| | |

SEC Technical Report Summary Initial Assessment Wodgina Western Australia

Effective Date: September 30, 2020 Report Date: December 31, 2021 Amended Date: December 16, 2022 |

Report Prepared for Albemarle Corporation 4250 Congress Street Suite 700 Charlotte, North Carolina 28209

|

Report Prepared by SRK Consulting (U.S.), Inc. 1125 Seventeenth Street, Suite 600 Denver, CO 80202

SRK Project Number: 515800.040 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page ii |

Table of Contents

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page iii |

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page iv |

| | | | | |

| 83 |

| 84 |

| 85 |

| 86 |

| 86 |

| 87 |

| 88 |

| 89 |

| 90 |

| 91 |

| 92 |

| 93 |

| 94 |

| 94 |

| 95 |

| 96 |

| Signature Page | 97 |

List of Tables

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page v |

List of Figures

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page vi |

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page vii |

List of Abbreviations

The metric system has been used throughout this report. Tonnes are metric of 1,000 kg, or 2,204.6 lb. All currency is in U.S. dollars (US$) unless otherwise stated.

| | | | | |

| Abbreviation | Unit or Term |

| A | ampere |

| AA | atomic absorption |

A/m2 | amperes per square meter |

| °C | degrees Centigrade |

| CoG | cut-off grade |

| cm | centimeter |

cm2 | square centimeter |

cm3 | cubic centimeter |

| cfm | cubic feet per minute |

| ConfC | confidence code |

| CRec | core recovery |

| ° | degree (degrees) |

| dia. | diameter |

| g | gram |

| g/t | grams per tonne |

| ha | hectares |

| ICP | induced couple plasma |

| IDW2 | inverse-distance squared |

| IDW3 | inverse-distance cubed |

| kg | kilograms |

| km | kilometer |

km2 | square kilometer |

| kt | thousand tonnes |

| kt/d | thousand tonnes per day |

| kt/y | thousand tonnes per year |

| kV | kilovolt |

| kW | kilowatt |

| kWh | kilowatt-hour |

| kWh/t | kilowatt-hour per metric tonne |

| L | liter |

| L/sec | liters per second |

| L/sec/m | liters per second per meter |

| LOI | Loss On Ignition |

| LoM | Life-of-Mine |

| m | meter |

m2 | square meter |

m3 | cubic meter |

| masl | meters above sea level |

| mg/L | milligrams/liter |

| mm | millimeter |

mm2 | square millimeter |

mm3 | cubic millimeter |

| Mt | million tonnes |

| MTW | measured true width |

| MW | million watts |

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page viii |

| | | | | |

| m.y. | million years |

| % | percent |

| ppm | parts per million |

| QA/QC | Quality Assurance/Quality Control |

| RC | rotary circulation drilling |

| RoM | Run-of-Mine |

| RQD | Rock Quality Description |

| SEC | U.S. Securities & Exchange Commission |

| sec | second |

| SG | specific gravity |

| t | tonne (metric ton) (2,204.6 pounds) |

| t/h | tonnes per hour |

| t/d | tonnes per day |

| t/y | tonnes per year |

| TSF | tailings storage facility |

| V | volts |

| VFD | variable frequency drive |

| W | watt |

| XRD | x-ray diffraction |

| y | year |

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 9 |

1Executive Summary

This report was prepared as an Initial Assessment-level (IA) Technical Report Summary in accordance with the Securities and Exchange Commission (SEC) S-K regulations (Title 17, Part 229, Items 601 and 1300 until 1305) for Albemarle Corporation (Albemarle) by SRK Consulting (U.S.), Inc. (SRK) on the Wodgina Mine asset (Wodgina).

The report was amended to include additional clarifying information in December 2022. The basis of the report is unchanged. The summary of the changes and location in document are summarized in Chapter 2.2.

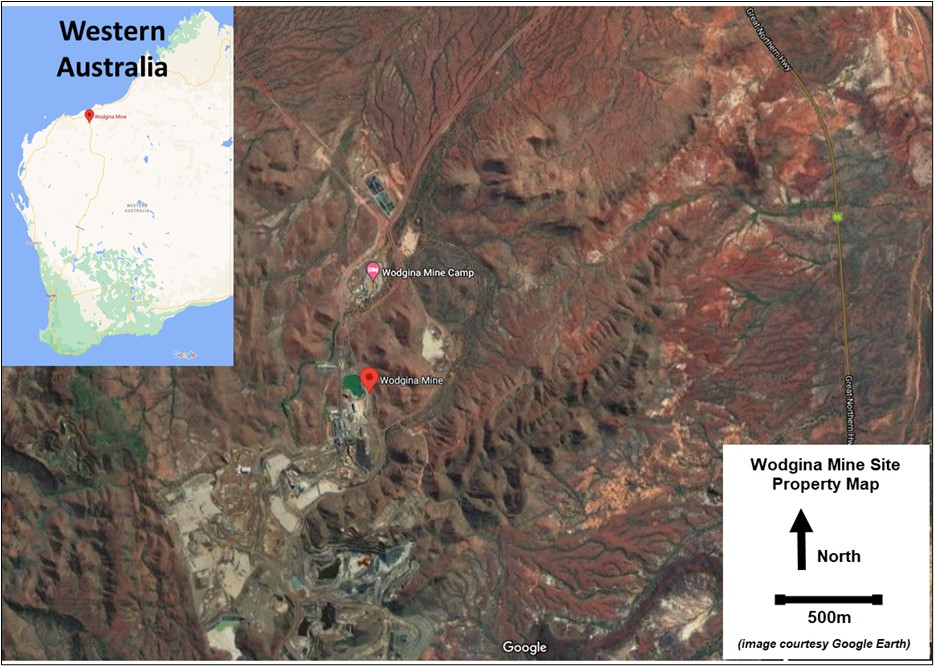

1.1Property Description (Including Mineral Rights) and Ownership

The Wodgina property lies approximately 110 kilometers (km) south-southeast (S-SE) of Port Hedland, Western Australia between the Turner and Yule Rivers. The area includes multiple prominent ridges up to 180 m above mean sea level (mamsl) surrounded by plains and lowlands. The center of the property is located at Mount Cassiterite - 21° 11' 25"S, 118° 40' 25"E (World Geodetic System [WGS] 1984).

