Exhibit 99.1

|

Prepared by the following Qualified Persons:

▪ Mathieu Belisle, P.Eng...............BBA Engineering Ltd.

▪ Amanda Fitch, P.Eng................BBA Engineering Ltd.

▪ Sebastien Guido, P.Eng............Alius Mine Consulting Inc.

▪ Philip Clark, P.Eng......................Clean Energy Consulting Inc.

▪ Rob Griffith, P.Eng. ....................Falkirk Environmental Consultants Ltd.

▪ Katherine Mueller, P.Eng..........Falkirk Environmental Consultants Ltd.

▪ Nikolay Sidenko, P.Geo............Falkirk Environmental Consultants Ltd.

▪ Eric Lecomte, P.Eng..................InnovExplo Inc.

▪ Carl Pelletier, P.Geo. ................InnovExplo Inc.

▪ Tessa Scott, P.Geo. ..................InnovExplo Inc.

▪ A. J. MacDonald, P.Eng...........Integrated Sustainability Consultants Ltd.

▪ Jean-François Maillé, P.Eng.....JDS Energy & Mining Inc.

▪ Yapo Allé-Ando, P.Eng.............M.A. O’Kane Consultants Inc.

▪ Rachel Sawyer, P.Eng...............M.A. O’Kane Consultants Inc.

▪ Paul Gauthier, P.Eng.................WSP Canada Inc.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project

District of Wells, British Columbia, Canada

Prepared for:

Osisko Development Corp.

Effective Date: April 25, 2025

Signature Date: June 11, 2025 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

Date and Signature Page

This technical report is effective

as of the 25th day of April 2025.

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Mathieu Bélisle, P.Eng.

BBA Engineering Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Amanda Fitch, P.Eng.

BBA Engineering Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Sebastien Guido, P.Eng.

Alius Mine Consulting Inc. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Philip Clark, P.Eng.

Clean Energy Consulting Inc. |

|

Date |

| JUNE 2025 | BBA Document No.: 3772047-000000-40-ERA-0001-R00 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Rob Griffith, P.Eng.

Falkirk Environmental Consultants Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Katherine Mueller, P.Eng.

Falkirk Environmental Consultants Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Nikolay Sidenko, P.Geo.

Falkirk Environmental Consultants Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Eric Lecomte, P.Eng.

InnovExplo Inc. |

|

Date |

| JUNE 2025 | BBA Document No.: 3772047-000000-40-ERA-0001-R00 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Carl Pelletier, P.Geo.

InnovExplo Inc. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Tessa Scott, P.Geo.

InnovExplo Inc. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

A.J. MacDonald, P.Eng.

Integrated Sustainability Consultants Ltd. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Jean-François Maillé, P.Eng.

JDS Energy & Mining Inc. |

|

Date |

| JUNE 2025 | BBA Document No.: 3772047-000000-40-ERA-0001-R00 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Yapo Allé-Ando, P.Eng.

M.A. O'Kane Consultants Inc. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Rachel Sawyer, P.Eng.

M.A. O'Kane Consultants Inc. |

|

Date |

| |

|

|

| |

|

|

| “Signed and sealed on file” |

|

June 11, 2025 |

|

Paul Gauthier, P.Eng.

WSP Canada Inc. |

|

Date |

| |

|

|

| JUNE 2025 | BBA Document No.: 3772047-000000-40-ERA-0001-R00 |

|

990 de l’Église Rd, Suite 590,

Québec, QC, G1V 3V7

T +1 418.657.2110

F +1 450.464.0901

BBAconsultants.com

|

CERTIFICATE OF QUALIFIED PERSON

Mathieu Bélisle, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Mathieu Bélisle, P.Eng., as a co-author of the Technical

Report, do hereby certify that:

| 1. | I am a Metallurgist with the firm BBA Engineering Ltd., I am located at 990 route de

l’Église, Suite 590, Québec, QC, G1V 3V7, Canada. |

| 2. | I am a graduate of Laval University, with a Bachelor of Engineering in Metallurgy and Materials in

2002. |

| 3. | I am a member of the Ordre des Ingénieurs du Québec (OIQ 128549), Professional

Engineers of Ontario (PEO 10210546), and the Engineers and Geoscientists of British-Colombia (EGBC 49319). |

| 4. | My relevant experience includes 20 years of experience working for mining operations and engineering

consultants. I have been involved in numerous projects requiring detailed engineering design and produced several studies for the

mining industry. |

| 5. | I have read the definition of “qualified person” set out in the NI 43-101 –

Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of my education, affiliation with

a professional association, and past relevant work experience, I fulfill the requirements to be a qualified person for the

purposes of NI 43-101. |

| 6. | I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| 7. | I am author and responsible for the preparation of Chapters 13 and 17, and Sections 21.1.4.8,

21.1.5.9, and 21.2.5. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| 8. | I have not visited the Cariboo Property that is the subject of the Technical Report. |

| 9. | I have prior involvement with the Property that is the subject of the Technical Report as I was a

qualified person for the Preliminary Economic Assessment (“PEA”) report for the Cariboo Gold Project prepared for

Barkerville Gold Mines Ltd. dated August 18, 2019, for the PEA report prepared for Osisko Development Corp. dated May 24,

2022, and for the Feasibility Study report prepared for Osisko Development Corp., dated January 10, 2023 and amended

January 12, 2023. |

| 10. | I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been

prepared following NI 43-101 rules and regulations. |

| 11. | As at the effective date of the Technical Report, to the best of my knowledge, information and

belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is

required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed

and sealed on file |

|

| Mathieu

Bélisle, P.Eng. |

|

|

1050 West Pender Street, Suite 800

Vancouver,

BC, V6E 3S7

T +1 604.661.2111

BBAconsultants.com

|

CERTIFICATE OF QUALIFIED PERSON

Amanda Fitch, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Amanda Fitch, P.Eng., as a co-author of the Technical Report, do

hereby certify that:

| 1. |

I

am Regional Director – Mining and Metals Market with the firm BBA Engineering Ltd., I am located at 1050 West Pender Street,

Suite 800, Vancouver, BC V6E 3S7, Canada. |

| |

|

| 2. |

I

am a graduate of McGill University, with a Bachelor of Engineering in Mining in 2010. |

| |

|

| 3. |

I

am a member of the Engineers and Geoscientists of British-Columbia (EGBC 176727), the Ordre des Ingénieurs du Québec

(OIQ 5016750), and the Nevada State Board of Professional Engineers & Land Surveyors (NVBPELS 025156) |

| |

|

| 4. |

My

relevant experience includes 15 years of experience working for engineering consultants, and mining operations. I have been involved

in numerous Preliminary Economic Assessments, Prefeasibility and Feasibility Studies for the mining industry. |

| |

|

| 5. |

I

have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

|

| 6. |

I

am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

|

| 7. |

I

am responsible for the following chapters and sections: 1, 2, 3.2, 18, 18.1, 18.2, 18.2.1, 18.2.1.1, 18.3, 18.3.5, 18.3.5.4, 18.3.6,

18.3.6.7, 18.3.6.9, 18.4, 19, 21, 21.1, 21.1.1, 21.1.2, 21.1.2.1, 21.1.2.2, 21.1.3, 21.1.4, 21.1.4.6, 21.1.4.10, 21.1.4.11, 21.1.5,

21.1.5.6, 21.1.5.7, 21.2, 21.2.1, 21.2.2, 21.2.7, 21.2.8, 22, 25, 26 and 27. |

| |

|

| 8. |

I

have visited the proposed Mine Site Complex in Wells and the Bonanza Ledge site on November 8, 2024. |

| |

|

| 9. |

I

have prior involvement with the property that is the subject of the Technical Report. I was the lead integrating engineer for the

Preliminary Economic Assessment (“PEA”) report for the Cariboo Gold Project prepared for Barkerville Gold Mines Ltd.

dated August 18, 2019, for the PEA report prepared for Osisko Development Corp. dated May 24, 2022, and for the Feasibility

Study report prepared for Osisko Development Corp., dated January 10, 2023 and amended January 12, 2023. |

| |

|

| 10. |

I

have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

|

| 11. |

As

at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed

and sealed on file |

|

| Amanda Fitch, P.Eng. |

|

|

Alius Mine Consulting

info@aliusmining.com

www.aliusmining.com

|

CERTIFICATE OF QUALIFIED PERSON

Sebastien Guido, P.Eng., M.Sc.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Sebastien Guido, P.Eng., M.Sc., as a co-author of the Technical

Report, do hereby certify that:

| 1. |

I am a Senior Engineer, Rock Mechanics with Alius Mine Consulting Inc., located at 985 rue du Mont-Saint-Denis, Quebec City, Québec, Canada, G1S 1B4. |

| |

|

| 2. |

I am a graduate of Université Laval (Bachelor of Engineering) in Mining Engineering. I also obtained a Master of Science from the same university. |

| |

|

| 3. |

I am a member of the Ordre des ingénieurs du Québec (OIQ No. 5067847) and Engineers and Geoscientists British Columbia (EGBC No. 53592). |

| |

|

| 4. |

My relevant experience includes ten years in various roles, including a site geotechnical engineer, a consulting engineer and in academia (undergraduate level). I have actively worked as a geotechnical engineer since 2015. |

| |

|

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

|

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

|

| 7. |

I am author and responsible for Section 16.2. I am also co-author of the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| |

|

| 8. |

I have visited the Cariboo Property that is the subject of the Technical Report, on January 20 and 21, 2025 as part of this current mandate. |

| |

|

| 9. |

I have had prior involvement with the Cariboo Project that is the subject of the Technical Report as I supported the mine during the construction of the Cow Portal, the underground development and bulk sample associated with the Lowhee Zone. I have also supported the mine engineering team at Bonanza Ledge from July 2021 to August 2024. |

| |

|

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and regulations. |

| |

|

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed

and sealed on file |

|

| Sebastien Guido, P.Eng., M. Sc. |

|

CERTIFICATE OF QUALIFIED PERSON

Philip Clark, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Philip Clark, P.Eng., as a co-author of the Technical Report, do

hereby certify that:

| 1. |

I am employed as a senior transmission line engineer/VP, Operations with the firm Clean Energy Consulting Inc., located at 640 - 650 West Georgia St, Vancouver, BC V6B 4N8, Canada. |

| |

|

| 2. |

I am a graduate of the University of Canterbury, Christchurch, New Zealand with a Bachelor of Mechanical Engineering (with Honours), 2007. |

| |

|

| 3. |

I am a member of I am a member of Engineers and Geoscientists BC (EGBC), registration #46421 |

| |

|

| 4. |

My relevant experience includes more than 15 years in the areas of transmission lines and power supply. I have been directly involved in all levels of engineering studies from conceptual designs, preliminary economic assessments (PEAs), pre-feasibility studies, feasibility studies, and detailed design on various projects. |

| |

|

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

|

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

|

| 7. |

I am author and responsible for the preparation of Section(s) 18.3.6.6, 18.4.2, 21.2.4, and coauthor for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| |

|

| 8. |

I have not visited the Property that is the subject of the Technical Report, as it was not required for the purpose of this mandate. |

| |

|

| 9. |

I have had no prior involvement with the Property that is the subject of the Technical Report. I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and regulations. |

| |

|

| 10. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed

and sealed on file |

|

| Philip Clark, P.Eng. |

|

CERTIFICATE OF QUALIFIED PERSON

Rob Griffith, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Rob Griffith, P.Eng., as a co-author of the Technical Report, do

hereby certify that:

| 1. |

I am a sub-consultant to the firm Falkirk Environmental Consultants Ltd., located at 1199 West Hastings St, Vancouver, BC, V6E 3T5. |

| |

|

| 2. |

I graduated with a bachelor's degree in water resources engineering from the University of Guelph in 2002. |

| |

|

| 3. |

I am a practising member of Engineers and Geoscientists BC (EGBC), licence number 32112. |

| |

|

| 4. |

I have over 20 years of experience in consulting for the mining industry. Relevant experience includes hydrologic and meteorological site characterization, water management planning, hydraulic design, water balance modelling and water quality modelling. |

| |

|

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

|

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

|

| 7. |

I am author and responsible for Sections 16.3, 18.3.2 and 20.3.3.1. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| |

|

| 8. |

I have not visited the Property that is the subject of the Technical Report, as it was not required for the purpose of this mandate. |

| |

|

| 9. |

I have had prior involvement with the Property that is the subject of the Technical Report as I have participated on previous reports titled: |

| |

· |

Bonanza Ledge Mine, Water Balance and Water Quality Model 2022 Update – Round Two, Prepared by Mavin Terra Solutions. Prepared for Barkerville Gold Mines Ltd. December 31, 2022. |

| |

|

|

| |

· |

Bonanza

Ledge Mine, Post Closure Water Balance and Water Quality Model Validation Plan, Prepared by Mavin Terra Solutions. Prepared for Barkerville

Gold Mines Ltd. December 31, 2022. |

| 10. |

I

have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

|

| 11. |

As

at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed

and sealed on file |

|

| Rob Griffith, P.Eng. |

|

FALKIRK ENVIRONMENTAL CONSULTANTS LTD.

Suite 250, 1199 West Hastings Street,

Vancouver, BC V6E 3T5

T 604.336.6066 |

E info@falkirk.ca | W Falkirk.ca

CERTIFICATE OF QUALIFIED PERSON

Katherine Mueller, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Katherine Mueller, P.Eng., as a co-author of the Technical Report,

do hereby certify that:

| 1. |

I am a Professional Engineer with the firm Falkirk Environmental Consultants Ltd., located at 378 Esplanade E, North Vancouver, BC V7L

1A4. |

| |

| 2. |

I am a graduate of University of Saskatchewan, with a BSc in Engineering. |

| |

| 3. |

I am a practising member of Engineers and Geoscientists BC, membership #40116. |

| |

| 4. |

I have 26 years' experience as an engineer. My relevant experience includes environmental and regulatory compliance management for mining

operations, including comprehensive expertise in environmental assessment and mine permitting in British Columbia. |

| |

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

| 7. |

I am author and responsible for the preparation of Sections 4.6, 4.7, and Chapter 20, except Sections 20.3.1 and 20.3.2. I am also co-author

of the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| |

| 8. |

I have visited the Cariboo Property that is the subject of the Technical Report, on June 15 and 16, 2022. |

| |

| 9. |

I have prior involvement with the Property that is the subject of the Technical Report. I was a qualified person for the Preliminary

Economic Assessment report for the Cariboo Gold Project prepared for Osisko Development Corp., dated May 24, 2022, and for the Feasibility

Study report prepared for Osisko Development Corp., dated January 10, 2023 and amended January 12, 2023. |

| |

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

guidelines. |

| |

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Katherine Mueller, P.Eng. |

|

FALKIRK

ENVIRONMENTAL CONSULTANTS LTD.

Suite 250,

1199 West Hastings Street, Vancouver, BC V6E 3T5

T 604.336.6066

| E info@falkirk.ca | W Falkirk.ca

CERTIFICATE OF QUALIFIED PERSON

Nikolay Sidenko, P.Geo.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Nikolay Sidenko, P.Geo., as a co-author of the Technical Report,

do hereby certify that:

| 1. |

I am a Principal Geochemist with the firm Falkirk Environmental Consultants Ltd., located at 1199 West Hastings St, Vancouver, BC, V6E

3T5. |

| |

| 2. |

I am a graduate of Novosibirsk State University (Russia) with a Master of Science degree in geochemistry |

| |

| 3. |

I am a practising member of the Association of Professional Engineers and Geoscientists of British Columbia (Member #45969). |

| |

| 4. |

My relevant experience includes 29 years of combined academic and consulting experience in geochemistry of mine waste and acid rock drainage. |

| |

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

| 7. |

I am author and responsible for Section 20.3.1, 20.3.2., 20.3.3.2., and co-author for the relevant portions of Chapters 1, 2, 25,

26 and 27 of the Technical Report. |

| |

| 8. |

I have not visited the property that is the subject of the Technical Report as it was not required for the purpose of this mandate. |

| |

| 9. |

I have had no prior involvement with the property that is the subject of the Technical Report. |

| |

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Nikolay Sidenko, P.Geo. |

|

FALKIRK ENVIRONMENTAL CONSULTANTS

LTD.

Suite 250, 1199 West

Hastings Street, Vancouver, BC V6E 3T5

T 604.336.6066 |

E info@falkirk.ca | W Falkirk.ca

|

|

Head Office - Val-d’Or

560, 3e Avenue

Val-d’Or

(Quebec) J9P 1S4 |

| |

|

|

| Quebec Office |

Montreal Office |

Phone: 819.874-0447 |

| 725, boul. Lebourgneuf |

859, boul. Jean-Paul-Vincent |

Toll free: 866.749-8140 |

| Suite 310-12 |

Suite 201 |

Email: info@innovexplo.com |

| Quebec (Quebec) G2J 0C4 |

Longueuil (Quebec) J4G 1R3 |

Website: www.innovexplo.com |

| |

|

|

CERTIFICATE OF QUALIFIED PERSON

Eric Lecomte, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Eric Lecomte, P.Eng., as a co-author of the Technical Report, do

hereby certify that:

| 1. |

I am a Senior Engineer at InnovExplo Inc., 560 3e Avenue, Val-d’Or, Québec, Canada, J9P 1S4. |

| |

| 2. |

I am a graduate from Laval University, Québec, Canada with a Bachelor's degree in Mining Engineering in 1998. |

| |

| 3. |

I am a Professional Engineer registered with the Ordre des ingénieurs du Québec (OIQ Licence: 122047), Professional Engineers

of Ontario (PEO 100574333), and Professional Engineers and Geoscientists of British-Colombia (EGBC 56488). |

| |

| 4. |

I have worked as Mine Engineer for a total of twenty-four (24) years since graduating from university. My expertise was acquired while

working as a mining engineer. During these years, I have occupied different positions, both technical and operational, related to

mining engineering, and this, in underground operations as well as in open pit |

| |

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

| 7. |

I am author and responsible of Chapter 15 and Sections 14.12, 16.1, 16.4, 16.5, 16.8, 16.9, 16.10 and Sections 21.1.4.1, 21.1.5.1, 21.1.5.8,

21.2.3 (except for 21.2.3.10). . I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| |

| 8. |

I have visited the Cariboo Project that is the subject of the Technical Report, on February 25, 2022 and on September 11, 2024. |

| |

| 9. |

I have prior involvement with the property as I was a qualified person for the Preliminary Economic Assessment report for the Cariboo

Gold Project prepared for Osisko Development Corp. and dated May 24, 2022, and the Feasibility Study for the Cariboo Gold Project

dated January 10, 2023, and amended January 12, 2023. |

| |

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Eric Lecomte, P.Eng. |

|

|

|

Head Office - Val-d’Or

560, 3e Avenue

Val-d’Or

(Quebec) J9P 1S4 |

| |

|

|

| Quebec Office |

Montreal Office |

Phone: 819.874-0447 |

| 725, boul. Lebourgneuf |

859, boul. Jean-Paul-Vincent |

Toll free: 866.749-8140 |

| Suite 310-12 |

Suite 201 |

Email: info@innovexplo.com |

| Quebec (Quebec) G2J 0C4 |

Longueuil (Quebec) J4G 1R3 |

Website: www.innovexplo.com |

| |

|

|

CERTIFICATE OF QUALIFIED PERSON

Carl Pelletier, P.Geo.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Carl Pelletier, P.Geo., as a co-author of the Technical Report,

do hereby certify that:

| 1. |

I am the Director of Mining at InnovExplo Inc., 560 3e Avenue, Val-d’Or, Québec, Canada, J9P 1S4. |

| |

| 2. |

I graduated with a Bachelor’s degree in Geology (B.Sc.) from Université du Québec à Montréal (Montréal,

Québec) in 1992, and I initiated a Master's degree at the same university for which I completed the course program but not the

thesis. |

| |

| 3. |

I am a member of the Ordre des Géologues du Québec (OGQ, no. 384), the Association of Professional Geoscientists of Ontario

(APGO, no. 1713), the Association of Professional Engineers and Geoscientists of British Columbia (APEGBC, no. 43167) and of the Canadian

Institute of Mines (CIM). |

| |

| 4. |

My relevant experience includes a total of 31 years since my graduation from university. My mining expertise has been acquired at the

Silidor, Sleeping Giant, Bousquet II, Sigma-Lamaque and Beaufor mines. My exploration experience has been acquired with Cambior Inc.

and McWatters Mining Inc. I have been a consulting geologist for InnovExplo Inc. since February 2004 where I contributed to multiple

mandates of mineral resources estimation. I have relevant experience in various types of mineral deposits: precious metals (Au, Ag),

base metals (Cu, Zn, Ni), industrial and high technology (graphite, Li, Be, Ta, U, Sc and REE) as well as for different types of operations

(underground and open pit mines). |

| |

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101 |

| |

| 7. |

I am author and responsible for the following Chapters and Sections: 3.1 and 23. I am co-author and share responsibility on Chapters

and Sections 4.1 to 4.5, 5 through 12 and 14 except 14.12. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and

27. |

| |

| 8. |

I have visited the Cariboo Project on two different occasions, February 1-4, 2016 and on May 3-12, 2016. |

| |

| 9. |

I have prior involvement with the Property that is the subject of the Technical Report. I was a qualified person for the NI 43-101 Technical

Report for the Cariboo Gold Project and Mineral Resource Estimate (“MRE”) on the Barkerville Mountain Deposit dated May 16,

2017, the NI 43-101 Technical Report and MRE Update for the Cariboo Gold Project dated June 14, 2018, the NI 43-101 Technical Report

and MRE Update for the Cariboo Gold Project dated July 11, 2019, the Preliminary Economic Assessment (“PEA”) report

for the Cariboo Gold Project prepared for Barkerville Gold Mines Ltd. dated August 18, 2019, the PEA report prepared for Osisko

Development Corp. dated May 24, 2022, and the Feasibility Study for the Cariboo Gold Project dated January 10, 2023 and amended

January 12, 2023. |

| |

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Carl Pelletier, P.Geo. |

|

|

|

Head Office - Val-d’Or

560, 3e Avenue

Val-d’Or

(Quebec) J9P 1S4 |

| Quebec Office |

Montreal Office |

Phone: 819.874-0447 |

| 725, boul. Lebourgneuf |

859, boul. Jean-Paul-Vincent |

Toll free: 866.749-8140 |

| Suite 310-12 |

Suite 201 |

Email: info@innovexplo.com |

| Quebec (Quebec) G2J 0C4 |

Longueuil (Quebec) J4G 1R3 |

Website: www.innovexplo.com |

| |

|

|

CERTIFICATE OF QUALIFIED PERSON

Tessa Scott, P.Geo.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Tessa Scott, P.Geo., as a co-author of the Technical Report, do

hereby certify that:

| 1. |

I am a Senior Resource Geologist with the firm InnovExplo Inc. located at 1245 Brickyard Rd g30, Salt Lake City, UT 84106, USA. |

| |

| 2. |

I am a graduate of Western Washington University with a bachelors in geology. |

| |

| 3. |

I am a practicing member of Engineers and Geoscientists BC, membership #169677. |

| |

| 4. |

My relevant experience includes 14 years as a geologist for mining operations and as a consultant. I have worked on numerous exploration

and mining projects, |

| |

| 5. |

I have read the definition of “qualified person” set out in the NI 43-101 – Standards of Disclosure for Mineral Projects

(“NI 43-101”) and certify that, by reason of my education, affiliation with a professional association, and past relevant

work experience, I fulfill the requirements to be a qualified person for the purposes of NI 43-101. |

| |

| 6. |

I am independent of the issuer applying all the tests in Section 1.5 of NI 43-101. |

| |

| 7. |

I am a co-author and share responsibility for the following Chapters and Sections: 4.1 to 4.5, 5 through 12, and 14 except 14.12. I am

also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27. |

| |

| 8. |

I have not visited the proposed Mine Site Complex in Wells and the Bonanza Ledge for the purpose of the Technical Report. |

| |

| 9. |

I have prior involvement with the Property that is the subject of the Technical Report. I was the chief resource geologist from 2017

to the end of 2021. I was involved in the 3D modeling and estimation for the NI 43-101 Technical Report and Mineral Resource Estimate

Update for the Cariboo Gold Project dated June 14, 2018, the NI 43-101 Technical Report and Mineral Resource Estimate Update for

the Cariboo Gold Project dated July 11, 2019, and the Preliminary Economic Assessment (“PEA”) report for the Cariboo

Gold Project prepared for Barkerville Gold Mines Ltd. dated August 18, 2019. |

| |

| 10. |

I have read NI 43-101 and the sections of the Technical Report for which I am responsible have been prepared following NI 43-101 rules and

regulations. |

| |

| 11. |

As at the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical

Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the portions

of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Tessa Scott, P.Geo. |

|

CERTIFICATE OF QUALIFIED PERSON

A.J. MacDonald, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, A.J. MacDonald, P.Eng., as a co-author of the Technical Report,

do hereby certify that:

| 1. | I am Vice President, Engineering / Senior Technical Specialist

with Integrated Sustainability Consultants Ltd., located at Suite 620 - 1050 West Pender Street, Vancouver BC, V6C 3S7, Canada. |

| 2. | I am a graduate of Queen’s University, Kingston, Canada

(B.Sc., 2005) and Carleton University, Ottawa, Canada (M.A.Sc., 2007). |

| 3. | I am a Professional Engineer, and member of Engineers and Geoscientists

British Columbia, Association of Professional Engineers and Geoscientists of Alberta, Association of Professional Engineers and Geoscientists

of Saskatchewan, Professional Engineers Ontario, Professional Engineers Yukon, Engineers and Geoscientists New Brunswick, Professional

Engineers and Geoscientists of Newfoundland and Labrador, and Nevada Board of Professional Engineers and Land Surveyors. |

| 4. | I have practiced my profession for 19 years. I have been involved

or associated with the mining industry since 2007. I have participated in dozens of mining and other resource sector projects, with a

particular focus on water treatment process engineering, primarily in Western North America. My experience spans all phases of project

delivery including preliminary analysis, conceptual design, detailed design, construction, commissioning and optimization of infrastructure

at industrial water treatment facilities in Canada and around the world. |

| 5. | I have read the definition of “qualified person”

set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of

my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a

qualified person for the purposes of NI 43-101. |

| 6. | I am independent of the issuer applying all the tests in Section 1.5

of NI 43-101. |

| 7. | I am author and responsible for Sections 18.3.5.2, 18.3.6.4,

21.1.4.5, 21.2.6. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| 8. | I have not personally visited the Property that is the subject

of the Technical Report, as it was not required for the purpose of this mandate. |

| 9. | I have had prior involvement with the Property that is the subject

of the Technical Report as I have participated as qualified person on the previous report titled NI 43-101 Feasibility Study for the

Cariboo Gold Project prepared for Osisko Development Corp., dated January 10, 2023 and amended January 12, 2023. |

| 10. | I have read NI 43-101 and the sections of the Technical Report

for which I am responsible have been prepared following NI 43-101 rules and regulations. |

| 11. | As at the effective date of the Technical Report, to the best

of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical

information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| A.J. MacDonald, P.Eng. |

|

|

900-999, West Hastings St.

