REalloys Inc.

Exhibit 96.1

|

REalloys Inc. |

1.0 Executive summary

| 1.1 | Introduction |

REalloys Inc. (REalloys) has retained Micon International Limited (Micon) to independently review and verify the previous mineral resource estimate (MRE) for the Hoidas Lake Rare Earth Element (REE) Project (Hoidas Lake Project) located in the Province of Saskatchewan, Canada, and to compile an American SK 1300 Technical Report disclosing the results of the MRE. Barr Engineering Co. (Barr) supplied the electronic resource database for the Project to Micon as Barr had previously undertaken the MRE for the Hoidas Lake Project.

A site visit was conducted from August 19, 2024, to August 21, 2024, by Micon to independently verify the geology, mineralogy, drilling program results and the Quality Assurance/Quality Control (QA/QC) programs at the Hoidas Lake Project.

When conducting, reviewing and validating the mineral resource estimate, REalloys and Micon used the following guidelines, published by the Canadian Institute of Mining, Metallurgy and Petroleum (CIM):

| 1. | The CIM Definitions and Standards for Mineral Resources and Reserves, adopted by the CIM council on May 10, 2014. |

| 2. | The CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines, adopted by the CIM Council on November 29, 2019. |

This report discloses technical information, the presentation of which requires Micon to derive sub-totals, totals and weighted averages that inherently involve a degree of rounding and, consequently, introduce a margin of error. Where these occur, Micon does do not consider them to be material.

The conclusions and recommendations of this report reflect Micon’s best independent judgment in light of the information available to them at the time of writing. Micon reserves the right, but will not be obliged, to revise this report and conclusions if additional information becomes known to them subsequent to the date of this report. Use of this report acknowledges acceptance of the foregoing conditions.

This report is intended to be used by REalloys subject to the terms and conditions of its agreement with Micon and Barr. That agreement permits REalloys to file this report as a Technical Report with the Securities and Exchange Commission (SEC) in the United States.

Neither Micon nor Barr have, nor have they previously had, any material interest in REalloys or related entities. The relationship with REalloys is solely a professional association between the client and the independent consultants. This report is prepared in return for fees based upon agreed commercial rates and the payment of these fees is in no way contingent on the results of this report.

Micon and Barr are pleased to acknowledge the helpful cooperation of REalloys management, personnel and consulting field staff, all of whom made any and all data requested available and responded openly and helpfully to all questions, queries and requests for material.

|

REalloys Inc. |

| 1.2 | Property Location, Description and Ownership |

The Hoidas Lake Project is located approximately 55 kilometres northeast of Uranium City, Saskatchewan, Canada. It consists of fourteen mineral claims comprising 12,522 hectares. The Property is centered on location 59⁰55 N Latitude, 107⁰49’ W Longitude. The claims are situated on NTS map sheet 74-O-13 in the northern mining district of Saskatchewan and are contiguous.

The mineral claims comprising the Hoidas Lake property are 100% owned by Strategic Metals Development Corp. (Strategic Metals).

The mineral claims were originally field staked however, the claims are not required to be surveyed and no surveys have been performed, to date. Mineral claims in Saskatchewan provide the holder with the mineral rights to the mineral disposition as long as the appropriate fees and work commitments are met as detailed in the ‘Mineral Tenure Regulations, 2012’. These rights do not extend to the surface rights however, they do provide legal access to the land but with an obligation to consult with stakeholders including trappers, local First Nations etc.

To maintain active status, the claims are subject to an annual work commitment of $15 per hectare per annum, with the exception of claims S-104263 and S-104987 which are subject to $25 per hectare per annum. For the fourteen claims, this amounts to $207,400.00. Claims can be grouped for assessment purposes.

Micon understands that while all of the claims are currently owned by Strategic Metals, there is a 1.8% NSR royalty agreement with a prospector by the name of R. Dubnick which becomes payable when production begins. The NSR royalty has a maximum value of one million dollars.

There is a further reservation of interest with R. Dubnick that encompasses an area of 10 km around the original claim boundaries.

According to Billingsley, 2002, the current Hoidas Lake mineral depositions cover up to 26 known rare earth element (REO) showings discovered during the 1950s.

| 1.2.1 | REalloys Inc. (formerly Eagle Ridge Resource Inc.) Purchase Price Terms and Conditions |

In May, 2024, REalloys entered into a share purchase agreement to purchase 100% of Strategic Metals.

Subject to the terms and conditions provided for in the purchase agreement, the vendor (Strategic Metals) agreed to sell, assign and transfer to the purchaser (REalloys) and the purchaser agreed to purchase from the vendor, the purchased shares.

The purchase price to be paid by REalloys to Strategic Metals for the purchased shares shall be an aggregate sum of USD 46,500,000 (the purchase price).

2

|

REalloys Inc. |

| 3.2.1.1 | Payment of the Purchase Price |

The purchase price shall be paid by the REalloys to Strategic Metals (or as directed by Strategic Metals), pro-ratably in accordance with their respective holdings as set forth as follows:

| i. | As to the amount of USD 2,000,000 (first cash payment), with the payment to be made on or before June 4, 2024 (first closing date) in cash or by certified cheque. |

| ii. | As to the amount of USD 2,750,000, with the payment to be made on or before September 30, 2024 (second closing date) in cash or by certified cheque. |

| iii. | As to the amount of USD 3,750,000, with the payment to be made on or before December 31, 2024 (third closing date) in cash or by certified cheque. |

| iv. | As to the amount of USD 38,000,000, with the issuance on the first closing date to the vendors of USD 38,000,000 worth of special warrants, having the terms and conditions described in the special warrant certificate. The purchase price special warrants shall automatically convert into USD 38,000,000 worth of Purchaser’s common shares for no additional consideration upon completion by the purchaser of a listing or merger, reorganization, business combination, share exchange or acquisition by any person or related group of persons of beneficial ownership of all or substantially all of the purchased shares in one or more related transactions, or another similar transaction involving the purchaser, pursuant to which the shareholders of the purchaser receive cash or the securities od another issuer that are listed on a national securities exchange in the USA, as full or partial consideration for their common shares (liquidity event). |