The property tenure is held under the joint venture of Albemarle Wodgina Pty Ltd. and Wodgina Lithium Pty Ltd. with ownership structure of 60% Albemarle Corporation and 40% Mineral Resources Ltd. (MRL). The operating joint venture entity is known as MARBL.

1.2Geology and Mineralization

The Wodgina pegmatite deposits (including the historic Wodgina, Mt. Cassiterite, and Tinstone pits) are hosted within the Paleoarchean East Strelley Greenstone Belt in the Pilbara Craton of Western Australia, Australia.

The property is located within the Wodgina Pegmatite District. This pegmatite district is entirely hosted in the eastern limb of the Wodgina greenstone belt along the southern portion of the Wodgina-Strelley lineament. This greenstone belt is a north-northeast (N-NE) plunging synform separating the Yule and Carlindi granitoid complexes within Central zone of the Pilbara Craton.

The Mt. Cassiterite pegmatite group is classified as a rare element albite-spodumene type pegmatite. Spodumene (LiAlSi2O6) is the primary lithium-bearing mineral. It is massive to weakly layered pegmatite with comb-textured megacrystic microcline and spodumene with aplitic layers often displaying pseudo gneissic banding. Unlike many other Pilbara Craton pegmatite bodies, the Mt. Cassiterite pegmatites tend to not display internal structure such as mineralogical layering or banding. Lithium minerals are predominantly spodumene and lepidolite. Prior to focusing on lithium production, the Mt. Cassiterite deposit was exploited for tantalum-bearing wodginite and cassiterite with subordinate maganocolumbite and manganotantalite with associated microcline alteration (Huston, et al., 2001). Other significant minerals include spessartine (Mn aluminosilicate garnet), elbaite (Na-Li alumino-boro-silicate tourmaline) and native Bi.

1.3Status of Exploration, Development and Operations

The Wodgina property is currently on care and maintenance by MARBL. The site has experienced intermittent production since the early twentieth century. The Mt. Cassiterite pit, the primary focus of

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 10 |

this TRS, is an open pit with maintained infrastructure on-site and access to regional roads and ports.

1.4Mineral Resource and Mineral Reserve Estimates

Mineral Resources were updated in September 2020 by SRK as summarized in Table 1-1.

Table 1-1: Wodgina Summary Mineral Resources at End of Fiscal Year Ended December 31, 2021 SRK Consulting (U.S.), Inc.

| | | | | | | | | | | | | | | | | |

| Category | 100% | Attributable | Li2O (%) | Cut-Off (% Li2O) | Mass Yield (%) |

| Tonnes | Tonnes |

| (Mt) | (Mt) |

| Indicated | 22.3 | 13.4 | 1.39 | 0.50 | 15.06% |

| Inferred | 164.2 | 98.5 | 1.15 | 0.50 | 12.46% |

Source: SRK, 2020

Notes:

• The Summary Mineral Resources attributable tonnes reflects Albemarle’s 60% ownership percentage in the Wodgina project.

The effective date for this Mineral Resource is September 30, 2020. All significant figures are rounded to reflect the relative accuracy of the estimates.

• Tonnages are presented as million tonnes (Mt) with lithium oxide (Li2O) grades presented as percentages.

• The Mineral Resource estimate has been classified in accordance with SEC S-K 1300 guidelines and definitions.

• The Cassiterite Deposit comprises the historically mined Mt. Cassiterite pit and undeveloped North Hill areas.

• Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. Inferred Mineral Resources have a high degree of uncertainty as to their economic and technical feasibility. It cannot be assumed that all or any part of an Inferred Mineral Resources can be upgraded to Measured or Indicated Mineral Resources.

• Metallurgical recovery of lithium has been estimated on a block basis at a consistent 65% based on documentation from historical plant production.

• To demonstrate reasonable prospects for eventual economic extraction of Mineral Resources, a cut-off grade of 0.5% Li2O based on metal recoverability assumptions, long-term lithium price assumptions of US$584 per tonne (t), variable mining costs averaging $3.40/t, processing costs and G&A costs totaling $23/t.

• There are no known legal, political, environmental, or other risks that could materially affect the potential development of the Mineral Resources based on the level of study completed for this property.

As the project-level is current at Initial Assessment-level, the property contains no Mineral Reserves.

1.5Conclusions and Recommendations

Wodgina is a large spodumene pegmatite deposit that features existing infrastructure for spodumene concentrate production, but which currently sits in care and maintenance. The geology of the site is relatively complex and features a number of challenges due to variations in morphology and mineralogy of the pegmatites. Such variability is common in spodumene pegmatites and is generally related to inherent structural complexity of host rocks, rheology of host rocks and the characteristics of various phases of pegmatite intrusion which commonly accompany lithium mineralization. SRK has considered all provided and relevant data in developing a more robust structural and lithological interpretation to constrain and control the mineral resource estimation (MRE). The lack of sufficient data to adequately characterize these aspects of certain areas of the project has been incorporated in the mineral resource classification process. It is expected that risks in the geological interpretation and MRE are likely to remain until extensive additional geological work has been done across the deposit, and that ongoing de-risking through closely spaced drilling is likely to be a part of downstream mining development.

Wodgina is a previously mined project with an extensive operational background in elements other than lithium. Despite this, lithium production is a relatively recent addition to Wodgina (effectively post-2016), with the majority of the lithium information being generated or characterized from remnant historic tin/tantalum drilling. All data supporting the current MRE was provided to SRK by MARBL, and exploration and development of Wodgina continues.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 11 |

While Wodgina features extensive drilling and previous production, significant uncertainty around the deposit remains. SRK has accounted for these risks in the MRE process and classification, and notes that the following additional work is recommended for the project going forward:

•Characterize the mineralogy and process recoverability of both the Mt. Cassiterite and North Hill areas of Wodgina. SRK understands this to be ongoing in new drilling on the project at this time.

•Refine the structural model for Wodgina utilizing core drilling to collect accurate structural measurements and provide influence in updated geological modeling and MRE.

•Characterize the recoverability and process for the existing tin/tantalum operation tailings, which have been noted to contain significant quantities of lithium.

•If production is to be advanced at Wodgina, closely spaced grade control drilling and short-term planning should be considered to de-risk areas.

