13.13 Personnel |

| 187 |

|

| 13.14 Operations |

| 187 |

|

| 13.15 Recommendations |

| 189 |

|

| 14 Process and Recovery Methods |

| 190 |

|

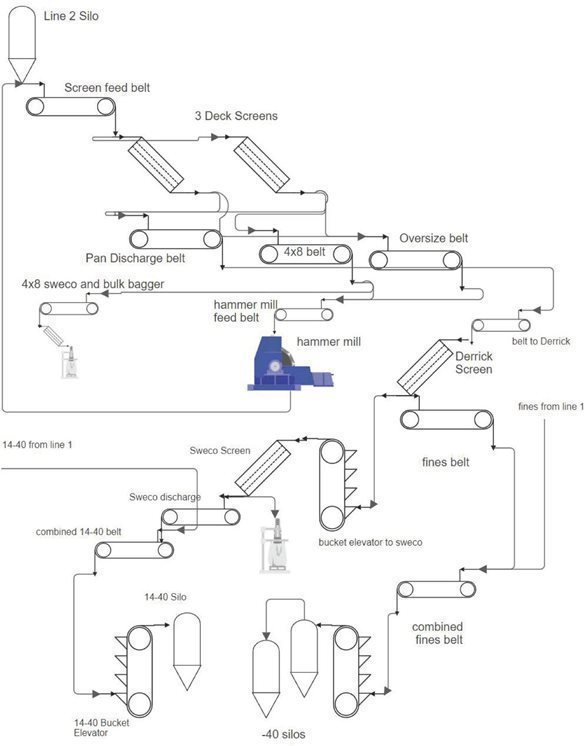

| 14.1 Process Flowsheet and Equipment Description |

| 190 |

|

| 14.2 Flowsheet |

| 193 |

|

| 14.3 Plant Throughput and Design |

| 196 |

|

| 14.3.1 Overview |

| 196 |

|

| 14.3.2 Packaging |

| 196 |

|

| 14.4 Process Facility Performance |

| 196 |

|

| 14.5 Equipment Specifications |

| 197 |

|

| 14.6 Power, Water, and Process Materials |

| 198 |

|

| 14.6.1 Power |

| 198 |

|

| 14.6.2 Water |

| 198 |

|

| 14.6.3 Consumables |

| 198 |

|

| 14.7 Personnel |

| 199 |

|

| 14.8 Conclusion |

| 199 |

|

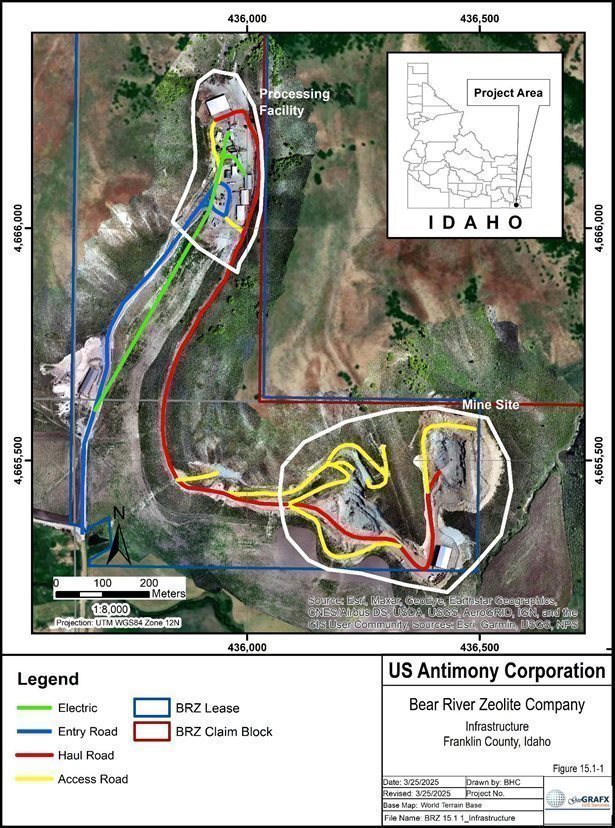

| 15 Infrastructure |

| 200 |

|

| 15.1 Overview |

| 200 |

|

| 15.2 Roads and Logistics |

| 202 |

|

| 15.3 Rail and Transport |

| 202 |

|

| 15.4 Stockpiles |

| 202 |

|

| 15.5 Waste Rock Storage Facilities |

| 202 |

|

| 15.6 Water Management |

| 203 |

|

| 15.7 Water Supply |

| 203 |

|

| 15.8 Site Buildings and Facilities |

| 203 |

|

| 15.9 Camps and Accommodation |

| 203 |

|

| 15.10 Power and Electrical |

| 204 |

|

| 15.11 Communications |

| 204 |

|

| 15.12 Fuel Storage |

| 204 |

|

| 15.13 Qualified Person’s Opinion |

| 205 |

|

| 16 Market Studies and Contracts |

| 206 |

|

| 16.1 Market Overview |

| 206 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 10 |

| 16.2 Product Portfolio |

| 207 |

|

| 16.3 Commodity Price Forecasts |

| 208 |

|

| 16.4 BRZ Product Pricing |

| 208 |

|

| 16.5 Mining, Processing, and Cost Structure |

| 209 |

|

| 16.6 Contracts |

| 209 |

|

| 16.7 Qualified Person Statement |

| 210 |

|

| 17 Environmental Studies, Permitting, and Plans, Negotiations, or Agreements with Local Individuals or Groups |

| 211 |

|

| 17.1 Introduction |

| 211 |

|

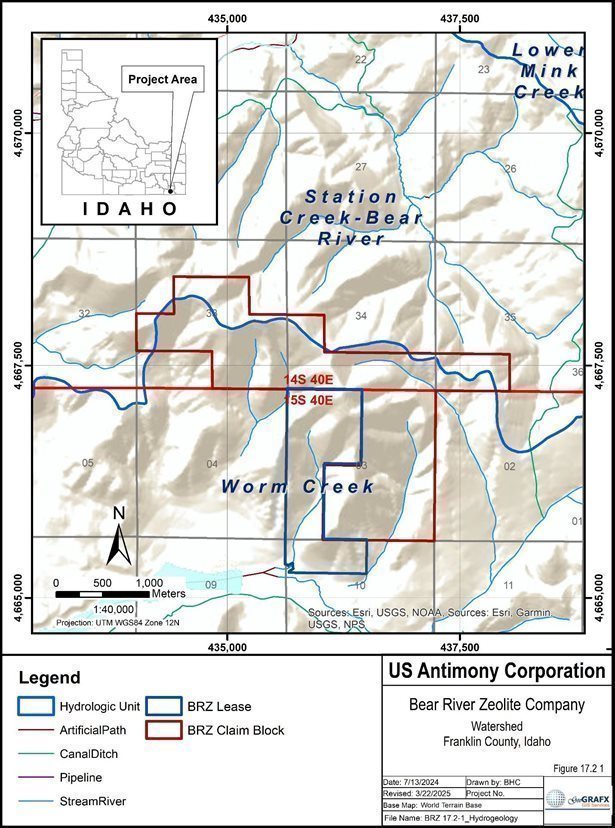

| 17.2 Baseline and Supporting Studies |

| 211 |

|

| 17.2.1 Land Use |

| 211 |

|

| 17.2.2 Climatology |

| 212 |

|

| 17.2.3 Air Quality |

| 213 |

|

| 17.2.4 Geochemistry |

| 215 |

|

| 17.2.5 Surface Water |

| 215 |

|

| 17.2.6 Groundwater Resources |

| 222 |

|

| 17.2.7 Soil Map Units and Composition |

| 223 |

|

| 17.2.8 Vegetation |

| 226 |

|

| 17.2.9 Wildlife Resources |

| 229 |

|

| 17.2.10 Habitat Setting |

| 230 |

|

| 17.2.11 Endangered Species and Critical Habitat |

| 231 |

|

| 17.3 Environmental Considerations/Monitoring Programs |

| 233 |

|

| 17.3.1 Waste Rock and Tailings Management |

| 233 |

|

| 17.3.2 Site Monitoring |

| 234 |

|

| 17.3.3 Water Management |

| 234 |

|

| 17.4 Project Permitting Requirements and Status |

| 235 |

|

| 17.4.1 Permitting Requirements |

| 235 |

|

| 17.4.2 Status of Permit Applications |

| 236 |

|

| 17.5 Social Considerations, Plans, Negotiations and Agreements |

| 236 |

|

| 17.5.1 Local Workforce and Economic Impact |

| 236 |

|

| 17.5.2 Support for Local Businesses: |

| 237 |

|

| 17.5.3 Community Engagement and Support: |

| 237 |

|

| 17.5.4 Social Considerations: |

| 237 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 11 |

| 17.5.5 Environmental and Social Responsibility |

| 237 |

|

| 17.5.6 Future Plans and Local Collaboration |

| 238 |

|

| 17.6 Closure and Reclamation Considerations |

| 238 |

|

| 17.6.1 Closure Plan and Regulatory Compliance |

| 238 |

|

| 17.6.2 Reclamation and Asset Retirement Obligations |

| 238 |

|

| 17.6.3 Financial Assurance and Bonding |

| 239 |

|

| 17.6.4 Post-Closure Monitoring and Reporting |

| 239 |

|

| 17.7 Qualified Person’s Opinion on Adequacy of Current Plans to Address Issues |

| 240 |

|

| 18 Capital and Operating Costs |

| 241 |

|

| 18.1 Basis of Estimate |

| 241 |

|

| 18.2 Capital Costs |

| 241 |

|

| 18.3 Operating Costs |

| 242 |

|

| 18.4 Economic Assumptions |

| 242 |

|

| 19 Economic Analysis |

| 243 |

|

| 19.1 Assumptions |

| 243 |

|

| 19.2 Cash Flow Summary |

| 243 |

|

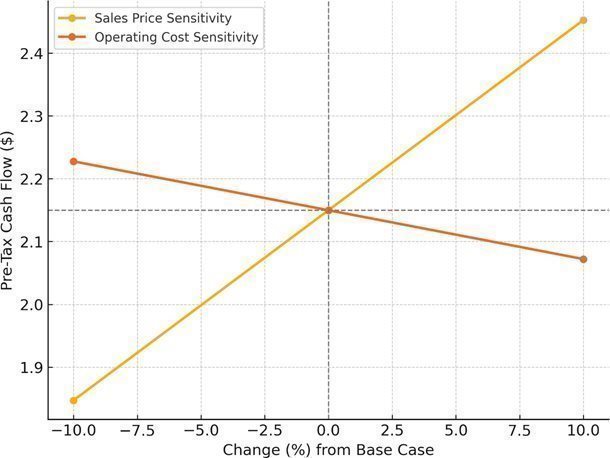

| 19.3 Sensitivity Analysis |

| 244 |

|

| 19.4 Conclusion |

| 245 |

|

| 20 Adjacent Properties |

| 246 |

|

| 21 Other Relevant Data and Information |

| 247 |

|

| 22 Interpretation and Conclusions |

| 248 |

|

| 22.1 Introduction |

| 248 |

|

| 22.2 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements |

| 248 |

|

| 22.2.1 Mineral Tenure and Land Control |

| 248 |

|

| 22.2.2 Surface Rights and Access |

| 248 |

|

| 22.2.3 Water Rights |

| 248 |

|

| 22.2.4 Royalties and Agreements |

| 249 |

|

| 22.2.5 Encumbrances and Legal Considerations |

| 249 |

|

| 22.3 Geology and Mineralization |

| 249 |

|

| 22.4 Exploration, Drilling, and Sampling |

| 250 |

|

| 22.4.1 Exploration (Other Than Drilling) |

| 250 |

|

| 22.4.2 Drilling Program |

| 251 |

|

| 22.4.3 Sampling Quality and Data Confidence |

| 251 |

|

| 22.4.4 Exploration Potential |

| 251 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 12 |

| 22.5 Data Verification |

| 252 |

|

| 22.6 Mineral Processing and Metallurgical Testing |

| 252 |

|

| 22.6.1 Testwork Overview |

| 253 |

|

| 22.6.2 Processing Methods |

| 253 |

|

| 22.6.3 Certifications |

| 254 |

|

| 22.6.4 Qualified Person’s Opinion |

| 254 |

|

| 22.7 Mineral Resource Estimate |

| 254 |

|

| 22.8 Mineral Reserve Estimates |

| 255 |

|

| 22.8.1 Summary |

| 256 |

|

| 22.8.2 Geological and Economic Viability |

| 256 |

|

| 22.8.3 Risk Factors |

| 256 |

|

| 22.8.4 Opportunities for Enhancement |

| 257 |

|

| 22.9 Mining Methods |

| 257 |

|

| 22.10 Processing and Recovery Methods |

| 257 |

|

| 22.11 Infrastructure |

| 258 |

|

| 22.11.1 Site Facilities |

| 258 |

|

| 22.11.2 Power and Utilities |

| 258 |

|

| 22.11.3 Communications |

| 258 |

|

| 22.11.4 Personnel and Logistics |

| 258 |

|

| 22.11.5 Limitations and Expansion Potential |

| 258 |

|

| 22.12 Market Studies |

| 259 |

|

| 22.13 Environmental, Permitting and Social Considerations |

| 259 |

|

| 22.13.1 Permitting |

| 259 |

|

| 22.13.2 Environmental Studies |

| 260 |

|

| 22.13.3 Closure and Reclamation |

| 260 |

|

| 22.13.4 Community and Social Engagement |

| 260 |

|

| 22.13.5 Qualified Person’s Opinion |

| 260 |

|

| 22.14 Capital and Operating Costs |

| 260 |

|

| 22.15 Economic Analysis |

| 261 |

|

| 22.16 Risks and Opportunities |

| 262 |

|

| 22.16.1 Risks |

| 262 |

|

| 22.16.2 Opportunities |

| 263 |

|

| 22.17 Conclusions |

| 263 |

|

| 23 Recommendations |

| 265 |

|

| 24 References |

| 266 |

|

| 25 Reliance on Information Provided by the Registrant |

| 269 |

|

| 26 Date and Signature Page |

| 271 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 13 |

Tables

| Table 1-1 Measured and Indicated Mineral Resources (Exclusive of Reserves) |

| 24 |

|

| Table 1-2 Inferred Mineral Resources (Exclusive of Reserves) |

| 24 |

|

| Table 1-3 Mineral Reserve for Bear River Zeolite Project |

| 26 |

|

| Table 1-4 Simplified Pre-Tax Cash Flow Summary |

| 32 |

|

| Table 2-1 Report Contributors and Responsibility |

| 37 |

|

| Table 3-1 Annual Claim Holding Costs |

| 46 |

|

| Table 3-2 Brear River Zeolite active placer claims |

| 46 |

|

| Table 3-3 Mine Safety Disclosure Information for the year ending December 31, 2024 |

| 53 |

|

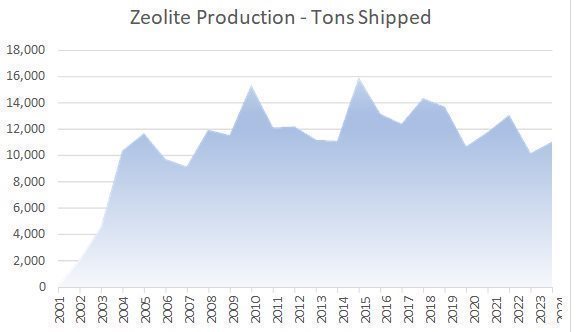

| Table 5-1 Zeolite Production |

| 63 |

|

| Table 6-1 Description of District Geology Map Units |

| 68 |

|

| Table 6-2 Description of Property Geology Map Units |

| 73 |

|

| Table 6-3 Stratigraphic Section of Worm Creek, Idaho |

| 74 |

|

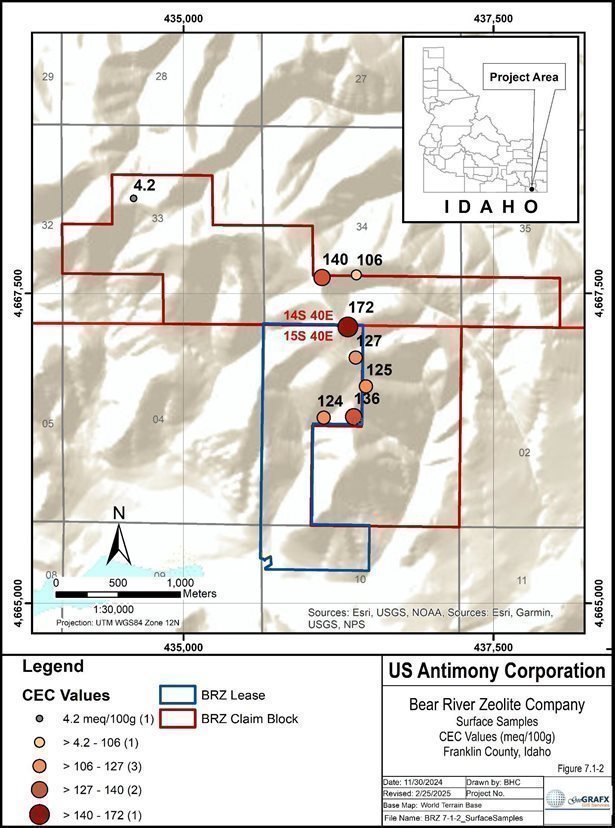

| Table 7-1 2024 Surface Rock Sample Results – CEC Analysis |

| 85 |

|

| Table 7-2 Summary Statistics for CEC Results Grouped by Lithology |

| 92 |

|

| Table 8-1 Descriptive Statistics for Bulk Density by Mineralized Zone |

| 100 |

|

| Table 8-2 Analytical Laboratories used by BRZ. |

| 100 |

|

| Table 8-3 Summary Counts of 2024 BRZ QA/QC Analyses |

| 103 |

|

| Table 8-4 Summary of Blank material submitted by the Company in sample submissions. |

| 104 |

|

| Table 8-5 CEC in blank reference materials |

| 104 |

|

| Table 9-1 Check assay results for 2024 air track drilling |

| 109 |

|

| Table 9-2 Check Coordinates for Drill Collar Locations |

| 113 |

|

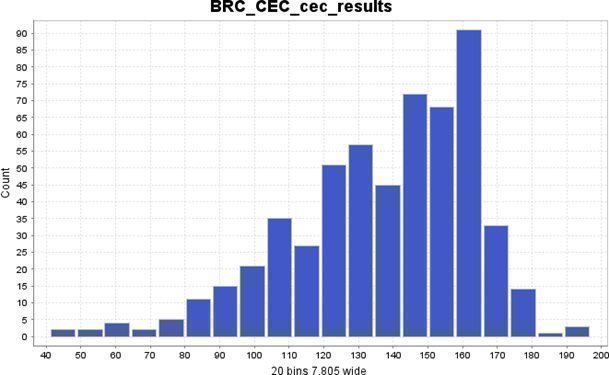

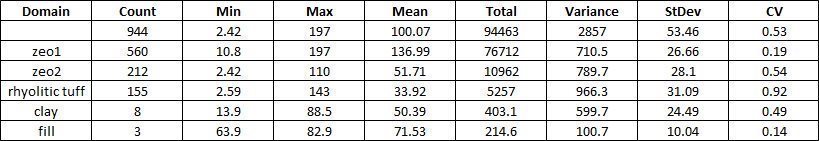

| Table 10-1 Summary Statistics for CEC Results for Zeo1 |

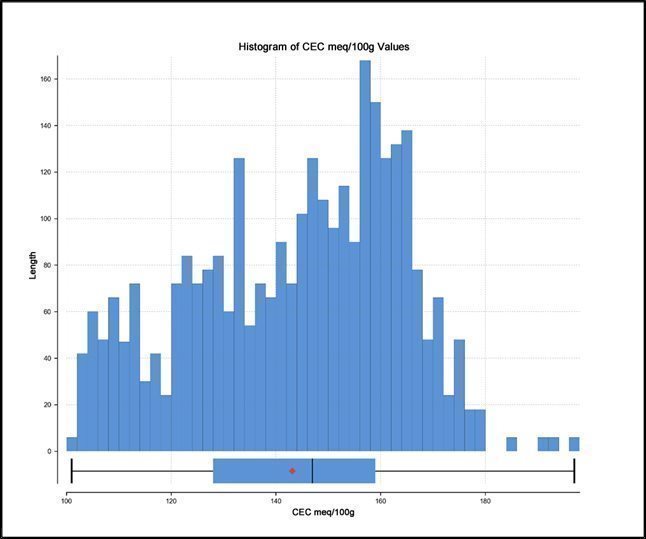

| 116 |

|

| Table 10-2 X-ray Diffraction (XRD) Analysis of Zeo1 Lithology in the Bear River Deposit |