Eagle Ridge Resources Inc. changed its name to REalloys Inc on October 31, 2024. The name change more accurately reflects the expanded mine to rare earth-metals/alloys-magnet strategy of the company.

| 1.3 | Accessibility, Climate, Physiography, Local Resources and Infrastructure |

| 1.3.1 | Accessibility |

Hoidas Lake is located approximately 55 km northeast of Uranium City, on the north side of Lake Athabasca. The site is accessed seasonally by ski- or float-equipped aircraft from Stony Rapids, 130 km southeast, or from Uranium City. Both communities have regularly scheduled commercial flights from Regina or Saskatoon. Stony Rapids has a year-round, permanent road that connects it with the southern communities. A winter road is maintained from Stony River to Uranium City.

| 1.3.2 | Climate |

The climate at Hoidas Lake will vary seasonally from daytime high temperatures in the summer of up to 30°C and -30°C in winter with extremes of +35°C and -45°C colder in the winter. Average monthly precipitation is 53 mm the summer and the average snow cover in the winter is 51 cm.

| 1.3.3 | Physiography and Vegetation |

The regional topography is relatively low, but with localized, rugged relief. Hoidas Lake is at an elevation of 451 m above mean sea level (amsl). Numerous hills and ridges can extend about 100 m above nearby lakes and muskegs. Throughout this area are lakes, bogs, forest and rock outcroppings. Black spruce and jack pine are the main trees of the area. Forest fires are a concern in this area, and Fireweed (Epilobium angustifolium) occurs in burnt areas. Lichen species provide ground cover and feather mosses such as Stair-Step Moss and Hypnum are amongst the undergrowth. Wildlife including black bear, wolverine, moose and timber wolf inhabit this region, with the migratory barren-ground caribou and associated arctic fox often appearing during winter. Birds include the common loon, greater yellowlegs, white-crowned sparrow and bald eagle, with willow ptarmigan appearing during winter. In the lakes are fish including lake trout, arctic grayling, whitefish, walleye and northern pike.

Rock outcrop exposure is generally poor, with less than 5% bedrock surface exposure within the Hoidas Lake property. Glacial outwash and till deposits cover and obscure much of the bedrock. Drainage from the area follows the Tazin River into Great Slave Lake in the Northwest Territories.

3

|

REalloys Inc. |

| 1.3.4 | Local Resources and Infrastructure |

Local infrastructure and resources are limited in scope. There are some local aggregate deposits near the Project, but the closest permanent housing, buildings, or light industries are found in Uranium City. The closest permanent road is located at Stony Rapids, which has a larger population base.

The camp will need to be re-established for any further exploration activities or more advanced activities at the site.

| 1.4 | Exploration History |

| 1.4.1 | 1936 to 1965 |

In 1936, regional geological mapping of the area was undertaken the Geological Survey of Canada (GSC). In 1950, the original recorded claims at the Hoidas Lake property were staked. Trenching of the main exposure occurred, but there are limited records due to government restrictions on uranium development, at the time. In 1955, D. Hogarth noted the occurrence of thorium in association with REE bearing apatite and hyalophane during a mineralogical investigation at Hoidas Lake. In 1961, an airborne radiometric and electromagnetic survey was undertaken by the Canadian Aero Service on Mineral Permit No. 1 which included the Hoidas Lake area. In 1965, six claims were staked to cover the main showings at Hoidas Lake. Radiometric surveys were conducted by the Globe Exploration Syndicate and widths of 2 m to 5 m along a strike length of 425 m were reported.

| 1.4.2 | 1980 to 1999 |

In 1980, the Hemmingson claims were acquired by Kintla Explorations Limited (Kintla) and used for uranium and thorium exploration.

In 1996, six new claims were staked at Hoidas Lake. These were vended to Daren Resources Limited. (Daren Resources), and subsequently, the first metallurgical work on Hoidas Lake samples was conducted. The results showed recoveries of 97.6% for the REE through gravity concentration and hydrochloric acid leaching. In 1999, Great Western Minerals Group Ltd. (Great Western Minerals) performed a trenching and sampling program at Hoidas Lake intersecting several REE-bearing veins and petrographic, assay, and geochemical studies were undertaken on the samples.

| 1.4.3 | 1999 to 2012 |

In 2001, the first drilling program at Hoidas Lake was conducted by Great Western Minerals. Magnetometer and very-low-frequency-electromagnetic (VLF-EM) surveys were also conducted at this time. Also in 2001, analytical and metallurgical test work was done on the drill core by Lakefield Research Ltd. (Lakefield Research). This work included the viability of concentration and dissolution of what is now termed the JAK Zone, and some initial environmental testing. A number of new elements were identified in the Hoidas Lake mineralization through this work. In 2004, Great Western Minerals acquired a 2,000 kg bulk sample through regional prospecting. A budget and work program for future development at the property was proposed. The program extended the geophysical coverage of the property, provided infill drilling of the 2001 program, and recommended further metallurgical testing and commencement of environmental baseline studies. Also in 2004, further mineralogical work on 2001 drill core was undertaken.

4

|

REalloys Inc. |

In 2005, a second drilling program was undertaken. Additionally, magnetometer and VLF-EM surveys were extended to tie into the work from the 2001 program and aerial photogrammetry began with some over flights.

In the winter of 2006, a third drilling program was undertaken at Hoidas Lake. The results confirmed the continuity of the vein system along strike of the northern half of the JAK Zone, as well as further delineating the Hanging Wall Zone intersected in 2005.

In the summer of 2006, a land-based VLF-EM survey work was carried out. This was an extension of the 2005 work that could not be completed due to weather conditions. In the winter of 2007, a bulk sample was taken at the JAK Zone from 32 diamond core drill holes, constituting the fourth drilling program at Hoidas Lake. 13.8 tonnes of metallurgical sample was extracted for use as feed for pilot-plant-scale testing.