•The project should advance to pre-feasibility study (PFS) levels of development with accompanying technical study of relevant modifying factors of the mineral resource.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 12 |

2Introduction

2.1Registrant for Whom the Technical Report Summary was Prepared

This Technical Report Summary was prepared in accordance with the SEC S-K regulations (Title 17, Part 229, Items 601 and 1300 through 1305) for Albemarle by SRK on the Wodgina property located in Western Australia, Australia. Albemarle has a 60% ownership in Wodgina with MRL retaining the remaining 40%. The joint venture operating entity is titled MARBL.

2.2Terms of Reference and Purpose of the Report

The quality of information, conclusions, and estimates contained herein are consistent with the level of effort involved in SRK’s services, based on i) information available at the time of preparation and ii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Albemarle, and is subject to the terms and conditions of its contract with SRK and relevant securities legislation. The contract permits Albemarle to file this report as a Technical Report Summary with American securities regulatory authorities pursuant to the SEC S-K regulations, more specifically Title 17, Subpart 229.600, item 601(b)(96) - Technical Report Summary and Title 17, Subpart 229.1300 - Disclosure by Registrants Engaged in Mining Operations. Except for the purposes legislated under securities law, any other uses of this report by any third party are at that party’s sole risk. The responsibility for this disclosure remains with Albemarle.

The purpose of this Technical Report Summary is to report mineral resources as part of an initial assessment. The IA is preliminary in nature, it includes Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that the IA will be realized. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

The report was revised to include additional clarifying information in December 2022. The basis of the report is unchanged. The changes and location in document are summarized as follows:

•Amended date of report on title page

•Resource totals adjusted to reflect Albemarle 60% ownership (Chapter 1.4 and 11.8)

•Additional QP comment on adequacy of metallurgical testing (Chapter 8.3, 10, 14)

2.3Sources of Information

This report is based, in part on internal Company technical reports, previous studies, maps, published government reports, Company letters and memoranda, and public information as cited throughout this report and listed in the References Section 24.

Reliance upon information provided by the registrant is listed in the Section 25, when applicable.

2.4Details of Inspection

Due to the global pandemic, no site inspection has been conducted on the property by Qualified Persons (QP). Site visits are in-plan by QPs once travel restrictions and health and safety are considered acceptable for travel.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 13 |

2.5Qualified Person

This report was prepared by SRK Consulting (U.S.), Inc., a third-party firm comprising mining experts in accordance with § 229.1302(b)(1). Albemarle has determined that SRK meets the qualifications specified under the definition of qualified person in § 229.1300. References to the Qualified Person or QP in this report are references to SRK Consulting (U.S.), Inc. and not to any individual employed at SRK.

2.6Report Version Update

This TRS is not an update of a previously filed Technical Report Summary. This report represents an IA as defined by SEC S-K 1300 definitions.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 14 |

3Property Description

3.1Property Location

The Wodgina property lies approximately 110 km S-SE of Port Hedland, Western Australia between the Turner and Yule Rivers. The area includes multiple prominent greenstone ridges up to 180 mamsl surrounded by granitic plains and lowlands. The center of the property is located at Mount Cassiterite - 21° 11' 25"S, 118° 40' 25"E (WGS, 1984).