| 123 |

|

| Table 10-3 Whole Rock Geochemistry of Zeo1 Lithology in the Bear River Deposit |

| 126 |

|

| Table 10-4 Elemental Analysis of Zeo1 Lithology in the Bear River Deposit |

| 127 |

|

| Table 10-5 Bear River Lithology Applications |

| 130 |

|

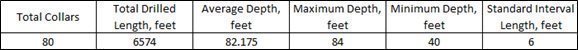

| Table 11-1 Drillhole Collar and Interval Statistics |

| 134 |

|

| Table 11-2 General CEC Statistics for the Drilling Database |

| 135 |

|

| Table 11-3: General CEC Drilling Statistics Broken Down by Lithologic Code |

| 138 |

|

| Table 11-4 Mineralized Envelope Statistics |

| 146 |

|

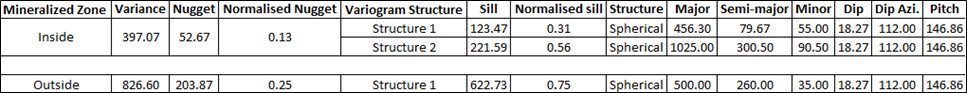

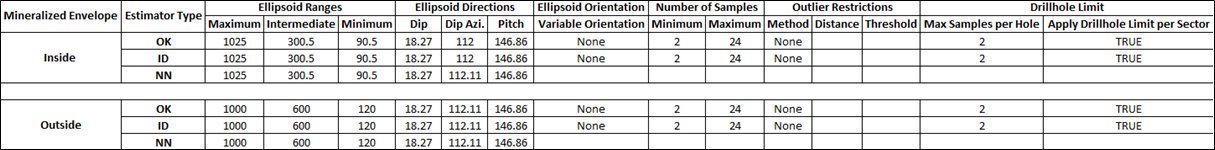

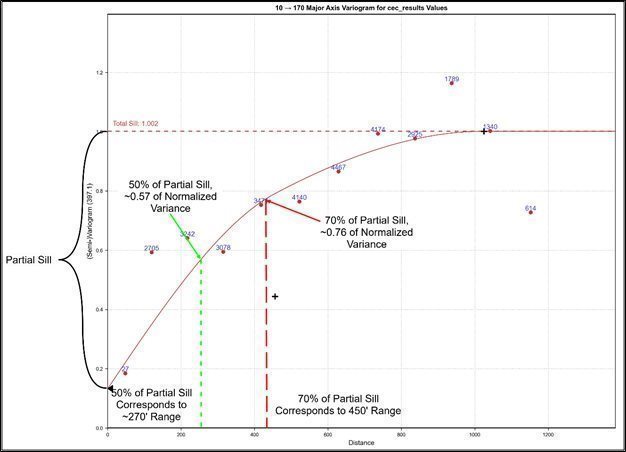

| Table 11-5: Variogram Parameters for Samples Inside and Outside the Mineralized Envelope |

| 153 |

|

| Table 11-6: Estimation Parameters for OK, ID2, and NN Estimators Inside and Outside Mineralized Envelope |

| 153 |

|

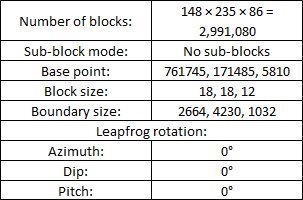

| Table 11-7: Block Construction Parameters |

| 156 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 14 |

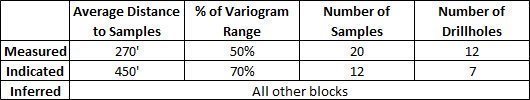

| Table 11-8 Categorization Parameters for Measured and Indicated Blocks |

| 157 |

|

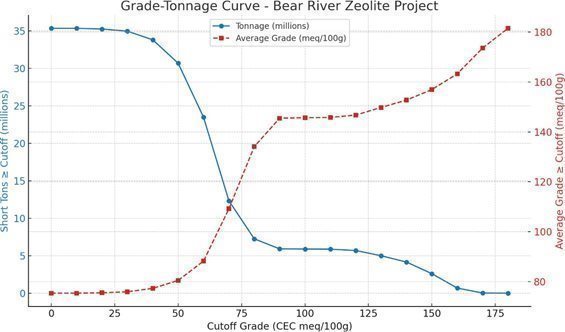

| Table 11-9 Grade-Tonnage Report Providing Short Tons and Average Grade of Various CEC Cutoffs, All Blocks Considered |

| 170 |

|

| Table 11-10 Total In-Situ Mineral Resource Estimate (Inclusive of Reserves) – Bear River Zeolite Project |

| 171 |

|

| Table 11-11 Measured and Indicated Mineral Resources (Exclusive of Reserves) |

| 172 |

|

| Table 11-12 Inferred Mineral Resources (Exclusive of Reserves) |

| 172 |

|

| Table 12-1 Mineral Reserve for Bear River Zeolite Project |

| 175 |

|

| Table 12-2 Ore and waste tonnage by pit bench elevation |

| 179 |

|

| Table 13-1 Mobile Equipment Fleet Supporting Bear River Zeolite Operations |

| 186 |

|

| Table 16-1 Bear River Zeolite Market Share by Application |

| 206 |

|

| Table 16-2 Historical Natural Zeolite Price Range |

| 208 |

|

| Table 16-3 BRZ Average Sale Price per Ton Sold (2013-2024) |

| 208 |

|

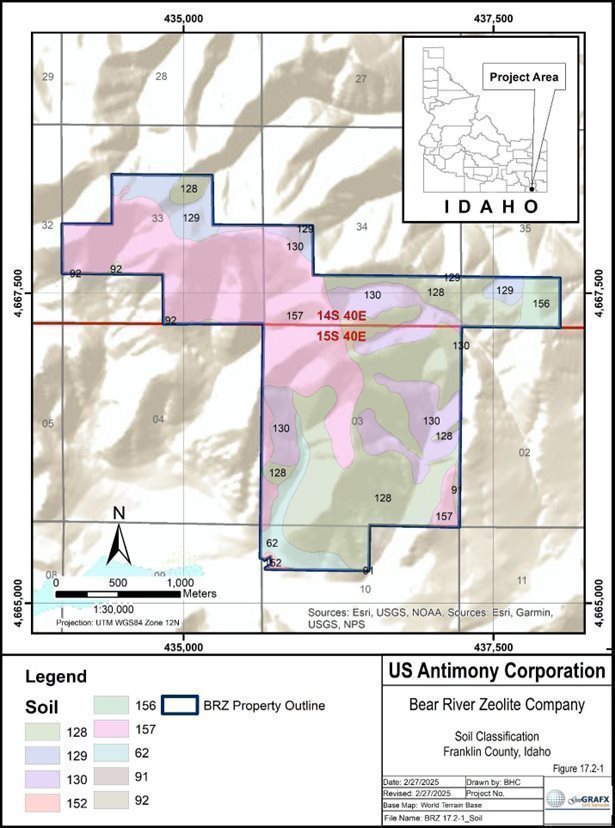

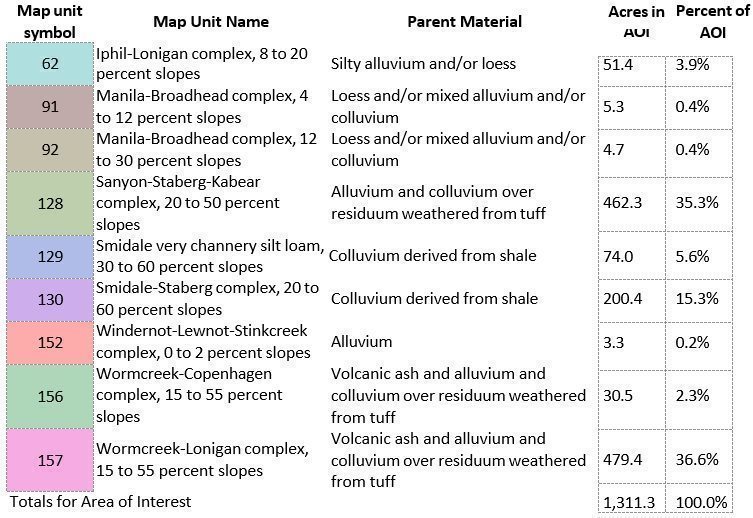

| Table 17-1 NRCS Soil Map Units Within the Bear River Zeolite Property |

| 225 |

|

| Table 17-2 Likely Wildlife Species Observed or Expected in the BRZ Area |

| 229 |

|

| Table 18-1 Bear River Zeolite Mine & Processing Capital Costs |

| 241 |

|

| Table 18-2 Operating Cost Summary |

| 242 |

|

| Table 19-1 Simplified Pre-Tax Cash Flow Summary |

| 244 |

|

| Table 19-2 Sensitivity of Pre-Tax Cash Flow to Sales Price and Operating Cost Assumptions (2025 Example) |