A fifth drilling program took place in the winter and summer of 2008 which included a geotechnical investigation for a possible future tailings pond location at Hoidas Lake. The fifth drilling program was designed to extend the strike and dip of the JAK Zone.

A mapping and radiometric prospecting program was carried out during the summer of 2012 with three main areas of interest being located and several isolated occurrences of mineralization were also found.

| 1.4.4 | 2012 to 2024 |

No work was done on the property from 2012 to September, 2024 when Axiom Geophysics and Remote Sensing (Axiom) flew airborne magnetics and radiometrics.

| 1.5 | Geological Setting, Mineralization and Deposit |

| 1.5.1 | Regional and Property Geological Setting |

The Hoidas Lake Project is situated within the Western Craton of the Precambrian Canadian and north of Lake Athabasca in northwest Saskatchewan. The Project occurs within the eastern margin of the former Ena Domain, but is now included in the Zemlak Domain, being several kilometres west of the Black Bay Fault or Shear Zone, which marks the boundary between the Zemlak Domain to the west and the Train Lake Domain to the east. The Zemlak Domain comprises mainly upper amphibolite facies tonalites, granodiorites, and leucogranites with lesser intermediate rocks, amphibolites, psammitic to pelitic gneisses and diatexites, and alkaline intrusive rocks. The Black Bay Fault is represented by a several kilometre-wide mylonite zone which extends westward from its trace along the Tazin River several kilometres east of Hoidas Lake. The Nisikkatch – Hoidas fault (mylonite zone) is probably a splay off the Black Bay Fault and passes through the area of interest. Younger brittle faults of several orientations offset the older mylonite zones.

The property is located approximately 4 km northwest of the Black Bay Fault. The Hoidas-Nisikkatch Fault parallels and is adjacent to the mineralized zone.

5

|

REalloys Inc. |

Geological mapping identified two major rock units; a possible Archean tonalite gneiss complex and granitic gneisses, which are probably mainly Paleoproterozoic in age. Minor rock units include: migmatitic psammitic to psammopelitic and pelitic gneisses, amphibolites of intermediate to mafic composition, early and late dioritic rocks, syenite – quartz syenite, hyalophane-bearing pegmatites, unmineralized diopside-hyalophane veins/dykes as well as REE mineralized varieties of them, and lamprophyre dykes representing the youngest intrusive event in the area. The last four rock units all have an alkaline magmatic affinity, and they generally show the least effects of regional deformation and metamorphism. Late brittle quartz veining and development of quartz-flooded breccias are probably the youngest rock forming events in the area.

The Tonalite Gneiss Complex comprises a variety of rock types ranging in composition from diorite to granite and varying in texture, colour and grain size. As a group they are light to medium to dark grey, and more pinkish coloured where granitic veins and dykes become more prevalent and can be strongly reddened due to hematite and/or potassic alteration along late fractures or adjacent to major faults or shear zones.

Dioritic gneiss forms a number of small mappable bodies which may be part of the tonalite complex or possibly a border phase to some of the larger granitic bodies. These rocks are fine to medium to very coarse grained, grey to dark grey and well foliated, with 30 to 50% mafic mineral content, with hornblende generally more abundant than biotite.

Supracarustal rocks include amphibolite and migmatitic metasedimentary gneisses. Amphibolite Gneiss occurs in several areas of the property, both alone and associated with the migmatitic metasedimentary gneisses.

There are also a number of younger intrusive rocks cross-cutting the above including granitic rocks, a syenite-quartz syenite suite, fine grained diorite dykes, hyalophane-bearing pegmatites, the diopside hyalophane plus REE suite of veins and dykes and the lamprophyre dykes.

Granitic rocks are the most abundant rock types in the area.

Pink leucogranite is also very prevalent in the areas underlain by the metasedimentary gneisses and might actually represent the roof of the pluton which upon intruding the metasediments produced a sheeted zone of alternating granite and metasediment.

Late diorite dykes intrude all of the above rocks but were not seen within the syenite.

| 1.5.2 | Mineralization |

The Diopside-Hyalophane and REE dykes/veins are currently found in two main areas;

| 1) | A zone at the north end of Hoidas Lake, approximately 600 m wide (Southeast to Northwest) and at least 1,000 m long (Southwest to Northeast), which includes the JAK Zone. |

| 2) | A 300 m wide zone at the southwest end of Hoidas Lake which includes the Hoidas South showing. The latter zone was only examined over a minimum strike length of about 200 m, but there are other known occurrences located farther southwest along the Nisikkatch–Hoidas Shear Zone. |

The REE mineralized veins/dykes are distinguished by the addition of, firstly, allanite and secondly, by various forms of apatite. Allanite can be intergrown with diopside and occurs also as massive veins. It can also be intergrown with apatite. The presence of allanite is commonly the main cause of the radioactivity which can reach several thousand counts per second. The apatite is typically coarse grained which show textures which suggest they invaded the earlier diopside-rich zones as indicated by veins cutting diopside, xenoliths or fragments of diopside within the apatite and by xenoliths of gneissic country rocks. The apatite phase commonly shows a breccia texture, which is best seen on weathered surfaces. Red apatite breccias, with minor green apatite, was the main variety found in the new showings around the Hoidas South and Hunter showings.

6

|

REalloys Inc. |

Hyalophane Pegmatites are found intruding all of the above rock types including the diopside-hyalophane veins, but there is also evidence to the contrary with diopside-hyalophane cutting hyalophane pegmatite. There are also some hyalophane-bearing pegmatites that contain the D2 deformational fabric, and it would appear that these pegmatites were possibly emplaced axial planar to tight to isoclinal F2 folds. Therefore, there is a significant range of ages of emplacement for these dykes. They range from a few centimetres to 1.5 m in width and have been traced for up to 10 m before disappearing under drift cover.