Vancouver, BC, V6C 2W2 |

CERTIFICATE OF QUALIFIED PERSON

Jean-François Maillé, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Jean-François Maillé, P.Eng., as a co-author of the Technical Report, do hereby certify that:

| 1. | I am a Project Manager with JDS Energy & Mining Inc.,

located at 900-999, West Hastings St., Vancouver, BC. |

| 2. | I am a graduate of École de Technologie Superieure (ÉTS)

in Montreal, Québec. |

| 3. | I am a member in good standing of the Ordre des ingénieurs

du Québec (OIQ) member #143426. |

| 4. | I have 18 years of experience as a project manager. My relevant

experience includes mining construction and heavy civil projects. |

| 5. | I have read the definition of “qualified person”

set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of

my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a

qualified person for the purposes of NI 43-101. |

| 6. | I am independent of the issuer applying all the tests in Section 1.5

of NI 43-101. |

| 7. | I am responsible for the following chapters and sections 18.3.1,

18.3.5.3, 18.3.5.5, 18.3.6.1, 18.3.6.2, 18.3.6.3, 18.3.6.5, 18.3.6.8, 18.4.1, 21.1.2.3, 21.1.4.4, 21.1.4.7, 21.1.4.9, 21.1.5.4, 21.1.5.5,

21.3, 24. I am also co-author of the relevant portions of Chapters 1, 2, 25, 26, 27. |

| 8. | I have visited the proposed Mine Site Complex in Wells and the

Bonanza Ledge Site on October 21 and 22, 2024. This site visit was intended as a refresher after having previously carried out field

work at the Bonanza Ledge site from January to September 2021 that is the subject of the Technical Report. |

| 9. | I have prior involvement with the Property that is the subject

of the Technical Report, as I was a qualified person for the NI 43_101 Feasibility Study for the Cariboo Gold Project prepared for Osisko

Development Corp., dated January 10, 2023 and amended January 12, 2023. I have been under contract by Barkerville Gold Mines

Ltd., wholly subsidiary of Osisko Development Corp. since 2021 to perform construction management on site. |

| 10. | I have read NI 43-101 and the sections of the Technical Report

for which I am responsible have been prepared following NI 43-101 rules and guidelines. |

| 11. | As at the effective date of the Technical Report, to the best

of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical

information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Jean-François Maillé, P.Eng. |

|

CERTIFICATE OF QUALIFIED PERSON

Yapo Allé-Ando, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Yapo Allé-Ando, P.Eng., as a co-author of the Technical Report, do hereby certify that:

| 1. | I am Professional Engineer with M.A. O’Kane Consultants

Inc., located at 905C Industrial Road 2, V1C 4C9 Cranbrook, British Columbia, Canada. |

| 2. | I am a graduate of École Polytechnique Montréal,

with a Bachelor of Engineering in Engineering Physics in 2001 and of the University of British Columbia with a Master of Applied Science

in Civil Engineering in 2005. |

| 3. | I am a member of Engineers and Geoscientists BC (EGBC 39379),

Engineers Yukon (4146) and Association of Professional and Geoscientists of Alberta (APEGA 320327). |

| 4. | My relevant experience includes over 20 years in the mining

industry with expertise on mine water management and water stewardship, including water strategy, policy, governance frameworks, management

standards, and sustainability development initiatives. My technical expertise includes climate and hydrology studies, infrastructure

design, water balance modelling, and mine water management planning. |

| 5. | I have read the definition of “qualified person”

set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of

my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a

qualified person for the purposes of NI 43-101. |

| 6. | I am independent of the issuer applying all the tests in Section 1.5

of NI 43-101. |

| 7. | I am author and responsible for Sections 18.2.1.2 and 18.3.3

and 18.3.4. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| 8. | I have visited the Mine Site Complex and Bonanza Ledge site

on October 2-3, 2024 as part of this current mandate. |

| 9. | I have had no prior involvement with the Property that is the

subject of the Technical Report. |

| 10. | I have read NI 43-101 and the sections of the Technical Report

for which I am responsible have been prepared following NI 43-101 rules and regulations. |

| 11. | As at the effective date of the Technical Report, to the best

of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical

information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Yapo Allé-Ando, P.Eng. |

|

M.A. O’Kane Consultants Inc.

CERTIFICATE OF QUALIFIED PERSON

Rachel Sawyer, P.Eng.

This certificate applies to the NI 43-101 Technical

Report titled “Feasibility Study for the Cariboo Gold Project, District of Wells, British Columbia, Canada” (the “Technical

Report”), prepared for Osisko Development Corp., dated June 11, 2025, and effective as of April 25, 2025.

I, Rachel Sawyer, P.Eng., as a co-author of the Technical Report, do

hereby certify that:

| 1. | I am a Professional Engineer with

M.A. O’Kane Consultants Inc., located at 700 – 1000 7th Ave SW, T2P 5L5, Calgary,

Alberta, Canada. |

| 2. | I am a graduate of the University of Saskatchewan, with a Bachelor

of Science in Geological Engineering in 1999. |

| 3. | I am a member of Engineers and Geoscientists BC (EGBC 58041),

Association of Professional Engineers and Geoscientists (APEGA 72617), Engineers Yukon (EY 3858), Professional Engineers Ontario (PEO

100636663), Northwest Territories and Nunavut Association of Professional Engineers and Geoscientists (NAPEG L5747). |

| 4. | My relevant experience includes over 25 years in the mine and

tailings industry in both consulting and directly for the operator. My experience spans from conceptual design through to construction,

operations, and closure of complex mine and tailings earthwork structures. I have led large field teams and integrated planning groups

responsible for the tactical haulage and construction plans through to the strategic life-of-mine plans. |

| 5. | I have read the definition of “qualified person”

set out in the NI 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) and certify that, by reason of

my education, affiliation with a professional association, and past relevant work experience, I fulfill the requirements to be a

qualified person for the purposes of NI 43-101. |

| 6. | I am independent of the issuer applying all the tests in Section 1.5

of NI 43-101. |

| 7. | I am author and responsible for the preparation of Sections

18.2.2 and 18.3.5.1. I am also co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27 of the Technical Report. |

| 8. | I did not personally visit the Cariboo Property that is the

subject of the Technical Report. |

| 9. | I have had prior involvement with the Property that is the subject

of the Technical Report. I was a Qualified Person for the Cariboo Gold Project – Waste Rock Storage Facility Phase 1 Detailed Design

and Specifications prepared for Osisko Development Corp. dated October 23, 2024. |

| 10. | I have read NI 43-101 and the sections of the Technical Report

for which I am responsible have been prepared following NI 43-101 rules and regulations. |

| 11. | As at the effective date of the Technical Report, to the best

of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical

information that is required to be disclosed to make the portions of the Technical Report for which I am responsible not misleading. |

Signed and sealed this 11th

day of June 2025.

| Signed and sealed on file |

|

| Rachel Sawyer, P.Eng. |

|

M.A. O’Kane Consultants Inc.

CERTIFICATE OF QUALIFIED PERSON PAUL GAUTHIER, P.Eng.

I, Paul Gauthier, P.Eng, state that:

| (a) | At the effective date of the Technical Report, I was a

Senior Principal Mining Engineer at: |

WSP Canada Inc.

1135, boulevard Lebourgneuf,

Quebec, QC, Canada, G2K 0M5

| (b) | This certificate applies to the technical report titled “Feasibility Study for the Cariboo Gold

Project, District of Wells, British Columbia, Canada” with an effective date of: Aprill 25, 2025 (the “Technical Report”). |

| (c) | I am a “qualified person” for the purposes of National Instrument 43-101 (“NI 43-101”).

My qualifications as a qualified person are as follows. I am a graduate of Laval University with a B. SC in Mining Engineering in 1977

and am registered with Ordre de Ingénieurs du Québec (OIQ #31178), Professional Engineer Ontario (PEO, #100080984) and Professional

Engineer and Geoscientist of BC (#56779). My relevant experience after graduation and over 45 years for the purpose of the Technical Report

includes working in the mining engineering operation departments in different roles for over 45 years in different commodities mines such

as base metal, gold and diamond. I have also managed multiple feasibility studies of simple and complex natures from scoping through feasibility

studies, detailed engineering, and mine development in Canada and USA. |

| (d) | The requirement for a site visit is not applicable to me. |

| (e) | I am responsible for Sections 16.6, 16.7, 21.1.4.2, 21.1.4.3, 21.1.5.2, 21.1.5.3, 21.2.3.10 of the Technical

Report, and co-author for the relevant portions of Chapters 1, 2, 25, 26 and 27. |

| (f) | I am independent of the issuer as described in section 1.5 of NI 43-101. |

| (g) | My prior involvement with the property that is the subject of the Technical Report is as follows. I was

a qualified person for the PEA report prepared for Osisko Development Corp. dated May 24, 2022, and for the Feasibility Study report

prepared for Osisko Development Corp., dated January 10, 2023, and amended January 12, 2023. |

| (g) | I have read NI 43-101 and the part of the Technical Report for which I am responsible has been prepared

in compliance with NI 43-101; and |

| (h) | At the effective date of the Technical Report, to the best of my knowledge, information, and belief, the

parts of Technical Report for which I am responsible, contains all scientific and technical information that is required to be disclosed

to make the Technical Report not misleading. |

Dated in Quebec City, Quebec, this 11th

of June 2025

| Signed and sealed on file |

|

| |

[Professional Seal or Stamp] |

| [Signature of Qualified Person] |

|

| |

|

| |

|

Paul Gauthier, P.Eng. Professional Engineer and Geoscientist of BC

(#56779)