| 244 |

|

| Table 22-1 Measured and Indicated Mineral Resources (Exclusive of Reserves) |

| 255 |

|

| Table 22-2 Inferred Mineral Resources (Exclusive of Reserves) |

| 255 |

|

| Table 22-3 Mineral Reserve for Bear River Zeolite Project |

| 256 |

|

| Table 22-4 Simplified Pre-Tax Cash Flow Summary |

| 261 |

|

Figures

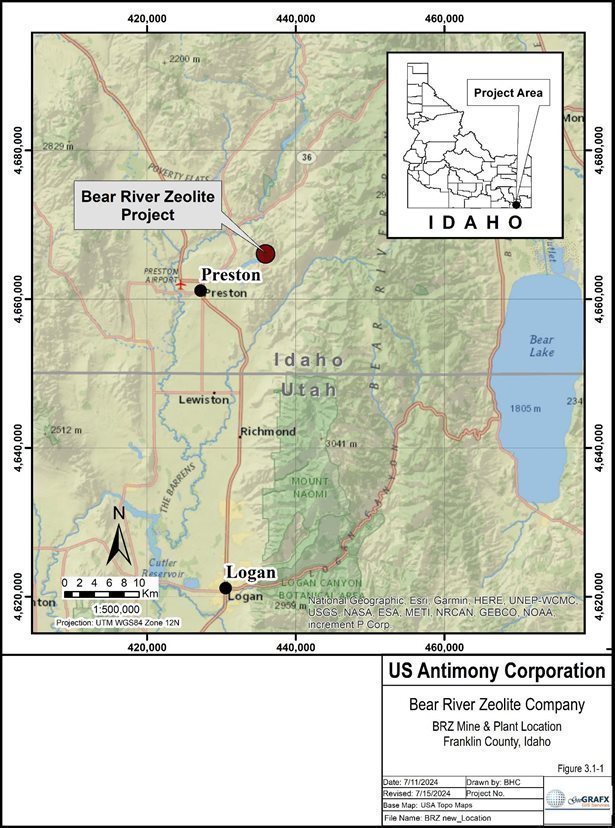

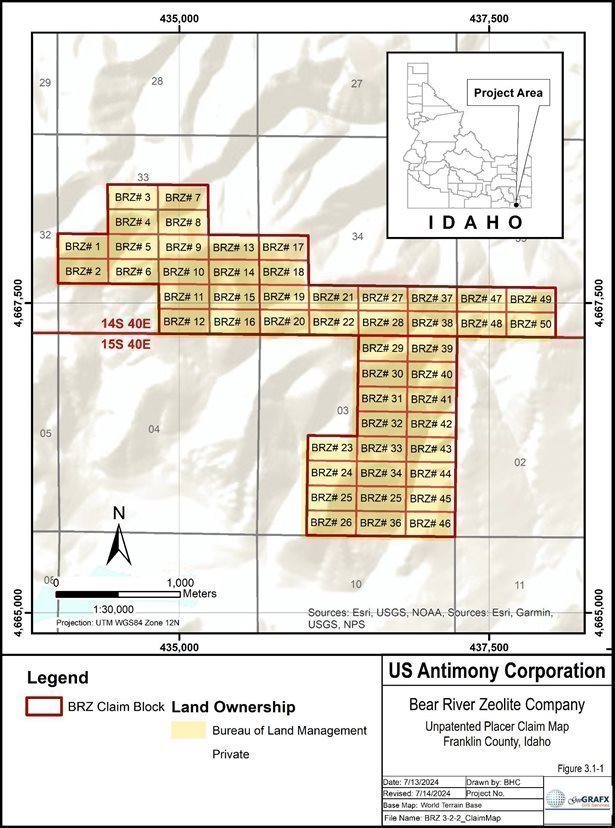

| Figure 3.1-1 Location Map |

| 42 |

|

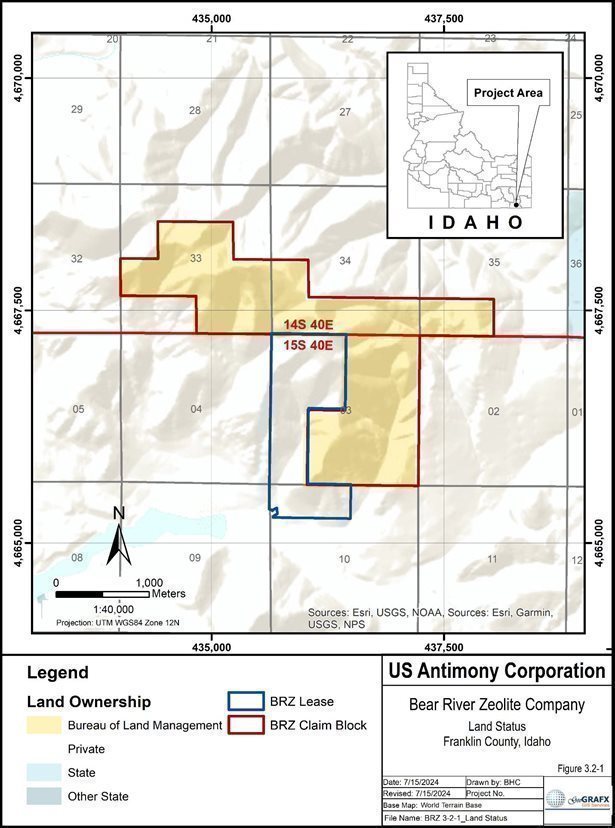

| Figure 3.2-1 Land Status Map |

| 44 |

|

| Figure 3.2-2 BRZ Unpatented Placer Claims |

| 47 |

|

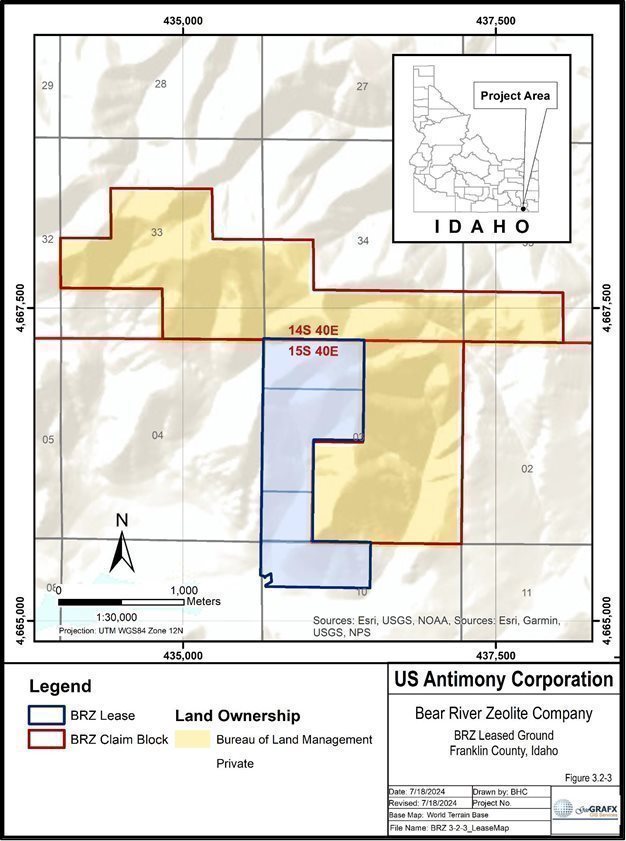

| Figure 3.2-3 BRZ Zeolite, LLC Leased Ground |

| 50 |

|

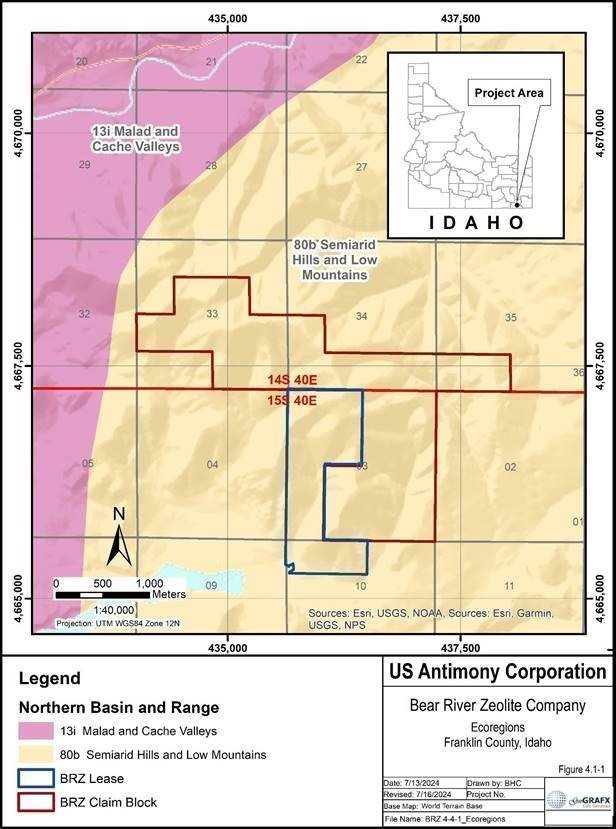

| Figure 4.4-1 Ecoregion Map |

| 57 |

|

| Figure 4.4-2 Typical Physiography of the Project Area |

| 58 |

|

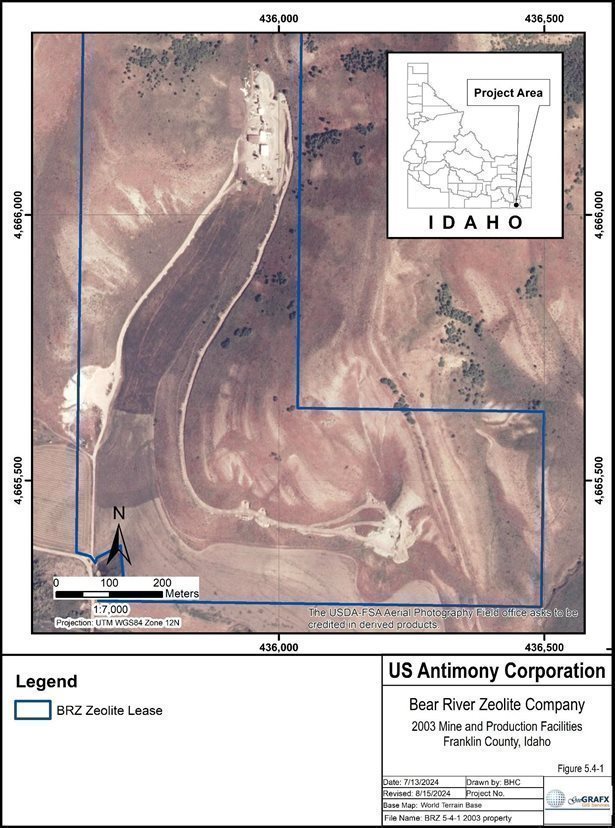

| Figure 5.5-1 2003 Mine and Production Facilities |

| 61 |

|

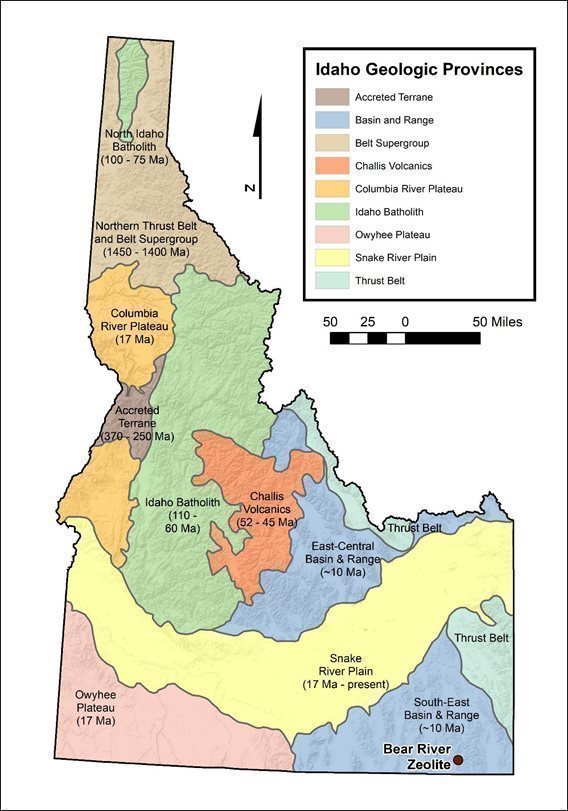

| Figure 5.7-1 Idaho Geologic Provinces |

| 65 |

|

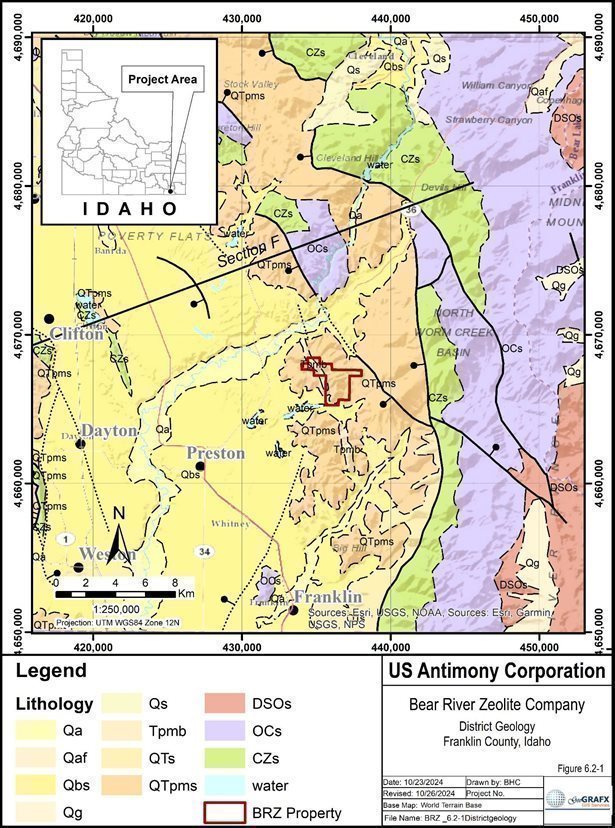

| Figure 6.1-1 District Geology |

| 67 |

|

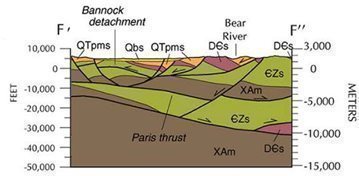

| Figure 6.1-2 Section F' - F" |

| 69 |

|

| Figure 6.1-3 Structural Geology of the Cache Valley Region |

| 70 |

|

| Figure 6.2-1 Property Geology |

| 72 |

|

| Figure 6.2-2 Map of Worm Creek Geology |

| 74 |

|

| Figure 6.3-1 Geology of the Bear River Zeolite Deposit |

| 77 |

|

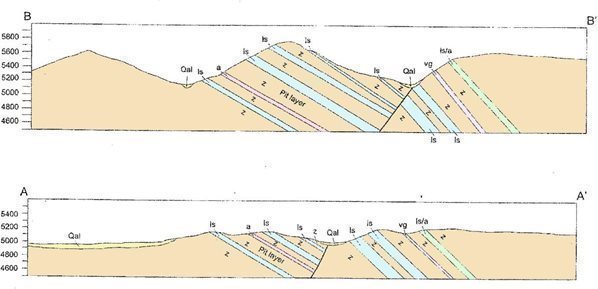

| Figure 6.3-2 Generalized Cross Sections of the BRZ Deposit |

| 78 |

|

| Figure 6.3-3 Bear River Middle Pit |

| 79 |

|

| Figure 6.4-1 Alteration mineral zoning in saline, alkaline lake environment. |

| 81 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 15 |

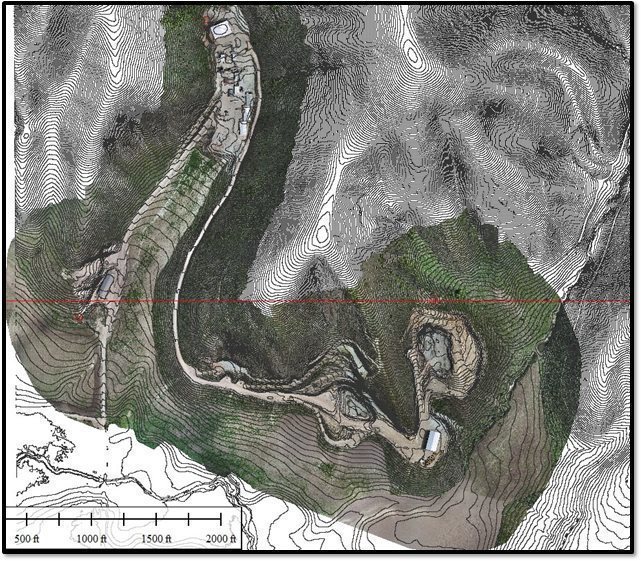

| Figure 7.1-1 2024 Surface Topography and Imagery |

| 84 |

|

| Figure 7.1-2 Surface Sample Locations and CEC Results |

| 86 |

|

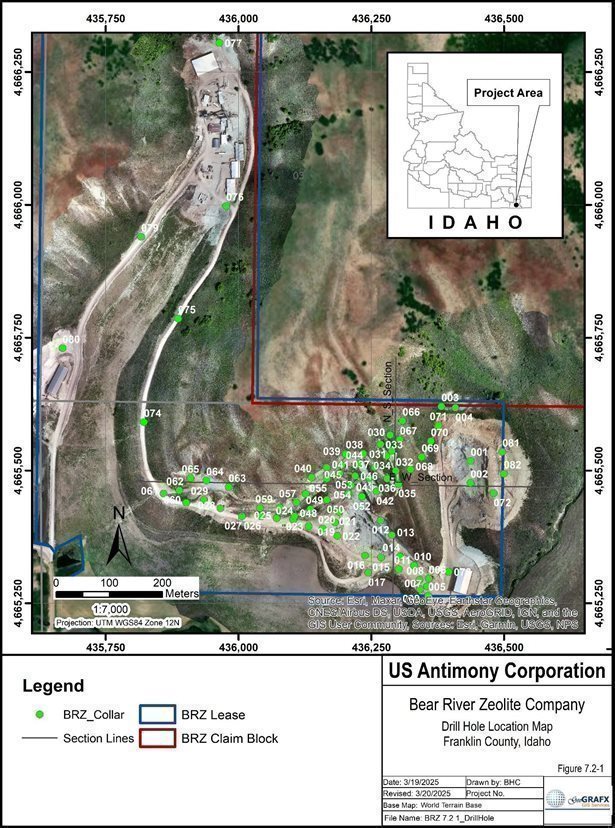

| Figure 7.2-1 Drill Hole Location Map |

| 88 |

|

| Figure 7.2-2 Furukawa HRC 1450 ED2 Hydraulic Percussion Drill |

| 89 |

|

| Figure 7.2-3 Chip Trays from 2024 Hydraulic percussion Drilling Program |

| 90 |

|

| Figure 7.2-4 N-S Cross Section |

| 91 |

|

| Figure 7.2-5 E-W Cross Section |

| 92 |

|

| Figure 7.2-6 Histogram of CEC Results Grouped by Lithology |

| 93 |

|

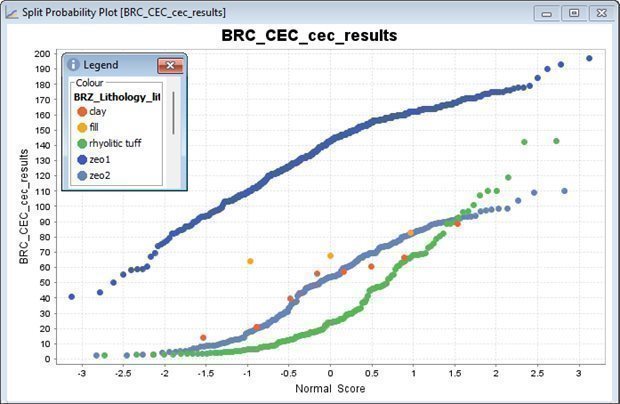

| Figure 7.2-7 Split Probability Plots of CEC Results Grouped by Lithology |

| 94 |

|

| Figure 7.2-8 Tukey Box Plots for CEC Results Grouped by Lithology |

| 96 |

|

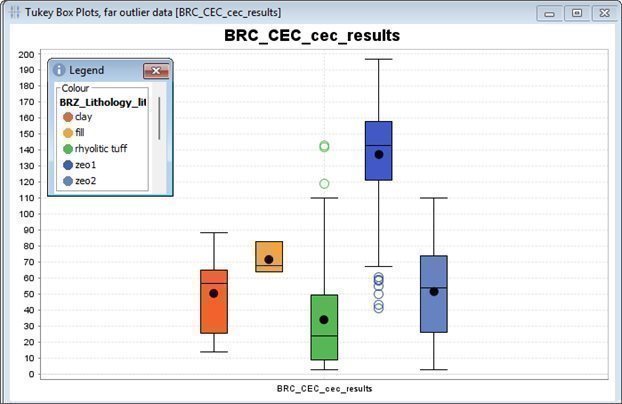

| Figure 8.7-1 CEC values in Blanks reference material control chart. |

| 104 |

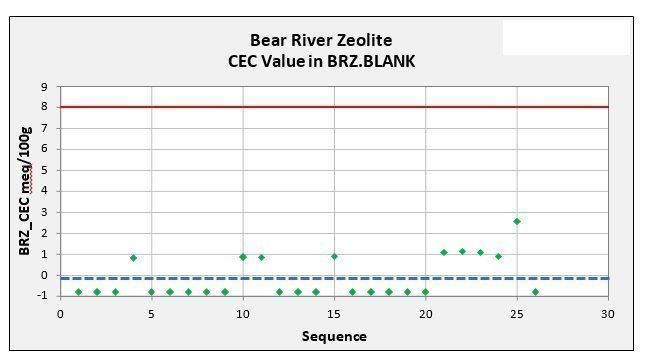

|

| Figure 8.7-2 BRZ Field Duplicate Graph |

| 106 |

|

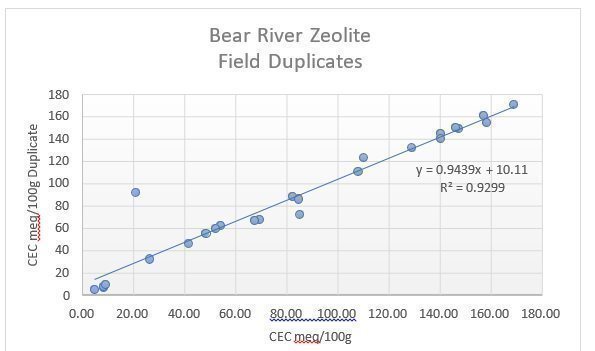

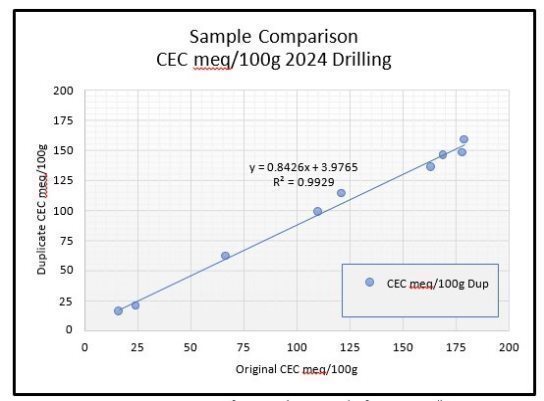

| Figure 9.2-1 Comparison of CEC meq/100g Samples from 2024 Drilling |

| 109 |

|

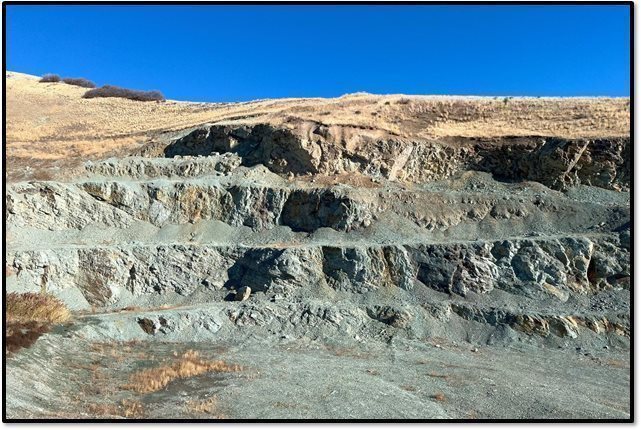

| Figure 9.3-1 Mineralized Zeolite Material in the Old Pit |

| 112 |

|

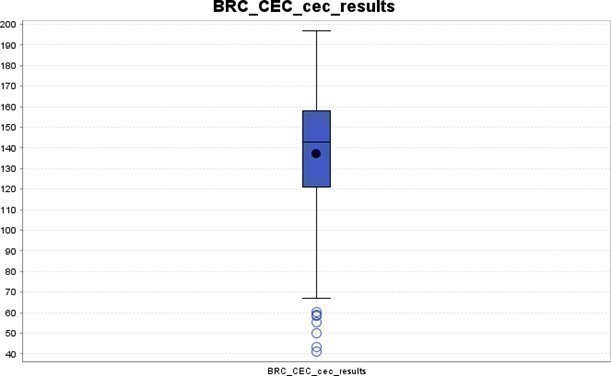

| Figure 10.2-1 Histogram of CEC values for zeo1 |

| 117 |

|

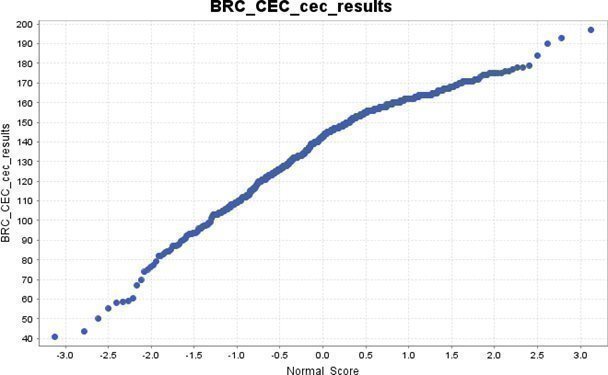

| Figure 10.2-2 Probability Plot of CEC values for zeo1 |

| 118 |

|

| Figure 10.2-3 Tukey Box Plot of CEC values for zeo1 |

| 119 |

|

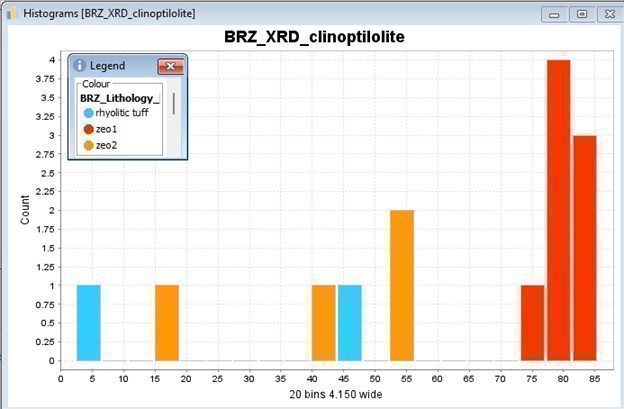

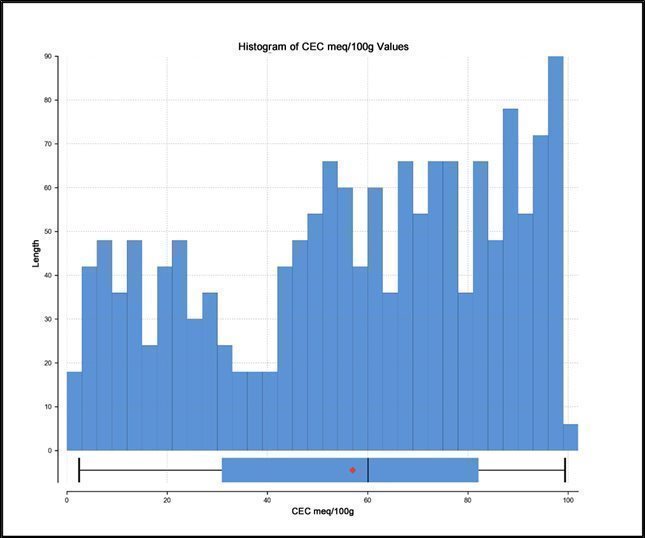

| Figure 10.2-4 Histogram of Cation Exchange Capacity (CEC) Values for Bear River Lithologies |

| 121 |

|

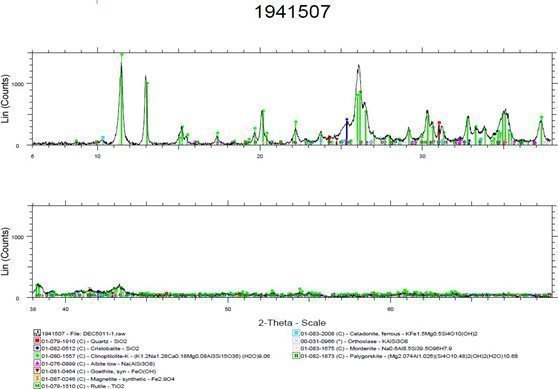

| Figure 10.2-5 X-ray Diffraction (XRD) Pattern of Sample 1941507 – Bear River Zeolite Deposit |

| 122 |

|

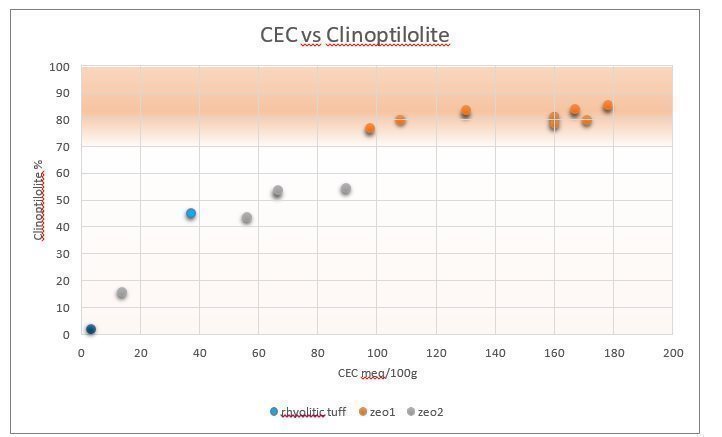

| Figure 10.2-6 Scatter Plot of CEC vs. % Clinoptilolite for Bear River Lithologies |

| 125 |

|

| Figure 11.3-1: Plan View of Drillhole Collars (Yellow) Relative to Lease Boundary (Red Overlay) and Aerial Photo |

| 136 |

|

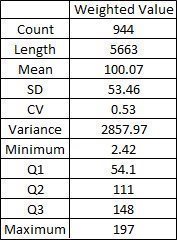

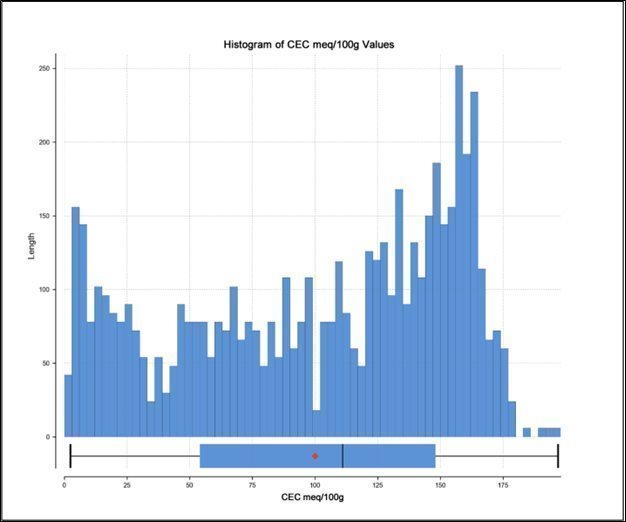

| Figure 11.3-2: Histogram of CEC Grade Distribution, All Drilling |

| 137 |

|

| Figure 11.3-3: CEC Histogram Broken Down by Lithologic Code, All Drilling Samples |