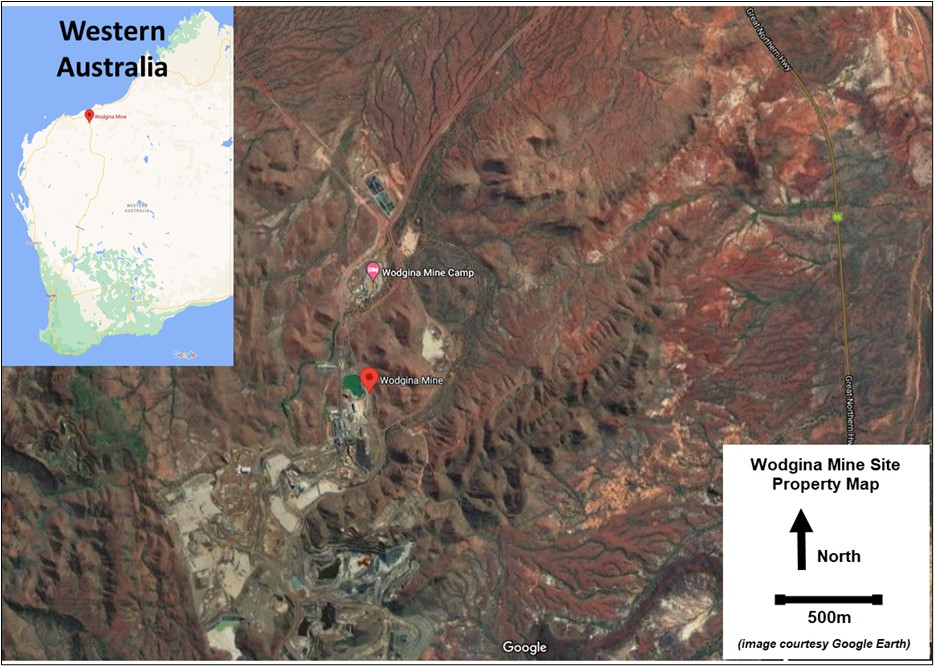

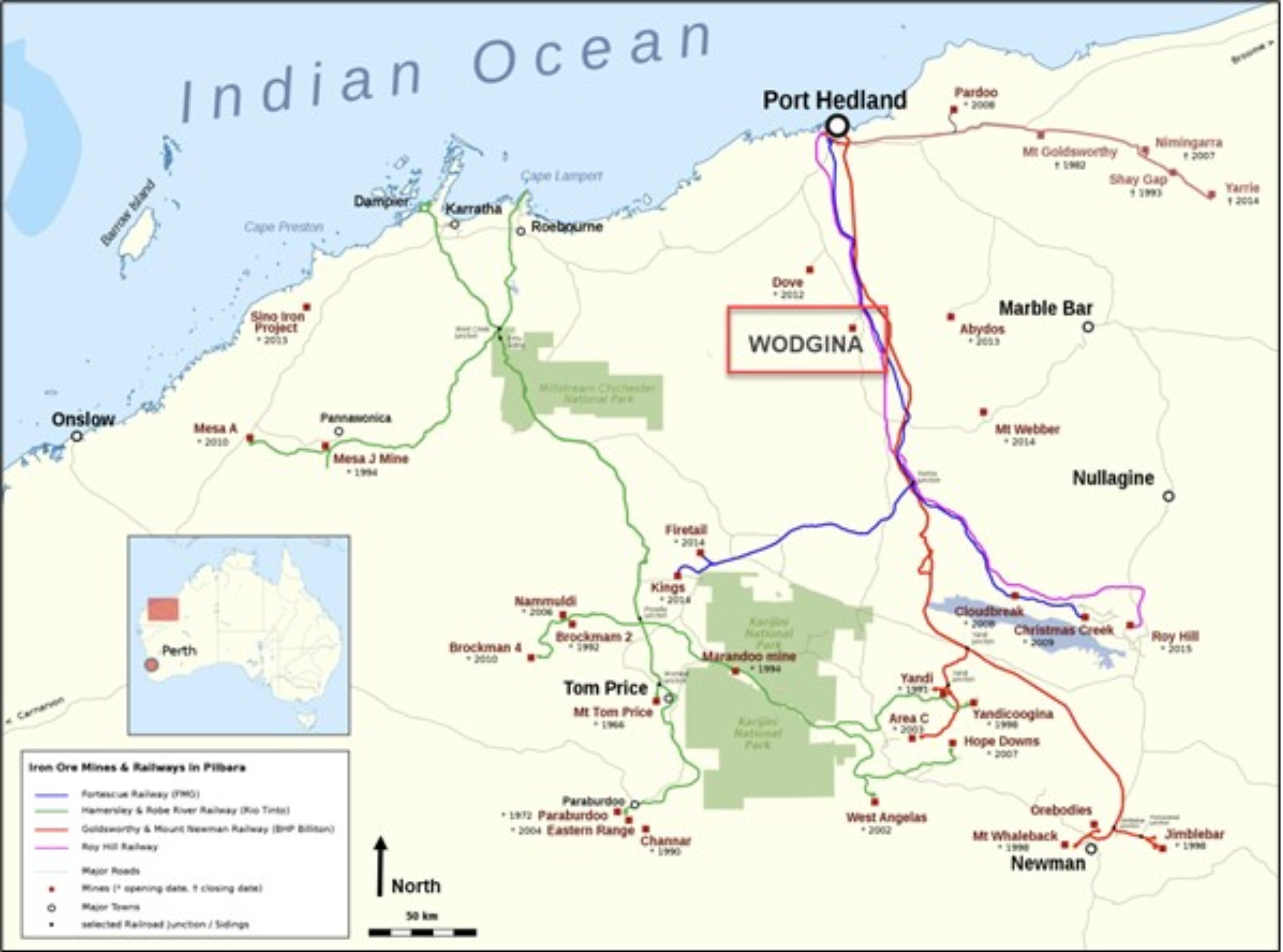

The property tenure is held under the joint venture of Albemarle Wodgina Pty Ltd. and Wodgina Lithium Pty Ltd. with ownership structure of 60% Albemarle and 40% MRL. The joint company is known as MARBL. A location map of the Wodgina property is shown in Figure 3-1 and Figure 3-2.

Source: Modified after Google

Source: Modified after GoogleFigure 3-1: Location Map of the Wodgina Property, Western Australia, Australia