The JAK zone occurs within this series of vein sets. It outcrops along the northwest shore of Hoidas Lake and exhibits open rare earth mineralization down dip below the lake, to the north and south. Individual outcropped veins are up to 5 m wide and can occur as fairly isolated small single mineralogical composition veinlets through to large multi-zoned veins exhibiting hyalophane, diopside and allanite at the hanging wall and foot wall contacts with apatite and breccias at the centre. The rare earth elements are hosted predominantly by apatite and allanite with minor amounts of mineralization in chevkenite, monazite and rare earth-bearing carbonates.

The rocks record four major deformation events, the earliest of which, D1, is difficult to recognize; however, the S1 foliation that was developed was subsequently isoclinally folded during D2 and resulted in a strong composite S1-S2 foliation being formed. This S1-S2 fabric is the main foliation observed in the area and generally trends northwesterly, west of Hoidas Lake. Peak metamorphism occurred at this time and attained upper amphibolite facies conditions and possibly was transitional to granulite facies. Third deformation, D3, is related to shear zone development and reactivation along the long-lived Black Bay Fault. This produced a weak to strong northeasterly overprint fabric, S3, on all but the lamprophyres. The intensity of S3 depends on the proximity to the major shear zones. For example, the REE mineralized veins at the Hoidas South showing are strongly deformed (folded, stretched, boudinaged, foliated) as they occur within the zone affected by the D3 Nisikkatch – Hoidas Shear Zone, whereas the JAK Zone and many of the new showings are only mildly or not obviously affected. A fourth event, D4, is marked by open north trending folds which did not develop a foliation. Brittle reactivation of faults apparently continued for some time after.

The REE mineralized diopside-hyalophane-apatite-allanite veins/dykes are structurally controlled and occupy structures that clearly cross-cut the composite S1-S2 fabric. The principal veins strike 040° to 050° and dip moderately to steeply southeast. A system of riedel shears is developed between the principal veins and the orientation of the diopside-hyalophane-filled R shears at 060° to 070° indicates a dextral sense of shear. This is also supported by drag folding of the S1-S2 fabric into the mineralized structures. Connecting R’ shears were also recognized at high angle to the R shears. Both R and R’ shears can be mineralized; thus, creating three orientations that can be mineralized. The amphibolite-hosted REE veins appear to be related to a different set of structures; a set that is sub- parallel to a northerly trending fault and a conjugate set of fractures related to the northerly fault.

| 1.6 | Mineral Processing and Metallurgical Testing |

The Hoidas Lake property includes both rare earth elements (REE) and phosphorus (apatite) mineralization. The rare earth metals at the Hoidas Lake property are primarily found in the bastnasite and allanite minerals, and secondly in the monazite, parasite, thorite and apatite minerals.

7

|

REalloys Inc. |

Testwork related to mineral processing and extractive metallurgy using composite samples representing the mineralization at the Hoidas Lake deposit was initiated in 2001 and continued into 2012. A number of programs have been completed using well known test laboratories located in Canada, USA and China.

The most recent study was completed by a Chinese technical institute in 2012 and indicated that it is technically feasible to recover a rare earth concentrate in the form of a mixed RE carbonate and phosphorus as a Nitrogen-Phosphorus or NP-fertilizer. The process developed comprises flotation and magnetic separation to produce a rare earth concentrate and an apatite concentrate. These concentrates are then treated separately using conventional hydrometallurgical technologies to extract rare earths and phosphorus. Table 1.1 provides a summary of results for the combined beneficiation and extractive metallurgical process. The overall RE recovery is 70% and phosphorus recovery is 93%.

Table 1.1

Summary of Results of the

Combined Beneficiation and Extractive Metallurgical Process

Description |

RE (TREO) | Phophorus (P2O5) | |||

| Grade (%) | Distribution (%) | Grade (%) | Distribution (%) | ||

| Feed sample | 2.72 | 100.00 | 12.50 | 100.00 | |

| Beneficiation | Rare Earth (RE) concentrate | 9.27 | 49.20 | 2.93 | 3.26 |

| Apatite concentrate | 2.78 | 40.25 | 31.29 | 94.95 | |

| Metallurgy | RE carbonate produced from RE conc. | 60.39 | 78.62 | - | - |

| RE carbonate from apatite conc. | 60.13 | 78.64 | - | - | |

| NP fertilizer from apatite conc. | - | - | 15.74 | 97.44 | |

| Combined beneficiation-metallurgy process | - | 70.33 | - | 92.52 | |

Additional testwork is recommended to first confirm then optimize the process flowsheet developed so far. The work should focus on the best technical and economic process solution for the Hoidas Lake Project.

Once the best techno-economic process has been selected then a variability test program should be undertaken to improve the geo-metallurgical understanding of the deposit.

| 1.7 | Hoidas Lake Mineral Resource Estimate |

| 1.7.1 | Introduction |

Barr supplied the electronic resource database for the Project to Micon as Barr had previously undertaken the mineral resource estimate in 2009 for the Hoidas Lake Project. Micon reviewed has accepted most of the estimation work conducted by Barr, however, Micon used its own judgement for mineral resource categorization, economic parameters assumptions and used an NSR approach to report the mineral resource statement.

This section describes the development of the resource estimate, including methods used and key assumptions considered during the estimation process.

This report discloses technical information, the presentation of which requires Micon to derive sub-totals, totals and weighted averages that inherently involve a degree of rounding and, consequently, introduce a margin of error. Where these occur, Micon does not consider them to be material.

8

|

REalloys Inc. |

| 1.7.2 | Mineral Resource Supporting Data and Block Model |

| 1.7.2.1 | Database |

Upon receipt of the previous mineral resource database from Barr, Micon conducted a thorough review of the database to ensure that the geological database was sufficient to support a mineral resource estimate. Micon’s review found no significant errors in the database and Micon concluded that it was acceptable to be used as the basis for the mineral resource update on the Hoidas Lake deposit.