| 138 |

|

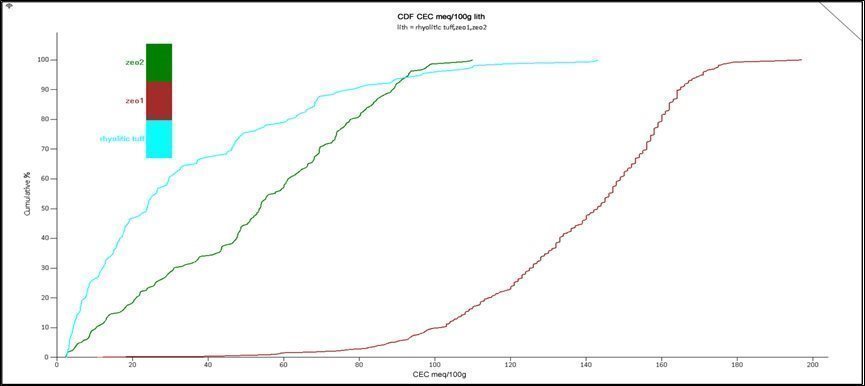

| Figure 11.4-1: Cumulative Frequency Plot of CEC within Rhyolite and Zeolite Lithologic Codes |

| 141 |

|

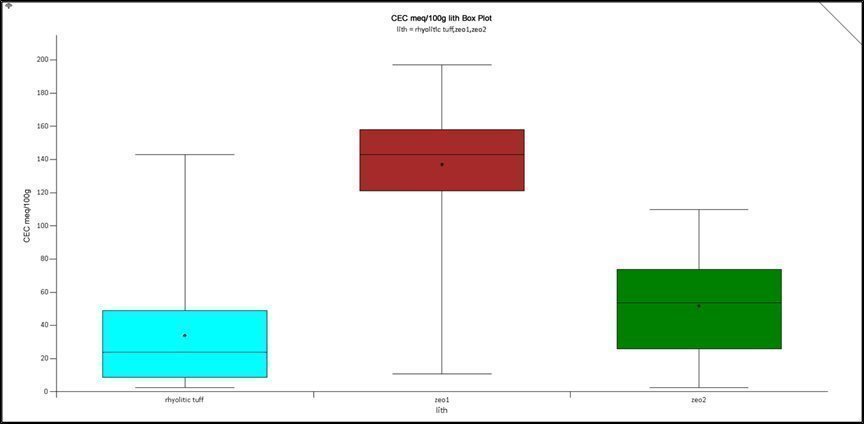

| Figure 11.4-2: Box Plot of CEC within Rhyolite and Zeolite Lithologic Codes |

| 142 |

|

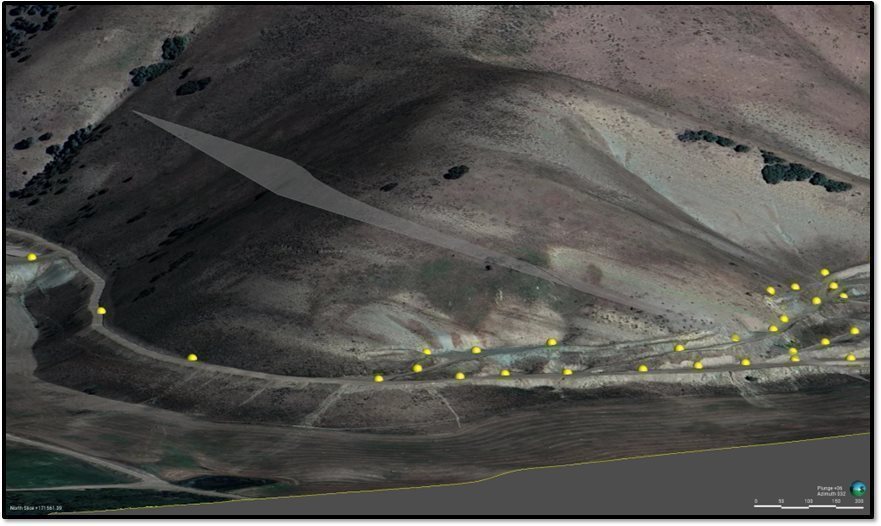

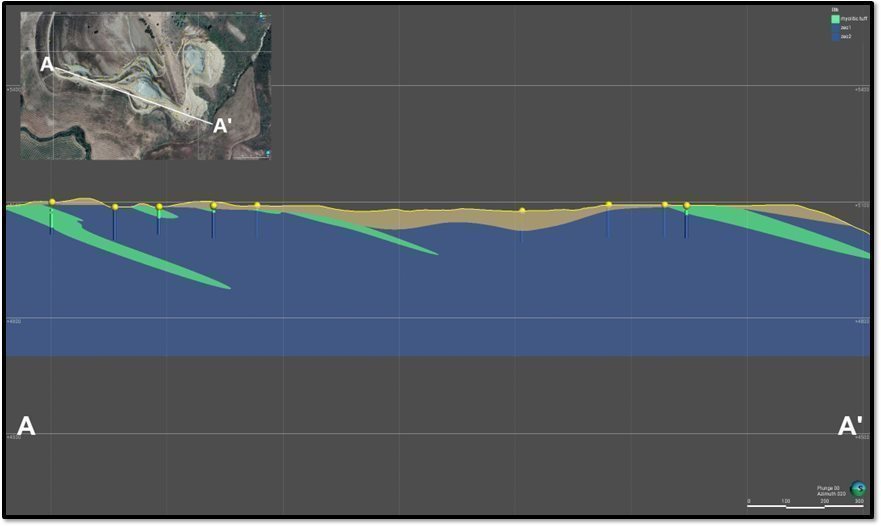

| Figure 11.4-3: Inclined View of Topography with Aerial Image Overlay Showing Zeolite/Rhyolite Bedding Relative to Reference Plane for Geological and Mineralization Modeling |

| 143 |

|

| Figure 11.4-4: Representative Cross-Sectional View of the Geologic Model and Drilling, Looking North- Northeast, with Rhyolite in Green, Topsoil in Tan, and Zeolite in Blue |

| 144 |

|

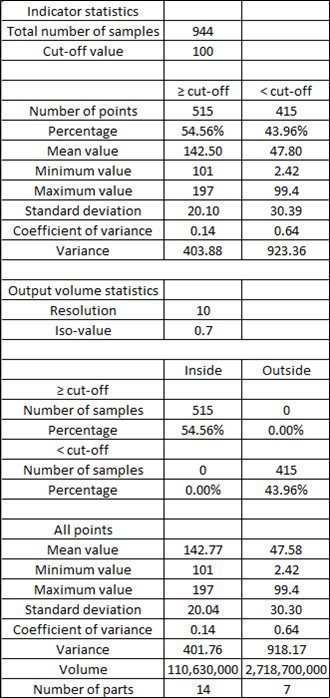

| Figure 11.4-5: Histogram of CEC Values Inside the Mineralized Envelope |

| 147 |

|

| Figure 11.4-6: Histogram of CEC Values Outside the Mineralized Envelope |

| 148 |

|

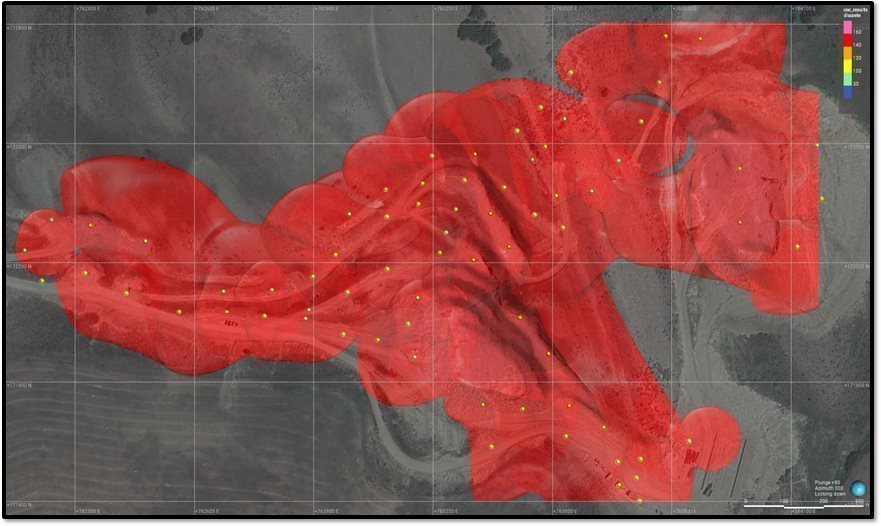

| Figure 11.4-7: 100 CEC Mineralized Envelope with CEC Drillhole Values, Plan View |

| 149 |

|

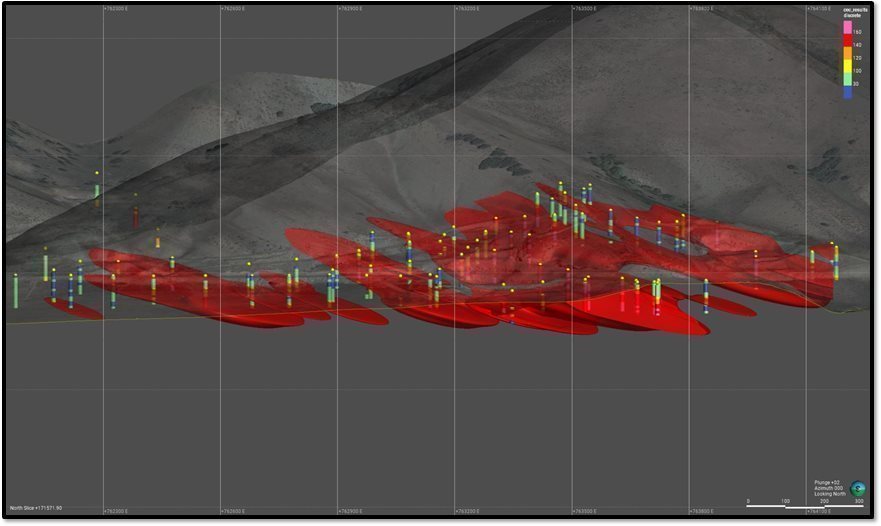

| Figure 11.4-8: 100 CEC Mineralized Envelope with CEC Drillhole Values, Rotated Aerial View Looking North |

| 150 |

|

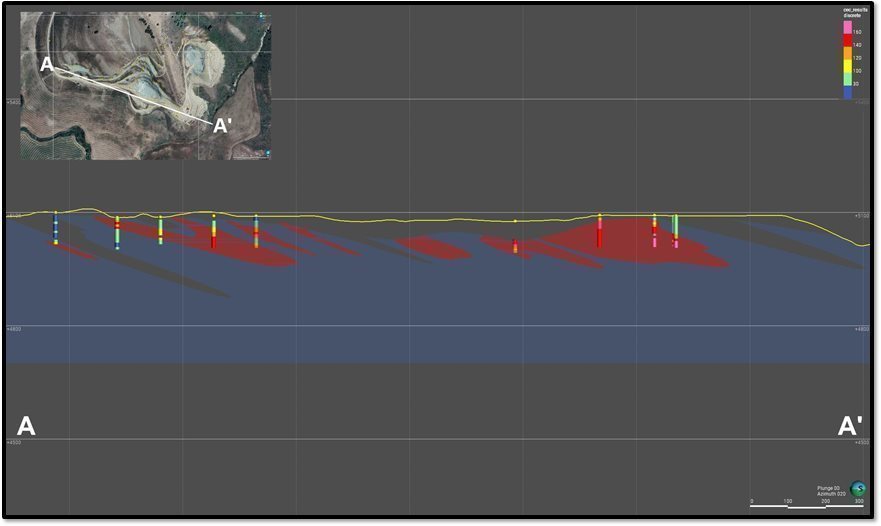

| Figure 11.4-9: 100 CEC Mineralized Envelope with CEC Drillhole Values, Representative Cross-Sectional View Looking North-Northeast |

| 151 |

|

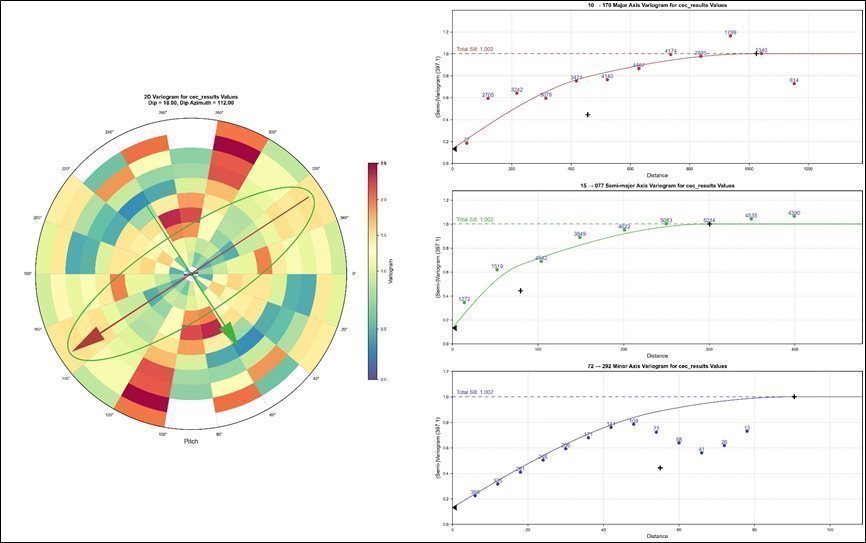

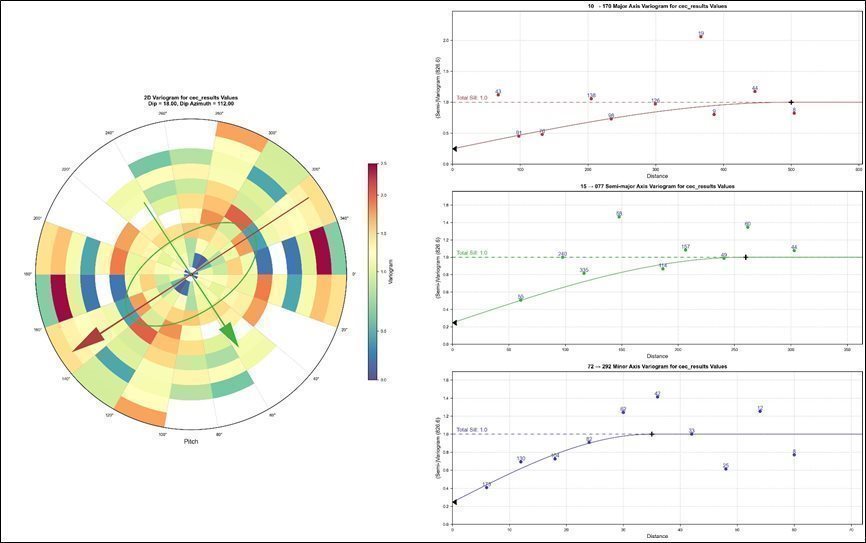

| Figure 11.6-1: Variograms Inside the Mineralized Envelope |

| 154 |

|

| Figure 11.6-2: Variograms Outside the Mineralized Envelope |

| 155 |

|

| Figure 11.8-1: Method for Obtaining the Average Distances Required for Measured and Indicated Categorizations from Variography |

| 157 |

|

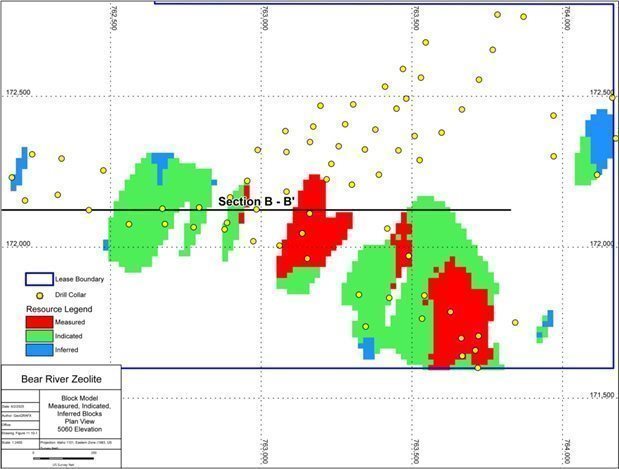

| Figure 11.8-2: Measured (Red), Indicated (Green), and Inferred (Blue) Resource Blocks, Plan View 5060 Level |

| 158 |

|

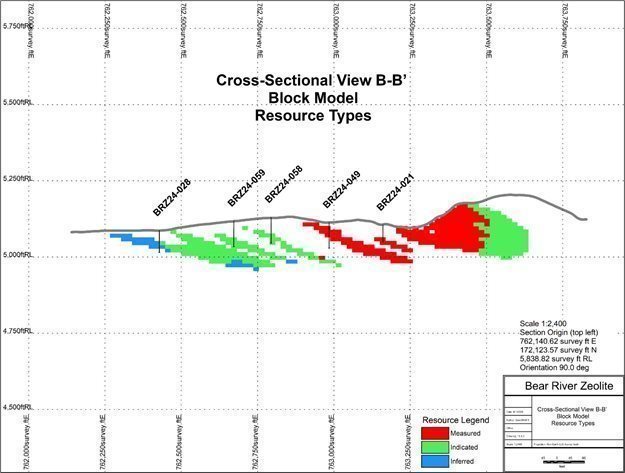

| Figure 11.8-3: Measured (Red), Indicated (Green), and Inferred (Blue) Blocks, Cross Section B-B’ |

| 159 |

|

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 16 |

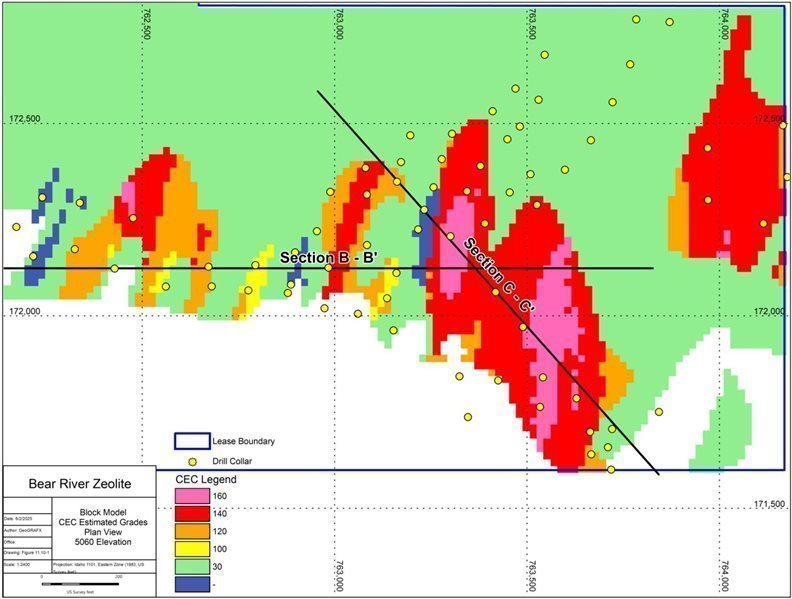

| Figure 11.9-1: Plan View of Block Model with Estimated CEC Grades, 5060 Level |

| 161 |

|

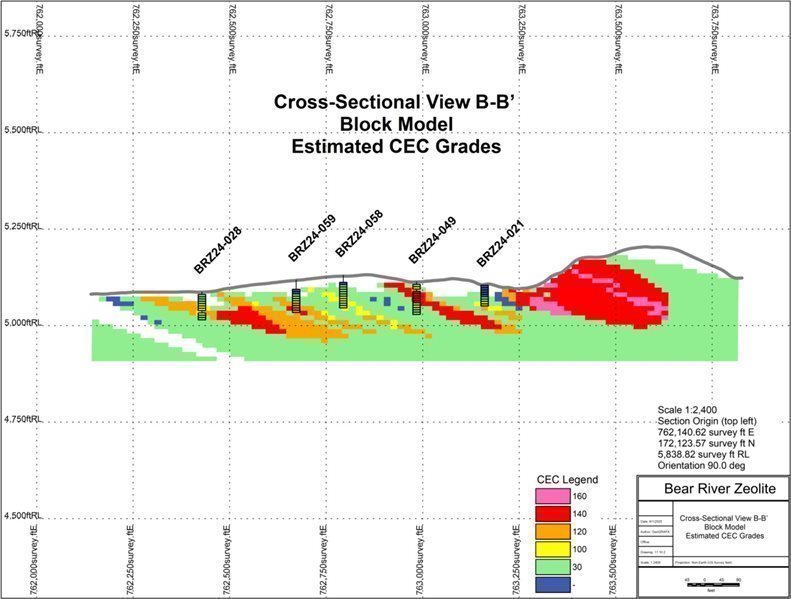

| Figure 11.9-2: Cross-Sectional View B-B’ of Block Model with Estimated CEC Grades |