QP Certificate_WSP_GAUTHIER Paul_ODV Cariboo FS 2025_SEDAR+

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

TABLE OF CONTENTS

| 1. |

Summary |

1-1 |

| |

1.1 |

Contributors |

1-3 |

| |

1.2 |

Key Project Outcomes |

1-5 |

| |

1.3 |

Summary of Changes from 2023 Feasibility Study |

1-6 |

| |

1.4 |

Property Description and Ownership |

1-8 |

| |

1.5 |

Geology and Mineralization |

1-9 |

| |

1.6 |

Status of Exploration and Drilling |

1-10 |

| |

1.7 |

Mineral Resource Estimate |

1-11 |

| |

1.8 |

Mineral Reserve Estimate |

1-14 |

| |

1.9 |

Mining Methods |

1-16 |

| |

|

1.9.1 |

Overview |

1-16 |

| |

|

1.9.2 |

Geotechnical Evaluation |

1-16 |

| |

|

1.9.3 |

Hydrogeology |

1-17 |

| |

|

1.9.4 |

Mining Method Description |

1-17 |

| |

|

1.9.5 |

Mine Design |

1-17 |

| |

|

1.9.6 |

Development Schedule |

1-18 |

| |

|

1.9.7 |

Underground Electrical Distribution and Communication |

1-18 |

| |

|

1.9.8 |

Mine Automation and Monitoring Systems |

1-19 |

| |

|

1.9.9 |

Ventilation |

1-19 |

| |

|

1.9.10 |

Production Rate |

1-19 |

| |

|

1.9.11 |

Production Plan |

1-19 |

| |

|

1.9.12 |

Mine Equipment and Personnel |

1-20 |

| |

1.10 |

Underground Infrastructure |

1-21 |

| |

|

1.10.1 |

Underground Materials Handling System |

1-21 |

| |

|

1.10.2 |

Paste Pumping Network |

1-21 |

| |

1.11 |

Mineral Processing and Metallurgical Testing |

1-22 |

| |

1.12 |

Recovery Methods |

1-22 |

| |

1.13 |

Project Infrastructure |

1-23 |

| |

|

1.13.1 |

Waste Management |

1-23 |

| |

|

1.13.2 |

Water Management |

1-23 |

| |

|

1.13.3 |

Water Treatment Plant |

1-24 |

| |

|

1.13.4 |

Water Treatment Conveyance Infrastructure |

1-25 |

| |

|

1.13.5 |

Substation and On-site Distribution |

1-25 |

| |

|

1.13.6 |

Mine Site Infrastructure |

1-25 |

| |

1.14 |

Environmental and Permitting |

1-26 |

| |

|

1.14.1 |

Regulatory Context and Environmental Studies |

1-26 |

| |

|

1.14.2 |

Considerations of Social and Community Impacts |

1-26 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

|

1.14.3 |

Mine Reclamation and Closure Plan |

1-27 |

| |

1.15 |

Capital and Operating Costs Estimates |

1-27 |

| |

|

1.15.1 |

Capital Costs |

1-27 |

| |

|

1.15.2 |

Operating Costs |

1-29 |

| |

1.16 |

Project Economics |

1-29 |

| |

1.17 |

Project Schedule and Organization |

1-33 |

| |

1.18 |

Interpretations and Conclusions |

1-34 |

| |

|

1.18.1 |

Risks and Opportunities |

1-35 |

| |

1.19 |

Recommendations |

1-37 |

| 2. |

Introduction |

2-1 |

| |

2.1 |

Barkerville Gold Mines Division |

2-1 |

| |

2.2 |

Basis of Technical Report |

2-1 |

| |

2.3 |

Report Responsibility and Qualified Persons |

2-2 |

| |

2.4 |

Effective Dates and Declaration |

2-5 |

| |

2.5 |

Sources of Information |

2-5 |

| |

|

2.5.1 |

General |

2-5 |

| |

|

2.5.2 |

BBA Engineering Ltd. |

2-6 |

| |

|

2.5.3 |

Alius Mine Consulting Inc. |

2-7 |

| |

|