A total of 188 drill holes were contained in the geological database but only which 110 drill holes occurred in the area of the Hoidas Lake deposit and were used in the estimation of the mineral resource. Figure 11.1 shows the drill hole location plan.

The only significant change to the database was that Barr provided Micon with the geological database and block model in a non-rotated local grid coordinate system, which is typical practice in many exploration projects. However, Micon undertook the transformation of the database local grid drill holes and block model into a UTM, datum NAD83 Zone 13N coordinate system to represent the true geographical location of the Hoidas Lake mineral deposit

| 1.7.2.2 | Topography |

No topographic surface was provided for the Hoidas Lake Project. As the local terrain is relatively flat and the current mineral resource is based upon an underground longhole mining method, Micon proceed to construct a new topographic surface from drill hole collar elevations.

| 1.7.2.3 | Rock Density |

The density value was provided in the block model as a single average value of 3.11 g/cc.

| 1.7.2.4 | Compositing |

The original composites for the previous Barr resource estimate were not provided to Micon. For compositing purposes, Micon recreated a set of 1 m equal length composites from the drill holes following the block model mineralization limits and attributes for the nearest sample distance.

| 1.7.2.5 | Variography |

Barr performed some variograms on multiple elements but with no meaningful results, concluding that the grade distribution of the deposit is isotropic and inverse distance cubed (ID3) method to populate the blocks within the model. Micon continued to use the ID3 method as this method.

| 1.7.2.6 | Block Model |

The original model was a non-rotated percent block model located in a local grid, using a block size of 2.0 m across strike by 2.5 m along strike with a 10 m height, a variable percentage (ZPERT) was used to better represent the mineralized and unmineralized volumes.

Micon proceed to transform the blocks into the UTM NAD83 Zone 13N coordinate system with a rotation of 49.5 degrees clockwise to situate the model into the correct geographical coordinates but otherwise used the same block model attributes as Barr.

9

|

REalloys Inc. |

| 1.7.2.7 | Block Model Validation |

The block model was validated against the supporting data using three methods, visual inspections, global statistical comparison and swath plots.

| 1.7.3 | Mineral Resource Estimate |

| 1.7.3.1 | Reasonable Prospects for Eventual Economic Extraction |

The CIM Standards require that an estimated mineral resource must have reasonable prospects for eventual economic extraction. To assess the economic value of the Hoidas Lake Deposit, Micon adopted an NSR approach with the bulk of the economic value at Hoidas Lake focused on the Light Rare Earth Elements (LREEs). Uranium and Thorium were added to the block model but not added to the resource estimation because they are both considered deleterious elements, the effects of which need to be mitigated during any potential mining process. Table 1.2 summarizes the economic parameters used for the NSR calculation.

Table 1.2

Economic Assumptions for the

NSR Calculation

Pricing and Costs |

Description | Units | Value | Comments |

| Rare Earth Oxide Pricing | Lanthanum oxide (La2O3) | US$/kg | 1.25 | Oxide factor = 1.173 (20.44% REO) |

| Cerium oxide (CeO2) | US$/kg | 1.03 | Oxide factor = 1.228 (46.62% REO) | |

| Praseodymium oxide (Pr6O11) | US$/kg | 95.00 | Oxide factor = 1.208 (5.97% REO) | |

| Neodymium oxide (Nd2O3) | US$/kg | 95.00 | Oxide factor = 1.166 (20.57% REO) | |

| Samarium oxide (Sm2O3) | US$/kg | 2.14 | Oxide factor = 1.160 (2.71% REO) | |

| Europium oxide (Eu2O3) | US$/kg | 27.82 | Oxide factor = 1.158 (0.54% REO) | |

| Gadolinium oxide (Gd2O3) | US$/kg | 25.82 | Oxide factor = 1.153 (1.24% REO) | |

| Terbium oxide (Tb4O7) | US$/kg | 1,500.00 | Oxide factor = 1.176 (0.11% REO) | |

| Dysprosium oxide (Dy2O3) | US$/kg | 375.00 | Oxide factor = 1.148 (0.35% REO) | |

| Holmium oxide (Ho2O3) | US$/kg | 74.61 | Oxide factor = 1.146 (0.00% REO) | |

| Erbium oxide (Er2O3) | US$/kg | 44.15 | Oxide factor = 1.144 (0.24% REO) | |

| Thulium (Tm2O3) | US$/kg | 114.98 | Oxide factor = 1.142 (0.00% REO) | |

| Ytterbium oxide (Yb2O3) | US$/kg | 14.27 | Oxide factor = 1.139 (0.05% REO) | |

| Lutetium oxide (Lu2O3) | US$/kg | 770.32 | Oxide factor = 1.137 (0.00% REO) | |

| Yttrium oxide (Y2O3) | US$/kg | 5.99 | Oxide factor = 1.270 (1.17% REO) | |

| Operating Costs, Metallurgical Recovery and Grade, Royalties | Underground Mining | US$/t | 70.0 | Assuming a long hole mining method |

| Beneficiation plant | US$/t | 25.0 | ||

| Hydrometallurgical plant | US$/t | 166.67 | ||

| General and Administration (G&A) | US$/t | 66.67 | ||

| Metallurgical Recovery | % | 70.0 | Based on GRINM Test Work Jan. 2009 | |

| Conc. Transportation | US$/t | 250.0 | Assumed to be dry concentrate. | |

| TREO Conc. Grade | % | 65.0 | ||

| Dubnick Royalty | % | 1.8 | From NSR, CA$1M max. over the LOM. |

10

|

REalloys Inc. |

Then the NSR calculation formula is:

Where:

x is Grade of each metal.

r is Metallurgical recovery of each metal.

R is Refining cost of each metal.

p is Smelting recovery of each metal.

V is Market price value of each metal.

K is Metric tonnes of ore required to produce one metric tonne of concentrate.

Cs is Smelter cost per tonne of concentrate.

Ct is Transportation cost per tonne of concentrate.

Once all the economic assumptions were processed, NSR values per block was calculated and attributed to the entire block model.