| 162 |

|

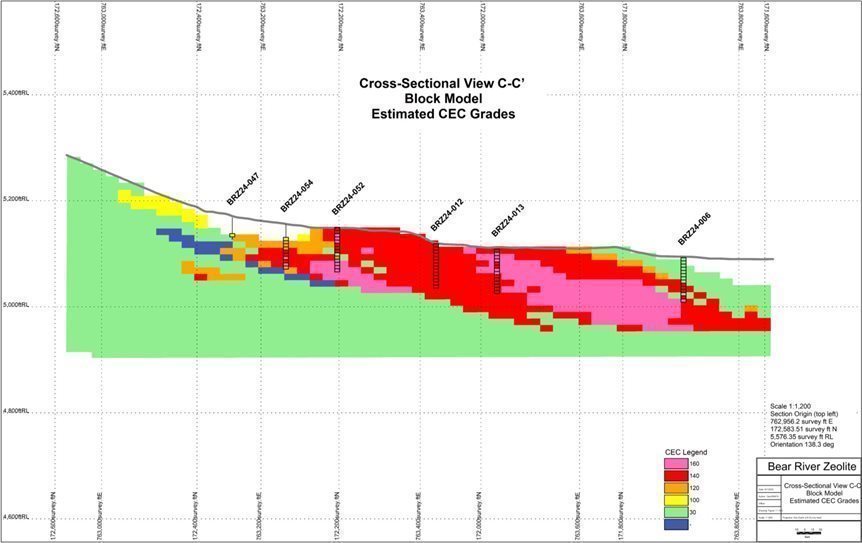

| Figure 11.9-3: Cross-Sectional View C-C’ of Block Model with Estimated CEC Grades |

| 163 |

|

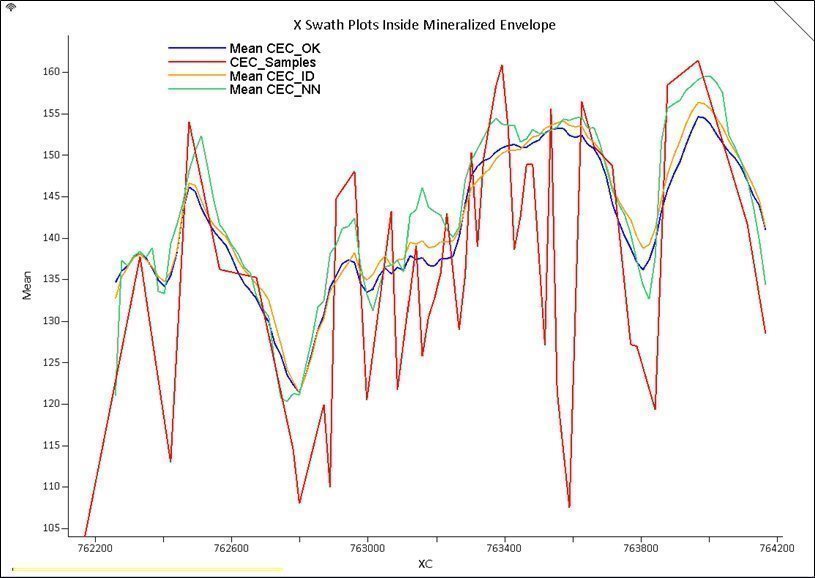

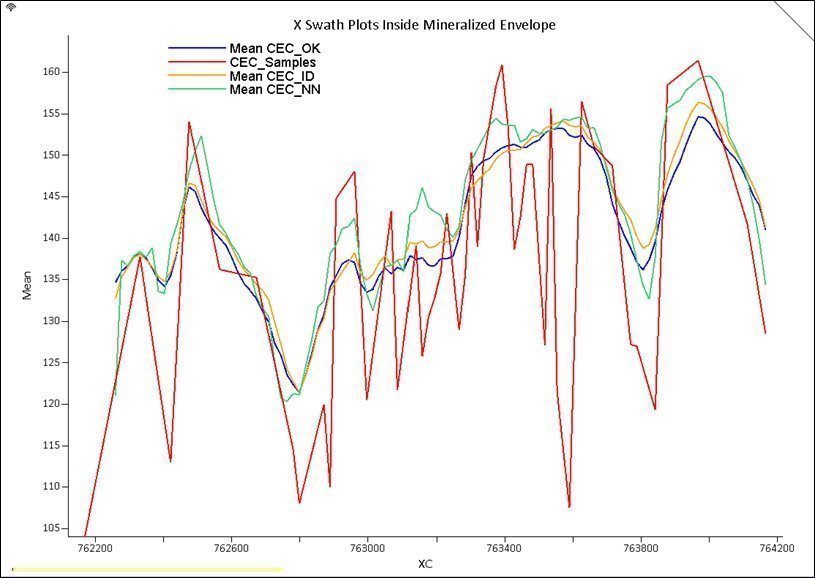

| Figure 11.9-4: Swath Plot in X (East) Direction, with OK (Blue), ID2 (Orange), and NN(Green) Block Grades Compared with Original Samples (Green) |

| 164 |

|

| Figure 11.9-5: Swath Plot in Y (North) Direction, with OK (Blue), ID2 (Orange), and NN(Green) Block Grades Compared with Original Samples (Green) |

| 165 |

|

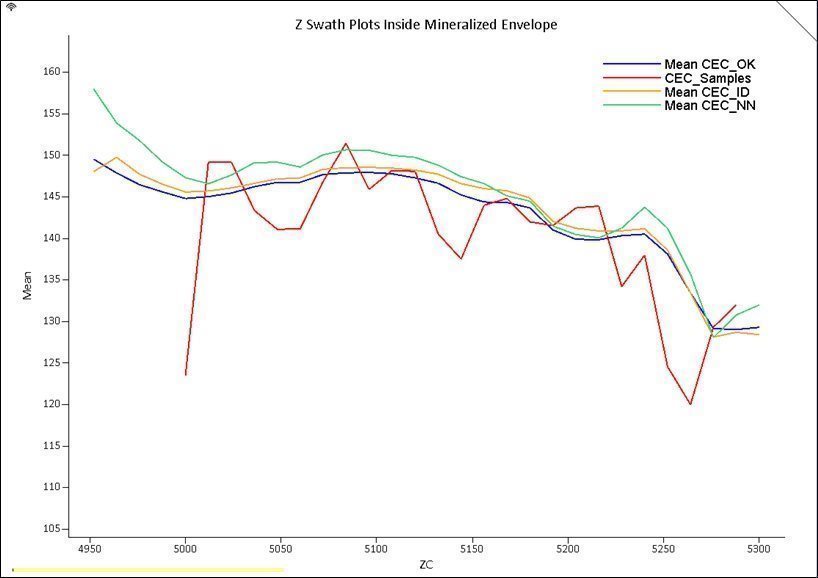

| Figure 11.9-6: Swath Plot in Z (Vertical) Direction, with OK (Blue), ID2 (Orange), and NN(Green) Block Grades Compared with Original Samples (Green) |

| 166 |

|

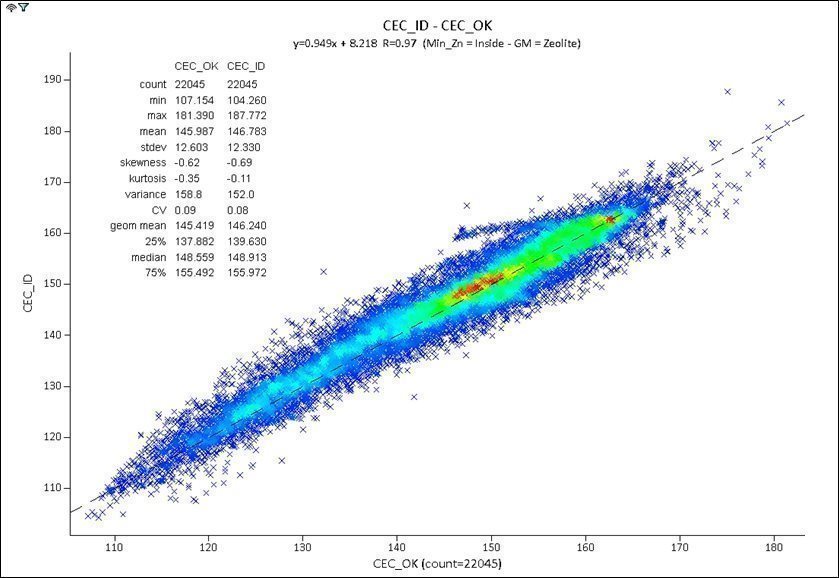

| Figure 11.9-7: Scatter Plot OK vs ID2 Block Grades in Mineralized Envelope |

| 167 |

|

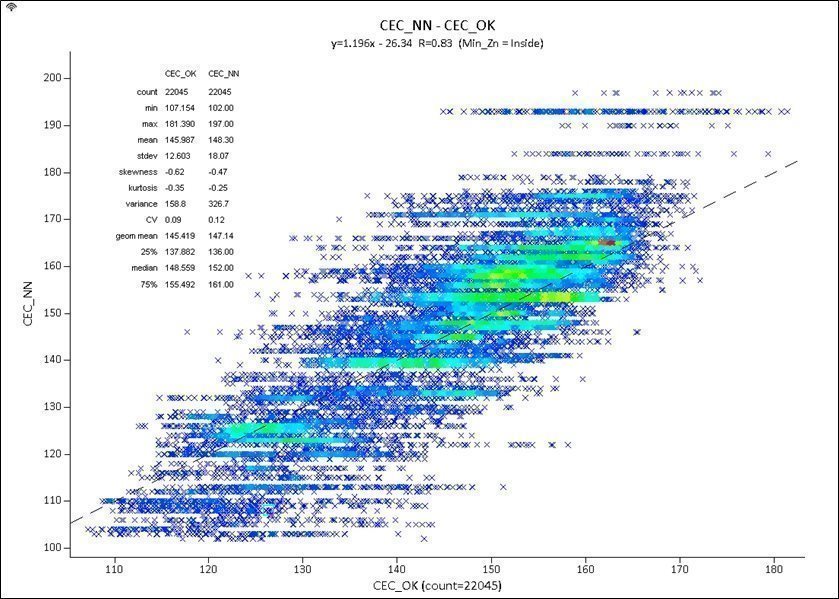

| Figure 11.9-8: Scatter Plot OK vs NN Block Grades in Mineralized Envelope |

| 168 |

|

| Figure 11.10-1 Grade Tonnage Curve of OK Estimations Showing the Effect of Various CEC Cutoffs, All Blocks |

| 169 |

|

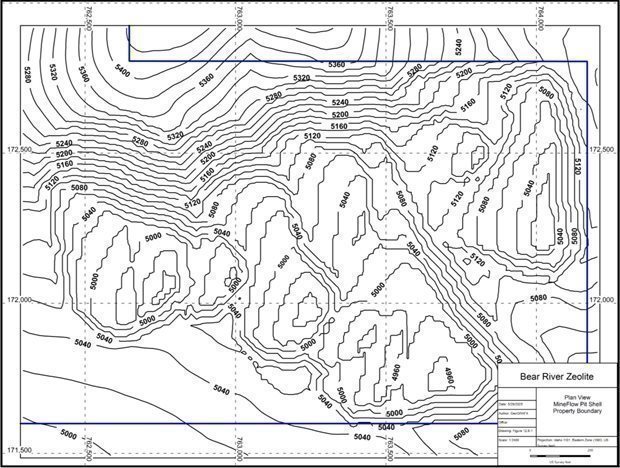

| Figure 12.6-1 Plan view of Mineflow™ 100% profit shell and ownership boundary |

| 177 |

|

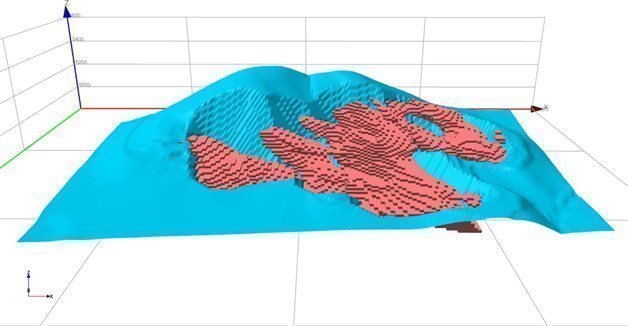

| Figure 12.6-2 Isometric view of zeolite ore blocks within pit shell |

| 178 |

|

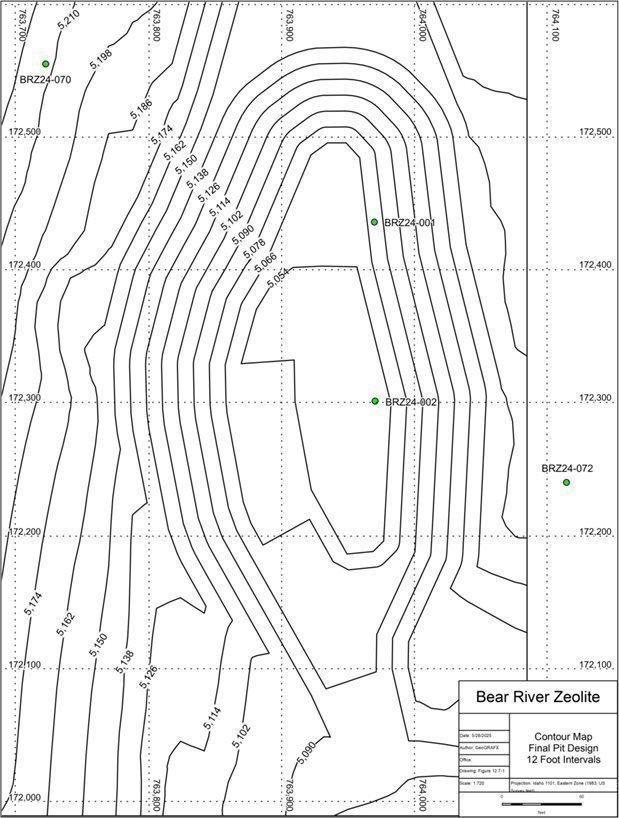

| Figure 12.7-1 Contour map of final pit design at 12-foot elevation intervals. |

| 180 |

|

| Figure 13.1-1 Drone image of Bear River Zeolite mine site, haul roads, and stockpile shelter (May 2024). |