2.5.4 |

Clean Energy Consulting Inc. |

2-7 |

| |

|

2.5.5 |

Falkirk Environmental Consultants Ltd. |

2-7 |

| |

|

2.5.6 |

InnovExplo Inc. |

2-8 |

| |

|

2.5.7 |

Integrated Sustainability |

2-9 |

| |

|

2.5.8 |

JDS Energy & Mining Inc. |

2-9 |

| |

|

2.5.9 |

M.A. O’Kane Consultants Inc. |

2-10 |

| |

|

2.5.10 |

WSP Canada Inc. |

2-10 |

| |

2.6 |

Site Visits |

2-10 |

| |

2.7 |

Currency, Units of Measurement, and Calculations |

2-13 |

| |

2.8 |

Acknowledgement |

2-13 |

| 3. |

Reliance on Other Experts |

3-1 |

| |

3.1. |

Mineral Tenure and Surface Rights |

3-1 |

| |

3.2. |

Taxation and Royalties |

3-1 |

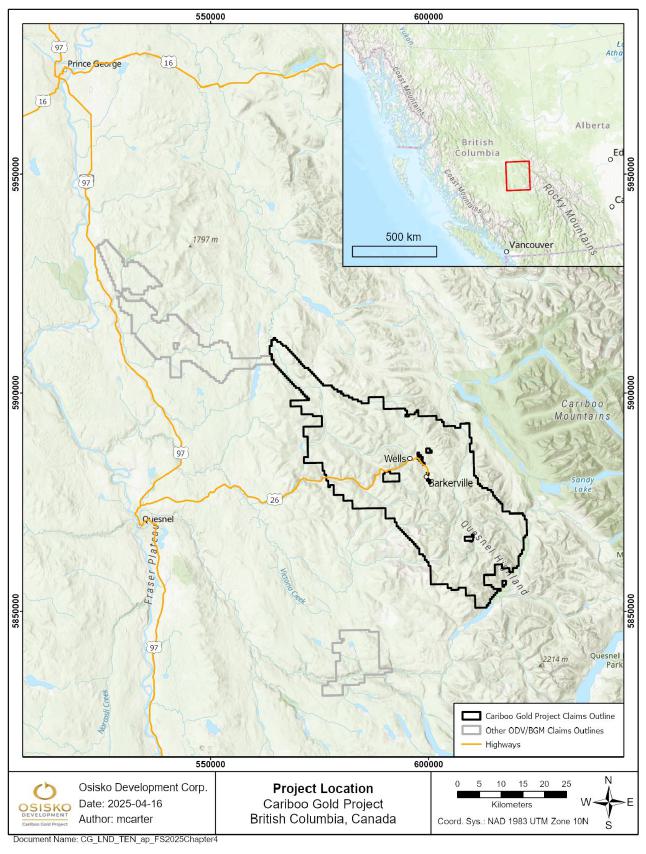

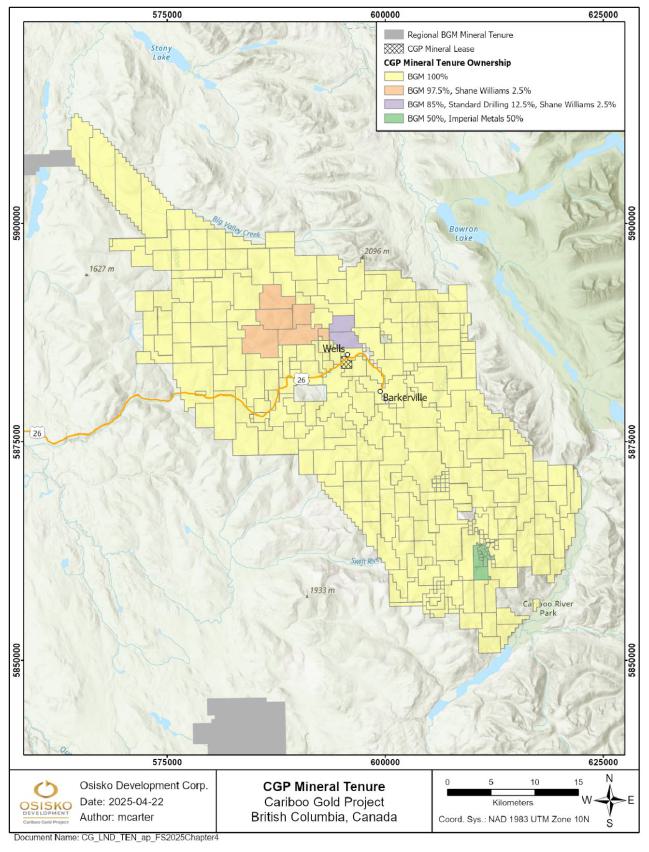

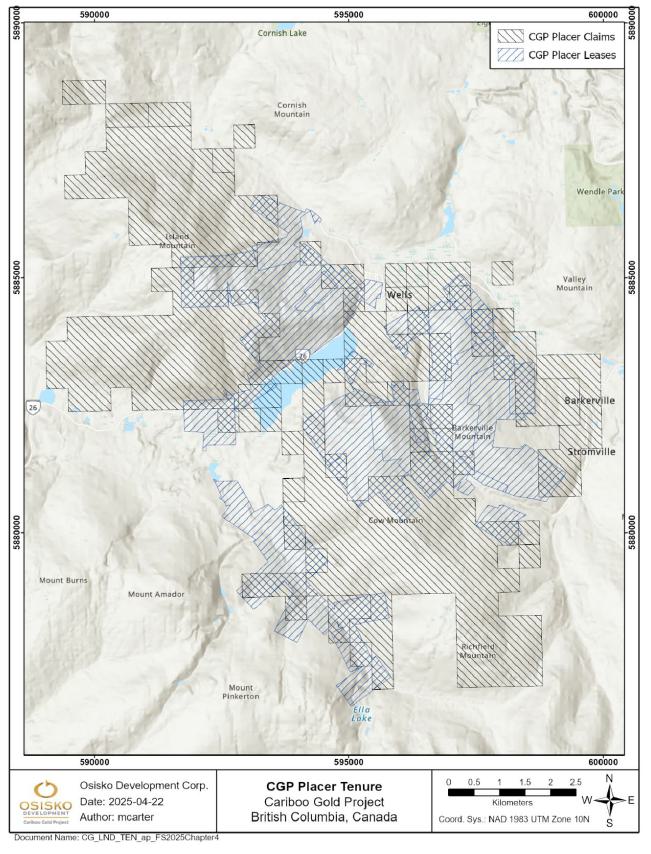

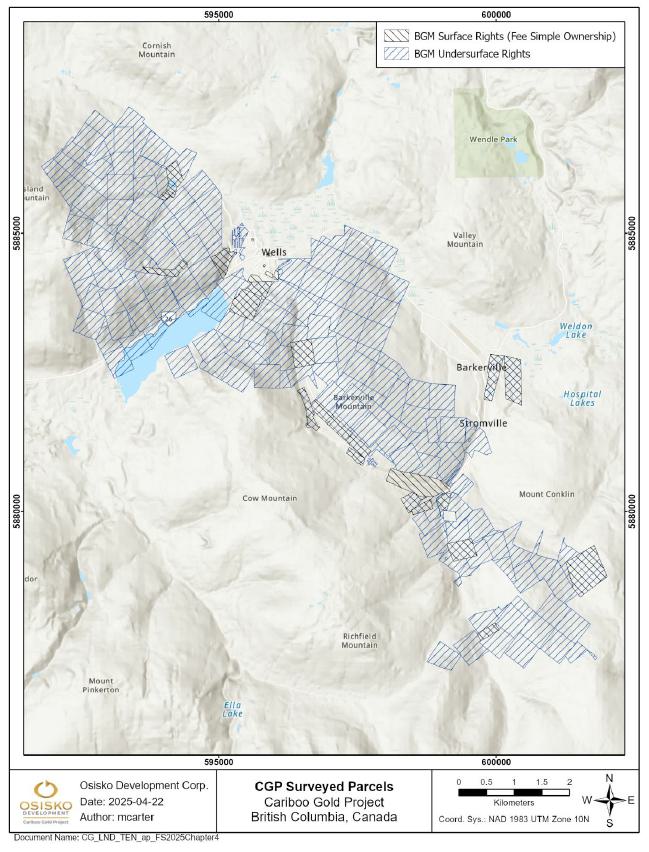

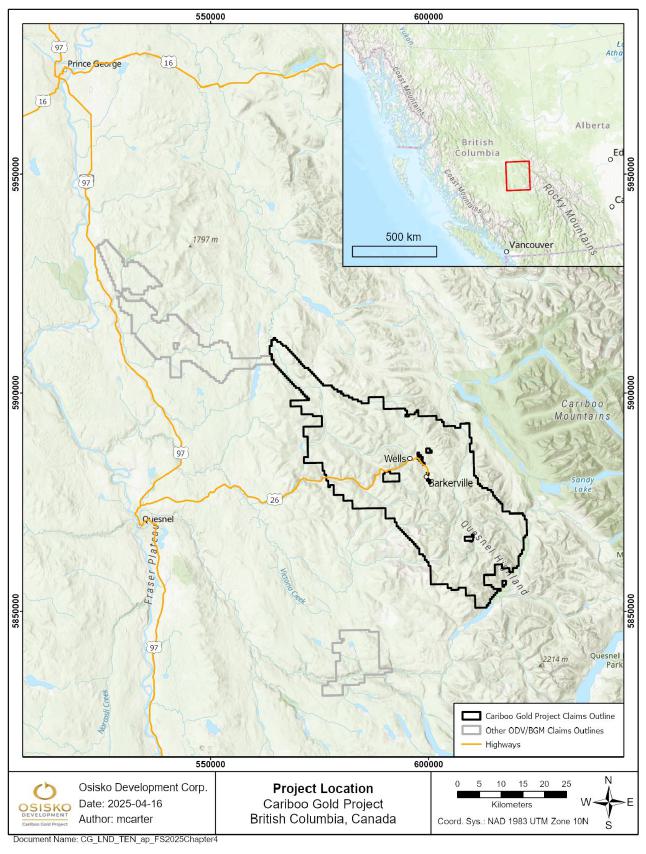

| 4. |

Property Description and Location |

4-1 |

| |

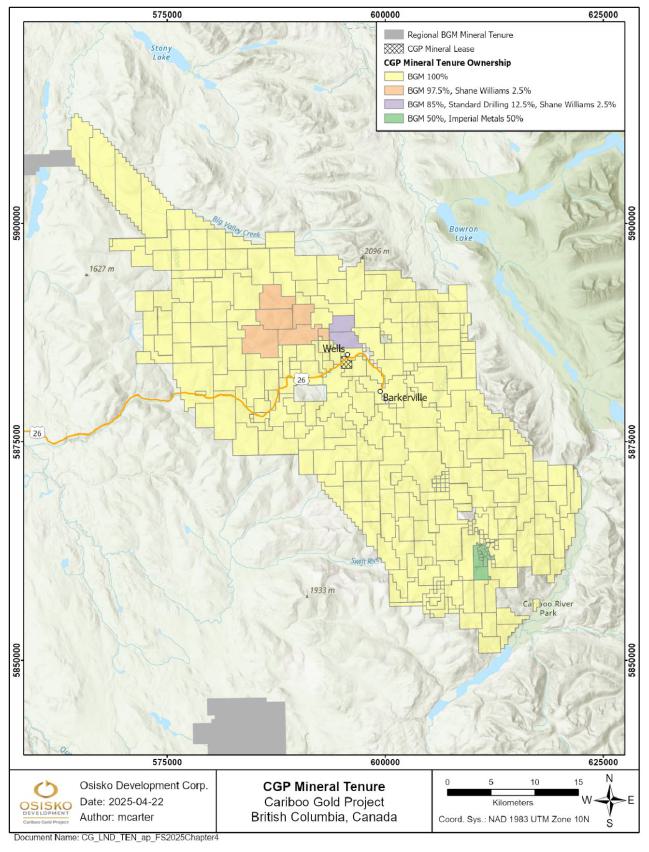

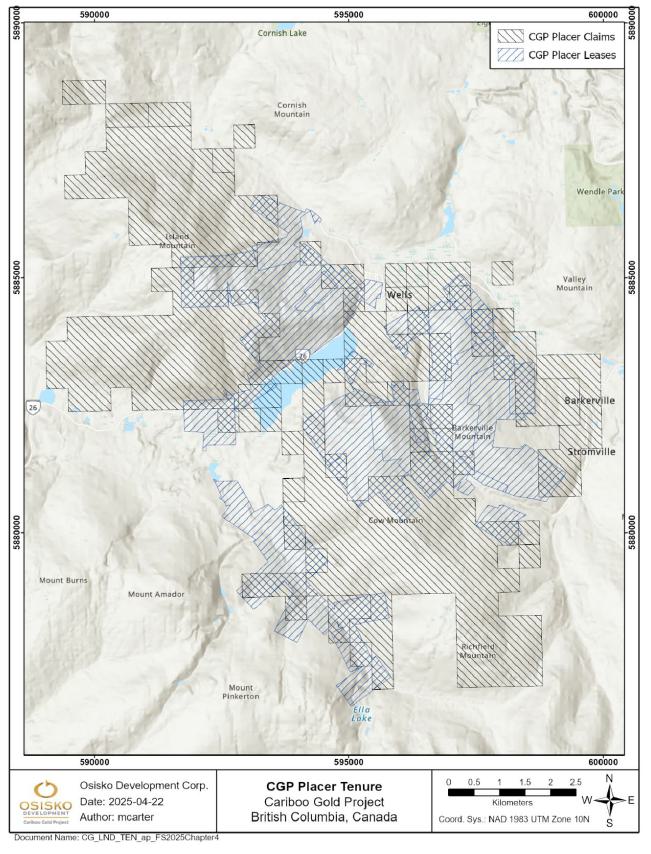

4.1. |

Mineral Title Status |

4-3 |

| |

4.2. |

Acquisition of the Cariboo Gold Project |

4-7 |

| |

4.3. |

Royalties and Ownership |

4-8 |

| |

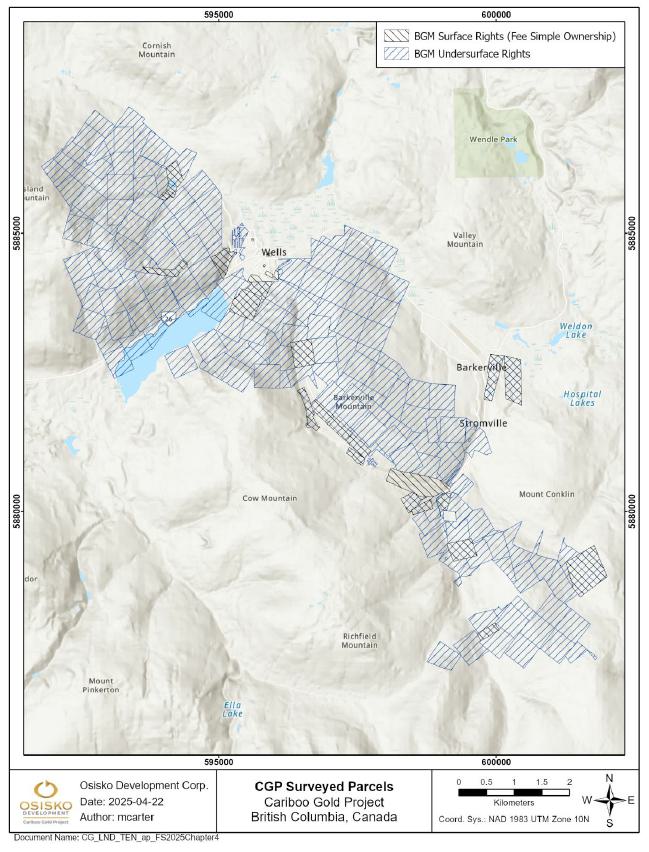

4.4. |

Surface Rights Option Agreements |

4-9 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

4.5. |

Statutory Obligations |

4-12 |

| |

|

4.5.1. |

Environmental Liabilities |

4-12 |

| |

|

4.5.2. |

Required Permits and Status |

4-12 |

| |

4.6. |

Communication and Consultation with the Community |

4-16 |

| |

|

4.6.1. |

Indigenous Nations |

4-16 |

| |

|

4.6.2. |

Stakeholders |

4-16 |

| 5. |

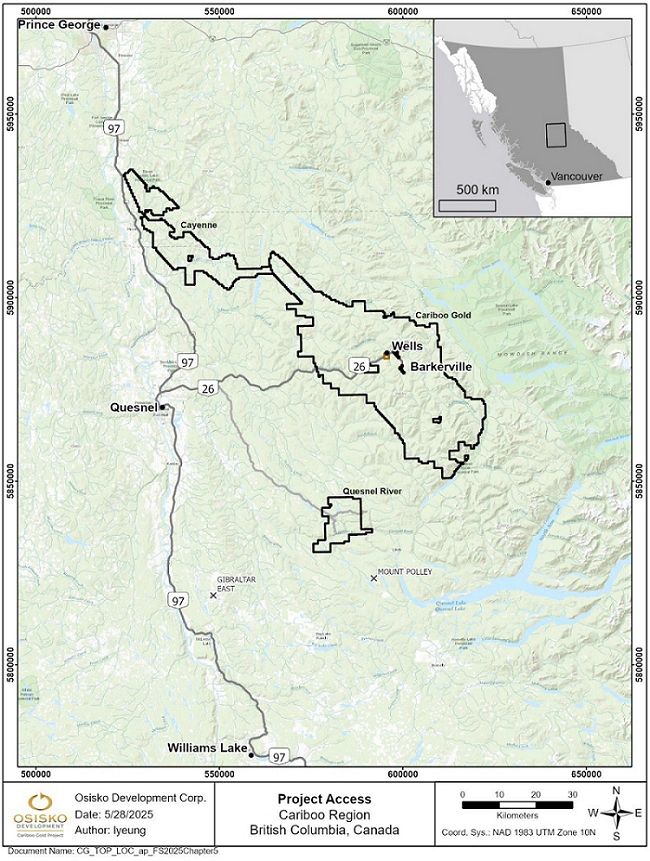

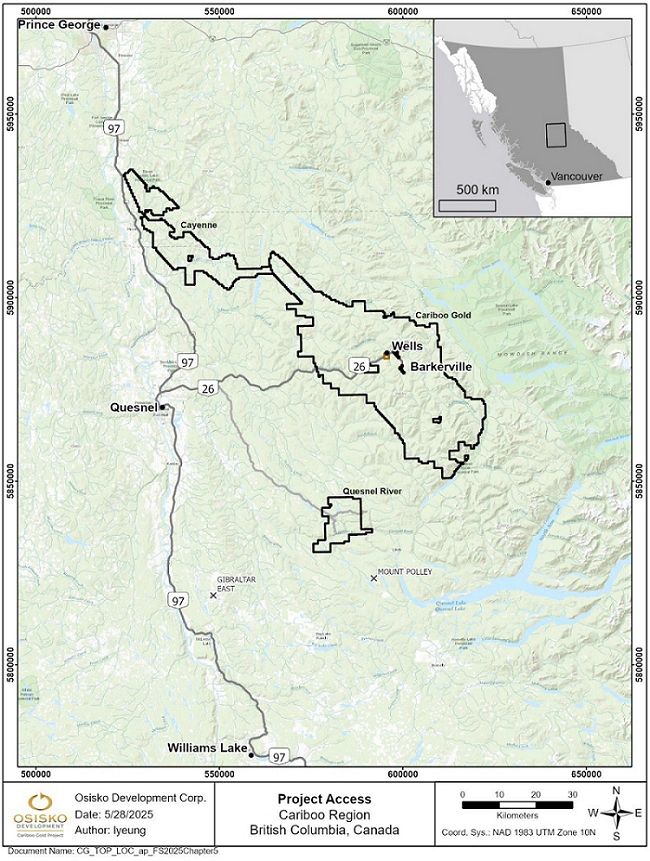

Accessibility, Climate, Local Resources, Infrastructure and Physiography |

5-1 |

| |

5.1 |

Accessibility |

5-1 |

| |

5.2 |

Infrastructure and Local Resources |

5-1 |

| |

5.3 |

Climate |

5-3 |

| |

5.4 |

Physiography |

5-3 |

| 6. |

History |

6-1 |

| |

6.1. |

Historical Mines |

6-1 |

| |

|

6.1.1. |

Cariboo Gold Quartz Mine |

6-1 |

| |

|

6.1.2. |

Island Mountain Mine (Aurum Mine) |

6-2 |

| |

|

6.1.3. |

Mosquito Creek Mine |

6-2 |

| |

6.2. |

Surface Work Programs |

6-3 |

| |

|

6.2.1. |

Cariboo Gold Quartz Mining Company Ltd. (1968) |

6-3 |

| |

|

6.2.2. |

Wharf Resources Ltd. (1980–1981) |

6-3 |

| |

|

6.2.3. |

Blackberry Gold Resources Inc. (1988) |

6-4 |

| |

|

6.2.4. |

Pan Orvana Resources Inc. (1989–1991) |

6-4 |

| |

|

6.2.5. |

Gold City Mining Corp. (1994–1995) |

6-4 |

| |

6.3. |

International Wayside Gold Mines Ltd. (1999–2014) |

6-5 |

| |

6.4. |

International Wayside Gold Mines Ltd. (1995–2009) |

6-6 |

| |

|

6.4.1. |

1995–1999 Work Programs |

6-6 |

| |

|

6.4.2. |

2000–2009 Work Programs |

6-7 |

| |

6.5. |

Barkerville Gold Mines Ltd. (2010-2014) |

6-11 |

| |

|

6.5.1. |

2010–2011 Work Programs |

6-11 |

| |

|

6.5.2. |

2012 Work Program |

6-12 |

| |

|

6.5.3. |

2013 Work Program |

6-13 |

| |

|