As the original mineralization wireframes were not available and to account for mining dilution, Micon used the ZPERT attribute multiplied by the density of 3.11g/cc to correct the tonnage, then all mining shape stopes were assigned an expected dilution base on their mining width as follows:

| ● | Stopes from 3 m to 10 m wide, 25% dilution at zero grade. |

| ● | Stopes from 10 m to 20 m wide, 15% dilution at zero grade. |

| ● | Stopes greater than 20 m wide, 10% dilution at zero grade. |

The application a dilution percentage to the various stope widths resulted in an average global dilution of 22% which was then was applied to the undiluted tonnes for the mineral resource statement.

| 1.7.3.2 | Mineral Resource Classification |

Barr originally based its resource classification by using the distance to the nearest sample together with number of drill holes and number of sample composites within a drill hole. Barr summarized this as follows: “for a block to be classified as Measured, at least two samples from at least two holes within less than 12 metres (40% of the variogram range) from the closest sample were required. Indicated required at least two samples from at least two holes within a search distance greater than 12 metres and at least lower than or equal to 30 metres. Inferred was classified as all the material searched over 30 metres with at least one composite per hole.” Micon generally agrees with Barr’s method but undertook a secondary visual assessment to eliminate the “Spotted Dog” effect that the original classification displayed.

11

|

REalloys Inc. |

| 1.7.3.3 | Mineral Resource Estimate |

The mineral resource estimate for the Hoidas Lake Project is summarized in Table 1.3 with a more detailed summary for the various elements in Table 1.4. The mineral resource estimate was determined using an NSR cut-off value of US$328.33/t, this value is the sum of mining, beneficiation, hydrometallurgy processing, G&A transportation and royalty costs along with recoveries. The mineral resource estimate has an effective date of October 30, 2024.

The 2024 Hoidas Lake Project mineral resource estimate is considered to be a reasonable representation of the mineral resources for the Hoidas Lake Project, based on the currently available data and geological knowledge.

Table 1.3

Hoidas Lake TREO Mineral

Resource Statement (Effective Date October 30, 2024)

Classification |

Tonnes | NSR US$ | TREO % |

| Measured | 711,000 | 397.17 | 1.858 |

| Indicated | 1,442,000 | 404.56 | 1.929 |

| Measured and indicated | 2,153,000 | 402.12 | 1.906 |

| Inferred | 1,602,000 | 419.62 | 2.089 |

Resource Estimate notes are found below Table 1.4.

Table 1.4

Hoidas Lake TREO Mineral

Resource Statement with REO Details (Effective Date October 30, 2024)

Item/Element |

Measured | Indicated | M+I | Inferred |

| Tonnes | 711,000 | 1,442,000 | 2,153,000 | 1,641,000 |

| NSR US$ | 397.17 | 404.56 | 402.12 | 377.94 |

| TREO % | 1.858 | 1.929 | 1.906 | 1.884 |

| La2O3 % | 0.370 | 0.395 | 0.387 | 0.379 |

| CeO2 % | 0.850 | 0.887 | 0.875 | 0.890 |

| Pr6O11 % | 0.113 | 0.118 | 0.116 | 0.108 |

| Nd2O3 % | 0.392 | 0.395 | 0.394 | 0.373 |

| Sm2O3 % | 0.057 | 0.057 | 0.057 | 0.055 |

| Eu2O3 % | 0.011 | 0.011 | 0.011 | 0.010 |

| Gd2O3 % | 0.026 | 0.026 | 0.026 | 0.025 |

| Tb4O7 % | 0.003 | 0.003 | 0.003 | 0.002 |

| Dy2O3 % | 0.007 | 0.007 | 0.007 | 0.007 |

| Ho2O3 % | 0.000 | 0.000 | 0.000 | 0.000 |

| Er2O3 % | 0.004 | 0.004 | 0.004 | 0.005 |

| Tm2O3 % | 0.000 | 0.000 | 0.000 | 0.000 |

| Yb2O3 % | 0.002 | 0.002 | 0.002 | 0.002 |

| Lu2O3 % | - | 0.000 | 0.000 | - |

| Y2O3 % | 0.023 | 0.023 | 0.023 | 0.026 |

Resource Estimate Notes:

| 1. | The effective date of the Mineral Resource Estimate is October 30, 2024. | |

| 2. | The mineral resource estimate was determined using an NSR cut-off value of US$328.33/t. | |

| 3. | The mineral resources disclosed in this report were estimated using the CIM standards for mineral resource and reserve definitions and the CIM best practices guidelines for resource estimation. |

12

|

REalloys Inc. |

| 4. | The mineral resources reported were considered to be mined using a Longhole mining methods and assumes an average dilution of 22% and with the original block model re-blocked to 20m x 20m x 20m. Mineralized blocks outside of the pit-shell are not considered to be part of the MRE. | |

| 5. | For the purposed of the block model and future economic studies uranium and thorium were modelled as deleterious elements. | |

| 6. | The mineral resource estimate has been classified according to CIM definitions of Measured, Indicated and Inferred Resources. The Mineral Resource classification has also been visually reviewed to eliminate any ‘Spotted Dog’ effect, commonly seen in computer-generated models. | |

| 7. | Mineral resources that are not mineral reserves do not have demonstrated economic viability. | |

| 8. | The tonnes and metal contents are rounded to reflect that the numbers are an estimate and any discrepancies in the totals are due to the rounding effects. | |

| 9. | Micon has not identified any legal, political, environmental, or other factors that could materially affect the potential development of the mineral resource estimate. |