| 182 |

|

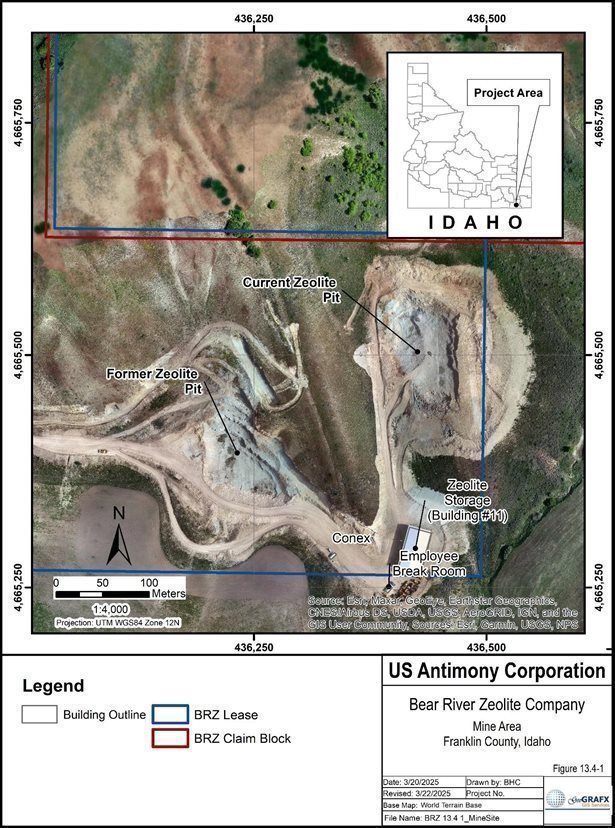

| Figure 13.14-1 Bear River Mine Site Layout |

| 188 |

|

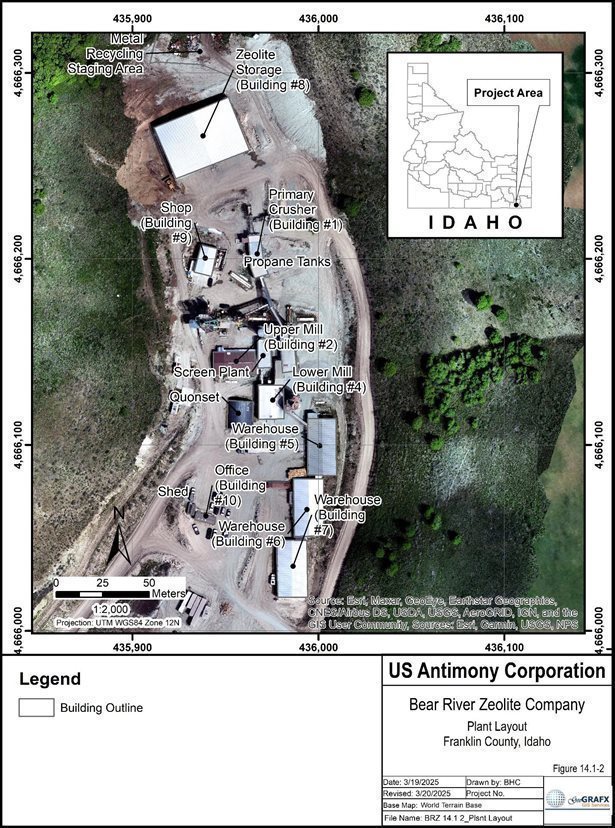

| Figure 14.1-1 Bear River Processing Facility |

| 190 |

|

| Figure 14.1-2 Processing Facility |

| 192 |

|

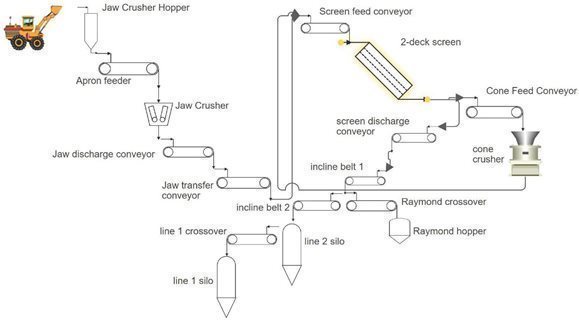

| Figure 14.2-1 BRZ Crushing and Screening Circuit Flowsheet |

| 193 |

|

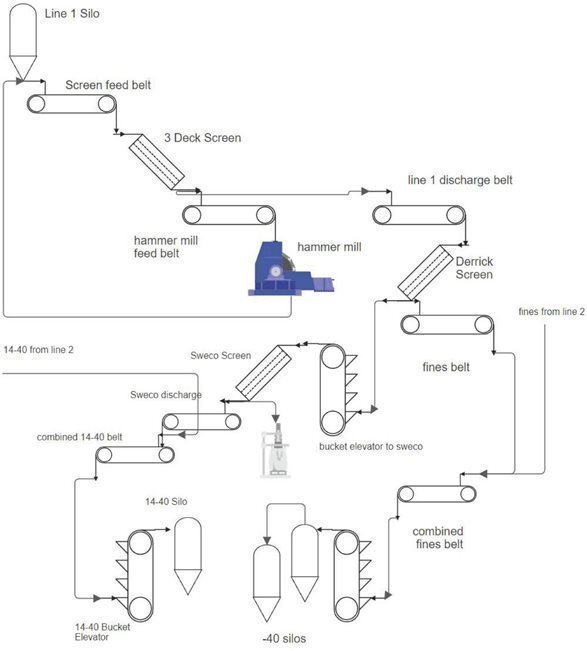

| Figure 14.2-2 BRZ Line 1 Screening Circuit Flowsheet |

| 194 |

|

| Figure 14.2-3 BRZ Line 2 Screening Circuit Flowsheet |

| 195 |

|

| Figure 15.1-1 BRZ Site Infrastructure |

| 201 |

|

| Figure 16.1-1 Bear River Zeolite Market Share by Application |

| 207 |

|

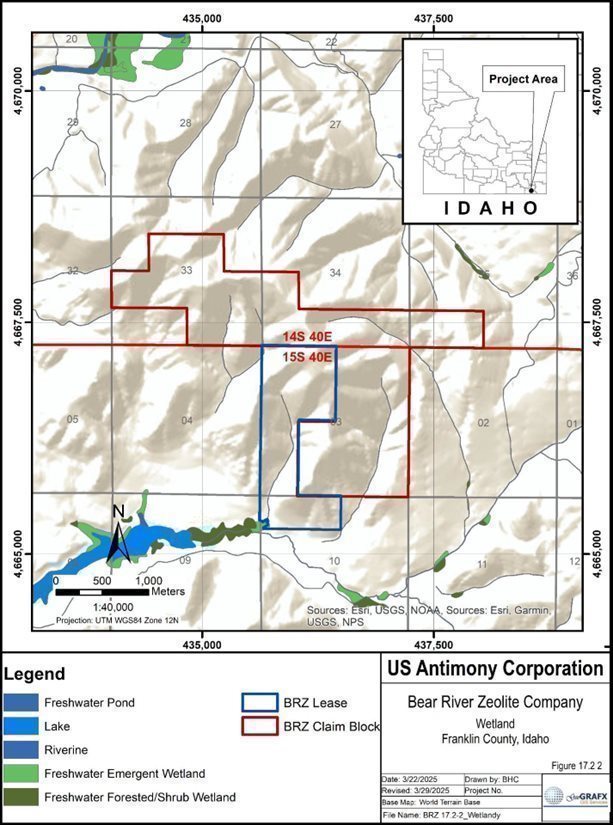

| Figure 17.2-1 Surface Water |

| 217 |

|

| Figure 17.2-2 Bear River Project Wetland Areas |

| 221 |

|

| Figure 17.2-3 NRCS Soil Classification |

| 224 |

|

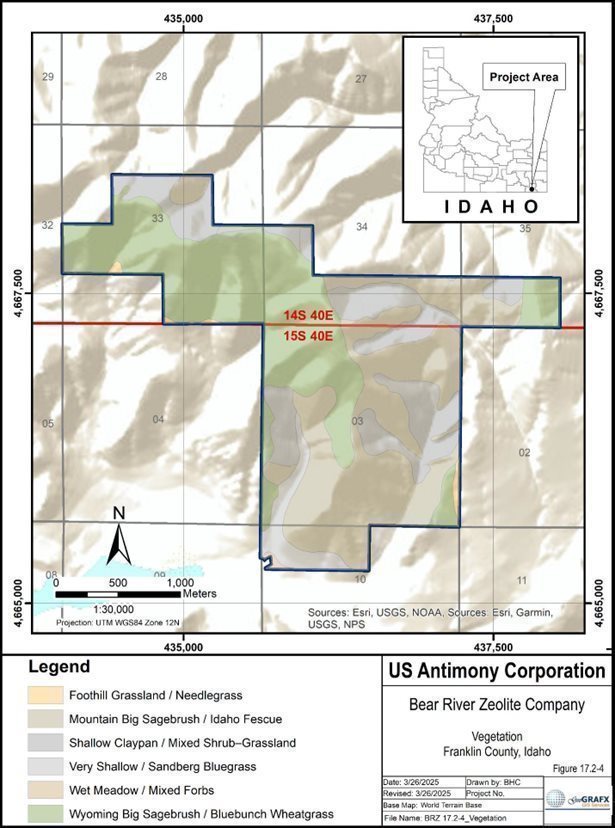

| Figure 17.2-4 Vegetation Classification Based on NRCS SSURGO Soil Units |

| 228 |

|

| Figure 19.3-1 Pre-Tax Cash Flow Sensitivity to Sales Price and Operating Cost (2025 Example) |

| 245 |

|

Appendix

| A. | Certificate of Qualified Person |

|

|

|

| B. | BRZ Unpatented Placer Mining Claims |

|

|

|

| C. | Drilling Collar Table |

|

|

|

| D. | Independent CEC Analysis |

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 17 |

1 Executive Summary

1.1 Introduction

Ms. Barbara Carroll, CPG, Mr. P. J. Hollenbeck, CPG, Mr. Randall K. Martin, RM, and Mr. L. J. Bardswich, PE were retained by United States Antimony Corporation (USAC) to prepare a Technical Report Summary (TRS) on the Bear River Zeolite Mine Operations (BRZ), located in southeastern Idaho.

USAC acquired the Bear River Zeolite operations in June 2000 from Bear River Zeolite, LLC. Operations are conducted by USAC’s wholly owned subsidiary, Bear River Zeolite Company, an Idaho corporation. In 2000. In 2000, shortly after acquisition, BRZ began construction of a processing plant on the property. Commercial mining of zeolite at the current site commenced in 2001.

1.2 Terms of Reference

The Report was prepared to be attached as an exhibit to support mineral property disclosure, including - Mineral Resource and Mineral Reserve estimates - for the Bear River Zeolite operation in United States Antimony Corporation’s (USAC’s) Form 10-K for the year ended December 31, 2024.

Mineral Resources and Mineral Reserves are reported based on a geologic block model and pit shell developed from the Bear River Zeolite deposit and are not limited to the currently active pit area. The deposit is currently mined using conventional drill, blast, truck-and-loader methods.

Unless otherwise stated, all financial values, including operating costs, capital costs, cash flows, taxes, revenues, expenses, and overhead distributions, are presented in United States currency (US$). This report uses the U.S. customary unit system for mineral resources, mineral reserves, and associated financials, unless otherwise noted.

Mineral resources and mineral reserves are reported using the definitions set forth in Item 1300 of Regulation S–K (17 CFR Part 229) (SK1300) of the United States Securities and Exchange Commission Illustrations and disclosures required by S-K 1300 are included in the relevant chapters of the Report, as specified.

1.3 Property Setting

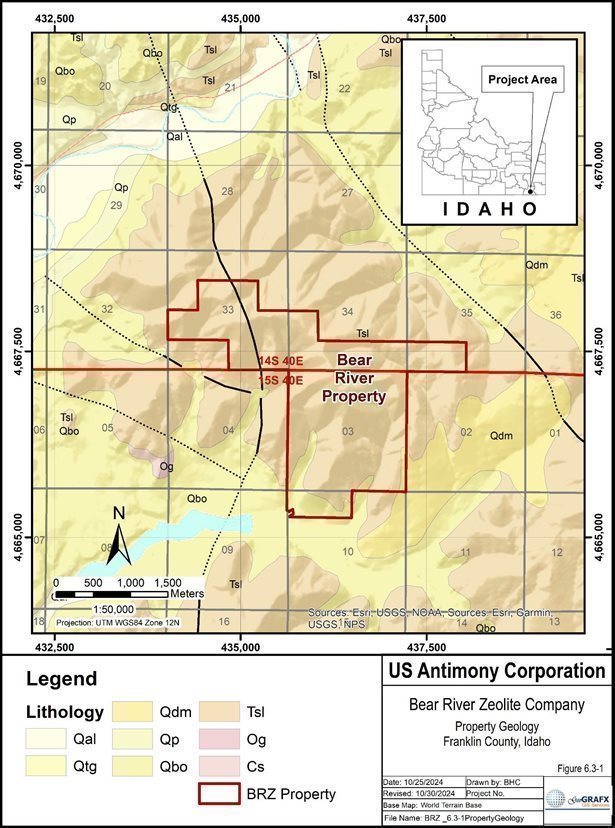

The Bear River Zeolite property is located in Franklin County, Idaho, approximately seven miles east of Preston, 34 miles north of Logan, Utah, 79 miles south of Pocatello, Idaho, and 100 miles north of Salt Lake City, Utah.

Access to the BRZ plant is via State Highway ID-34 from Preston, a paved route. Travel 1.8 miles north on ID-34 to East Glendale Road, then proceed 4 miles east on the paved road to the intersection with gravel road N2200 E. Turn left onto N2200 E and continue north for 0.5 miles to reach the processing plant, warehouses, and office building.

The climate at the BRZ operations area is classified as semi-arid. Mining operations have been demonstrated to be feasible year-round, though snow removal equipment is required during the winter months to maintain access roads.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 18 |

The mine is situated in a region characterized by rolling hills, mountain foothills, and broad valleys. Elevations in the area generally range from around 4,500 feet in the valleys to over 9,000 feet in the nearby mountain ranges. The terrain near the mine is moderately sloping, with low hills and ridgelines.

Vegetation in the vicinity reflects a transition between semi-arid plains and forested mountain environments. In the valleys and lower elevations, the landscape is dominated by sagebrush, grasses, and juniper, typical of high desert and steppe ecosystems. At higher elevations, particularly in the nearby Bear River Range, the terrain becomes increasingly forested, with stands of pine, fir, and aspen.

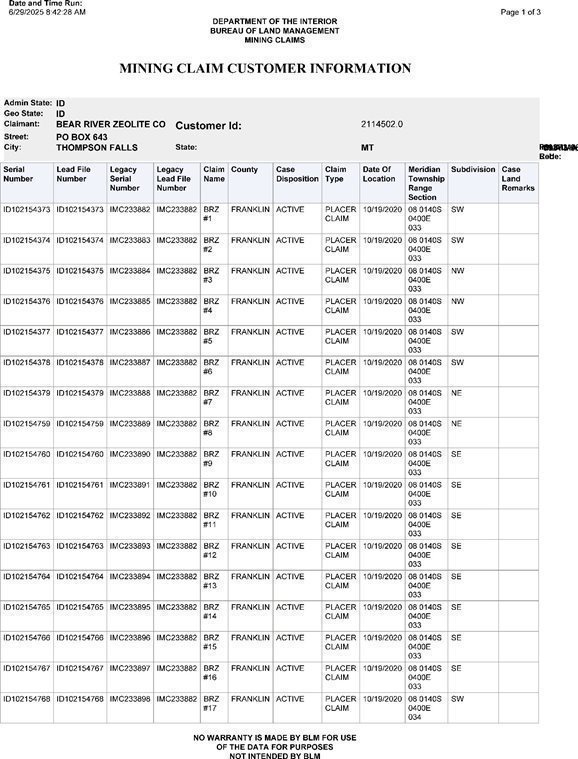

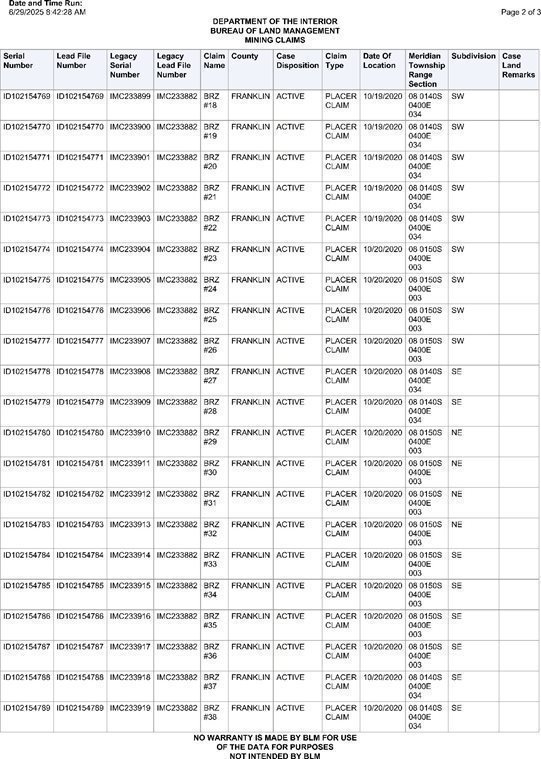

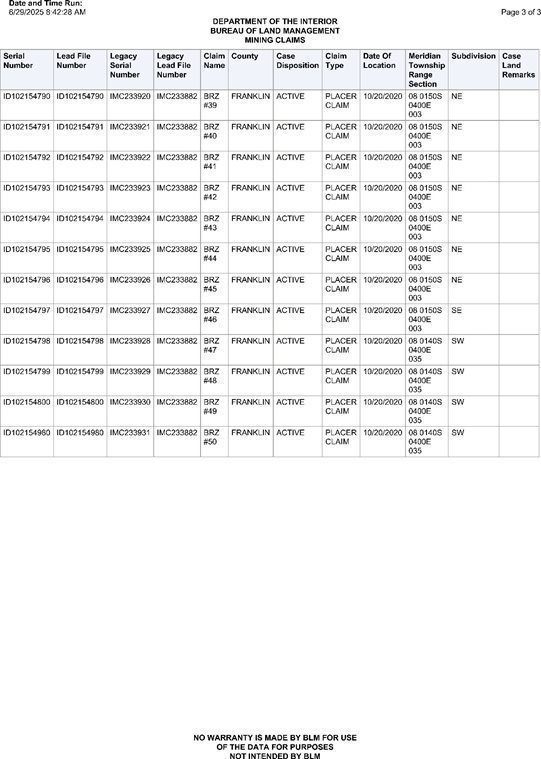

1.4 Mineral Tenure, Surface Rights, Water Rights, Royalties and Agreements

The Bear River Zeolite Project is situated on a combination of federal unpatented placer mining claims administered by the U.S. Bureau of Land Management (BLM) and privately owned leased lands. The property comprises 50 contiguous unpatented federal placer claims, each approximately 20 acres, covering a total of approximately 994 acres (402.26 hectares), held directly by Bear River Zeolite Company (BRZ). These claims are active and valid through August 31, 2025, with annual maintenance fees paid.

In addition, BRZ holds a long-term lease agreement with Zeolite, LLC covering approximately 320 acres (129.5 hectares) of private land. This lease was renewed effective January 1, 2025, and extends through December 31, 2034, with automatic annual renewal provisions unless terminated with 180 days’ written notice. There are no known encumbrances, disputes, or conflicting claims associated with the lease. The leased land includes the active open pit, processing plant, access roads, and stockpile areas, and BRZ maintains exclusive operational control.

Under the 2025 lease agreement, BRZ pays production royalties to Zeolite, LLC based on tonnage removed and shipped from the leased premises. The royalty structure is tiered as follows:

| 0K to 10K tons | - | $ 9.00 per ton |

| 10.1K to 20K tons | - | $ 10.50 per ton |

| 20.1K to 30K tons | - | $ 12.00 per ton |

| Over 30K tons | - | $ 8.00 per ton |

BRZ also pays royalties on any zeolite brought from nearby sources and shipped from the leased site. The lease guarantees Zeolite, LLC a minimum annual royalty of $100,000, with any shortfall to be paid within 90 days of year-end.

In addition to the Zeolite, LLC Amended and Restated Mining Lease royalties, there are additional royalty holders. Nick Raymond and the estate of George Desborough each have a graduated royalty of

$1.00 per ton to $5.00 per ton, depending on the sale price.

During 2002, the Company sold a 3% gross proceeds royalty on all zeolite extracted from BRZ to Delaware Royalty Company, Inc., a company controlled by a Al Dugan, a major shareholder.

On a combined basis, BRZ pays total royalties ranging from 8% to 13% of zeolite product revenue.

Surface rights are secured through federal mining claims and the private lease and are sufficient to support the life-of-mine (LOM) plan presented in this Report.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 19 |

Water for operations is sourced from onsite wells located on the leased private land. These sources provide sufficient water for dust control and site operations. No additional water rights are expected to be needed for the life-of-mine (LOM) operations.

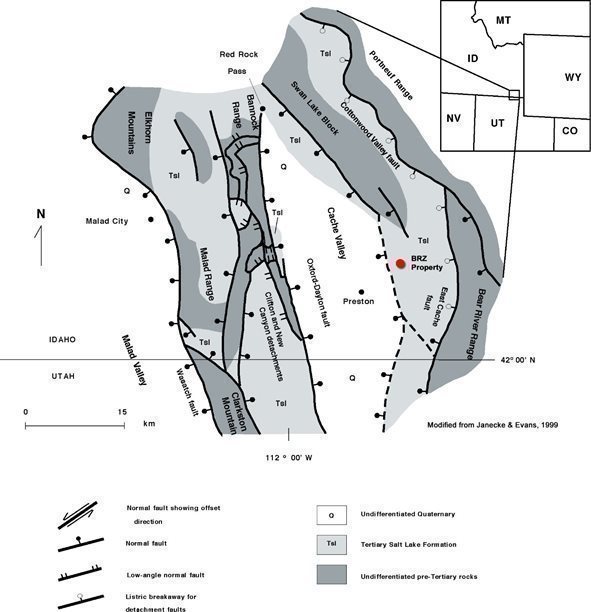

1.5 Geology and Mineralization

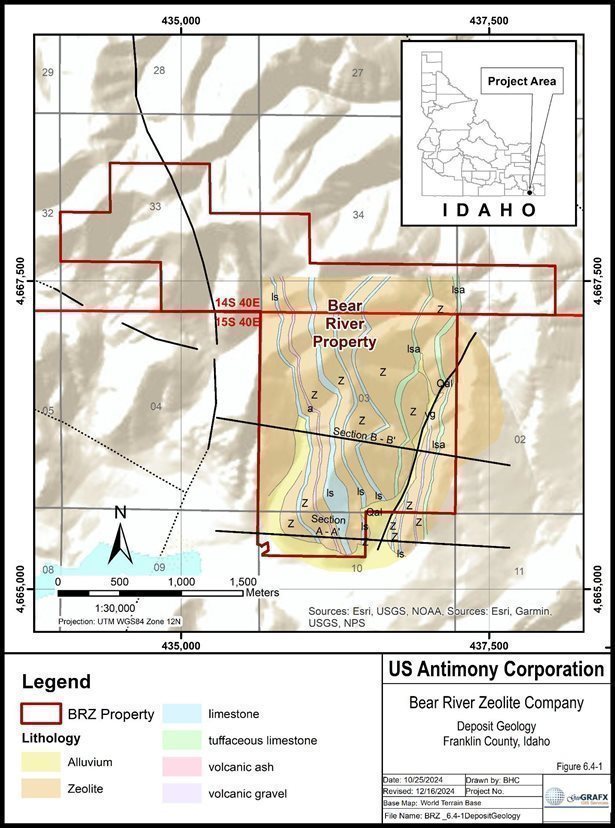

The zeolite-bearing units mined at the Bear River property occur within the Tertiary Cache Valley Formation of the Salt Lake Group. The zeolite mineralization is stratigraphic in nature, and the deposit type is considered an example of a sedimentary zeolite hosted in tuffaceous rocks deposited in a closed hydrologic system.

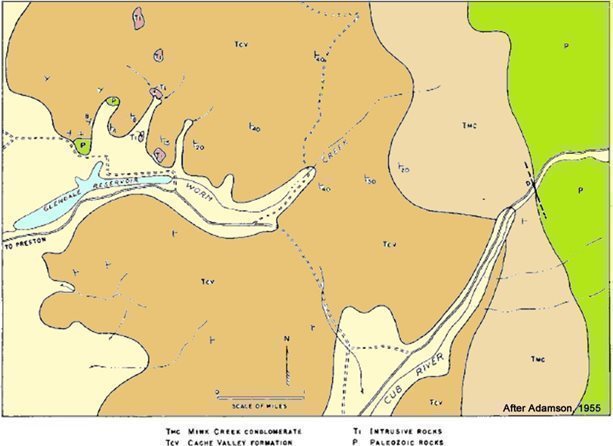

The Bear River Zeolite property is located on the western slope of the Bear River Range in southwest Idaho, within the Southeast Basin and Range Geologic Province. This range is located along the western margin of the Cordilleran overthrust belt that spans Idaho, Wyoming, and Utah. The belt features north- south-oriented, eastward-directed folds and imbricate thrust faults. In Idaho, the overthrust belt includes formations from the Laramide Orogeny (80–35 Ma) and the earlier Sevier Orogeny (160–50 Ma). About 17 million years ago, Basin and Range extension and normal faulting began, forming linear north-south and northwest-southeast trending mountain ranges in southeastern and east-central Idaho. This extension overlaid the older thrust belt, creating sedimentary basins with sandstone, conglomerate, and limestone deposits ranging in age from the Miocene to recent. The Salt Lake Group was deposited during Tertiary/Pliocene time, prior to the Quaternary/Pleistocene, Bonneville flood events which further shaped the region, carving drainage paths down-gradient to the Snake River Valley, including Cache Valley.