6.5.4. |

2014 Work Program |

6-13 |

| |

6.6. |

Barkerville Gold Mines Ltd. (2015–2022) |

6-13 |

| |

6.7. |

Regional Mineral Claims of the Cariboo Gold Project |

6-16 |

| 7. |

|

Geological Setting and Mineralization |

7-1 |

| |

7.1 |

Introduction and Clarification |

7-1 |

| |

7.2 |

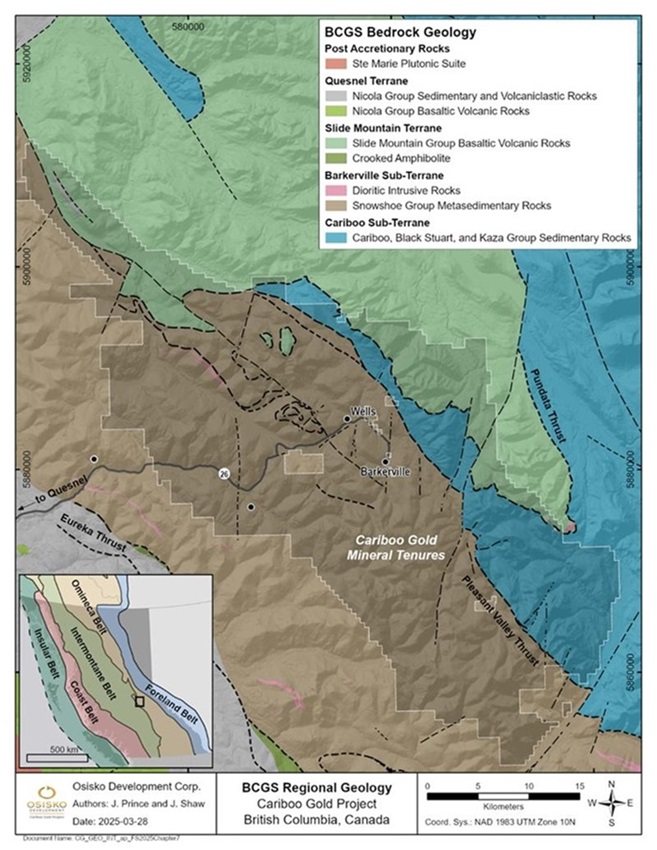

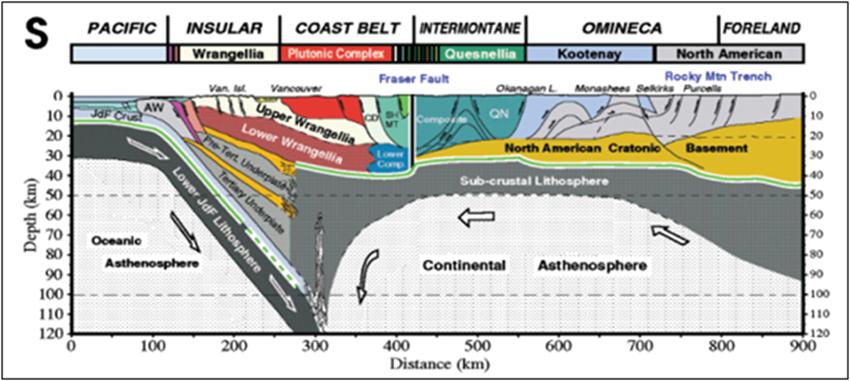

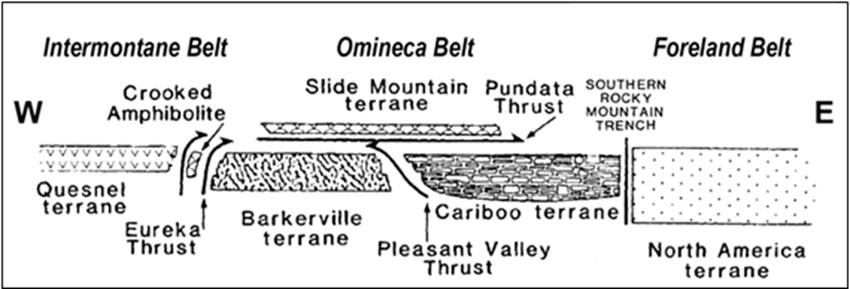

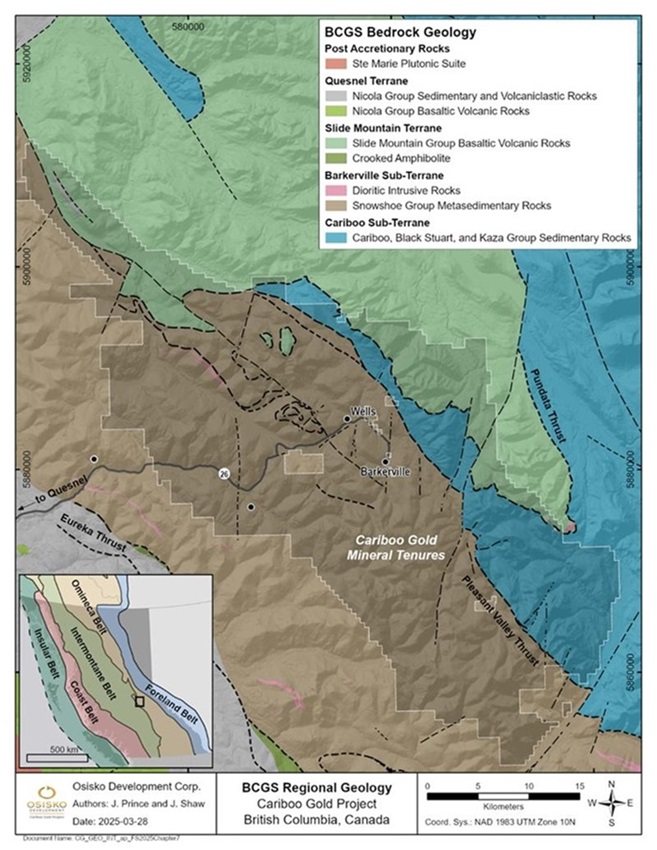

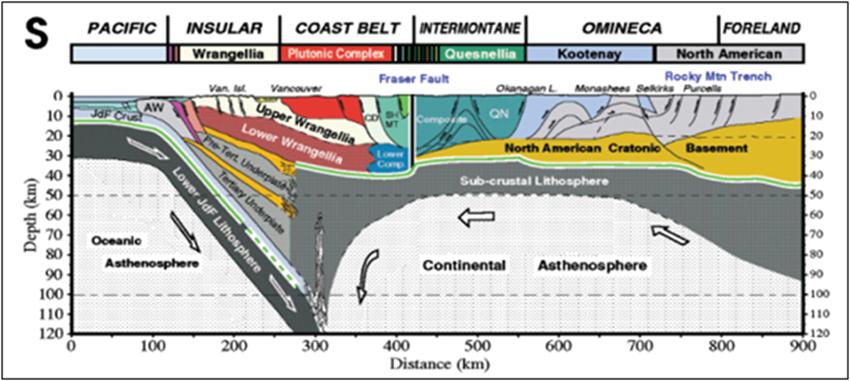

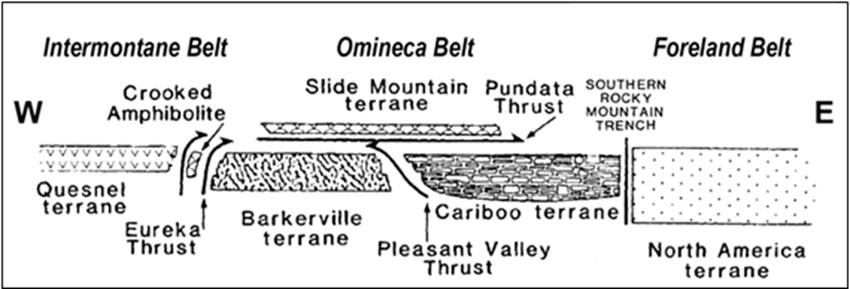

Regional Geological Setting |

7-1 |

| |

|

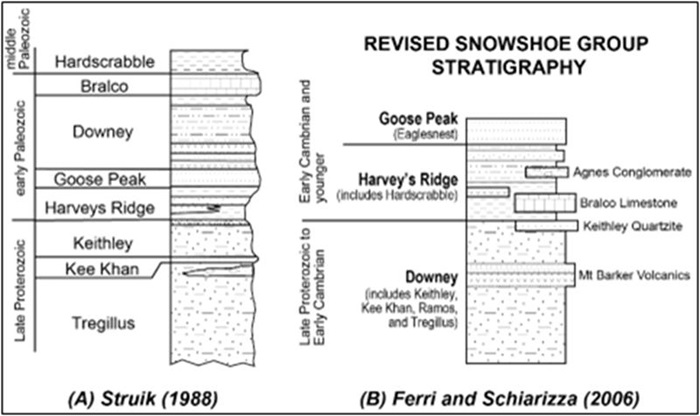

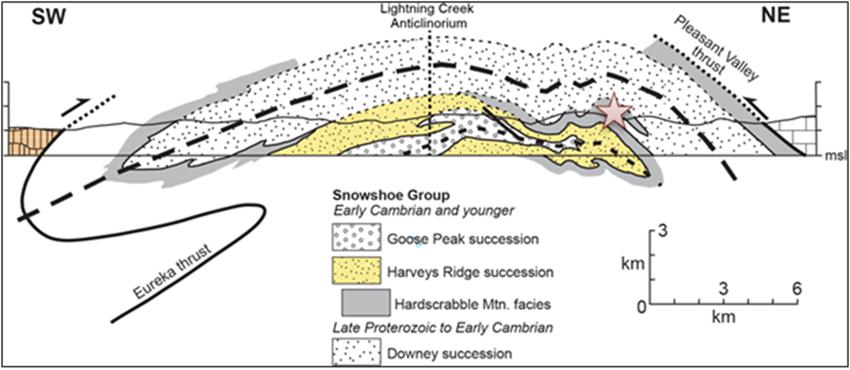

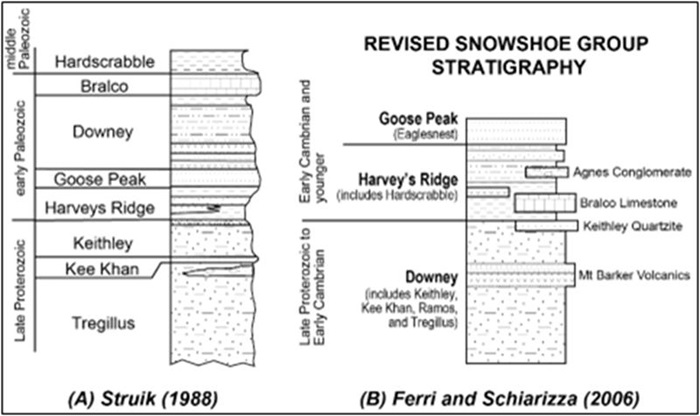

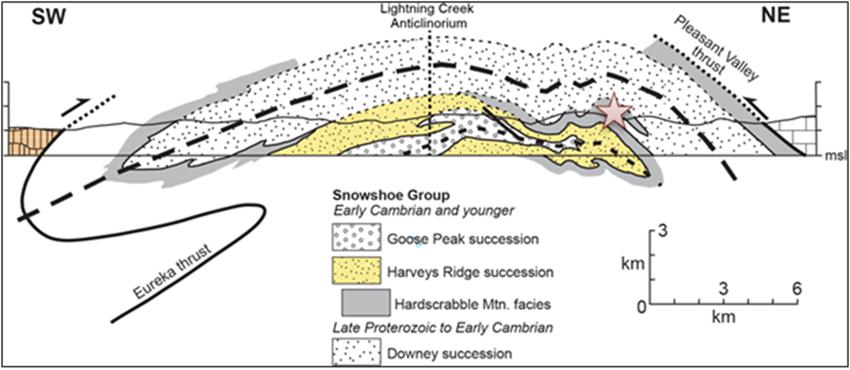

7.2.1 |

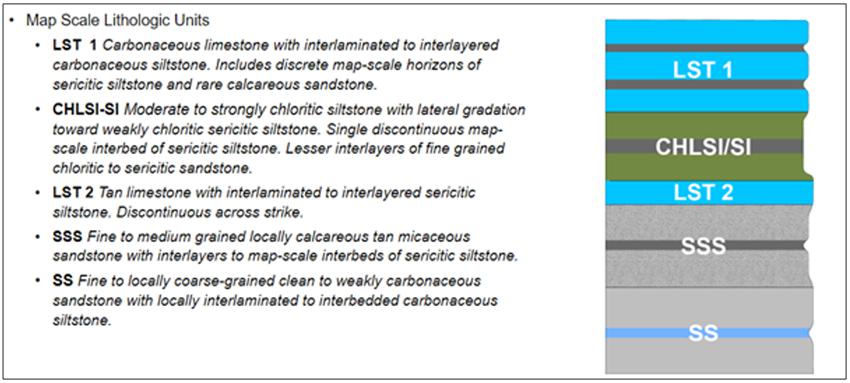

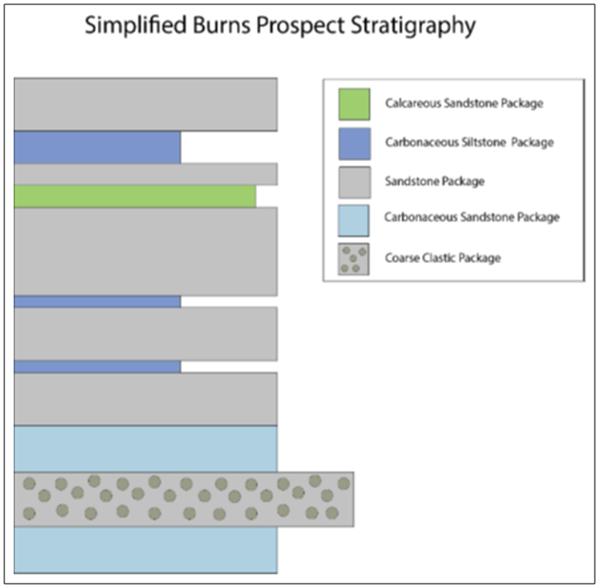

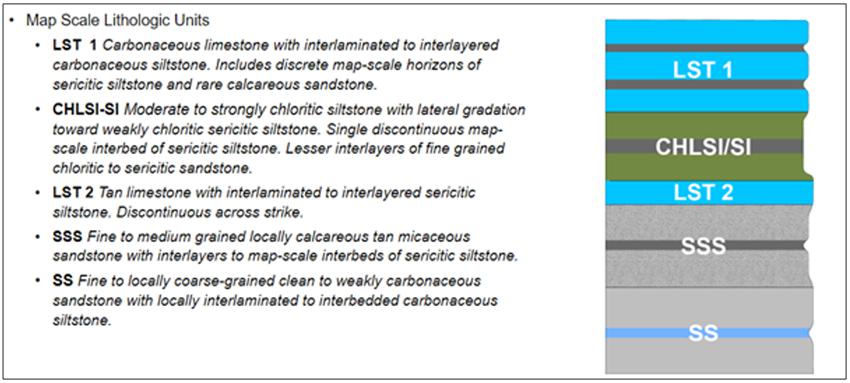

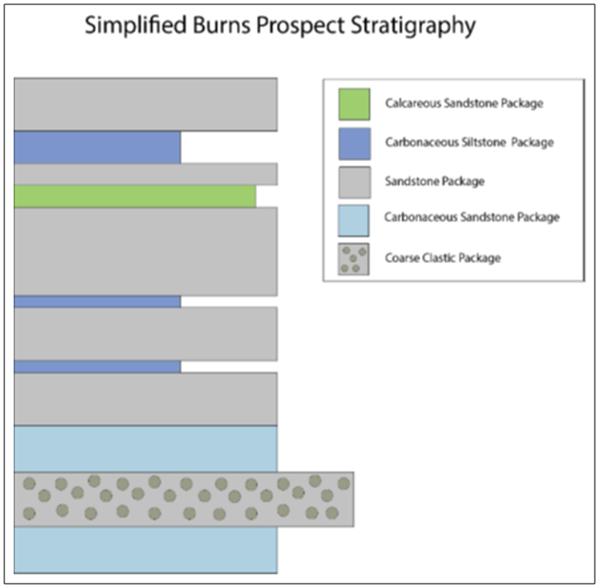

Snowshoe Group Stratigraphy |

7-7 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

|

7.2.2 |

Metamorphism |

7-9 |

| |

7.3 |

Property Geology |

7-10 |

| |

|

7.3.1 |

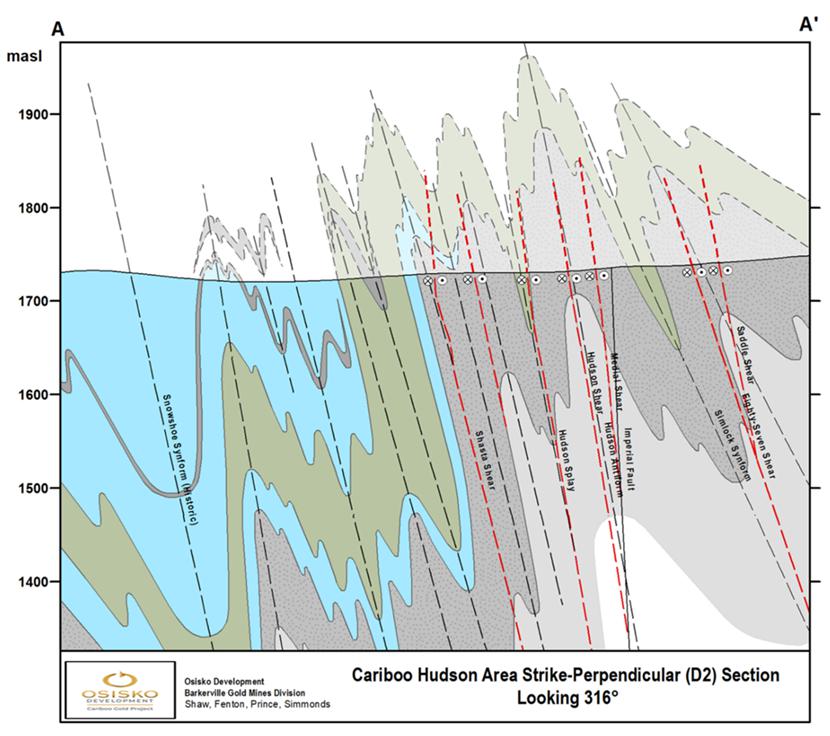

Cariboo Gold Project’s Core Area |

7-10 |

| |

|

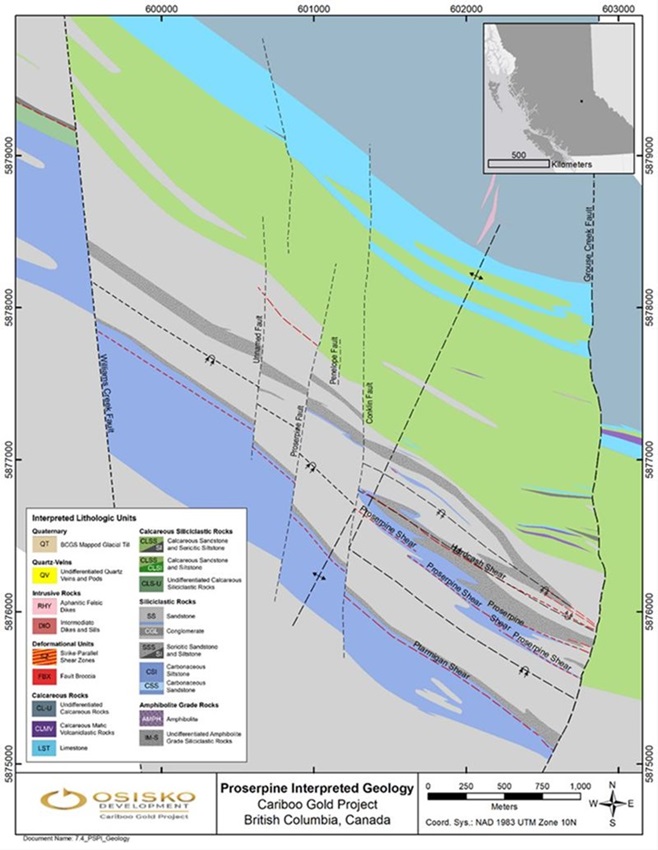

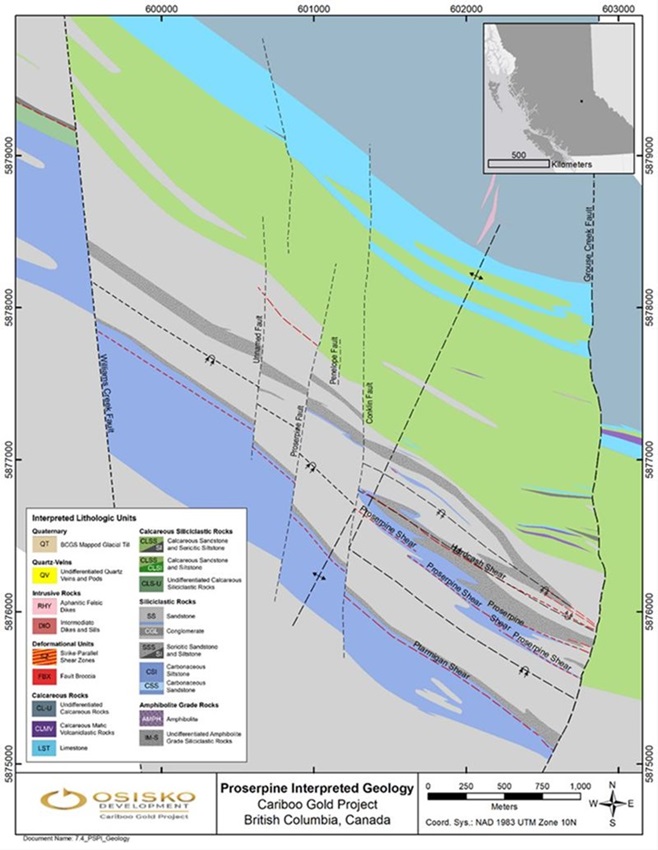

7.3.2 |

Proserpine Region |

7-18 |

| |

|

7.3.3 |

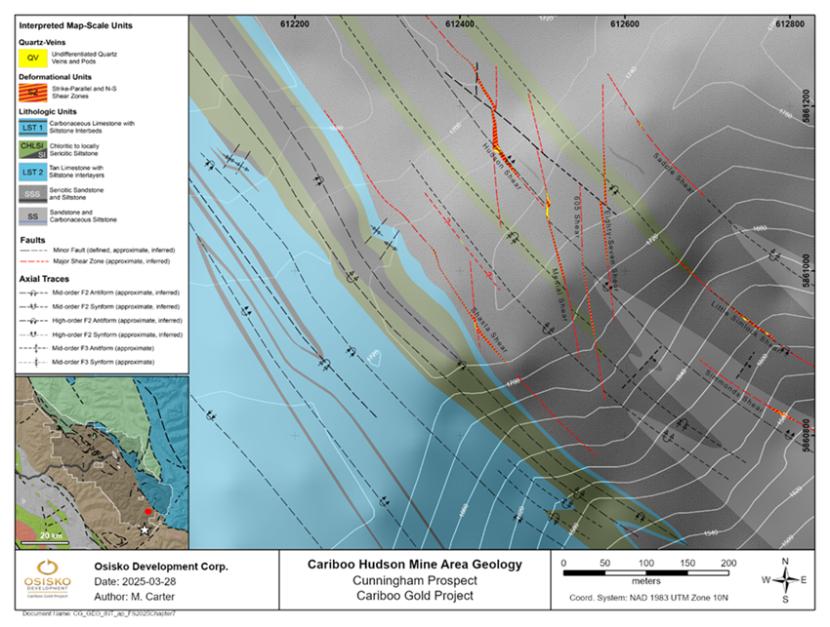

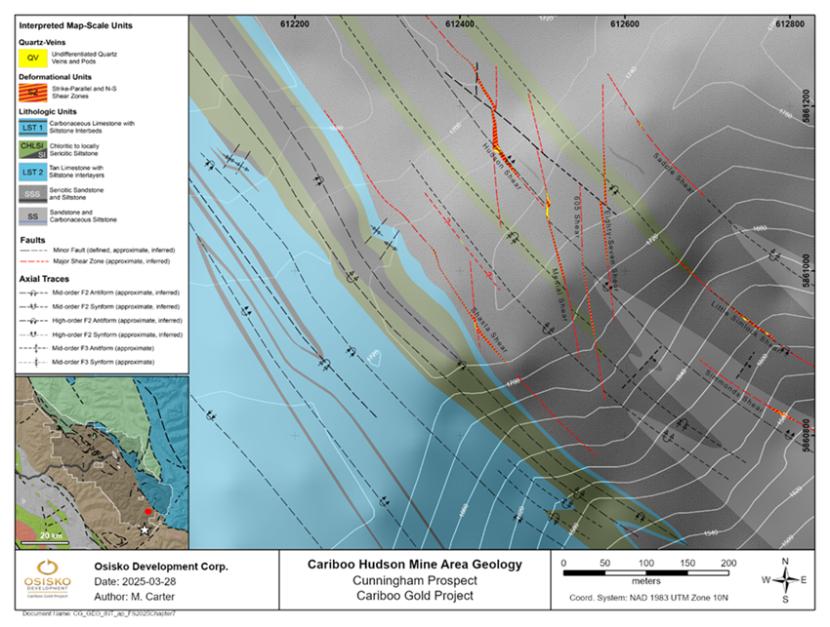

Cunningham Region |

7-20 |

| |

|

7.3.4 |

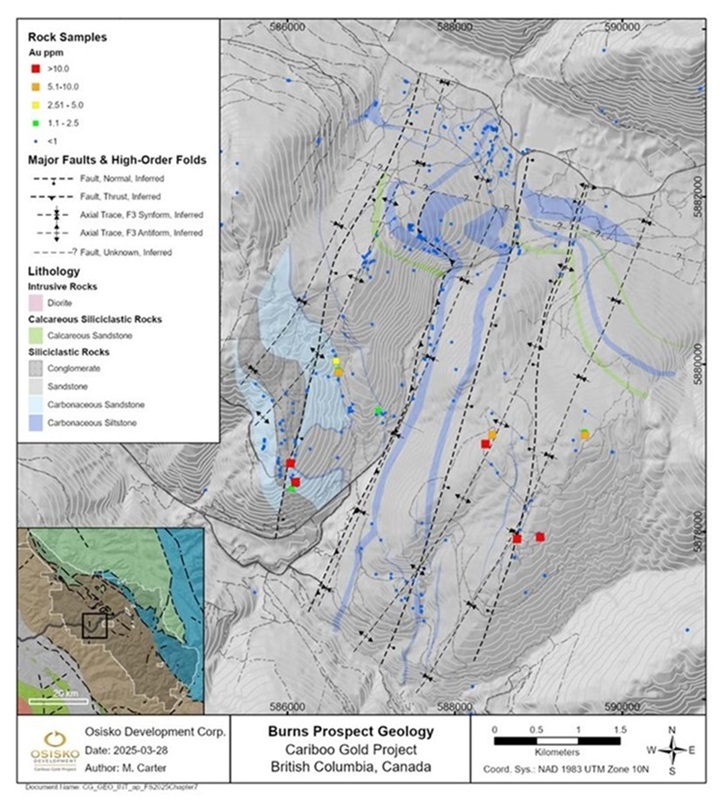

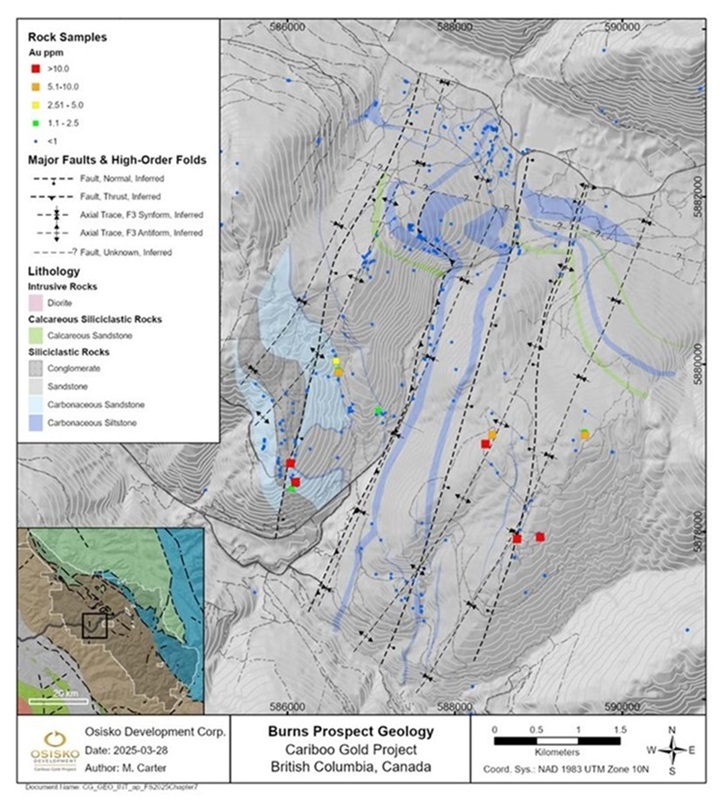

Burns Region |

7-22 |

| |

|

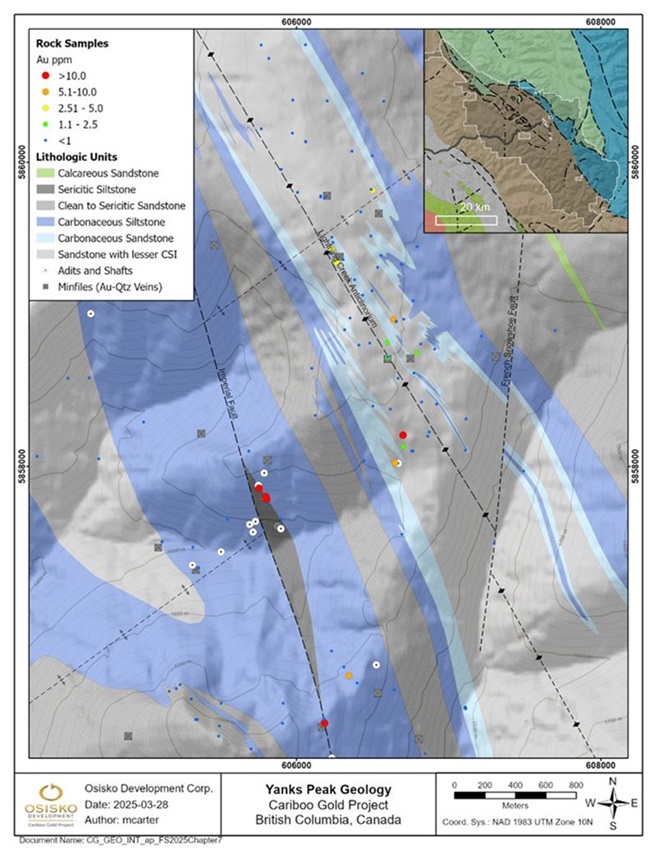

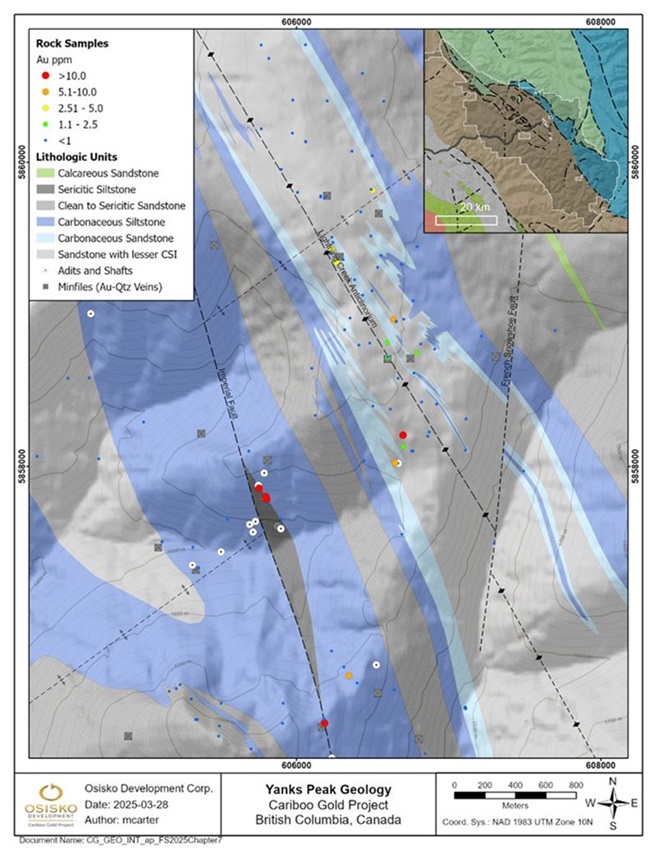

7.3.5 |

Yanks Peak Region |

7-25 |

| |

7.4 |

Structural Geology |

7-27 |

| |

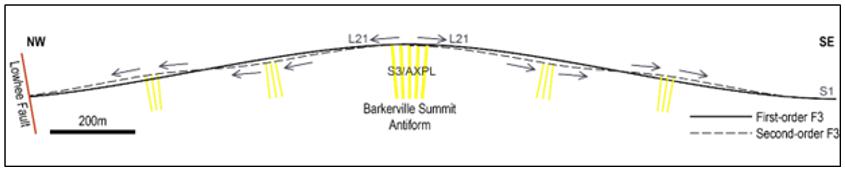

|

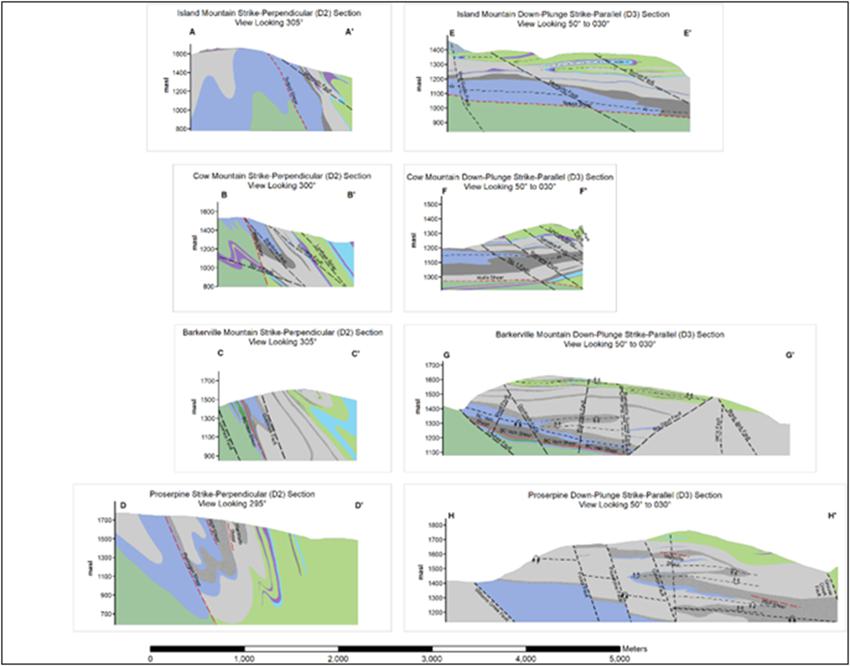

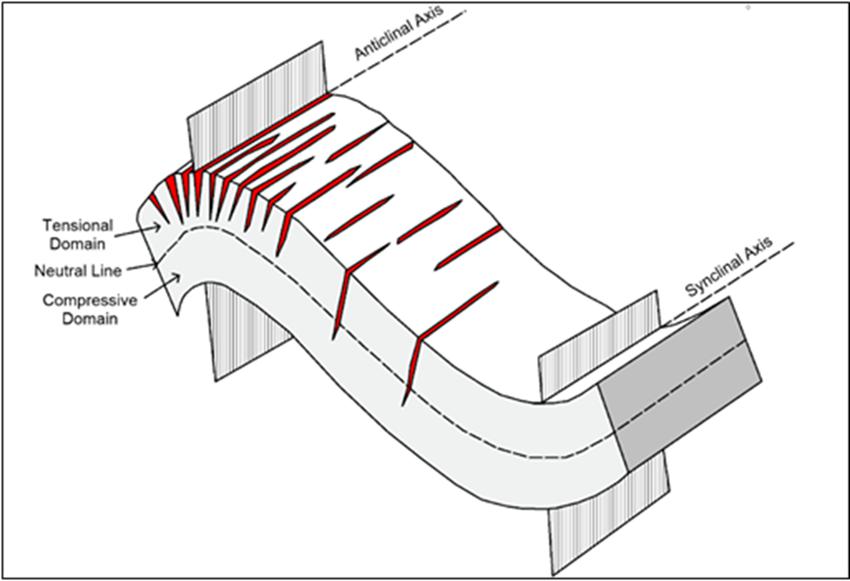

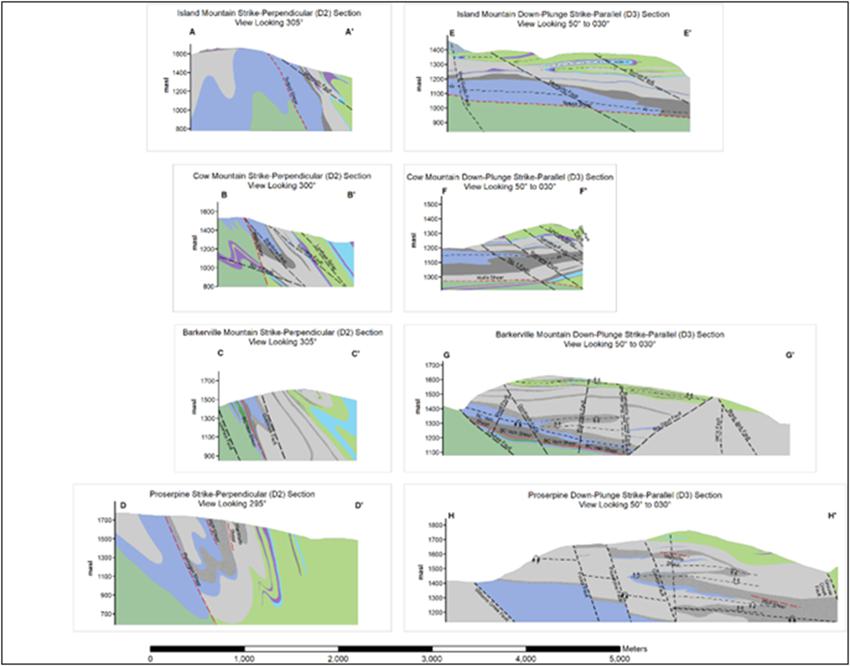

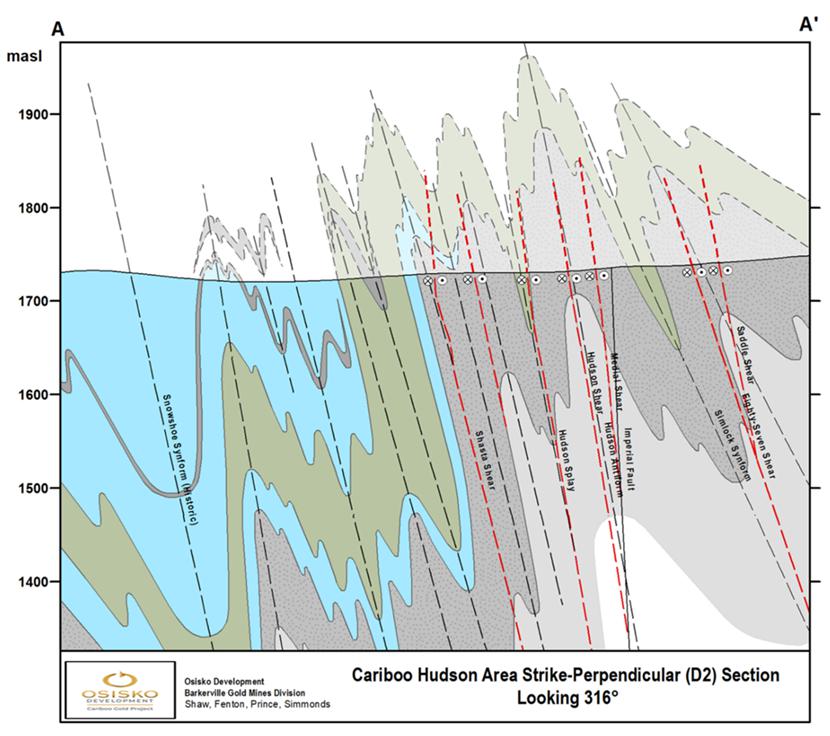

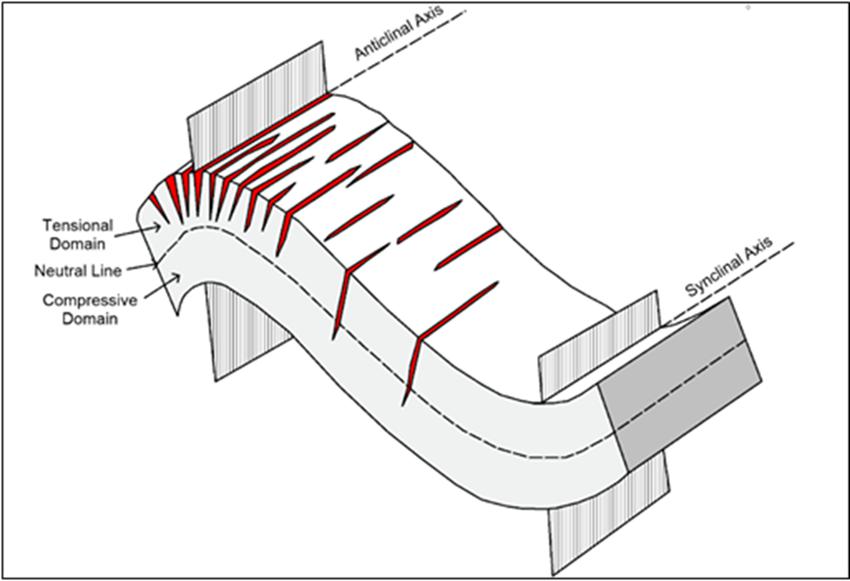

7.4.1 |

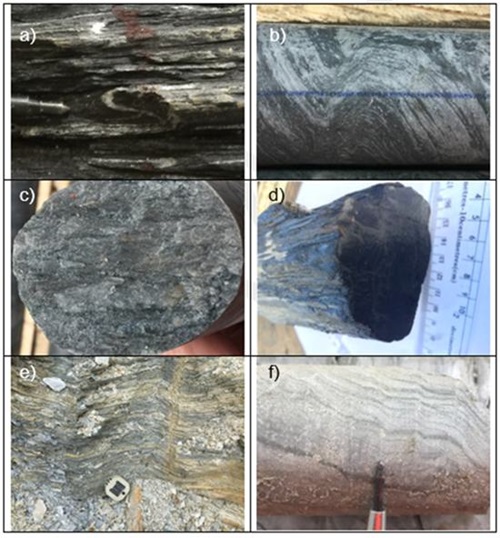

Deformation 1 |

7-27 |

| |

|

7.4.2 |

Deformation 2 |

7-28 |

| |

|

7.4.3 |

Deformation 3 |

7-28 |

| |

|

7.4.4 |

Deformation 4 |

7-30 |

| |

7.5 |

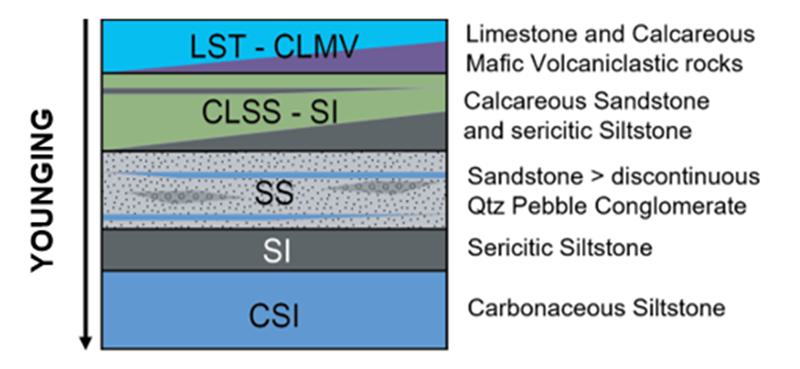

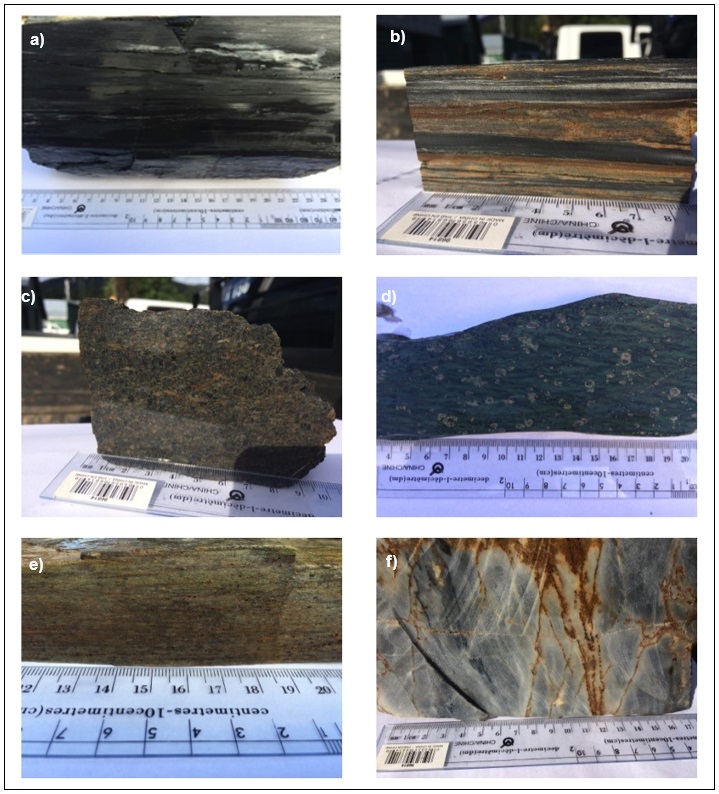

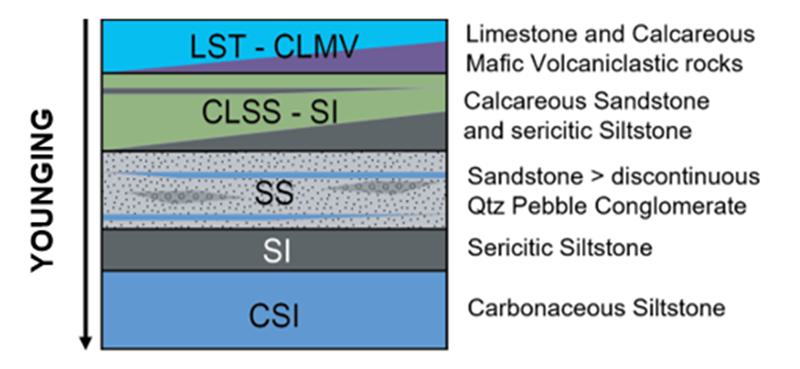

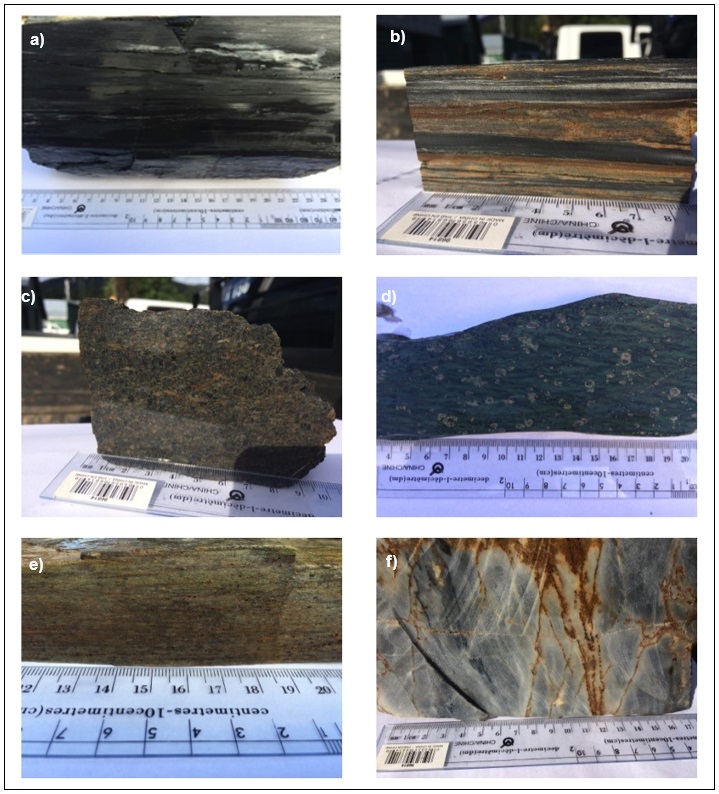

Mineralization and Alteration |

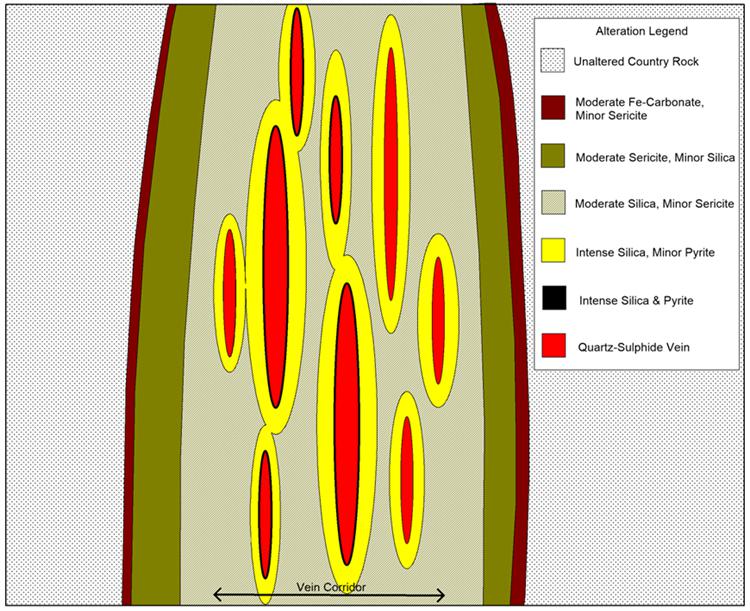

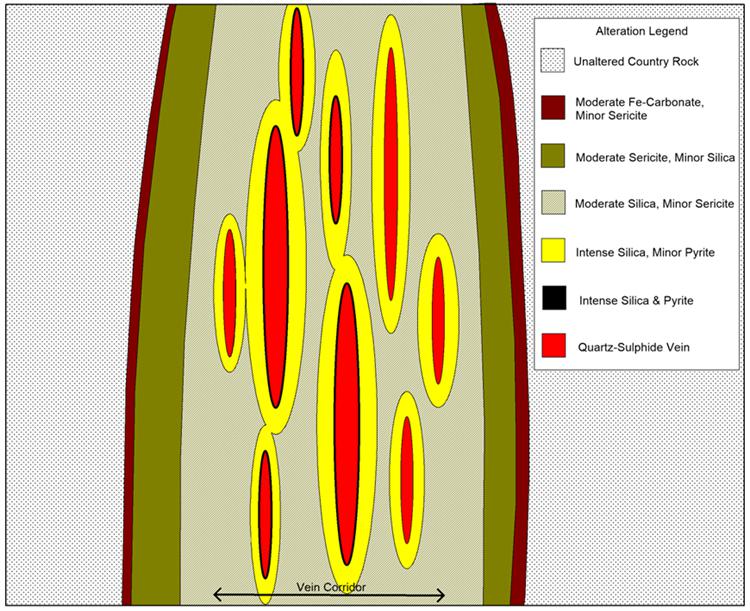

7-30 |

| |

|

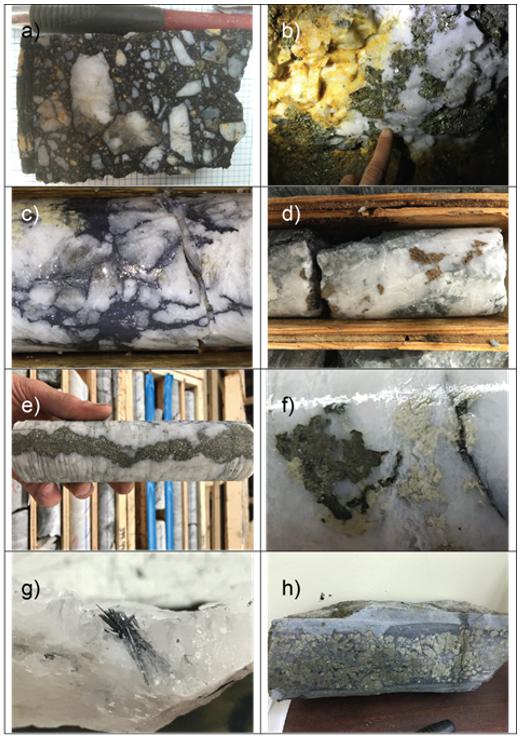

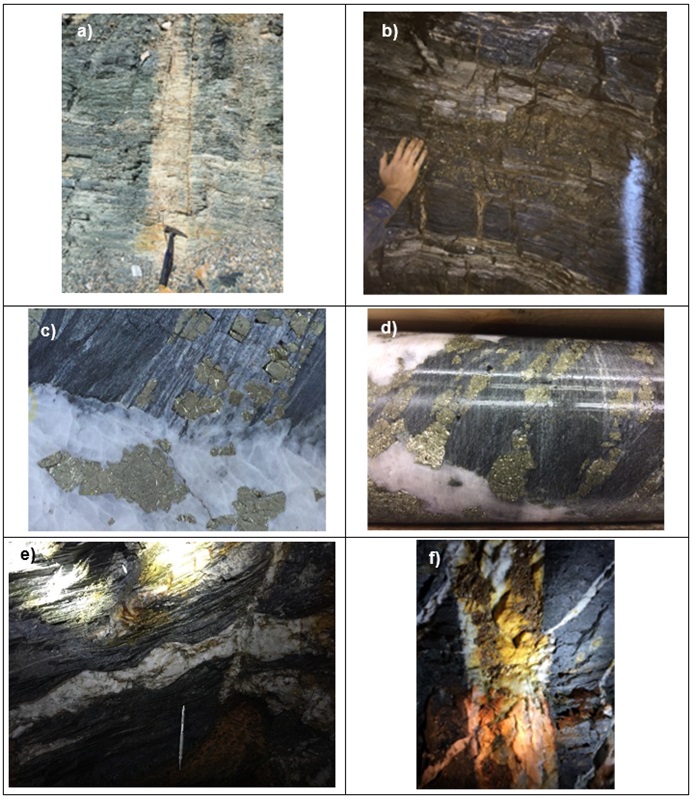

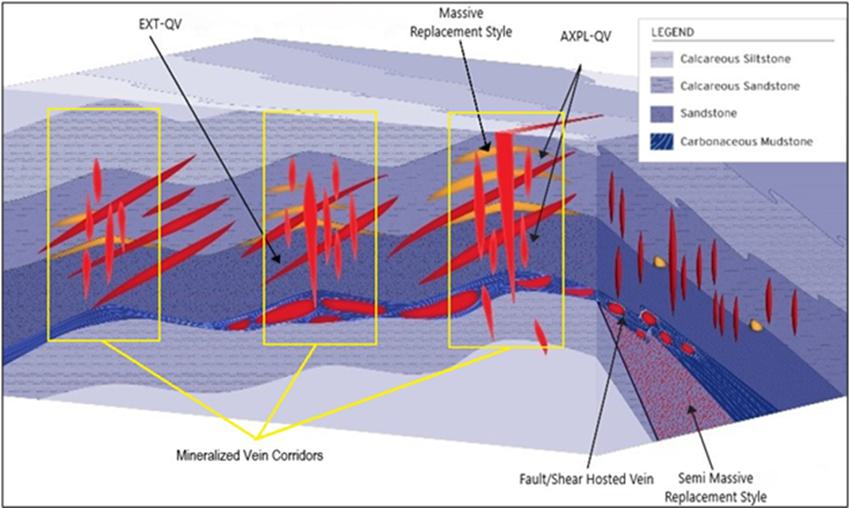

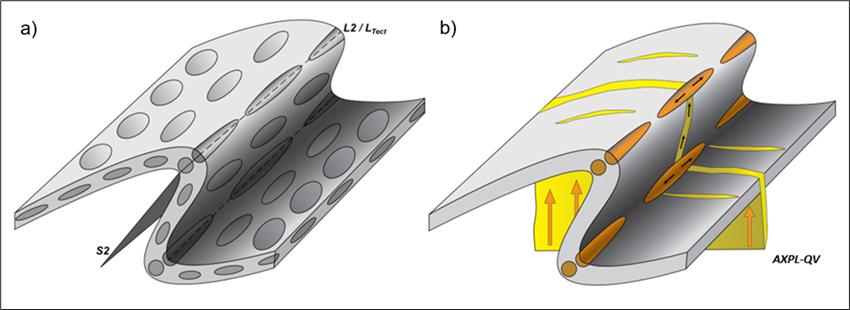

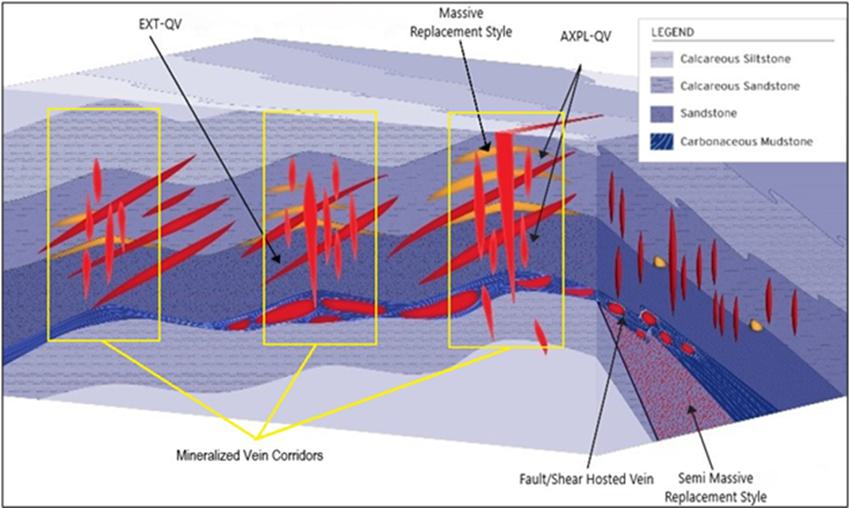

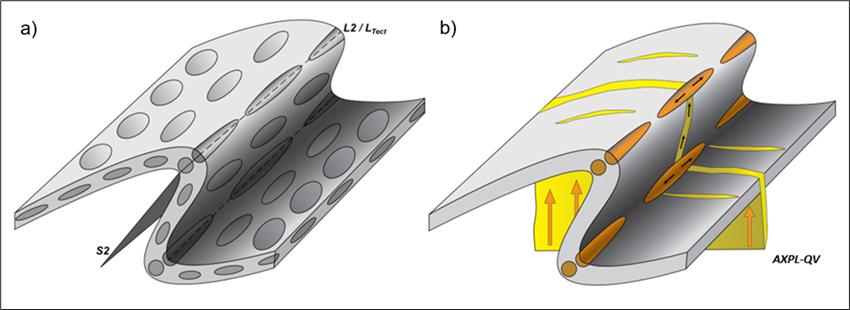

7.5.1 |

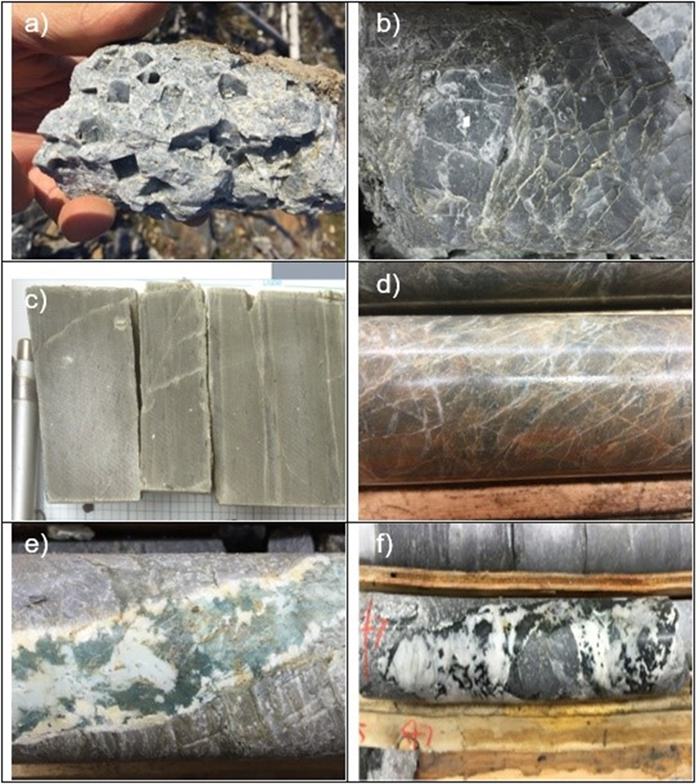

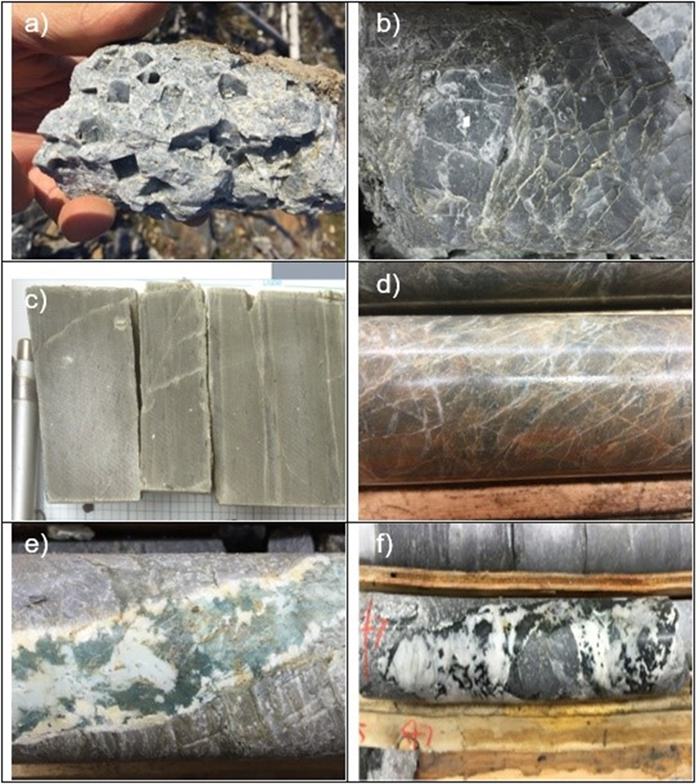

Vein-related Mineralization |

7-31 |

| |

|

7.5.2 |

Replacement-style Mineralization |

7-32 |

| |

|

7.5.3 |

Vein-related Alteration |