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 15 |

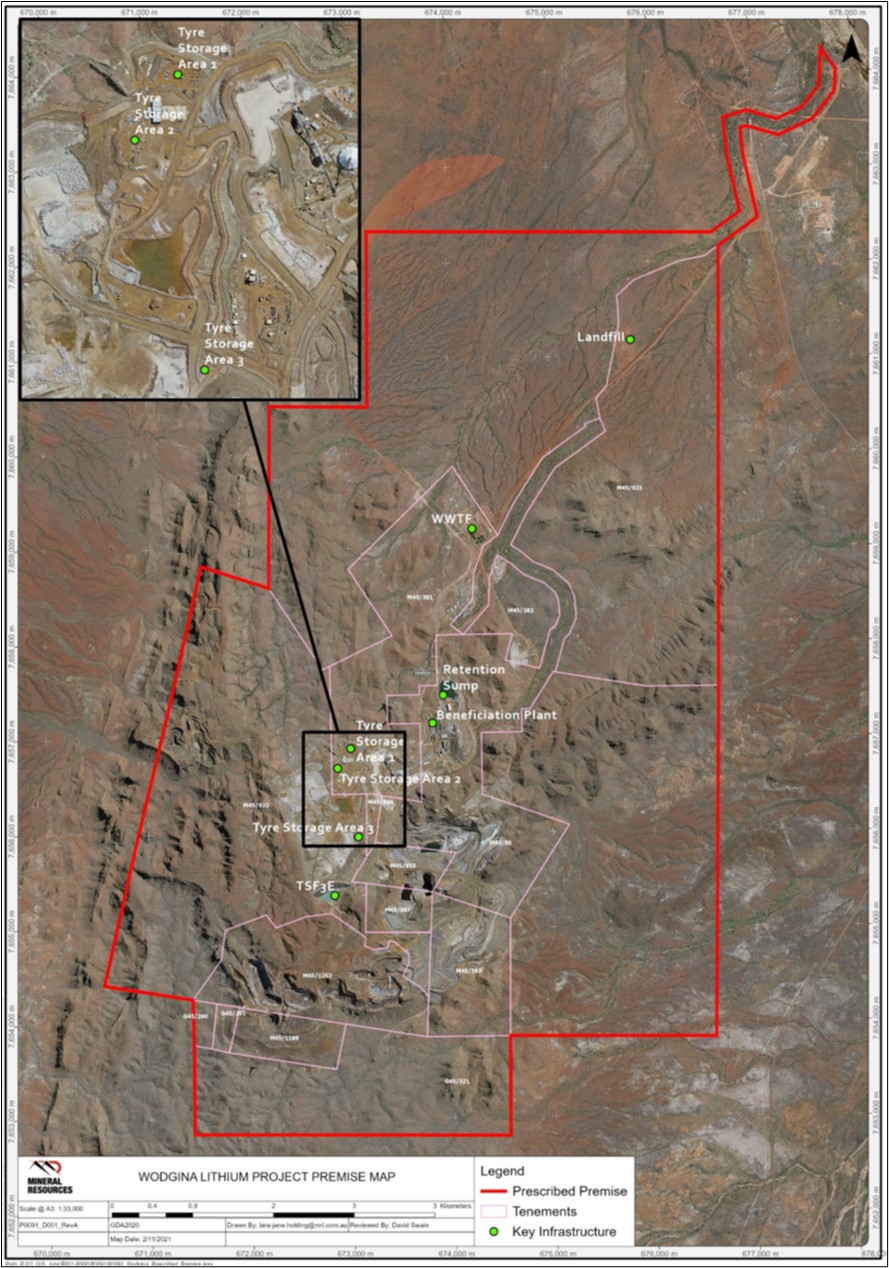

Source: MARBL, 2021

Figure 3-2: Wodgina Property Tenure Map

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 16 |

3.2Property Area

The total area of leases covering the Wodgina property cover a total of 111.4 square kilometers (km2) (43 square miles [mi]) (DMP, 2021). This includes various tenement types of general purpose and mining leases along with retention and miscellaneous licenses.

3.3Mineral Title, Claim, Mineral Right, Lease or Option Disclosure

The Wodgina property is located on Mining Lease M45/50, M45/353, and M45/887. These tenements are located within the Karriyarra native title claim and are subject to the Land Use Agreement dated March 2001 between the Karriyarra People and Gwalia Tantalum Ltd. (now the joint venture partners of Albemarle and MRL). All tenements are in good standing with no known impediments as of the effective date of this report (DMP, 2021).

Payment associated with tenement renewal to the State of Western Australia are:

•Mining Lease – AU$100 per hectare (ha), minimum AU$5,000

•General Purpose Lease – AU$17.90 per ha rent payment per annum

•Miscellaneous License – AU$17.90 per ha rent payment per annum

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 17 |

Table 3-1: Land Tenure Table

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| Tenement ID | Tenement Type | Survey Status | Status | Holders | Grant Date (DD/MM/YYYY) | End Date (DD/MM/YYYY) | Fmt_Tenid | Legal Area (Ha) | Special_ Ind | Extract_ Date |

| G4500029 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 18/07/1990 | 25/07/2032 | G45/29 | 9.6505 | | 11/05/2021 12:00:00 AM |

| G4500269 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 27/01/2005 | 28/01/2026 | G45/269 | 9.612 | | 11/05/2021 12:00:00 AM |

| G4500270 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 27/01/2005 | 28/01/2026 | G45/270 | 9.043 | | 11/05/2021 12:00:00 AM |

| G4500271 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 27/01/2005 | 28/01/2026 | G45/271 | 9.3595 | | 11/05/2021 12:00:00 AM |

| L4500093 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 25/03/1998 | 24/03/2023 | L45/93 | 134.9 | | 11/05/2021 12:00:00 AM |

| 4500058 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 09/12/1988 | 08/12/2023 | L45/58 | 95 | | 11/05/2021 12:00:00 AM |

| L4500064 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 18/05/1990 | 17/05/2025 | L45/64 | 1 | | 11/05/2021 12:00:00 AM |

| L4500105 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 01/06/2001 | 31/05/2022 | L45/105 | 1682 | | 11/05/2021 12:00:00 AM |

| L4500009 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 19/10/1984 | 03/07/2026 | L45/9 | 12.5 | | 11/05/2021 12:00:00 AM |

| L4500108 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 29/06/2001 | 28/06/2022 | L45/108 | 1560 | | 11/05/2021 12:00:00 AM |

| M4500050 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 28/06/1984 | 03/07/2026 | M45/50-I | 364.5 | I | 11/05/2021 12:00:00 AM |

| M4500382 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/07/1988 | 11/07/2030 | M45/382 | 58.24 | | 11/05/2021 12:00:00 AM |

| M4500886 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 22/03/2001 | 21/03/2022 | M45/886 | 6.81 | | 11/05/2021 12:00:00 AM |

| M4500887 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 22/03/2001 | 21/03/2022 | M45/887-I | 30.575 | I | 11/05/2021 12:00:00 AM |

| M4500049 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 28/06/1984 | 03/07/2026 | M45/49 | 85.95 | | 11/05/2021 12:00:00 AM |

| M4500924 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 26/03/2001 | 25/03/2022 | M45/924-I | 520.1 | I | 11/05/2021 12:00:00 AM |

| M4500383 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/07/1988 | 11/07/2030 | M45/383-I | 110.6 | I | 11/05/2021 12:00:00 AM |

| M4500925 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 26/03/2001 | 25/03/2022 | M45/925-I | 612.55 | I | 11/05/2021 12:00:00 AM |

| M4500950 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 11/07/2001 | 10/07/2022 | M45/950-I | 677.8 | I | 11/05/2021 12:00:00 AM |

| M4500949 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 11/07/2001 | 10/07/2022 | M45/949 | 804.15 | | 11/05/2021 12:00:00 AM |

| M4500254 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 19/10/1987 | 28/10/2029 | M45/254 | 77.97 | | 11/05/2021 12:00:00 AM |

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 18 |

| | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | | |

| M4500353 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 15/05/1988 | 18/05/2030 | M45/353 | 35.395 | | 11/05/2021 12:00:00 AM |

| M4500381 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/07/1988 | 11/07/2030 | M45/381 | 287.65 | | 11/05/2021 12:00:00 AM |

| M4500365 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 02/10/1988 | 09/10/2030 | M45/365-I | 206.6 | I | 11/05/2021 12:00:00 AM |

| M4500888 | Mining lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 22/03/2001 | 21/03/2022 | M45/888 | 12.755 | | 11/05/2021 12:00:00 AM |

| G4500290 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 22/01/2010 | 21/01/2031 | G45/290 | 9.945 | | 11/05/2021 12:00:00 AM |

| G4500291 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 22/01/2010 | 21/01/2031 | G45/291 | 9.677 | | 11/05/2021 12:00:00 AM |

| G4500321 | General purpose lease | Surveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/10/2011 | 04/10/2032 | G45/321 | 296.55 | | 11/05/2021 12:00:00 AM |

| L4500443 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/11/2018 | 04/11/2039 | L45/443 | 196.405 | | 11/05/2021 12:00:00 AM |

| L4500451 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/02/2019 | 04/02/2040 | L45/451 | 1.674 | | 11/05/2021 12:00:00 AM |

| R4500004 | Retention license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 21/07/2017 | 20/07/2022 | R45/4 | 2469 | | 11/05/2021 12:00:00 AM |

| L4500452 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 05/02/2019 | 04/02/2040 | L45/452 | 5.992 | | 11/05/2021 12:00:00 AM |

| L4500437 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 11/04/2018 | 10/04/2039 | L45/437 | 733.23 | | 11/05/2021 12:00:00 AM |

| L4500441 | Miscellaneous license | Unsurveyed | Live | Albemarle Wodgina Pty Ltd; Wodgina Lithium Pty Ltd | 21/11/2018 | 20/11/2039 | L45/441 | 0.82 | | 11/05/2021 12:00:00 AM |