Tertiary rocks of the Salt Lake Group consist of conglomerates, siltstones, sandstones, limestones, and tuffaceous sedimentary units deposited in and along the flanks of extensional basins. The Cache Valley Formation of the Salt Lake Group contains the zeolite beds that form the basis for this current investigation into the zeolite mineralization found at the Bear River deposit.

Cache Valley is a long, narrow intermontane basin, approximately 60 miles by·l7 miles wide, tapering gradually at both ends. The valley floor rises gently northward from 4,400 feet near Hyrum, Utah to 4,800 feet: near Banida, Idaho. Structurally, Cache Valley, directly to the west of the property, lies along the Wasatch Fault Zone, part of the Basin and Range Province. It is characterized by north-striking, high- angle normal faults (the East Cache and West Cache fault zones). The valley is a result of crustal extension that began around 15 to 20 million years ago. Here, the Paleozoic rocks were folded into northward and southward trending flexures and dislocated by high-angle faults. The Cenozoic beds, in most localities, dip eastward at relatively low angles and are displaced only to a minor degree by faulting. They overlie the older rocks with pronounced unconformity.

The Bear River Zeolite deposit itself is a thick sedimentary deposit of zeolitized volcanic ash of Tertiary age deposited in the Cache Valley Formation of the Salt Lake Group. The sedimentary interval in which the clinoptilolite occurs is more than 1000 feet thick in this area. Thick intervals of the zeolite are separated by thin beds of limestone which was deposited in the freshwater lake where the volcanic ash accumulated. The zeolite and limestone layers are overlain by zeolite rich soil varying in thickness from a few inches to approximately 12 feet.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 20 |

The Bear River zeolites consist of a recurring sequence of over 93 feet of olive green to gray green tuffaceous zeolite bearing sediments interspersed with lenses of what is locally termed “limey shale” overburden which is locally derived from thinly layered rhyolitic tuff. In some areas, this cap exceeds 40 feet in thickness and forms a mechanically competent layer that supports ridgelines. Where this cap is thin or absent, increased erosion of the underlying zeolitized tuff is observed.

Mineralogically, the Bear River Zeolite consists of approximately 77 to 85% clinoptilolite with the remainder consisting primarily of opaline silica. Clinoptilolite is a natural zeolite mineral, primarily composed of hydrated aluminosilicates of sodium, potassium, and calcium with the chemical formula (Na, K, Ca)2-3Al3(Al, Si)2Si13O.12H2O. Its unique, porous crystal structure enables it to absorb and exchange ions, making it valuable in filtering, detoxifying, and nutrient exchange applications.

The properties of the zeolite at BRZ reflect its formation conditions, including:

|

| · | The temperature of the air-fall tuff at the time of deposition; |

|

| · | The composition of the felsic volcanic ash; |

|

| · | And the chemistry of the lake waters in which the ash was altered. |

The primary alkali component—whether calcium, sodium, or potassium—is largely determined by the chemical composition of these waters.

BRZ clinoptilolite samples typically exhibit high cation exchange capacity (CEC) values ranging from 98 to 178 meq/100g, low sodium content (<0.5%), high potassium content, and a Mohs hardness of 3.5 to 4. The consistency of these geochemical and physical properties across the deposit supports a robust geologic model and contributes to predictable product performance.

The zeolite deposits in the Tertiary Cache Valley Formation of the Salt Lake Group formed in a lacustrine depositional environment characterized by:

|

| · | Low-energy lake basins that accumulated thick layers of volcanic ash. |

|

| · | Interaction of volcanic ash with alkaline/saline waters, leading to diagenetic alteration. |

|

| · | Stable geochemical conditions that promoted zeolite mineral growth, particularly clinoptilolite, analcime, and chabazite. |

The deposit type is considered an example of a sedimentary zeolite in tuffs of a closed hydrologic system.

1.6 History and Exploration

Early work by the U.S. Bureau of Mines and U.S. Geological Survey identified the zeolite occurrences in the Salt Lake formation at the Bear River location as a potential source of clinoptilolite.

During 2000, USAC formed a 75% owned subsidiary, Bear River Zeolite Company (BRZ), to mine and market zeolite and zeolite products from a mineral deposit in southeastern Idaho. In 2001, an operating plant was constructed at the zeolite site and zeolite extraction and sales commenced. During 2002, USAC acquired the remaining 25% of BRZ and continued to extract and sell zeolite products.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 21 |

Shortly after its formation, BRZ constructed a processing plant on the property, which has been routinely upgraded to accommodate increased demand, expanded product lines, and improved operating efficiency. Groundbreaking for an additional warehouse and equipment shop began in 2021, and both facilities were completed in 2023.

A vertical-shaft impactor (VSI) crusher was replaced by a hammer mill in 2021 for Crushing Line #1, increasing production rates. A replacement jaw crusher was also installed in 2021 and was enhanced later that year with a variable-speed apron feeder. Substantial improvements were made to the jaw crusher system again in 2022.

Historic exploration was limited to examination and sampling of surface outcrops. Modern exploration activities resumed in 2024, including topographic surveys, geologic mapping in the pit area, and surface geochemical sampling.

The 2024 program also marked the first exploration drilling campaign conducted on the property.

Since its inception in 2000, BRZ has conducted drilling, mining studies, metallurgical testing, permitting and environmental activities, and active mining operations, as described in this report.

1.7 Drilling and Sampling

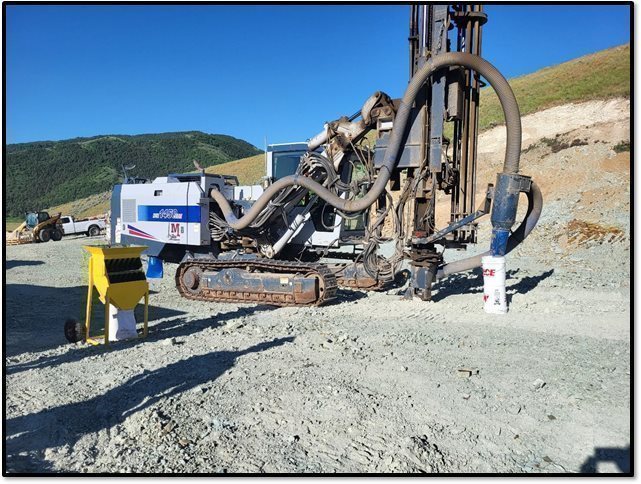

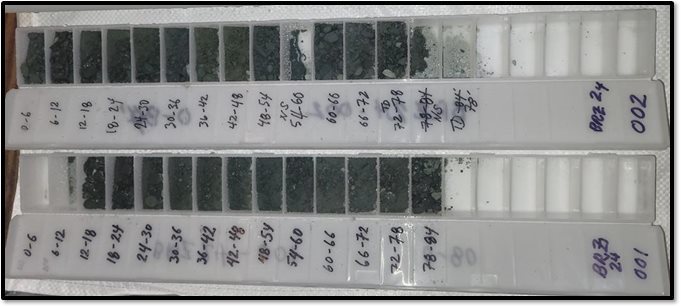

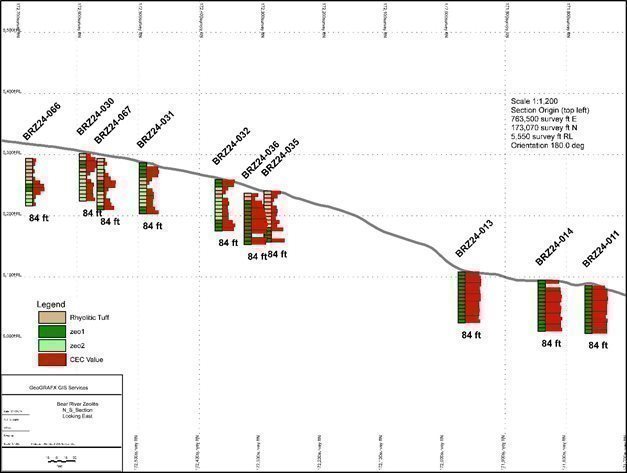

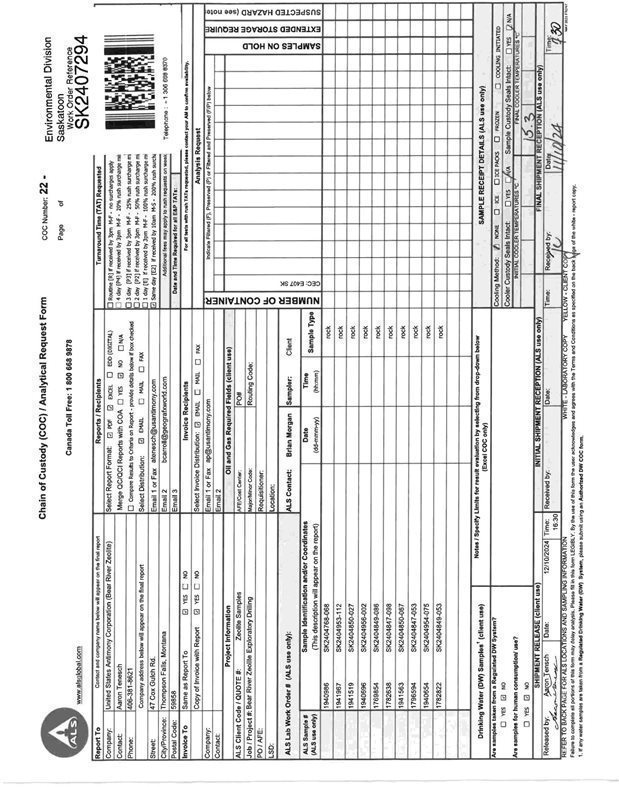

In June 2024, a drilling contractor conducted a drilling program using a percussion rock drill. The percussion rig drilled 82 shallow, vertical holes with a diameter of 3.5 inches, reaching a maximum depth of 84 feet each. Of these, 80 holes were successfully completed, totaling 6,713 feet (2,046 meters) of drilling. The drill holes were spaced approximately 100 feet apart and positioned using the available access roads.

The BRZ contract geologist logged the drill holes for rock type and lithology using small, washed, representative chip samples. The logging information was recorded on paper forms and then later entered into electronic spreadsheets.

Drill collars were initially located by the project geologist using UTM coordinates and downloaded onto a handheld GPS unit. Each proposed drill pad was located in the field using a differential GPS (DGPS) unit with a positional accuracy of approximately 2.5 meters. A wooden stake marked with the pad name was placed at each location. Upon hole completion, all drill collars were marked with a survey flag attached to a metal stake inserted into the collar plug. Collar locations were entered into electronic spreadsheets for data management.

Cuttings from the drill rig were collected from an air exchange purge valve mounted on the drill rig in six-foot increments, then split, bagged and tagged. The entire drill hole was sampled.

Fourteen representative samples for bulk density measurement were collected by the contract geologist from three main excavations on the mine site. Samples were dried, coated in paraffin, and processed using the water displacement method. Bulk density values ranged from 2.0 to 2.6 g/cm³, depending on lithology, and were used in resource estimation.

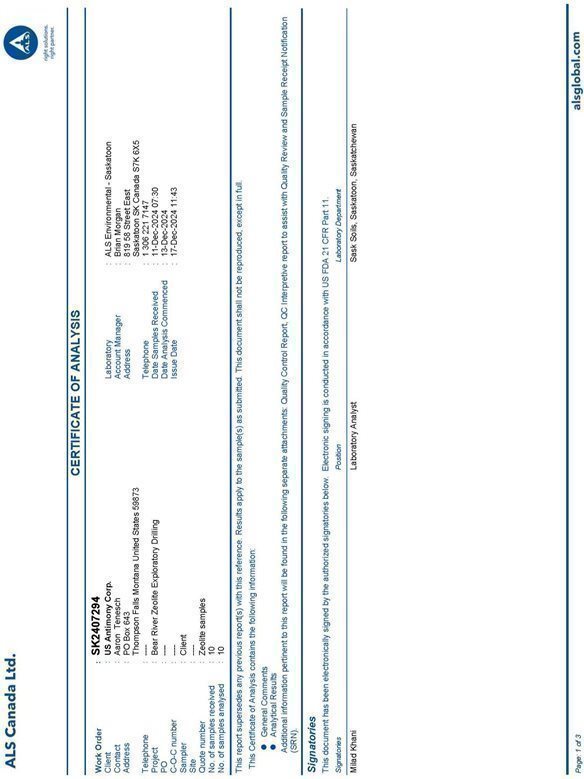

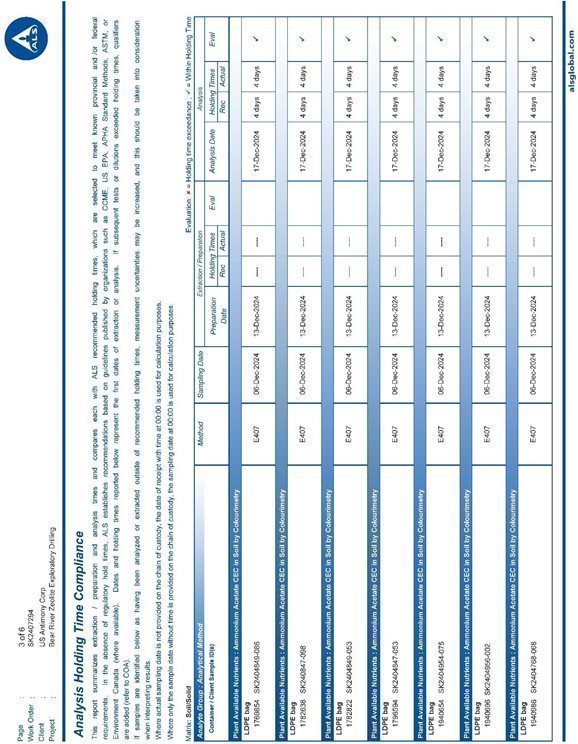

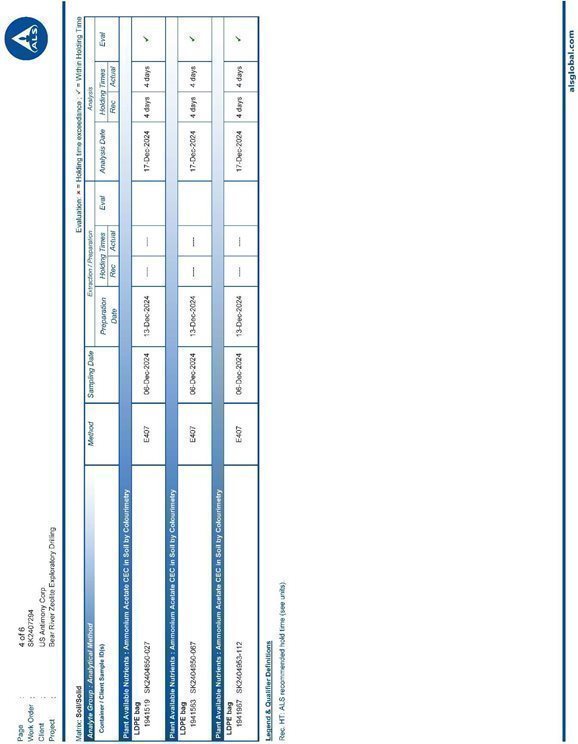

Independent, ISO/IEC 17025:2017-accredited laboratories used for analysis include ALS Global (ALS) in North Vancouver, BC, Canada, ALS Environmental in Saskatoon, SK, Canada, and SGS Canada, Inc. located in Lakefield, Ontario, Canada. All laboratories are independent of BRZ and its parent company, US Antimony Corporation.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 22 |

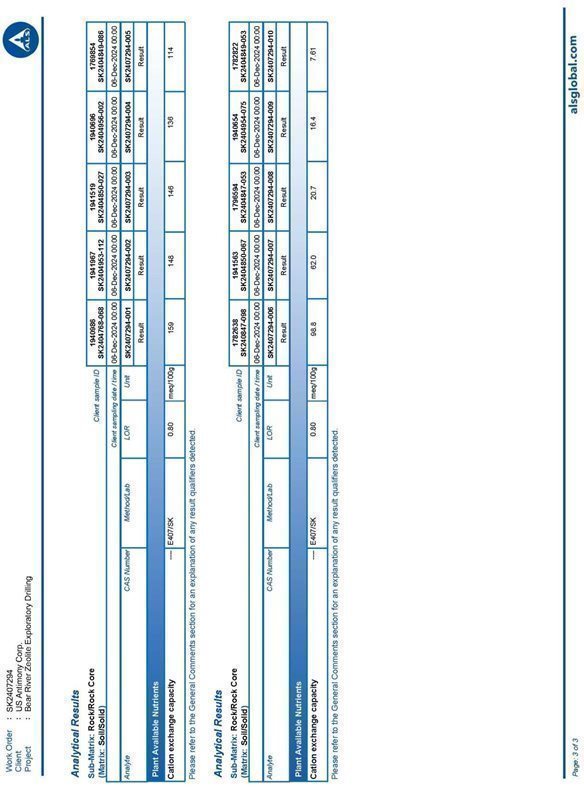

At ALS laboratory in North Vancouver, samples were dried, crushed to greater than 70% of the sample passing 2mm, and pulverized to greater than 85% passing a 425μm screen. Pulverized splits from each of the prepared samples was sent to the ALS Environmental Lab in Saskatoon, Saskatchewan, Canada for Cation Exchange Capacity (“CEC”) determination (ALS Code: E407). Cation Exchange Capacity was determined by ammonium acetate (NH4Oac) extraction. The ammonium ions will displace cations present on exchange sites in the sample. The ammonium acetate solution is flushed from the sample using alcohol. The treated sample is then extracted using potassium chloride where potassium ions displace the ammonium on the active sites in the sample. The ammonium ions in solution are then analyzed by the colorimetric method using a discrete analyzer. The ammonium concentration in the extract is a direct representation of the cation exchange capacity of the sample. Values were reported in milliequivalents per 100 grams (meq/100 g).

Based on the CEC analytical results, fourteen representative samples were sent to SGS Canada, Inc. in Lakefield, Ontario, each weighing up to 250 g for assay and X-ray diffraction (XRD) analysis. Bulk crystalline minerals identified by X-ray diffraction analysis were processed using RIR method and reported in weight percent. Mineral abundances generated by RIR method XRD analysis were reconciled with a Whole Rock Analysis plus any other major elements contained in the sample and reported.

BRZ implemented QA/QC protocols to monitor precision and accuracy of sampling, preparation, and analysis. Commercial standards were not available for natural zeolite, which is typical for industrial minerals of this type and composition. As a result, certified reference materials could not be included in the sample stream. Instead, BRZ’s QA/QC program included the routine insertion of coarse blanks and field duplicate samples to monitor analytical precision and contamination.

QA/QC samples were inserted at a frequency of approximately 1 in 20 samples, including 26 blanks and 25 duplicates—representing 5.4% of all assayed intervals. Field duplicates were collected at the rig in real time with the primary sample. Assay results of blanks and duplicates were monitored routinely.

Blanks returning values more than ten times the detection limit were flagged as analytical failures. Review of 2024 QA/QC data indicated no material bias or contamination in the sample stream.

1.8 Data Verification

Data verification activities included review of CEC assay results, confirmation of spatial and lithological data integrity, and field inspections. This process involved an independent comparison of Cation Exchange Capacity (CEC) values for selected samples, as well as a systematic review of the project database for internal consistency, including checks for unique sample identifiers, non-overlapping intervals, and correct collar coordinates.

The Qualified Person (QP) personally verified a total of 182 assay records in the drillhole database, and reviewed the 2024 QA/QC program, including blank and duplicate results. The QP also confirmed the land status of BRZ’s unpatented placer mining claims and conducted field verification of selected drill collar locations to ensure positional accuracy.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 23 |

The QP believes that the data verification procedures adequately support the geological interpretation, ensure the reliability of analytical data and database structure, and are appropriate for use in Mineral Resource and Reserve estimation, as well as for ongoing mine planning.

1.9 Mineral Processing and Metallurgical Testing

The Bear River Zeolite (BRZ) Project involves industrial mineral processing, rather than conventional metallurgical extraction. The value of the deposit lies in the natural ion-exchange, adsorption, and filtration properties of high-purity clinoptilolite zeolite. Testing has focused on characterizing the physical and chemical attributes of the zeolite—particularly its Cation Exchange Capacity (CEC), mineralogical composition, and suitability for industrial, environmental, and agricultural applications. The results of these investigations support the technical and economic assumptions used in this Report.