7-35 |

| |

7.6 |

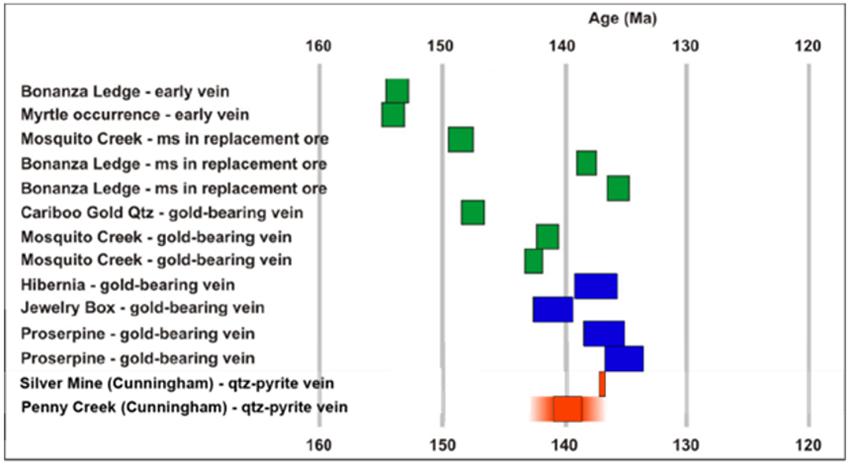

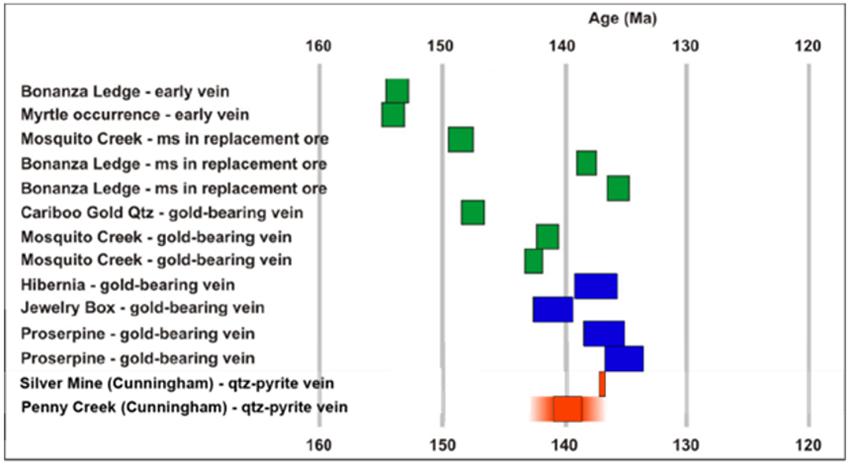

Age of Mineralization |

7-37 |

| |

7.7 |

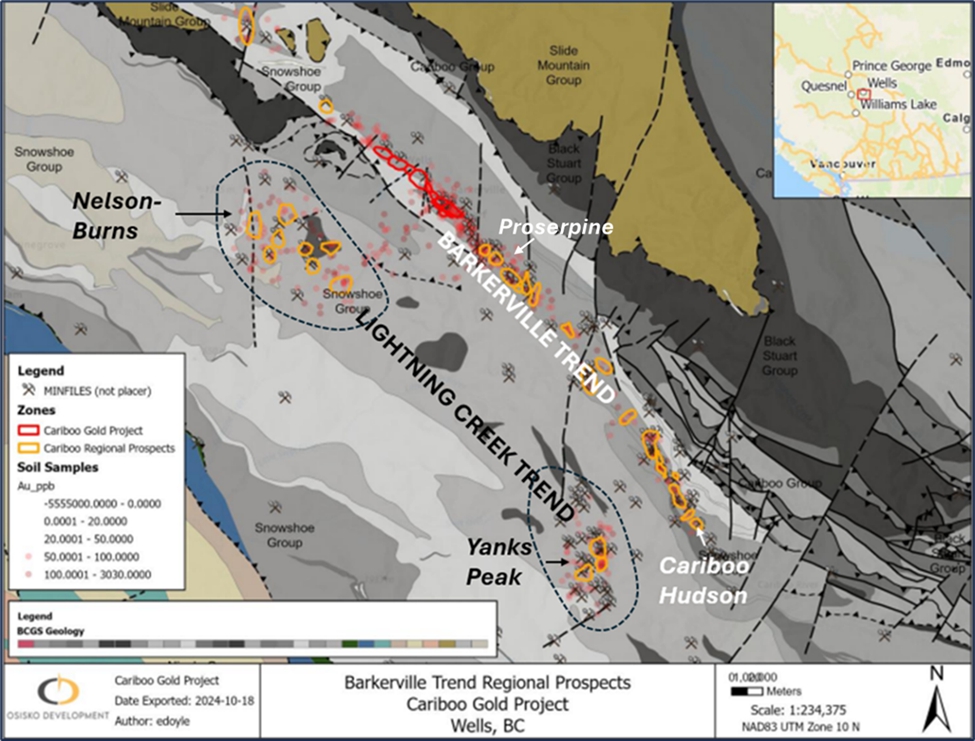

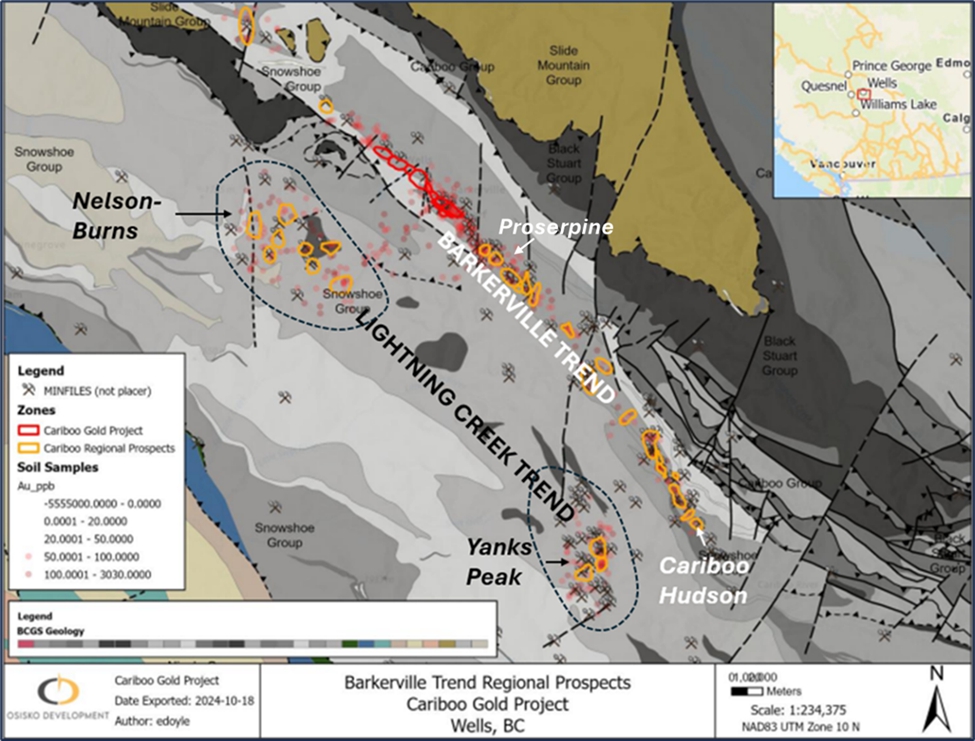

Summary of Mineralized Occurrences (MINFILEs) |

7-37 |

| 8. |

Deposit Types |

8-1 |

| |

8.1. |

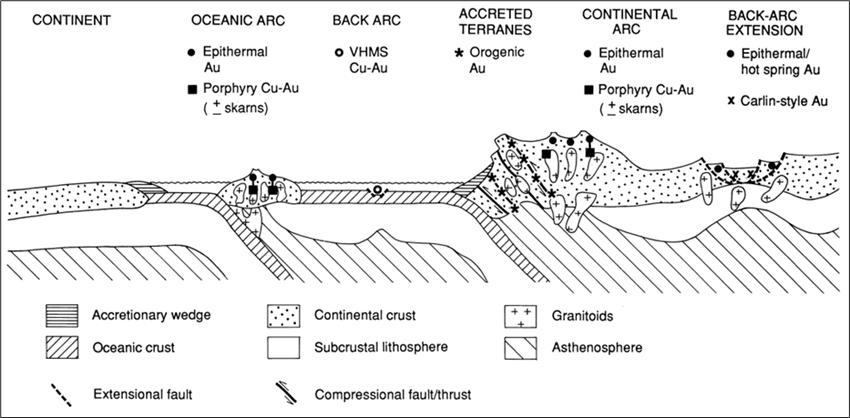

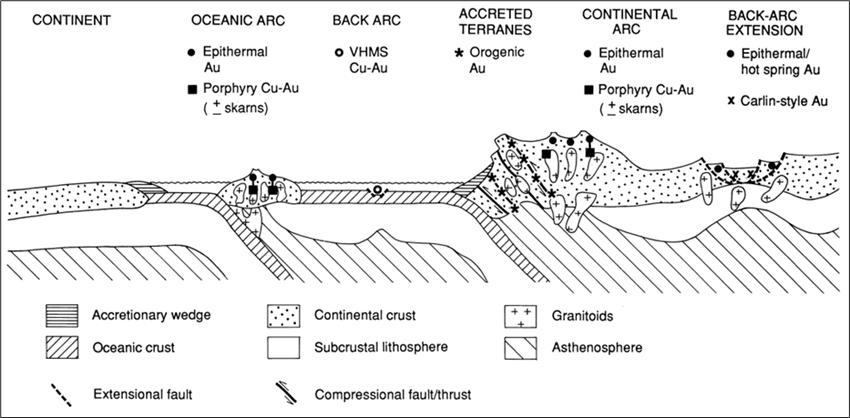

Orogenic Gold Deposits |

8-1 |

| |

|

8.1.1. |

Vein Deposits |

8-3 |

| |

|

8.1.2. |

Replacement Deposits |

8-6 |

| |

|

8.1.3. |

Shear Zone Deposits |

8-6 |

| 9. |

Exploration |

9-1 |

| |

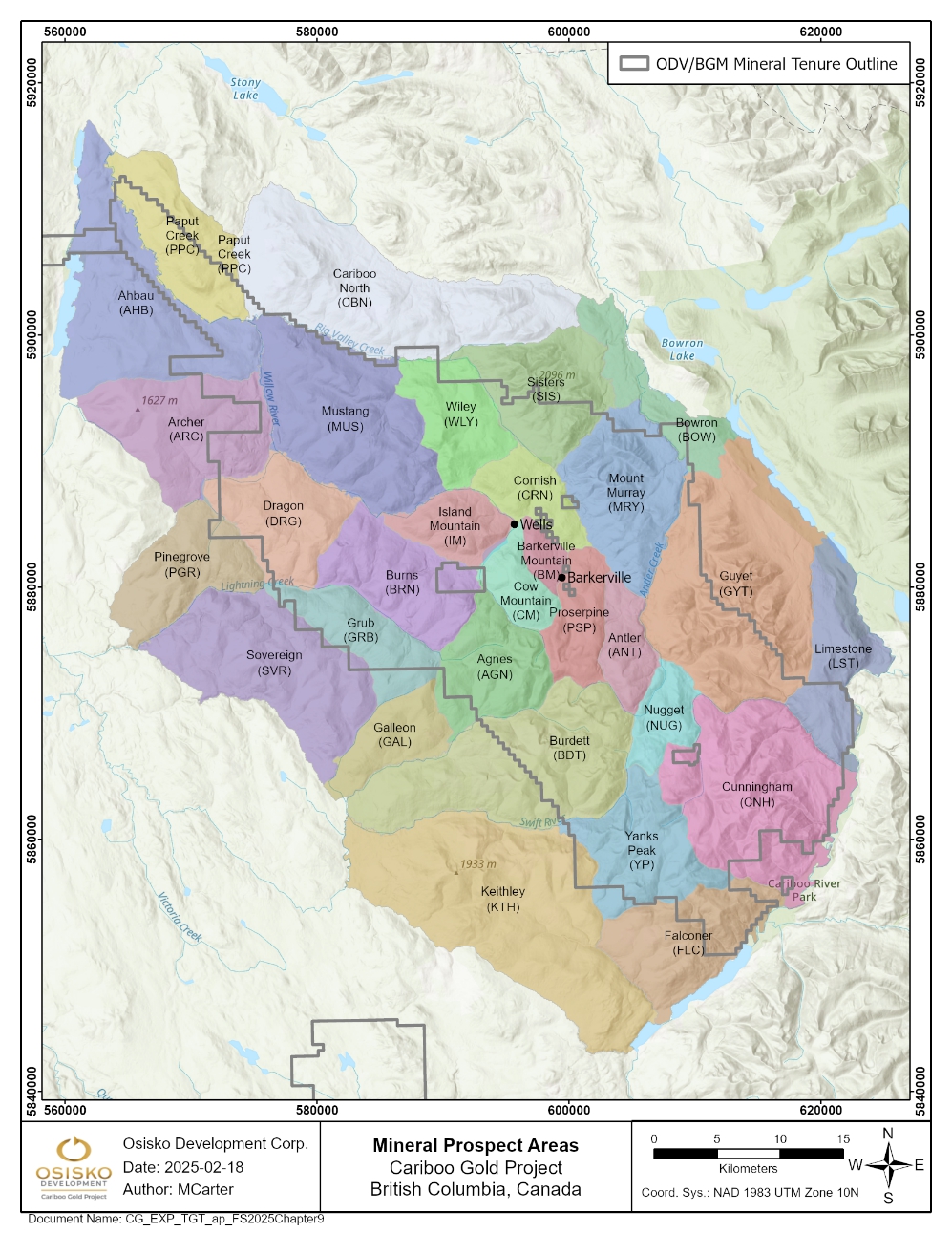

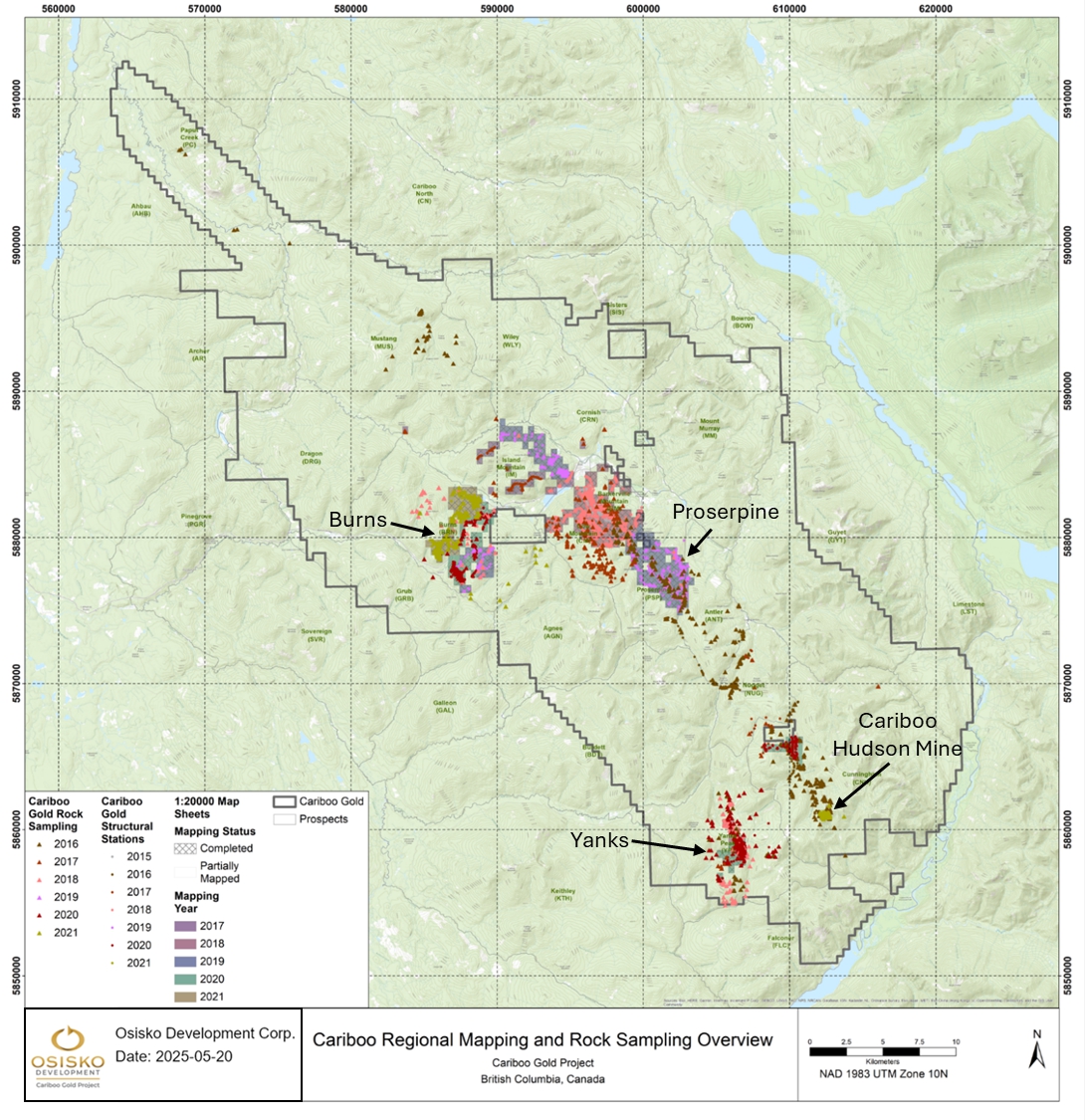

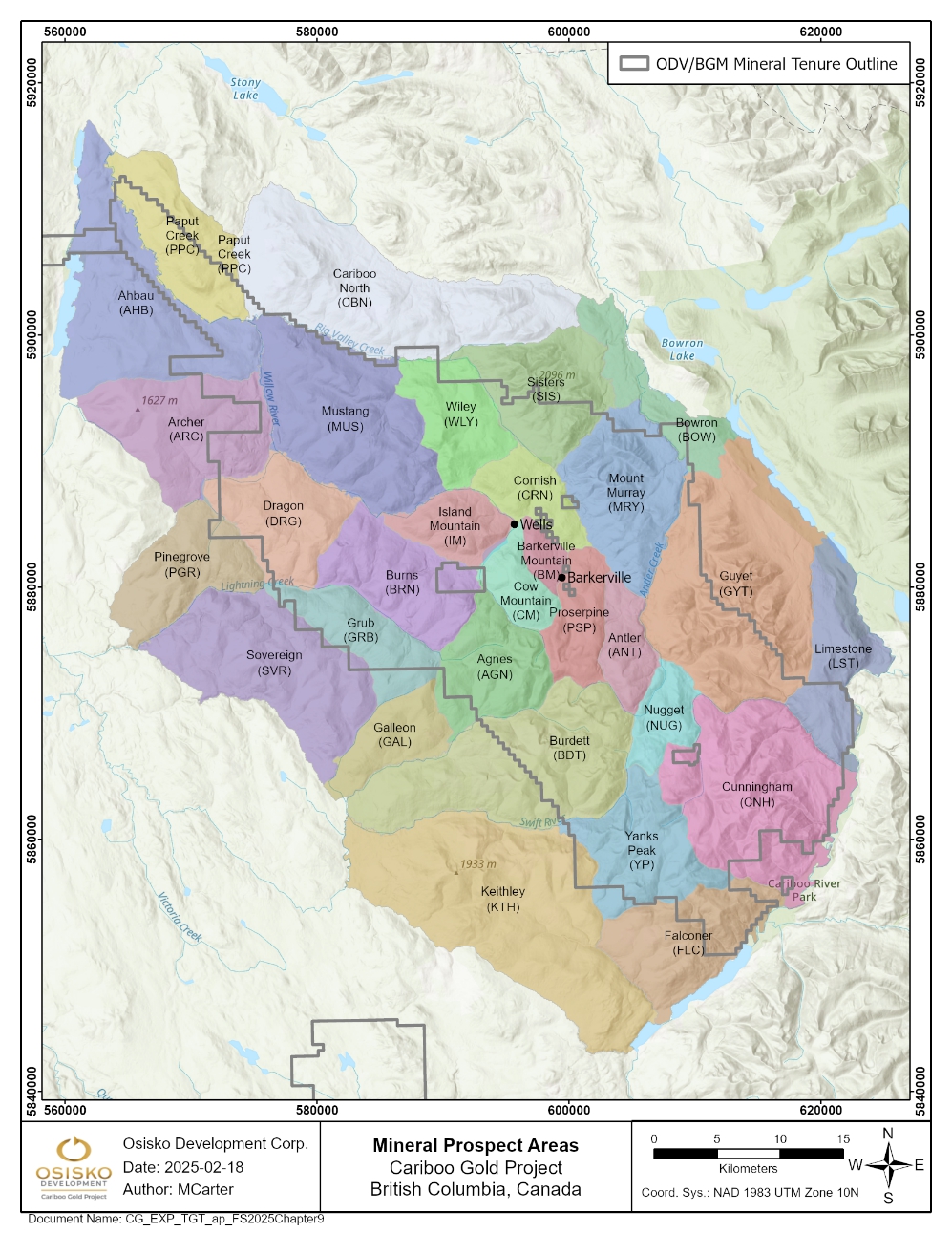

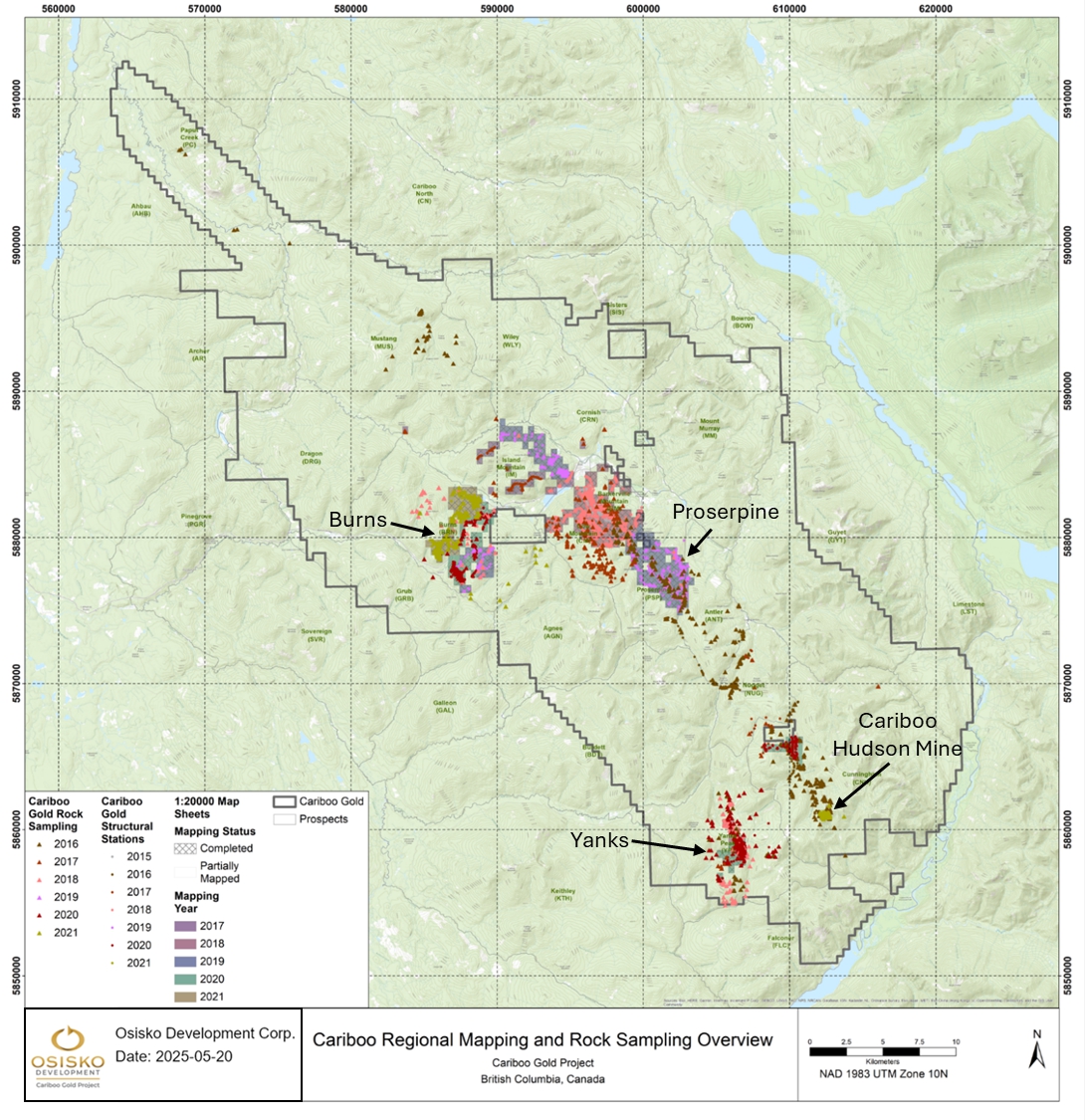

9.1 |

Program Purpose and Methodology |

9-5 |

| |

|

9.1.1 |

Geologic Mapping |

9-5 |

| |

|

9.1.2 |

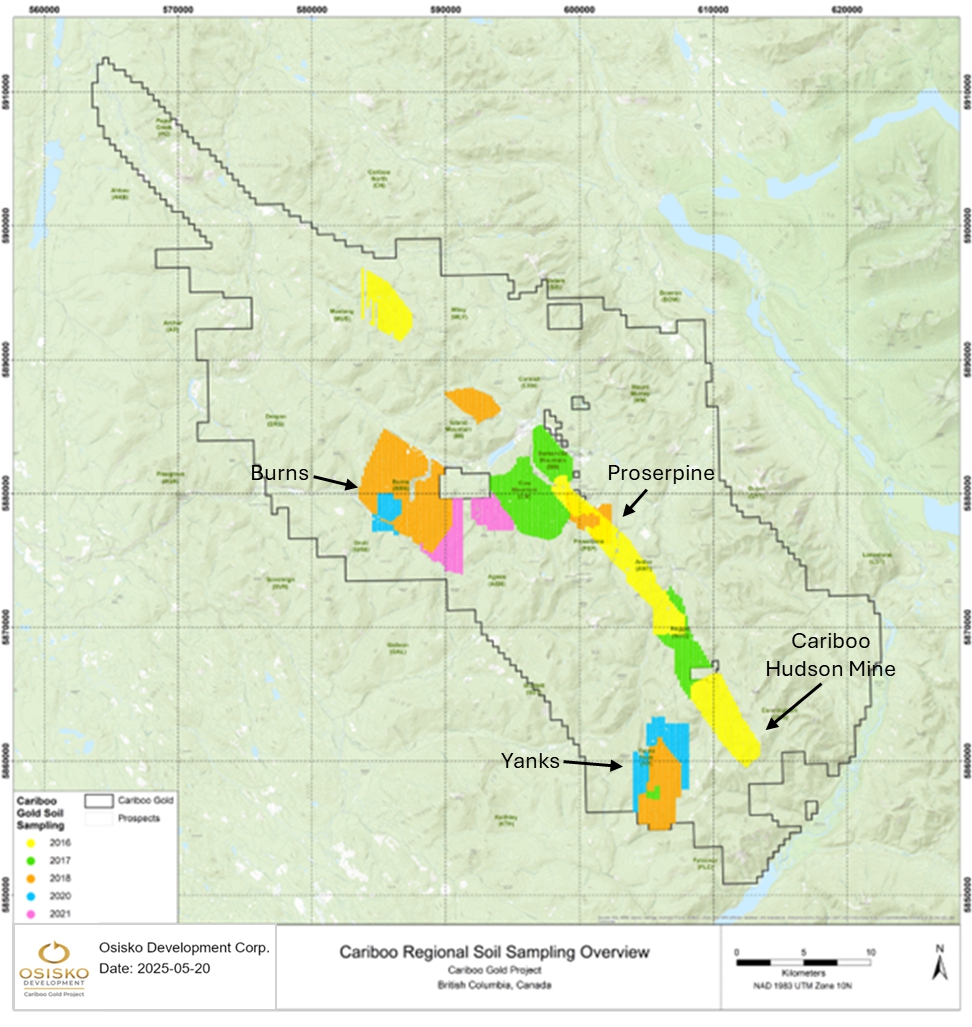

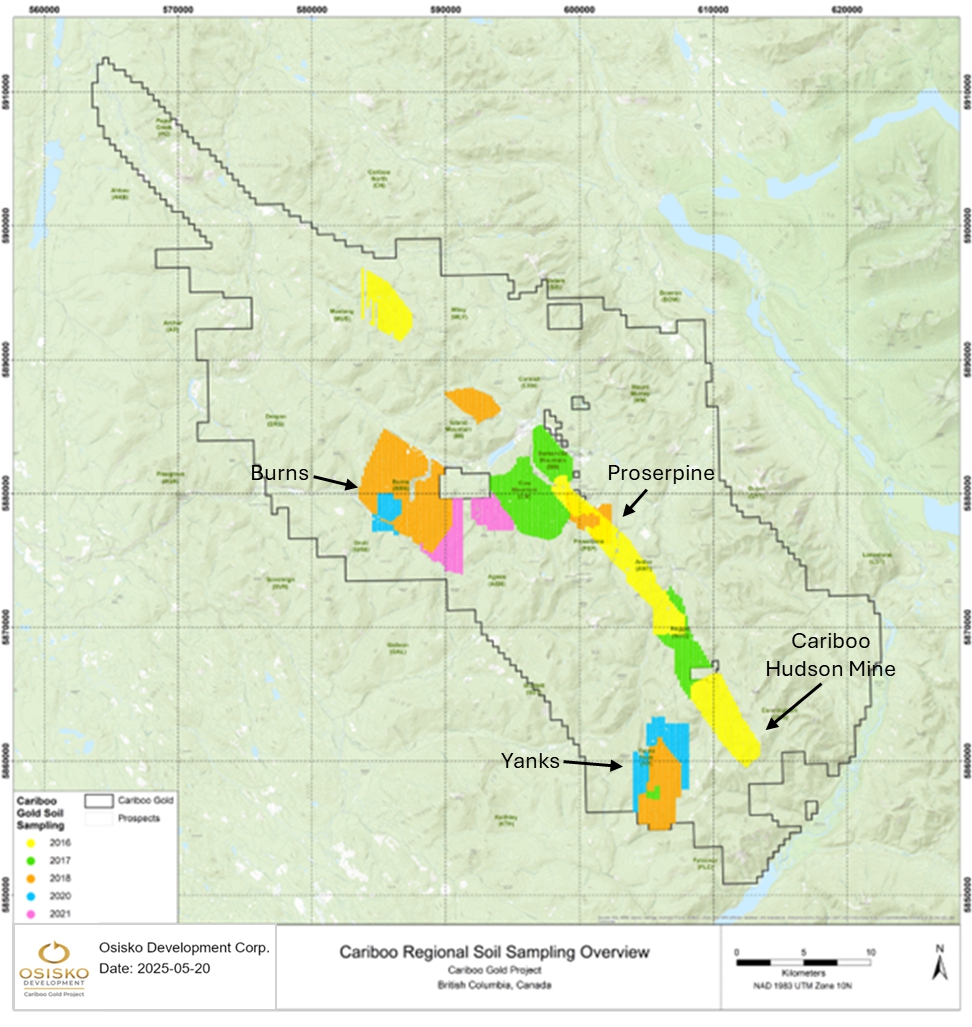

Soil Sampling |

9-5 |

| |

|

9.1.3 |

Underground Development |

9-5 |

| |

9.2 |

Program Objectives and Results |

9-8 |

| |

|

9.2.1 |

2015–2019 Geochemical and Mapping Programs |

9-8 |

| |

|

9.2.2 |

2016 Magnetic and VTEM Survey Program |

9-8 |

| |

|

9.2.3 |

2020 Geochemical and Mapping Programs |

9-9 |

| |

|

9.2.4 |

2021 Geochemical and Mapping Programs |

9-10 |

| |

|

9.2.5 |

2024 Underground Development Program |

9-11 |

| 10. |

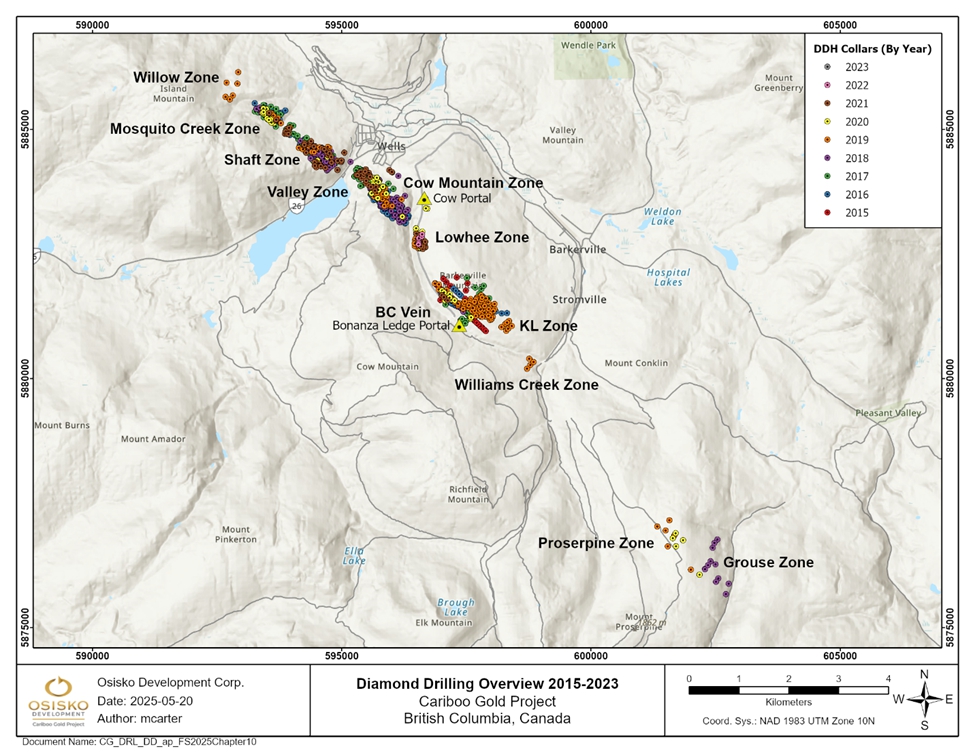

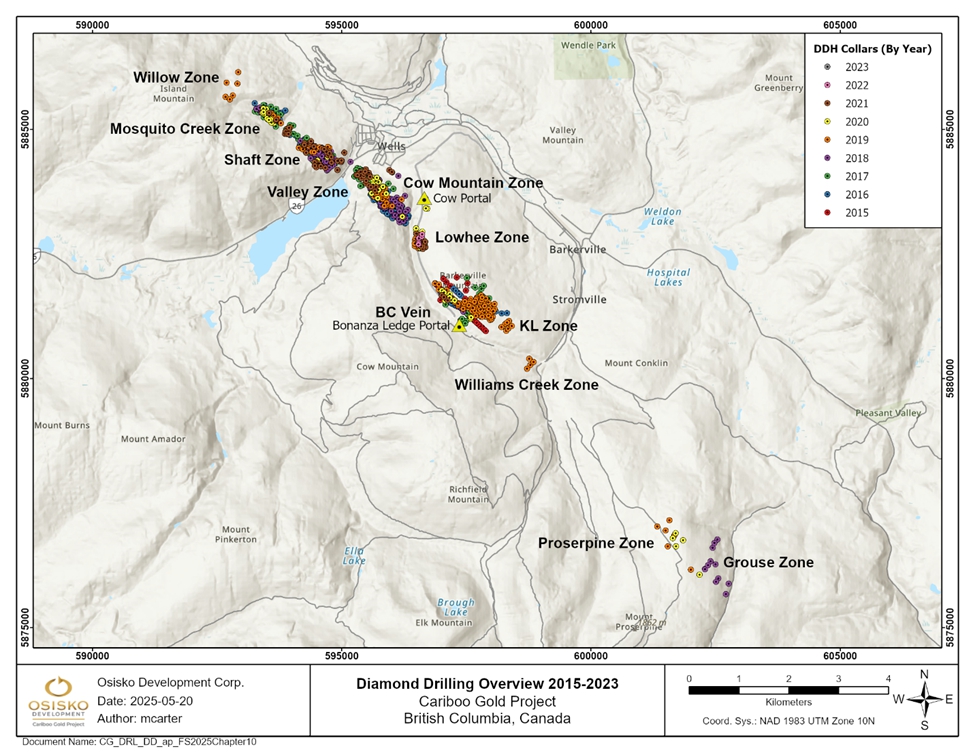

Drilling |

10-1 |

| |

10.1 |

Drilling Methodology |

10-1 |

| |

10.2 |

Core Logging Procedures |

10-2 |

| |

10.3 |

2015 to 2019 Drilling |

10-3 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

10.4 |

2020 Drilling Program |

10-6 |

| |

10.5 |

2021 Drilling Program |

10-8 |

| |

10.6 |

2022 Drilling Program |

10-9 |

| |

10.7 |

2023 Drilling Program |

10-9 |

| |

10.8 |

QP Comments on 2015-2022 Drilling |

10-10 |

| |

10.9 |

QP Comments on Post-2022 Drilling |

10-10 |

| 11. |

Sample Preparation, Analyses, and Security |

11-1 |

| |

11.1 |

Core Handling, Sampling, and Security |

11-1 |

| |

11.2 |

Laboratories Accreditation and Certification |

11-2 |

| |

11.3 |

Sample Preparation and Assay |

11-2 |

| |

|

11.3.1 |

Sample Preparation |

11-2 |

| |

|

11.3.2 |

Gold Assaying |

11-3 |

| |

|

11.3.3 |

Multi-element Assaying |

11-3 |

| |

|

11.3.4 |

Specific Gravity Measurements |

11-3 |

| |

11.4 |

Quality Assurance and Quality Control |

11-3 |

| |

|

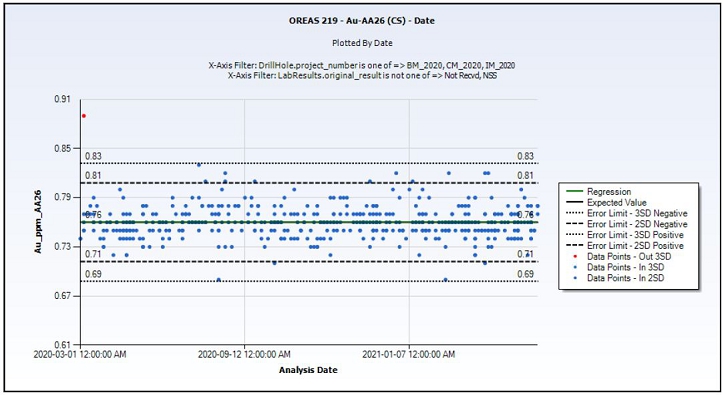

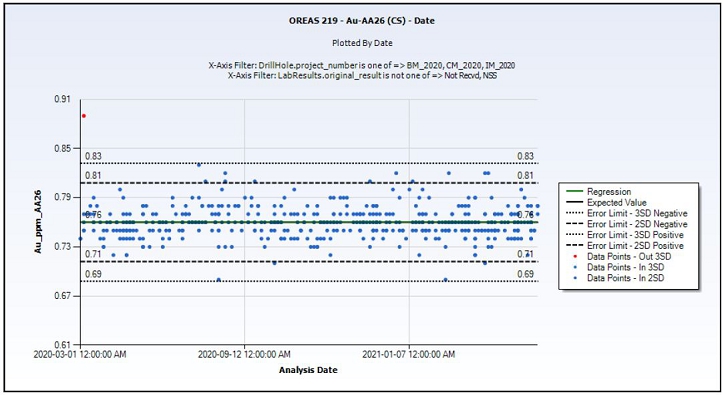

11.4.1 |

Certified Reference Materials (Standards) |

11-4 |

| |

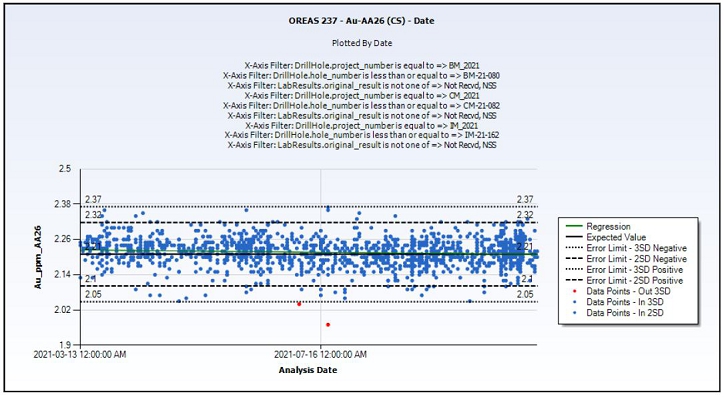

|

11.4.2 |

2020 Certified Reference Materials (Standards) Performance |

11-4 |

| |

|

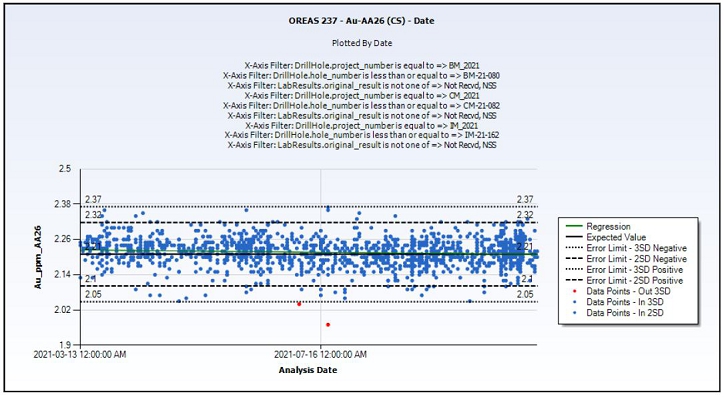

11.4.3 |

2021 Certified Reference Materials (Standards) Performance |

11-5 |

| |

|

11.4.4 |

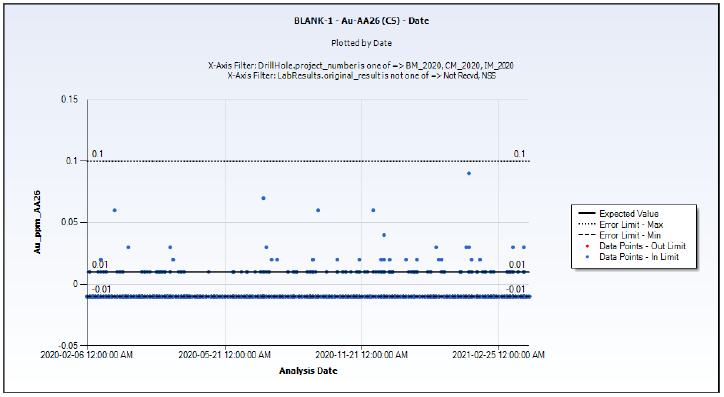