Source: DMP, 2021

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 19 |

1.4Mineral Rights Description and How They Were Obtained

Mineral rights were obtained by the registrant through a joint venture agreement (JV) in 2018 between Albemarle Corporation and Mineral Resources Ltd when the registrant acquired a 60% interest in the Wodgina property to form the JV MARBL.

The mining lease tenements are retained through meeting the requirements set forth by the State of Western Australia, Department of Mines and Petroleum (DMP). Renewal applications are met for 12-month periods by providing justification to the DMP for reasons of renewal with accompanying rent payments.

1.5Encumbrances

SRK has relied upon the legal information regarding title provided by Albemarle as noted in section 25, and is unaware of any encumbrances upon the Wodgina property.

1.6Other Significant Factors and Risks

SRK is unaware of any significant factors or risks that may affect property access, title or the right to perform work on the Wodgina property.

1.7Royalties or Similar Interest

Table 3-2 represents the royalty and liabilities in-place for the Wodgina property.

Table 3-2: Summary Royalty and Liabilities.

| | | | | |

| Royalties/Liability | Details of Amounts Payable |

| Mine Rehabilitation Fund (MRF) Funding for Closure including payment offset obligations | Annual MRF levy $ 157,093.76 (1% of the Liability according to the MRF) Based on 653.46Ha Disturbance and 242.32Ha Rehabbed |

| Royalties payable under Pastoral and Native Title Agreements | $450,000 per annum payment owed to the Kariyarra People’s Trust (pursuant to Land Use Agreement for Wodgina Mine between the Karriyarra People and Gwalia Tantalum Pty Ltd dated 8 March 2001) We did not identify a royalty fee for the Wallareenya Pastoral Lease. |

| Royalties payable under Global Advanced Metals (GAM) Agreement | Royalties owed by Wodgina Lithium Pty Ltd (WLPL) to GAM: M 45/381 (WLPL to pay 1.75% royalty to GAM). M 45/382 M 45/383 M 45/886 (WLPL to pay 1.75% royalty to GAMG). Clause 2 of the Lithium Royalty Deed dated 8 September 2016 between Global Advanced Metals Wodgina Pty Ltd (GAMW), GAMG and Global Advanced Metals (GAM) provides that the Royalty payable by the Grantor (GAMW) to the Grantee (GAMG) will be 1.75% on Gross Revenue (in relation to Lithium extracted and recovered from processing the Tailings extracted from the Tailings Dam situated on the dam or reservoir situated on the area the subject of the Tenements) in respect of each Royalty Period (30/6, 30/9, 31/12, 31/3). |

Source: Personal Communication – MRL, 2021

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 20 |

4Accessibility, Climate, Local Resources, Infrastructure and Physiography

The Wodgina property lies approximately 110 km south-southeast of Port Hedland, Western Australia between the Turner and Yule Rivers. The area includes multiple prominent greenstone ridges up to 180 mamsl surrounded by granitic plains and lowlands. The center of the open cut mine at Mount Cassiterite is located at the latitude and longitude of -21° 11' 25"S, 118° 40' 25"E.