| 1.7.3.4 | Mineral Resource NSR Sensitivity Analysis |

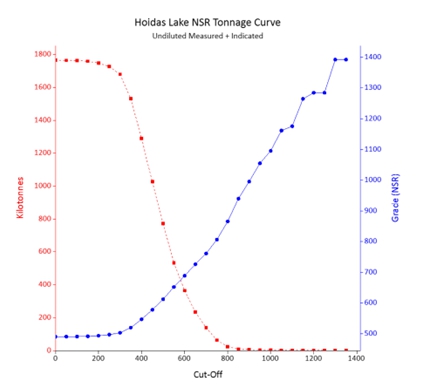

For the 2024 Hoidas Lake Project mineral resource estimate, a grade sensitivity analysis has been conducted on the basis of different NSR $/t value cut-off for the measured and indicated undiluted mineralization. Table 1.5 summarizes the NSR $/t value cut-off sensitivity analysis for Hoidas Lake Project. The reader should be cautioned that the figures provided in Table 1.5 should not be interpreted as a mineral resource statement. Figure 1.1 shows the graphical representation of the relationship between different NSR $/t value cut-off grades and tonnages for the Hoidas Lake Project. Micon has reviewed the NSR $/t value cut-off grades used in the sensitivity analysis, and it is the opinion of Micon that they meet the test for reasonable prospects of eventual economic extraction at varying metal prices or other underlying parameters.

Table 1.5

Hoidas Lake Project

Sensitivity Analysis to the NSR $/t Value Cut-Off*

NSR Cut-Off (US$/t)

|

Tonnes | Average NSR (US$/t) |

| 50.00 | 1,763,938 | 490.80 |

| 100.00 | 1,762,249 | 491.19 |

| 150.00 | 1,758,927 | 491.88 |

| 200.00 | 1,747,948 | 493.84 |

| 250.00 | 1,725,938 | 497.23 |

| 300.00 | 1,678,940 | 503.38 |

| 350.00 | 1,530,444 | 520.22 |

| 400.00 | 1,288,563 | 547.28 |

| 450.00 | 1,025,913 | 578.38 |

| 500.00 | 771,162 | 612.61 |

| 550.00 | 533,640 | 652.45 |

| 600.00 | 364,032 | 689.22 |

| 650.00 | 234,077 | 726.43 |

| 700.00 | 138,934 | 761.50 |

| 750.00 | 63,354 | 806.68 |

| 800.00 | 23,768 | 865.78 |

| 850.00 | 9,260 | 939.95 |

| 900.00 | 5,028 | 995.68 |

| 950.00 | 2,894 | 1,055.07 |

| 1,000.00 | 1,932 | 1,095.78 |

| 1,050.00 | 1,030 | 1,161.53 |

| 1,100.00 | 898 | 1,175.65 |

| 1,150.00 | 330 | 1,264.78 |

| 1,200.00 | 262 | 1,284.68 |

| 1,250.00 | 262 | 1,284.68 |

| 1,300.00 | 41 | 1,392.59 |

| 1,350.00 | 41 | 1,392.59 |

| * | Note the sensitivity tonnages are the combined undiluted measured and indicated material only. |

13

|

REalloys Inc. |

Figure 1.1

Hoidas Lake Project NSR

Cut-Off Sensitivity Graph

Figure dated November, 2024.

| 1.7.4 | Factors that Could Affect the Mineral Resource Estimate |

All estimation models have a degree of uncertainty associated with them, due to the assumptions used in their development. These uncertainties lead to risks in the relative accuracy of the models. In Micon’s independent review and verification of the previous mineral resource estimate model for the Hoidas Lake Project, Micon has used industry best practice guidelines and have reasonably mitigated much of the potential risks.

It is the Micon’s opinion that the factors set out below could affect the mineral resource estimate.

| ● | The geological interpretations and assumptions used to generate the estimation domain. |

| ● | Mineralization and geologic geometry and continuity of the mineralized zones. |

| ● | Estimates of mineralization and grade continuity. |

| ● | The grade interpolation methods and estimation parameter assumptions. |

| ● | The confidence assumptions and methods used in the mineral resource classification. |

| ● | The density and the methods used in the estimation of density. |

| ● | Metal price and other economic assumptions used in the cut-off grade determination. |

| ● | Input and design parameter assumptions that pertain to the open pit mining constraints. |

| ● | Assumptions as to the continued ability to access the test mine site, retain mineral and surface rights titles, maintain the operation within environmental and other regulatory permits, and maintain the social license to operate. |

| ● | Currently there are no environmental, permitting, legal, title, taxation, socio-economic, marketing, political or other relevant factors known to Micon that would materially affect the estimation of Mineral Resources, other that those discussed previously in this report. |

| 1.8 | Risks and Opportunities |

All mineral resource estimates have a degree of uncertainty or risk associated with them due to technical, environmental, permitting, legal, title, taxation, socio-economic, marketing or political factors, among others. All mineral resource estimates also present their own opportunities. Table 1.6 outlines some of the Hoidas Project risks, their potential impact and possible means of mitigation. Table 1.6 also outlines some of the Hoidas Lake Project opportunities and potential benefits.

14

|

REalloys Inc. |

Table 1.6

Risks and Opportunities at the

Hoidas Lake Project

Risk |

Description and Potential Impact | Possible Risk Mitigation |

| Local grade continuity issues | Poor grade forecasting. | Undertake further infill drilling to establish continuity of mineralization. |

| Local density variability | Misrepresentation of the in-situ tonnes, which also affects the in-situ metal content estimate. | It is recommended to develop a procedure of collecting density measurements spatially throughout the deposit at regular intervals in all rock/alteration types and implement their use in future mineralization models. |

| Geologic Interpretation. | If the geologic interpretation and assumptions (geometry and continuity) used are inaccurate, then there is a potential lack of grade or continuity. | Continue infill drilling to confirm the grade continuity which will also tend to upgrade the mineral inventory to at least the Indicated category. |

| Metallurgical recoveries are based on limited test work. | Recovery might be lower than that which is currently being assumed or vary with rock type. | Conduct additional metallurgical tests on all rock types. |

| Difficulty in attracting experienced professionals. | Technical work quality will be impacted and/or delayed. | Refine recruitment and retention planning and/or make use of consultants. |

| Conceptual mine plans in future are based on limited geotechnical test work. | Mining methods and dimensions selected might be different from what is currently being assumed. |