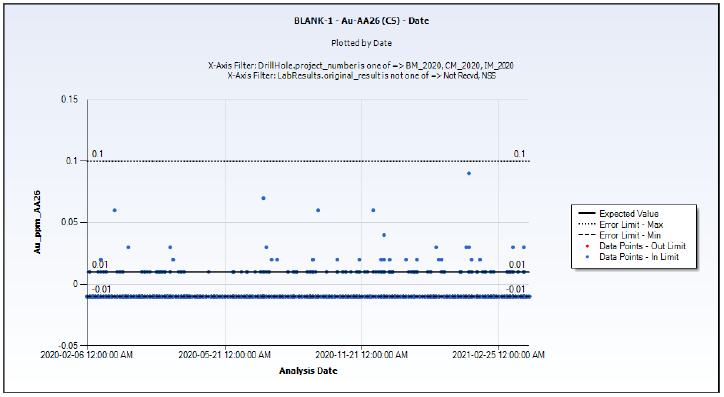

Blank Samples |

11-7 |

| |

|

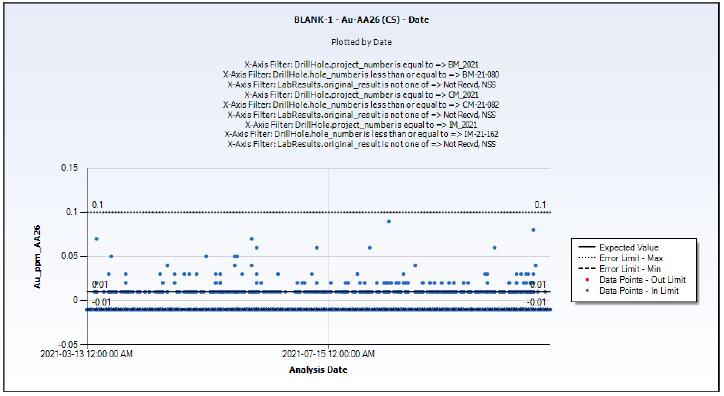

11.4.5 |

2020 Blank Samples Performance |

11-7 |

| |

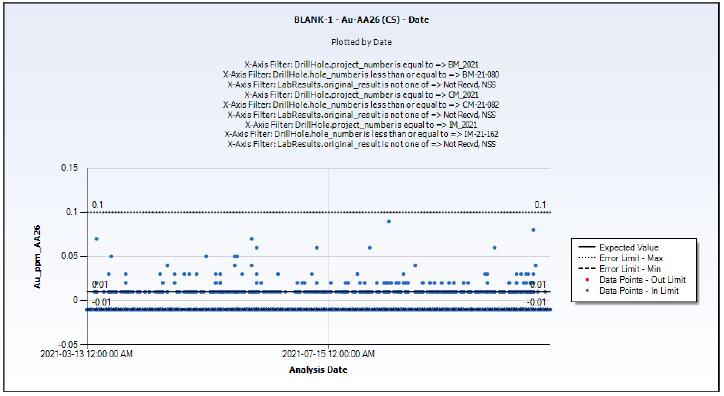

|

11.4.6 |

2021 Blank Samples Performance |

11-8 |

| |

11.5 |

Conclusions |

11-9 |

| 12. |

Data Verification |

12-1 |

| |

12.1. |

Historical Work |

12-2 |

| |

12.2. |

ODV Databases |

12-2 |

| |

|

12.2.1. |

ODV Drill Hole Collar and Downhole |

12-2 |

| |

|

12.2.2. |

Assays |

12-2 |

| |

12.3. |

Mined-out Voids |

12-3 |

| |

12.4. |

ODV Logging, Sampling, and Assaying Procedures |

12-3 |

| |

12.5. |

Mineral Resource Estimation Process |

12-6 |

| |

|

12.5.1. |

Bulk Sample and Drilling Pattern |

12-6 |

| |

12.6. |

Conclusion |

12-7 |

| 13. |

Mineral Processing and Metallurgical Testing |

13-1 |

| |

13.1 |

Sample Selection and Characterization |

13-2 |

| |

|

13.1.1 |

SGS – 2018 |

13-2 |

| |

|

13.1.2 |

SGS – 2020 |

13-7 |

| |

|

13.1.3 |

SGS – 2022 |

13-7 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

|

13.1.4 |

Base Met Labs – 2024 |

13-8 |

| |

13.2 |

Comminution Test W |

13-15 |

| |

|

13.2.1 |

SGS – 2018 |

13-15 |

| |

|

13.2.2 |

SGS – 2022 |

13-15 |

| |

|

13.2.3 |

Base Met Labs – 2024 |

13-15 |

| |

13.3 |

Ore Sorting Test Work |

13-20 |

| |

|

13.3.1 |

Steinert – 2018 |

13-20 |

| |

|

13.3.2 |

Tomra – 2020 (Shaft Zone) |

13-26 |

| |

|

13.3.3 |

Steinert – 2022 (Lowhee Zone) |

13-28 |

| |

|

13.3.4 |

Base Met Labs – 2024 |

13-28 |

| |

13.4 |

Gravity Concentration |

13-32 |

| |

|

13.4.1 |

SGS – 2018 |

13-32 |

| |

|

13.4.2 |

SGS – 2021 |

13-32 |

| |

|

13.4.3 |

SGS – 2022 |

13-33 |

| |

|

13.4.4 |

Base Met Labs – 2024 |

13-33 |

| |

13.5 |

Flotation Test Work |

13-37 |

| |

|

13.5.1 |

SGS – 2018 |

13-37 |

| |

|

13.5.2 |

SGS – 2020 (Shaft Zone) |

13-42 |

| |

|

13.5.3 |

Base Met Labs – 2024 |

13-47 |

| |

13.6 |

Leaching Test Work |

13-54 |

| |

13.7 |

Thickening, Filtration, and Rheology |

13-55 |

| |

|

13.7.1 |

Pocock Industrial – 2018 |

13-56 |

| |

|

13.7.2 |

FLSmidth – 2022 (Shaft Zone) |

13-59 |

| |

|

13.7.3 |

SGS – 2022 |

13-63 |

| |

|

13.7.4 |

Metso – 2024 |

13-66 |

| |

13.8 |

Paste Backfill |

13-71 |

| |

|

13.8.1 |

Paste and Solid-Liquid Investigation - Golder – 2019 |

13-71 |

| |

|

13.8.2 |

Feasibility Paste Fill Testing - WSP Golder – 2022 |

13-75 |

| |

|

13.8.3 |

T Engineering – 2024 |

13-81 |

| |

|

13.8.4 |

Backfill Analysis |

13-87 |

| |

13.9 |

Recovery Considerations |

13-88 |

| |

|

13.9.1 |

Ore Sorting |

13-89 |

| |

|

13.9.2 |

Gravity Concentration |

13-89 |

| |

|

13.9.3 |

Flotation |

13-90 |

| |

|

13.9.4 |

Lock Cycle Test |

13-90 |

| 14. |

Mineral Resource Estimates |

14-1 |

| |

14.1 |

Methodology |

14-1 |

| |

14.2 |

Drill Hole Database |

14-3 |

| |

14.3 |

Geological Model |

14-6 |

|

Osisko Development Corp.