4.1Topography, Elevation and Vegetation

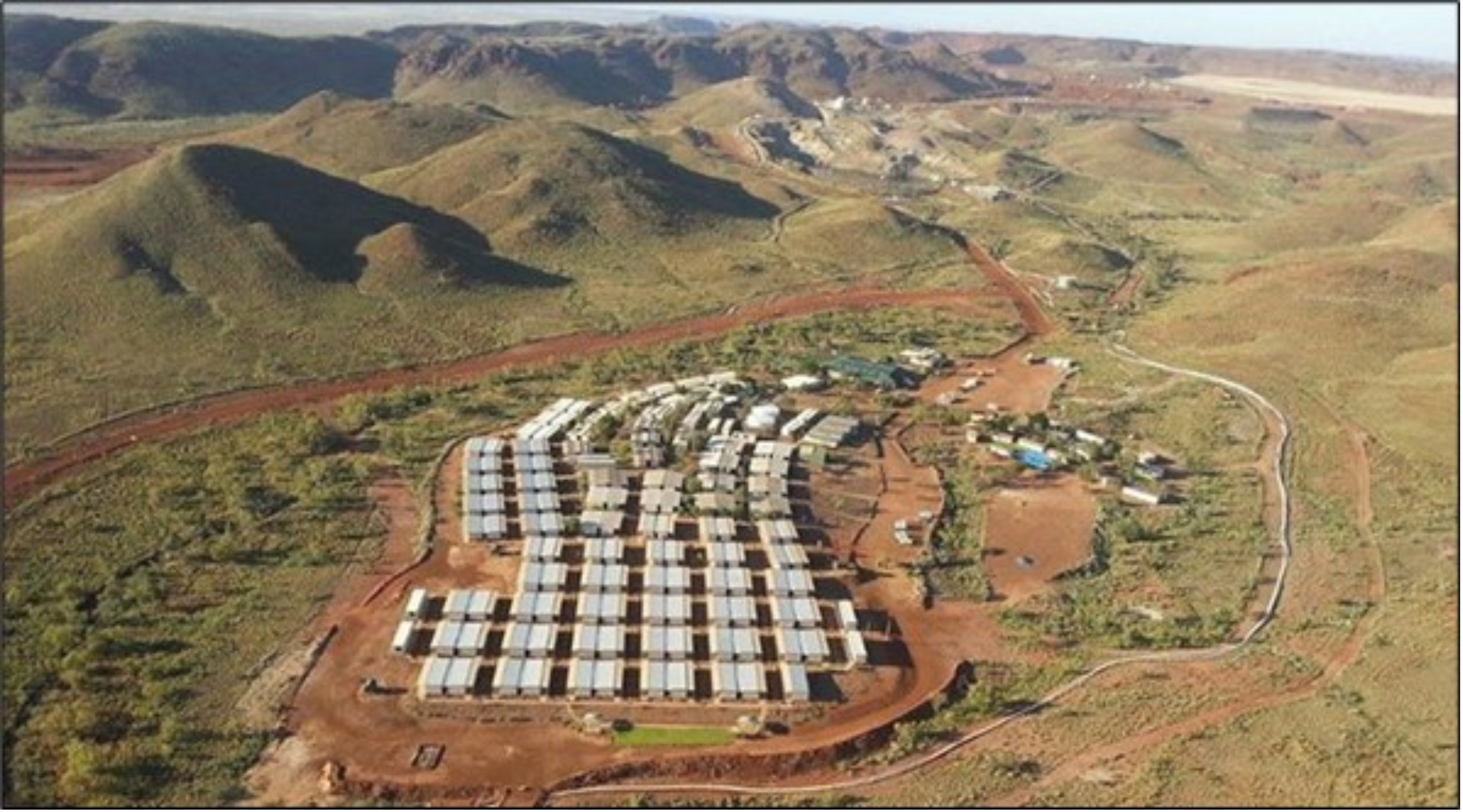

The topography onsite varies between 150 mamsl and 330 mamsl (500 ft and 1,100 ft) and is described as rolling hills and valleys. The vegetation onsite is considered a combination of grassland with spare shrubs with predominant species being Triodia basedowii and Triodia schinzii. The general topography and site elevation is demonstrated in Figure 4-1.

Source: Atlas Iron Ore, 2021

Figure 4-1: Oblique Aerial View of the Wodgina Camp Looking South to the Minesite

4.2Means of Access

The property is accessible via National Highway 1 to National highway 95 to the Wodgina camp road. All roads to site are sealed bitumen. The nearest large regional airport is in Port Hedland which also hosts an international deep-water port facility. A site dedicated all-weather airstrip is located onsite capable of landing A320 jet aircrafts.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 21 |

Source: Modified after MRL, 2018

Figure 4-2: Regional Road and Rail Infrastructure

4.3Climate and Length of Operating Season

The climate of the Wodgina property is categorized as a hot desert climate characterized by hot summers (average 40 to 45º Celsius [C]) and mild winters (average 20ºC). The majority of precipitation occurs during the summer months with annual averages around 300 millimeters (mm) per year (DPIRG, 2021).

Due to the hot to mild climate of the area, the Wodgina property maintains a year-round operating season.

4.4Infrastructure Availability and Sources

The Wodgina property has year-round availability of infrastructure; a water bore field, a natural gas pipeline, an accommodation camp, sealed road access, and a dedicated airstrip able to service A320 jets.

The property is currently in care and maintenance with site infrastructure available but not currently in-use. Equipment, infrastructure, and assets at the Wodgina property including the following:

•Three stage crushing plant capable of sustaining 5.65 million tonnes per annum (Mt/a) of ore feed to the Spodumene concentration plant

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 22 |

•Administrative and office buildings

•750-room accommodation camp on the property

•81 km long, 10-inch gas pipeline to site

•32 each 2-megawatt (MW) gas gensets for a total power station size of 64 MW

•Three mature and reliable water bore fields with minimal contaminant removal required

•All weather airstrip capable of landing A320 jet aircraft

•Extension of TSF3 for future tailing storage

4.4.1Water

Water is obtained from three dedicated water bore fields located on the property.