Incorporate more comprehensive geotechnical data from drilling. Conduct additional geotechnical assessment and analysis. |

| Environmental or social Issues | Further studies may be delayed, and the project may not advance due to environmental or social issues | Conduct meetings with all potential stake holders throughout the exploration and advanced development stages. Hire locals whenever possible |

| Opportunities | Explanation | Potential Benefit |

| Surface exploration drilling. | Potential to identify additional prospects and resources. | Adding resources increases the economic value of the Project. |

| Potential improvement in metallurgical recoveries. | Additional metallurgical test work can be performed to determine if recovery can be improved through ore sorting, flotation or cyanidation. |

Lower capital and operating costs.

|

| Potential improvement in mining assumptions. | Geotechnical analysis may determine that mining methods and dimensions can be improved. | Improved mining productivity and lower costs. |

| Potential additional economic minerals | All potentially economic minerals must be placed in the model such that changes in metal prices potentially allow for these to be added to the mineral resource estimate. | Further metallurgical test work to determine if any other minerals can be recovered economically, than those already identified. |

| 1.9 | Conclusions |

The 2024 mineral resource estimate has allowed REalloys to demonstrate that the Hoidas Lake Project has reasonable prospects for eventual economic extraction. Further exploration and metallurgical test work will be necessary to refine the extent and nature of economic REE mineralization.

It is Micon’s opinion that the exploration programs conducted by the previous operators were conducted according to industry best practices as outlined by the CIM. Micon has also reviewed the QA/QC conducted by the previous operators of the Hoidas Lake Project and finds that the information obtained is suitable to be used as the basis for the 2024 mineral resource estimate. Therefore, Micon believes that the 2024 mineral resource estimate can be used as the basis for further exploration and development work on the Hoidas Lake Project.

15

|

REalloys Inc. |

| 1.10 | Budget and Further recommendations |

| 1.10.1 | Budget |

The budget presented in Table 1.7 summarizes the estimated costs for completing further exploration programs, metallurgical testwork, begin baseline studies, conduct social outreach programs with the various local groups and fast track further studies related to the Hoidas Lake Project. The budget is a cost estimate for two phases of work culminating in a current mineral resource estimate and PEA after the second phase.

Table 1.7

Hoidas Lake Project,

Recommended Budget for Further Work

Phase |

Description | Item | Period or Amount | Cost | Total (CDN$) |

| 1 |

Drilling and Data Interpretation (Late January – May 2025)

|

Geological staff, camp staff, and equipment rentals | 2 month rentals | $474,535.00 | |

| Camp Implementation and Rental | $63,416.67 | ||||

| Drilling | 2,500 m | $420/m | $1,041,600.00 | ||

| Geochemical Assay | 40% sampling rate | $63,537.60 | |||

| Mobilization and crew transportation | $80,000.00 | ||||

| Phase 1 Sub Total: | $1,723,089.27 | ||||

| Metallurgical Testwork | Ore sorting tests; bench scale beneficiation and hydrometallurgical tests to optimize the flowsheet and produce RE carbonates | $150,000.00 | |||

| Total Phase 1: | $1,873,089.27 | ||||

| 2 | Drilling and Field Work (Late June - October 2025) | Geological staff, camp staff, and equipment rentals | Concurrent 2 to 4 month drill prtogram and a 3 to 4 week field program | $791,099.32 | |

| Camp Implementation and Rental | 5 month rental | $70,200.00 | |||

| Drilling | 7,500 m | $420/m | $3,225,600 | ||

| Geochemical Assay | 40% sampling rate | $1,512,727.27 | |||

| Mobilization and crew transportation | $92,000.00 | ||||

| Phase 2 Subtotal: | 5,691,626.27 | ||||

| Metallurgical Testwork | Larger scale continuous or semi-continuous pilot plant testing including separation to produce RE oxides | $300,000 | |||

| Total Phase 2: | 5,991,626.27 |

It is the opinion of the Micon that all of the recommended work noted in the budget is warranted. Micon appreciates that the nature of the programs and expenditures may change as the further studies are undertaken, or the company priorities change and that the final expenditures and results may not be the same as originally proposed.

Micon is of the opinion that REalloys’s recommended work program and proposed expenditures are appropriate and well thought out. Micon believes that the proposed budget reasonably reflects the type and amount of the activities required to advance the Hoidas Lake Project, with next phase culminating in the publication of an economic study for the Project.

16

|

REalloys Inc. |

| 1.10.2 | Recommendations |

Micon recommends further exploration and development of the Hoidas Lake Project. It is recommended that REalloys continues with exploration at the Hoidas Lake deposit as well as other REE mineralization showings on the property. It is also recommended that REalloys continues to conduct further metallurgical testwork at the Hoidas Lake Project. To that end, Micon makes the following recommendations for the Hoidas Lake Project.

| 1) | Undertake a Lidar topographic survey of the Hoidas Lake Project, concentrating on those areas covered by the mineral deposits as well as any areas that would be potentially used for mine infrastructure. |

| 2) | Undertake further mapping and sampling across the mineral deposits paying particular attention to changes in alteration and geology. |

| 3) | Conduct continuous channel sampling across the Hoidas Lake deposit, at regular intervals along the strike of the deposit, as this information could be potentially incorporated into future mineral resource estimates. |

| 4) | Conduct detailed relogging of a number of drill holes to review the geological units and alteration types for the mineralized zones. |

| 5) | Conduct further density sampling to see if there is any variation between the mineralized zones or geological units. |

| 6) | Complete further resource infill and expansion drilling on the Hoidas Lake deposit to increase the confidence of the continuity of the REE mineralization and grade. |

| 7) | Metallurgical testwork should be conducted on the Hoidas Lake and other mineralized showings to see if the metallurgical recoveries are different in the various geological rock types. |

| 8) | Conduct further diamond drill testing of the secondary exploration targets on the Hoidas Lake property. |

| 9) | Complete a new mineral resource estimate along with an economic study. |

17