NI 43-101 Technical Report

Feasibility Study for the Cariboo Gold Project |

|

| |

14.4 |

Voids Model |

14-11 |

| |

14.5 |

Compositing |

14-14 |

| |

14.6 |

High-grade Capping |

14-16 |

| |

14.7 |

Density |

14-18 |

| |

14.8 |

Block Model |

14-19 |

| |

14.9 |

Variography and Search Ellipsoids |

14-21 |

| |

14.10 |

Grade Interpolation |

14-22 |

| |

14.11 |

Block Model Validation |

14-24 |

| |

14.12 |

Economic Parameters and Cut-off Grade |

14-28 |

| |

14.13 |

Mineral Resource Classification |

14-29 |

| |

|

14.13.1 |

Cow, Valley, Shaft, Mosquito, KL, Lowhee, and BC Vein Deposits |

14-29 |

| |

|

14.13.2 |

Bonanza Ledge Deposit |

14-31 |

| |

14.14 |

Mineral Resource Estimate |

14-32 |

| 15. |

Mineral Reserve Estimates |

15-1 |

| |

15.1 |

Introduction |

15-1 |

| |

15.2 |

Estimation Procedure |

15-1 |

| |

|

15.2.1 |

Cut-off Grades Calculations |

15-2 |

| |

|

15.2.2 |

Dilution Factor Calculation |

15-3 |

| |

|

15.2.3 |

Mining Losses |

15-4 |

| |

|

15.2.4 |

Stope Shape Optimization |

15-4 |

| |

|

15.2.5 |

ESG Modifying Factors |

15-5 |

| |

15.3 |

Mineral Reserve Statement |

15-6 |

| |

15.4 |

Factors that May Affect the Mineral Reserves |

15-7 |

| 16. |

Mining Methods |

16-1 |

| |

16.1 |

Introduction |

16-1 |

| |

16.2 |

Rock Engineering |

16-2 |

| |

|

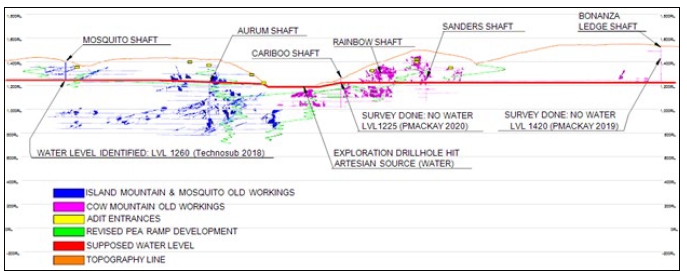

16.2.1 |

Geotechnical Field and Test Work Programs |

16-2 |

| |

|

16.2.2 |

Structural Geology |

16-6 |

| |

|

16.2.3 |

Geotechnical Design |

16-6 |

| |

|

16.2.4 |

Ground Support Recommendations |

16-12 |

| |

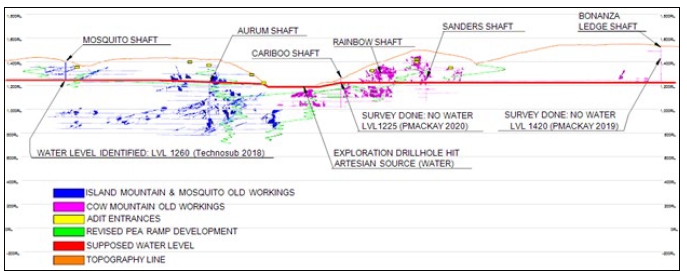

16.3 |

Mine Hydrogeology |

16-15 |

| |

|

16.3.1 |

Mine Site Area Hydrogeology |

16-15 |

| |

|

16.3.2 |

Groundwater Inflow Predictions – Mine Site Complex Area |

16-15 |

| |

|

16.3.3 |

Limitations of Inflow Predictions |

16-16 |

| |

16.4 |

Underground Mining Method |

16-16 |

| |

|

16.4.1 |

Cut-off Grade Calculation |

16-19 |

| |

|

16.4.2 |

Selection of Economical Material for Life of Mine |

16-19 |

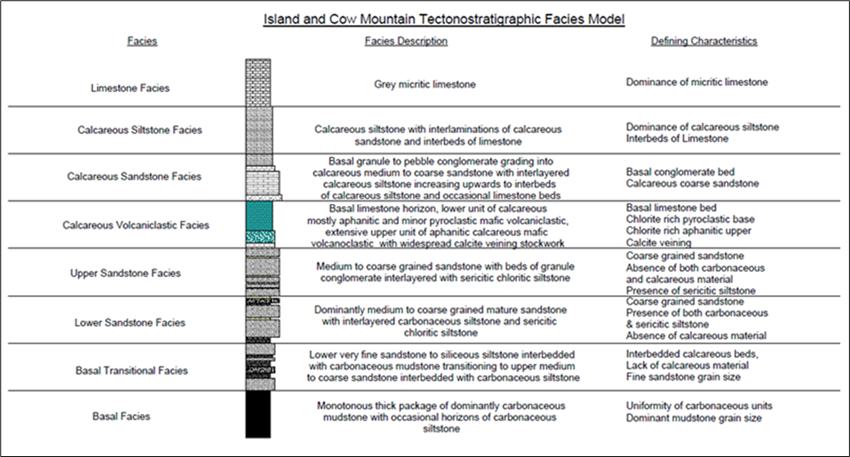

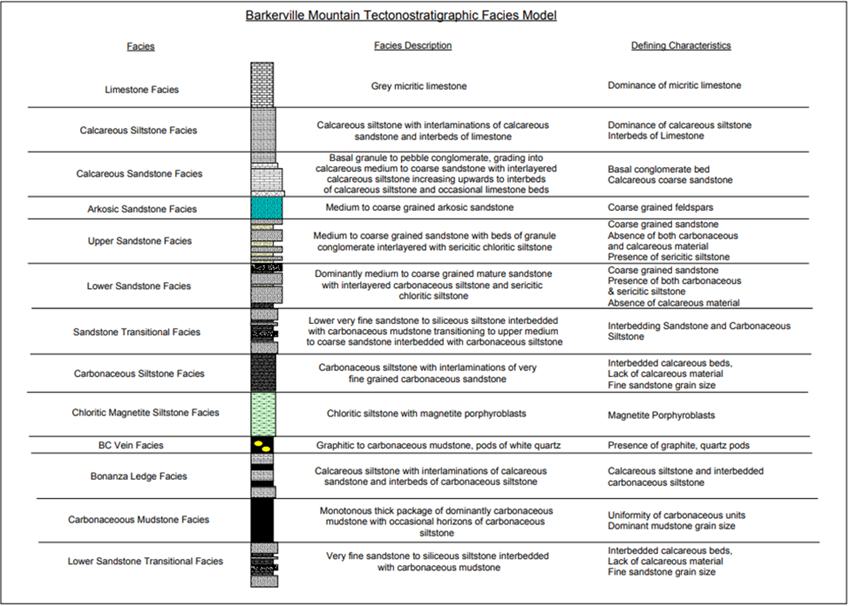

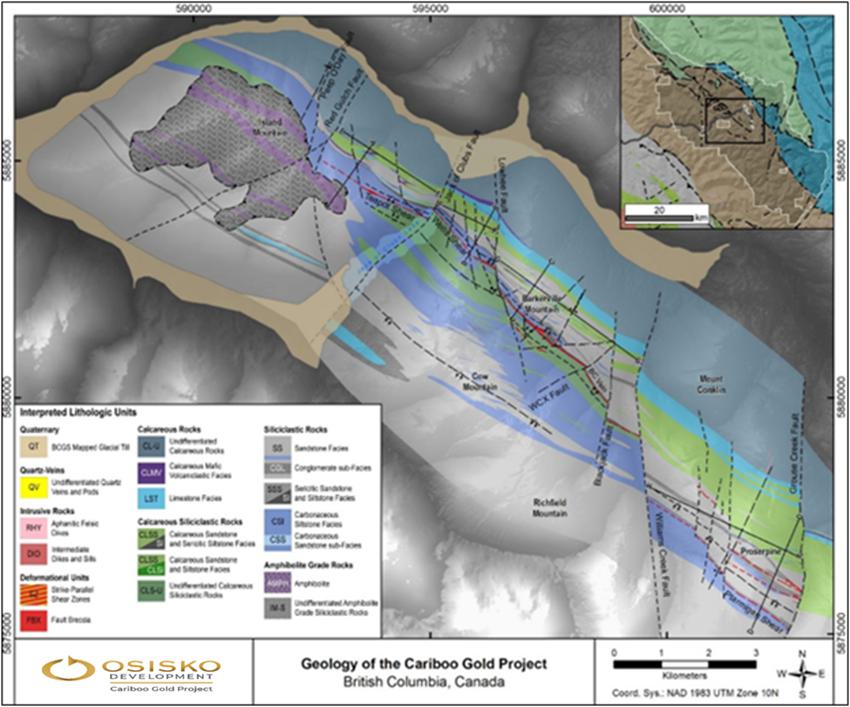

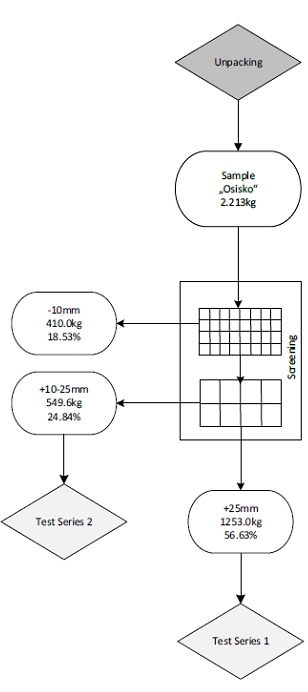

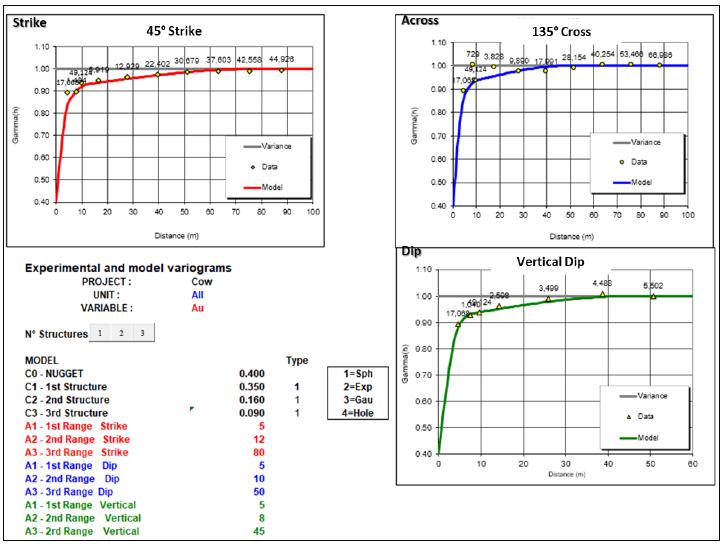

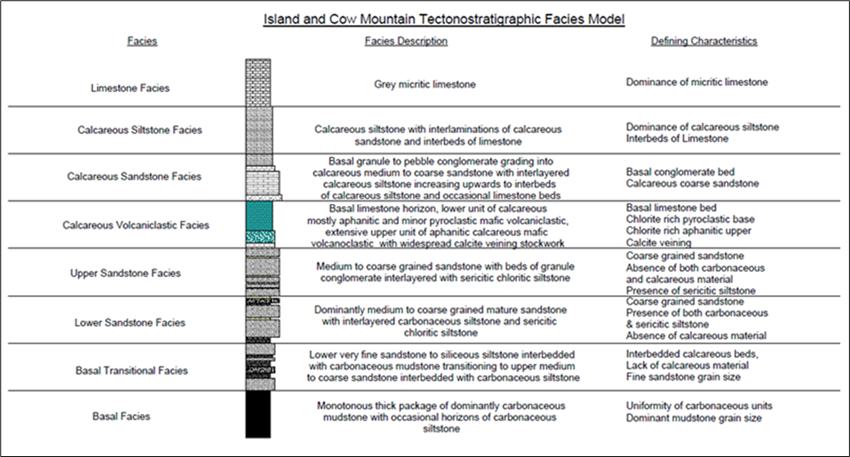

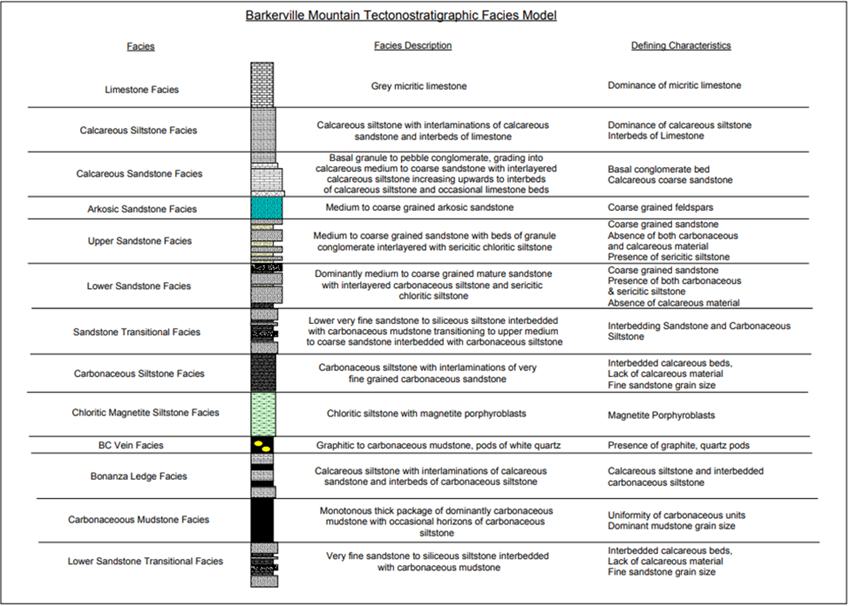

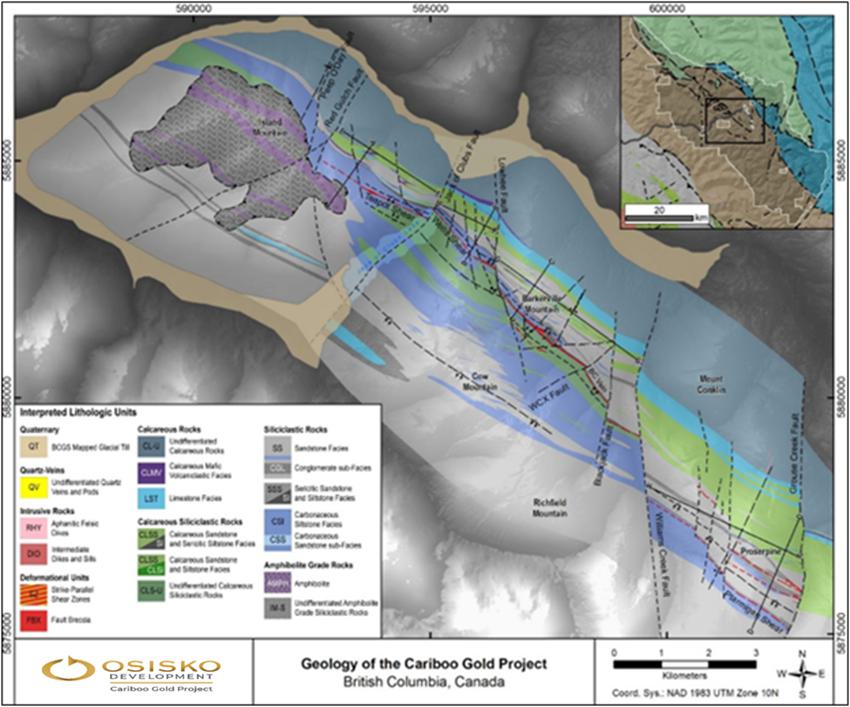

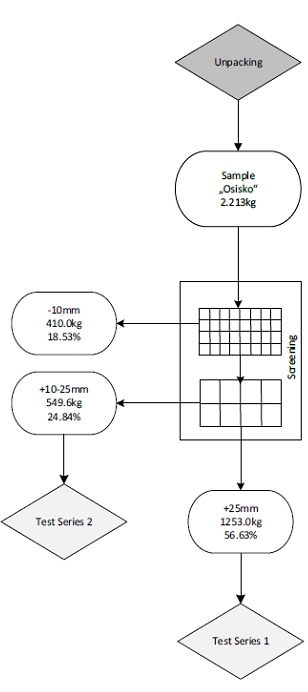

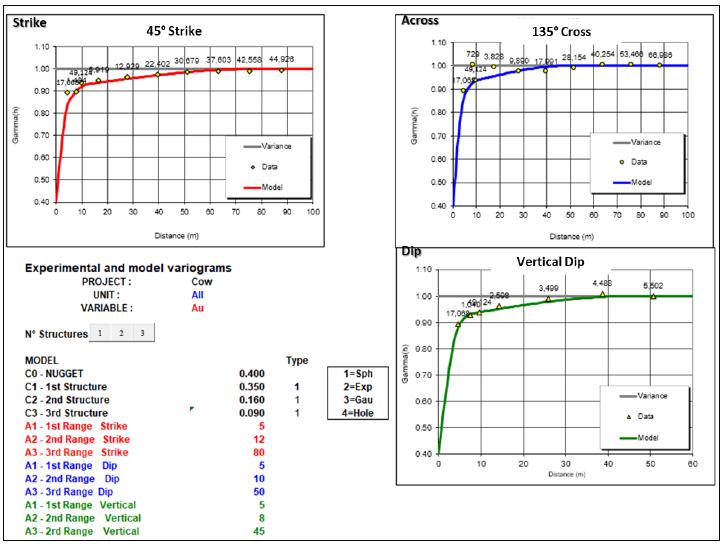

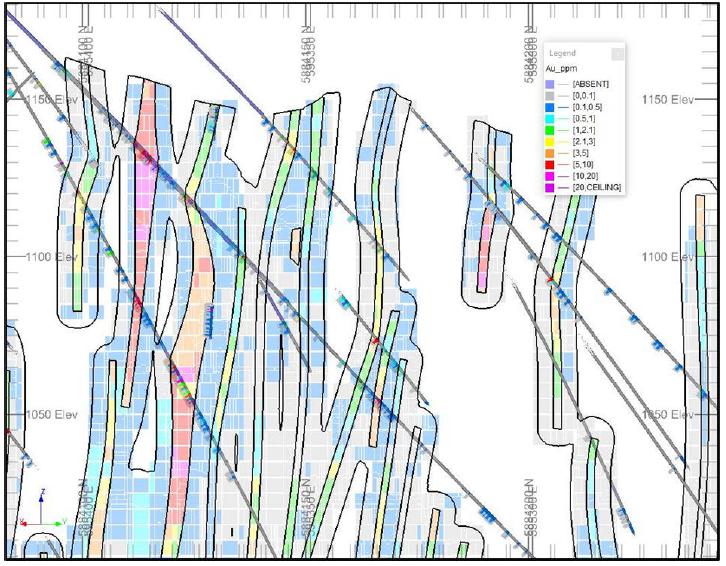

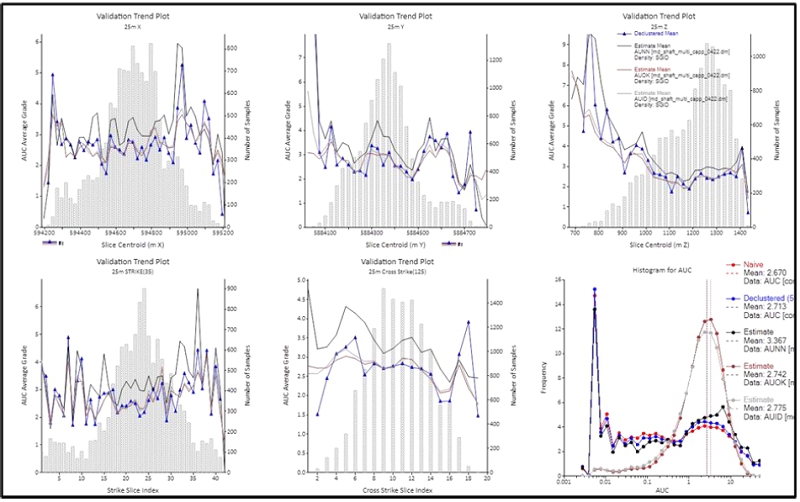

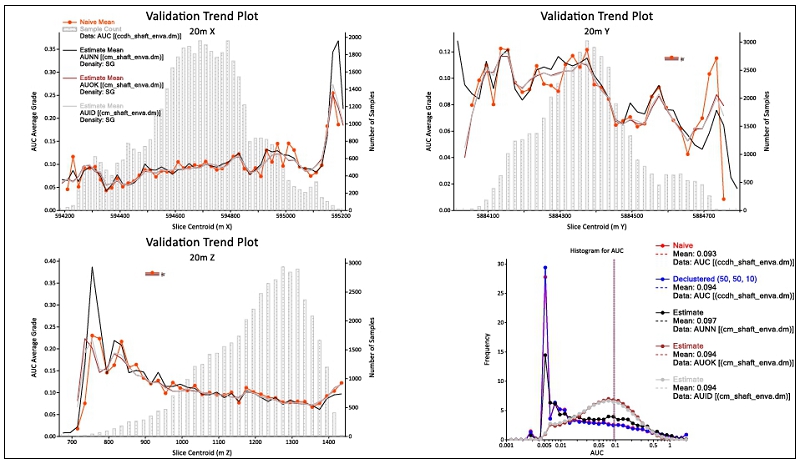

|