1.9.1 Testing Overview and Methodology

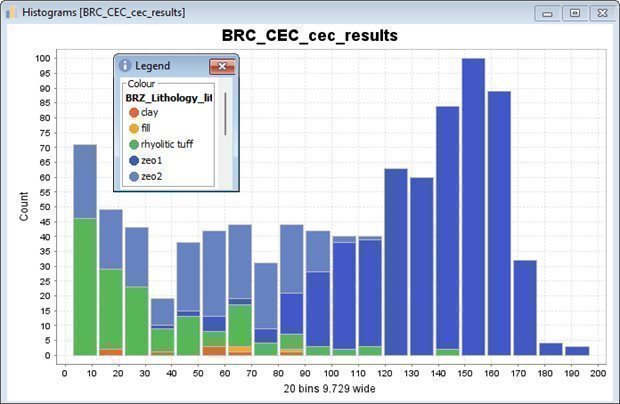

Metallurgical and analytical testing for the BRZ Project focused on evaluating the CEC, mineralogical composition, and geochemical consistency of the Zeo1 lithologic unit, which forms the economic core of the deposit. Key testwork included:

|

| · | CEC Analysis: A total of 559 Zeo1 samples from the 2024 drill program were analyzed by ALS Environmental Lab, Saskatoon, Canada, using ammonium acetate extraction (ALS Code E407). |

|

|

|

|

|

| · | X-Ray Diffraction (XRD): Fourteen representative samples were analyzed by SGS Canada, Inc., (Lakefield, Ontario) to determine mineralogical composition using the RIR method. |

|

|

|

|

|

| · | Whole Rock and Elemental Analysis: Eight Zeo1 samples were analyzed for major and trace elements by SGS Canada labs. |

Both ALS and SGS are ISO/IEC 17025:2017 accredited and independent of Bear River Zeolite and US Antimony Corporation.

1.9.2 Key Findings and Mineralogical Characteristics

|

| · | Clinoptilolite Content: Average 81.2%, ranging from 76.6% to 85.4%. |

|

| · | CEC Values: Average 146.45 meq/100g, ranging from 97.6 to 178 meq/100g. |

|

| · | Purity: No detectable calcite, dolomite, or sulfides; trace quartz, feldspar, cristobalite, and iron oxides present |

|

| · | Bulk Chemistry: Silica-rich (~67.2%), aluminosilicate dominant; low Fe₂O₃ (~2.3%) and MgO (~0.56%) content. |

The correlation between clinoptilolite content and CEC values confirms that the deposit meets industry standards for ion-exchange and filtration performance. These characteristics support the material’s application in water treatment, soil remediation, animal nutrition, and odor control.

1.9.3 Qualified Person’s Assessment

The Qualified Person considers the test data to be technically sufficient and representative for use in the Technical Report Summary. The analytical protocols followed accepted industry standards and were conducted by independent, certified laboratories. The extensive CEC dataset and supporting mineralogical analyses provide a reliable basis for product specification and mine planning. Variability in test results reflects expected heterogeneity in grain size, alteration intensity, and lithologic mixing, and does not materially impact confidence in the processing assumptions or product performance.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 24 |

1.10 Mineral Resource Estimation

The Mineral Resource estimate for the Bear River Zeolite Project reflects the application of SEC Regulation S-K 1300 standards and is based on three-dimensional geologic modeling of zeolite-bearing units constrained by grade, continuity, and data confidence. The following subsections summarize the estimation methodology, classified Mineral Resources exclusive of reserves, and factors that may influence the estimate over time. The full Mineral Resource statement, including Effective Date and Qualified Person responsibility, is presented in Section 11 of this report.

1.10.1 Estimation Methodology

The Mineral Resource estimate was prepared using a 3D block model constrained by geologic interpretation and a cutoff grade of 100 meq/100g CEC. Resources were classified as Measured, Indicated, or Inferred based on drill density, lithologic confidence, and data quality. No capping or compositing was required. Estimation was conducted in accordance with SEC Regulation S-K 1300 standards using validated drill data and surface mapping.

1.10.2 Mineral Resource Statement

As of May 22, 2024, the Bear River Zeolite Project is estimated to contain the following in-situ Mineral Resources, reported above a cutoff grade of 100 meq/100g CEC and exclusive of Mineral Reserves.

Measured and Indicated Mineral Resources are summarized in Table 11-11 in compliance with SEC Regulation S-K 1300, and Inferred Mineral Resources are summarized separately in Table 11-12.

Table 1-1 Measured and Indicated Mineral Resources (Exclusive of Reserves)

| Geologic Model | Category | Mass short tons | Average Value All Material OK CEC |

| Zeolite | Measured | 54,000 | 147.16 |

| Indicated | 285,000 | 145.41 | |

| Measured + Indicated | 339,000 | 146.16 | |

| Differences may occur in totals due to rounding | |||

Table 1-2 Inferred Mineral Resources (Exclusive of Reserves)

| Geologic Model | Category | Mass short tons | Average Value All Material OK CEC |

| Zeolite | Inferred | 426,000 | 139.71 |

| Differences may occur in totals due to rounding | |||

These estimates are based on validated drill data and block modeling of zeolite-bearing tuffs, incorporating all drilling, sampling, and technical data available through May 22, 2024. The Mineral Resource estimates reflect the tonnage and grade of material with reasonable prospects for economic extraction under current conditions.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 25 |

1.10.3 Factors That May Affect the Mineral Resource Estimate

The estimate may be affected by future changes in cutoff grade, market demand for zeolite, mining recovery factors, or additional drilling that could better define grade continuity and extend known mineralized zones. No known legal, technical, or permitting limitations currently affect the accessibility or extractability of the Mineral Resources.

1.11 Mineral Reserve Estimation

The Mineral Reserve estimate for the Bear River Zeolite Project reflects a robust evaluation of the economically mineable portion of the Measured and Indicated Mineral Resources, using well-supported modifying factors and established pit design parameters. Prepared in accordance with SEC Regulation S- K 1300, the Reserve estimate demonstrates the Project’s economic viability under current operating and market conditions. This section summarizes the estimation methodology, Reserve classification results, and key risk factors that may influence Reserve confidence or long-term extraction potential. The full Mineral Reserve statement, including Effective Date and Qualified Person responsibility, is presented in Section 12 of this report.

1.11.1 Estimation Methodology

The Mineral Reserve estimate was prepared in compliance with the disclosure standards of SEC Regulation S-K 1300 by independent Qualified Person Randall K. Martin, SME-RM. The estimate is based on the Measured and Indicated Mineral Resources, incorporating inputs derived from the 2024 geologic model and operational data provided by site management. A 3D pit optimization analysis was conducted utilizing the Colorado School of Mines MineFlow™ software, incorporating geotechnical slope angles, economic assumptions, and operational data provided by site management.

Key modifying factors applied in the reserve estimation include:

|

| · | Long-term zeolite product price: $287.93/ton |

|

| · | Mining cost: $7.50/ton mined |

|

| · | Processing cost: $159.24/ton processed. |

|

| · | G&A cost: $76.19/ton processed. |

|

| · | Specific gravity: 2.2 g/cc for zeolite |

|

| · | Processing recovery: 100% |

|

| · | Mining dilution and recovery: 0% dilution, 100% recovery |

|

| · | Pit slope angle: 45 degrees. |

|

| · | Property limits: Only blocks within company-owned boundaries included. |

Inferred Resources were excluded from the estimate. Only blocks within the final pit shell and within the company-owned property boundaries were considered.

1.11.2 Mineral Reserve Statement

As of the effective date of May 31, 2025, the Bear River Zeolite Project hosts the following Mineral Reserves, reported as dry in situ tons and exclusive of Mineral Resources summarized in Table 12-1 below:

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 26 |

Table 1-3 Mineral Reserve for Bear River Zeolite Project

| Classification | Tonnage short tons | Grade (CEC meq/100g) | Recovery (%) | Saleable Product short tons |

| Proven | 2,267,000 | 147.0 | 100 | 2,267,000 |

| Probable | 2,860,000 (*) | 145.5 | 100 | 2,860,000 |

| Total | 5,127,000 (*) | 146.2 | 100 | 5,127,000 |

(*) The Probable category has been adjusted downward to reflect approximately 12,600 tons of material mined between the date of topographic survey (May 22, 2024) and the report effective date (May 31, 2025). All mined material was sourced from the Probable category.

At the current production rate of approximately 12,600 short tons per year, the Reserve supports a theoretical mine life exceeding 400 years. Even with a 20-fold increase in production, the Reserve could support two or more decades of operations.

1.11.3 Factors That May Affect the Mineral Resource Estimate

The Qualified Person has identified several risk factors that could materially affect the Mineral Reserve estimate:

|

| · | Market Volatility: Fluctuations in zeolite prices may impact on economic viability. |

|

| · | Geological Variability: Changes in mineral quality (CEC, % clinoptilolite) or continuity not captured by current drilling may affect reserve confidence. |

|

| · | Cost Inflation: Increases in fuel, labor, haulage, and processing costs could reduce margins. |

|

| · | Regulatory Risk: Future environmental or permitting constraints may limit mine operations or expansion. |

|

| · | Logistics and Infrastructure: Transport capacity or access limitations could restrict throughput. |

|

| · | Drillhole Spacing: Some zones remain classified as Probable due to sparse drilling; infill drilling is recommended to upgrade classification to Proven. |

1.12 Mining Methods

The Bear River Zeolite Project utilizes conventional open-pit mining methods, employing a truck-and- loader fleet in conjunction with controlled drilling and blasting. The operation is optimized for the selective recovery of high-grade zeolite from shallow, gently dipping beds within the Cache Valley Formation.

Mining is conducted on 20-foot benches, with visual ore control performed in the field by trained operators and geologists. This allows for real-time differentiation between ore and waste materials, ensuring high selectivity and minimal dilution. Due to the strong lithologic contrast between zeolite-rich units and waste (e.g., rhyolitic tuff or limey shale), dilution is not a significant concern, and no explicit dilution factor is applied in the mine plan.

No ore blending is required at the pit level. Ore is delivered either directly to the processing plant or stockpiled, depending on plant feed needs and operational logistics. Overburden stripping is conducted as needed using conventional dozers and hydraulic excavators.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 27 |

Pit advancement is phased to maintain multiple working faces and provide operational flexibility. This ensures continuous access to ore while allowing for concurrent waste stripping and road maintenance. The current mining configuration is well-suited to the geometry and geomechanical characteristics of the deposit and is expected to remain appropriate over the life of mine.

1.13 Processing and Recovery Methods

The Bear River Zeolite Project utilizes a dry mechanical processing system consisting of crushing, screening, and packaging facilities located on site. Run-of-mine (ROM) material is transported directly from the pit to a surface stockpile, from which it is fed into the primary crushing circuit.

The processing system is designed to produce multiple particle size fractions in accordance with customer specifications. All processing occurs within enclosed shelters to protect the zeolite material from moisture prior to and during handling. No chemical reagents or water are used, and no tailings or wastewater streams are generated, as the beneficiation process relies solely on size reduction and material classification.

The final product is packaged in customer supplied (25 to 55 lb.) bags, bulk bags (supersacks) or loaded as bulk material for shipment to customers.

The plant currently operates at a nominal throughput rate of approximately 12,600 short tons per year, consistent with market demand and sales volumes. This throughput rate forms the basis for the Mineral Reserve estimate (Section 12) and the economic analysis (Section 22).

Historical production in 2024 totaled 11,095 short tons. Incremental improvements to the crushing and screening circuits are underway, with a target throughput increase to 14–18 tons per hour projected by late 2025. These upgrades are designed to improve operational efficiency without materially altering the flowsheet or processing methodology, which remains consistent with historical practice at the site.

First quarter 2025 production totaled 3,802 short tons, up from 2,273 short tons in Q1 2024—an increase of 1,529 short tons year-over-year. This growth underscores the effectiveness of recent equipment and operational enhancements.

1.14 Infrastructure

All infrastructure necessary to support mining and processing operations at the Bear River Zeolite (BRZ) Project is fully constructed, operational, and considered sufficient to support the life-of-mine (LOM) plan. The site includes all-weather mine access roads, power supply, water systems, communications infrastructure, and on-site processing facilities. No material infrastructure gaps have been identified by the Qualified Person that would limit the feasibility of continued operations.

1.14.1 Site Facilities and Layout

The BRZ site includes an open pit mine, a fully equipped processing plant with crushing, screening, and packaging circuits, enclosed ore storage sheds, a warehouse, administrative offices, and ancillary buildings. The infrastructure layout supports efficient internal logistics and operational safety through controlled site access, fencing, and natural topographic features that function as barriers.

On-site employee accommodations are not required, as the workforce commutes from nearby towns with established housing, utilities, and services.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 28 |

1.14.2 Power and Communications

Electricity is supplied by Rocky Mountain Power via a 12.47 kV line and a 750 kVA transformer, currently operating at approximately 50% of peak capacity. The utility has confirmed adequate capacity to support future site expansions up to 2,000 kVA.

Site communications are well-developed, with dual internet systems (Rise Broadband and Starlink), VoIP phone service, Ubiquiti-managed Wi-Fi, two-way radios, and a signal-boosted Verizon cellular system.

Uninterruptible power supply (UPS) units protect critical networking equipment during short-term outages.

1.14.3 Water and Fuel Supply

Water for dust control and general operational use is sourced from a well located on leased private land, under agreement with the landowner. Potable water is delivered by a third-party vendor (Culligan). Dust suppression is conducted using water trucks and engineered drainage channels to manage stormwater.

Fuel infrastructure includes:

|

| · | A 2,000-gallon diesel aboveground storage tank (AST) |

|

| · | A 200-gallon mobile diesel tank |

|

| · | A skid-mounted gasoline tank used for small engines and equipment. |

1.14.4 Roads, Rail, and Transportation

The site is accessed via a combination of paved highways (ID-34 and Glendale Road) and a maintained gravel road suitable for semi-truck transport. Internal haul roads connect the mine, plant, and stockpile areas.

Preston, Idaho, is served by the Union Pacific Railroad’s Cache Valley branch. Although the BRZ site is not directly rail-served, regional freight access via Union Pacific and BNSF routes through Pocatello provide logistical flexibility for bulk product transport.

1.14.5 Waste and Reclamation Management

Due to the deposit’s low strip ratio, minimal waste rock is generated during operations. Waste material is inert and is used for internal road construction and site reclamation. Formal Waste Rock Storage Facilities (WRSFs) are not required.

Topsoil is stripped selectively and used for reclamation as needed. No long-term top-soil stockpiles are maintained beyond operational requirements.

Qualified Person’s Assessment

The Qualified Person has reviewed the BRZ site’s infrastructure and confirms that it is adequate to support both current and planned operations and the projected life-of-mine plan. No infrastructure deficiencies were identified that would materially affect the implementation of the mine plan or processing strategy.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 29 |

1.15 Markets and Contracts

The Bear River Zeolite (BRZ) Project produces high-purity natural clinoptilolite zeolite for a wide range of industrial, agricultural, and environmental applications. Unlike commodity metal markets, the value of BRZ's products is tied to their functional properties—particularly ion-exchange capacity and adsorption performance—rather than to market-based metal pricing. Recent market analysis and internal sales data indicate growing demand for BRZ’s product line across multiple sectors, supporting the long-term economic viability of BRZ’s operations.

1.15.1 Market Overview and Product Positioning

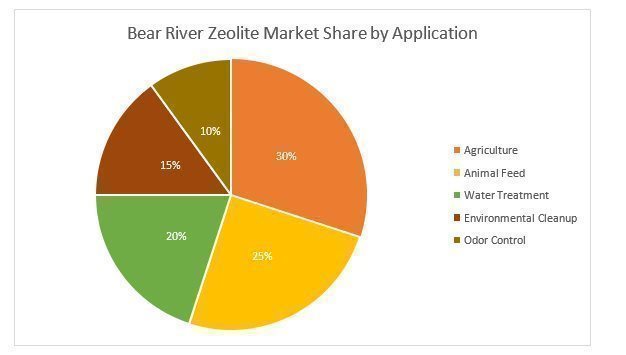

Natural zeolite is a niche industrial mineral with diverse applications. BRZ holds approximately 22% of the North American zeolite market, supplying product across sectors including agriculture, animal feed, water treatment, and environmental cleanup. The global market for natural zeolites reached $7.3 billion in 2023 and is projected to grow at a 2.9% CAGR, reaching $9.4 billion by 2032, according to Acumen Research and Consulting.

BRZ offers a range of granular, powdered, and blended zeolite products, tailored to specific market segments. In 2024, BRZ launched CattleMax™, a branded livestock feed additive, to expand its presence in the animal health sector. Key application areas and estimated revenue distribution include:

|

| · | Agriculture (30%): Soil conditioning and water retention |

|

| · | Animal Feed (25%): Digestive health and toxin absorption |

|

| · | Water Treatment (20%): Ammonia and heavy metal removal |

|

| · | Environmental Cleanup (15%) |

|

| · | Odor Control (10%) |

1.15.2 Pricing and Sales Strategy

BRZ's average sales price reached $264 per ton in 2024, reflecting enhancements to product quality and packaging. The company anticipates a 10% price increase in 2025, based on sustained demand and cost recovery. Zeolite pricing remains highly dependent on grade, particle size, and intended application— ranging from $50/ton for bulk soil additives to over $300/ton for specialized industrial and environmental products.

BRZ operates without long-term offtake or hedging contracts. Sales are managed through spot or short- term agreements, with terms negotiated directly with end users or distributors. All commercial terms are consistent with prevailing industry practices, and there are no related-party transactions or insider arrangements associated with the sale of the product.

Qualified Person's Assessment

The Qualified Persons have reviewed BRZ’s market share, historical pricing, and contracting strategies and consider the supporting data to be reasonable and appropriate for use in economic evaluations, Mineral Reserve estimation, and mine planning. The company’s flexible product portfolio, regional market position, and ongoing operational enhancements are expected to support continued growth and sustained market participation.

| GeoGRAFX GIS Services | July 2, 2025 |

| Bear River Zeolite Project Franklin County, USA | Page: 30 |

1.16 Environmental, Permitting and Social Considerations

The Bear River Zeolite property includes both privately leased ground and adjacent federal (BLM- managed) mining claims. All current mining and processing operations are confined to the private lease area. No baseline field studies were required at the time of mine development. However, the Company has undertaken desktop environmental analyses and permitting actions consistent with Idaho state regulations and to satisfy SEC Regulation S-K 1300 disclosure requirements.

All permits necessary for current operations have been obtained and are summarized below. Each permit outlines potential environmental impacts, includes required operational controls, and incorporates closure and reclamation provisions where applicable.

1.16.1 Permitting

Permitting for the BRZ Project is managed primarily at the state and county levels. The following authorizations are in place:

|

| · | Idaho Department of Environmental Quality (IDEQ) Air Quality Permit to Construct No. P- 2007.0025 (Rev. January 2025). |

|

|

|

|

|

| · | Franklin County land use and zoning compliance for mineral processing and industrial operations. |

|

|

|

|

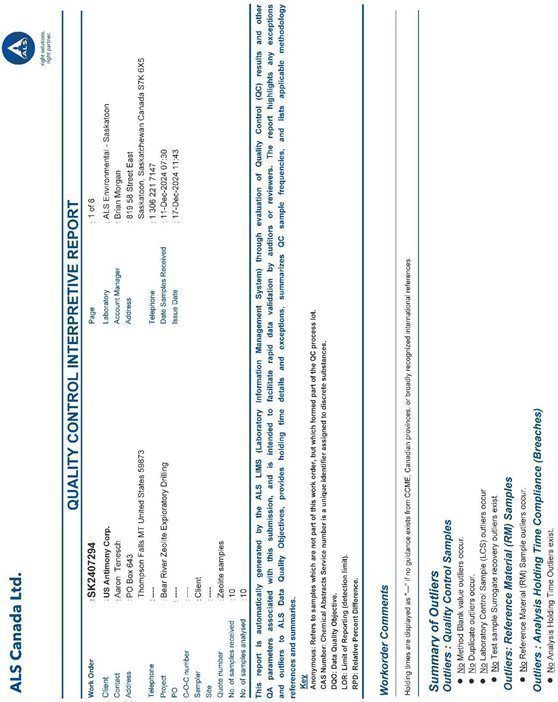

|