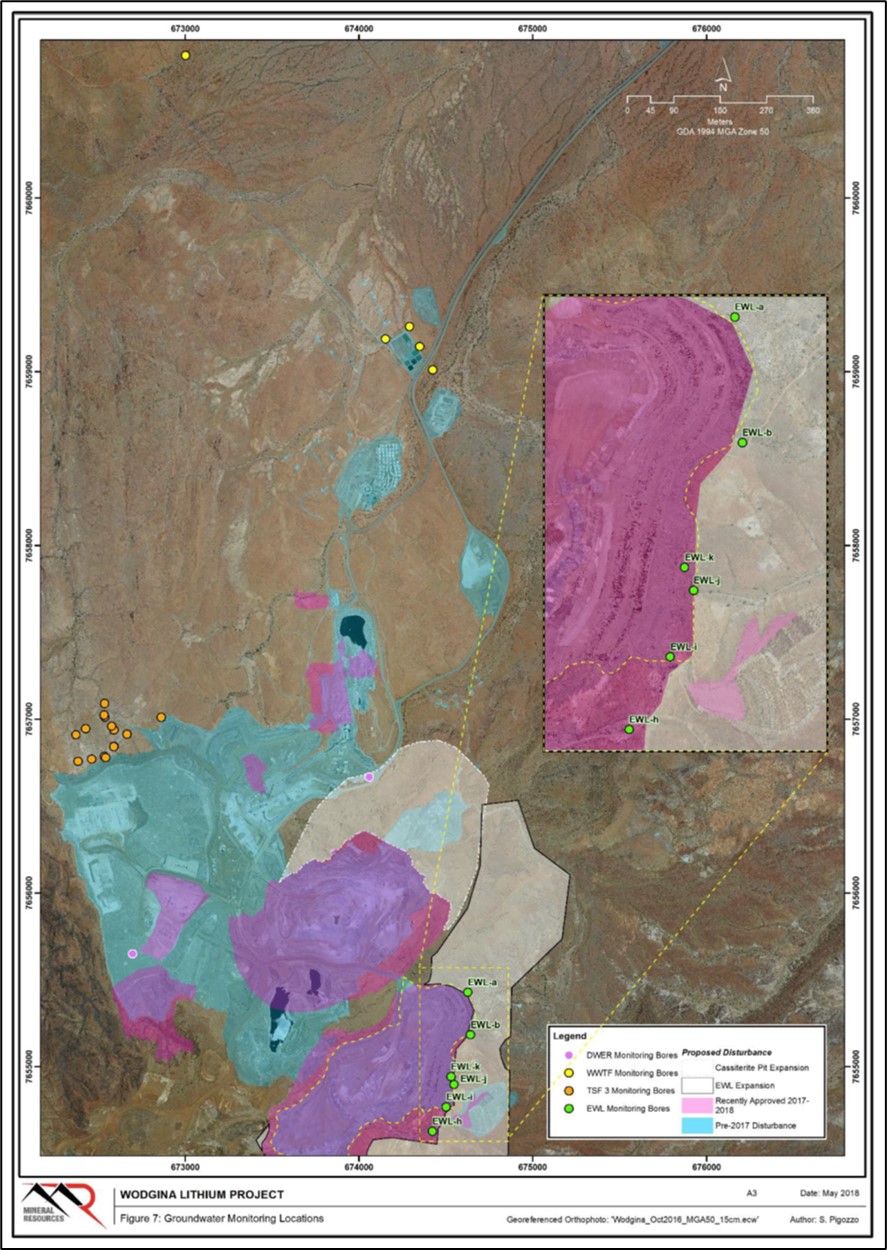

A series of monitoring bores are installed around the toe of the Eastern Waste Landform (EWL). These monitoring bores require monthly reporting on water levels and quarterly reporting on ambient groundwater quality and will continue to be monitored for any analytical signs that acid production is occurring within the waste landform.

Groundwater data for the EWL monitoring bores is only in its infancy for WLPL, monitoring was conducted from September 2017 through closure of the operation in November 2019. Data collected from these monitoring bores in the last year of the operation has been compared against Australian and New Zealand Environment and Conservation Council’s (ANZECC) livestock drinking water guideline. The only exceedance reported was for total dissolved solids (TDS), which is consistent with the natural variation in the area.

4.4.2Electricity

The Wodgina property has a dedicated 10-inch natural gas pipeline which runs from the Pilbara Energy pipeline to the property. The pipeline feeds the site power station which consists of 32 generator sets sized at 2 MW each with a total capacity of 64 MW. The natural gas pipeline was upgraded from 4-inch to 10-inch pipe in 2019.

4.4.3Personnel

The Wodgina property maintains a 750-room accommodation camp located on-site. Personnel access the camp via sealed highway or the on-site airstrip servicing a fly-in fly-out (FIFO) workforce based in a larger population area such as Perth.

4.4.4Supplies

The Wodgina property is supplied via road access well-maintained roadways or via the on-site airstrip.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 23 |

5History

The Wodgina pegmatite deposits were discovered in 1902. Since then, the pegmatite-hosted deposits have been mined for tin, tantalum, beryl, and lithium. Tantalum production began in 1905, with most early production sourced from alluvial and eluvial deposits.

Tantalite was discovered at the location in 1901 by Francis and William Michell, who subsequently mined 70 t of ore between 1905 and 1909. In the early part of the twentieth century, Tantalite was a rare commodity, and despite its remoteness, Wodgina supplied most of the world's Tantalite. In the early years of mining, the ore was carted by camel to the coast for export. Tantalite Ltd was formed by Lady Deborah V. Hackett-Moulden and N.S. Young. Tantalite Ltd mined the site between 1925 to 1943, exporting tantalite ore concentrate mainly to the United States.

In 1943, the mine was taken over by the Australian Government as part of its wartime effort. Tantalite concentrate continued to be exported to the United States, and in addition, during this period beryl was exported. In 1927, geologist E.S Simpson had identified large masses of cesium bearing white beryl at the northern end of the pegmatite.

After World War II, Tantalite Ltd, continued to operate the mine, however, by 1953 it had run out of funds, and the mine was sold to Northwest Tantalum Ltd. This company found its new purchase to be uneconomic and relinquished the lease by 1957. Between 1957 to 1963 the mine was operated by prospector L.J. Wilson. In 1963, the mine was purchased by J.A. Johnson and Sons Pty Ltd, by Avela in 1967, and by Goldrim Mining in 1968. Goldrim formed a partnership with Goldfield Corp (New York) and Chemalloy Minerals Ltd (Toronto).

The investigations into the pegmatite by this last JV discovered the new species Wodginite. Mining occurred sporadically until Goldrim formed a new partnership with Pan West Tantalum Pty Ltd, who began open pit mining at the site in 1989. By 1994, most of the pegmatite had been removed and mining ceased from the Wodgina Pit.

The Mount Cassiterite pit operations were established in 1989 and progressively expanded during the 1990s. A major expansion in 2002 increased the mine's capacity to 635 t of tantalum pentoxide (Ta2O5) per annum. The mining operation extracted tantalum bearing pegmatite ores from the Mount Cassiterite and Tinstone open pits. The ores were crushed, milled and fed into the Wodgina plant's advanced gravity separation. A primary tantalum concentrate is produced at Wodgina, and then sent to the Greenbushes mining operation for secondary processing to produce on-specification, saleable tantalum products. The mine was placed on care and maintenance in 2008, 2012, and most recently in 2019. The current owners of the Wodgina property are the JV MARBL. There is no active mining on the property at the time of this report.

5.1Previous Operations

The ownership of the Wodgina property has changed multiple time since initial mineralization discovery in 1902. Details of past owners have been compiled from various sources but remain incomplete and vague in terms of the details around ownership (Table 5-1).

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 24 |

Table 5-1: Ownership History of the Wodgina Property

| | | | | |

| Years | Owners |

| 1901 - 1909 | Francis and William Michell |

| 1925 - 1943 | Tantalite Ltd. |

| 1943 - 1945 | Australian Commonwealth government |

| 1945 - 1953 | Tantalite Ltd. |

| 1953 - 1957 | Northwest Tantalum Ltd. |

| 1957 - 1963 | L. J. Wilson |

| 1963 - 1967 | J.A. Johnson and Sons Pty Ltd. |

| 1967 | Avela |

| 1968 - 1989 | Goldrim Mining/Goldfield Corp |

| 1989 - 2001 | Goldrim and Pan West Tantalum Pty Ltd. JV |

| 2001 - 2005 | Sons of Gwalia |

| 2005 - 2009 | Talison Minerals |

| 2009 - 2016 | Global Advanced Metals (previously known as Talison Tantalum) |

| 2016 - 2019 | Mineral Resource Ltd. |

| 2019 | MARBL (JV between Mineral Resource Ltd. and Albemarle Corp.) |

Source: SRK, 2020 compiled from multiple publications.

5.2Exploration and Development of Previous Owners or Operators

There is no known documentation available related to historic exploration work on the Property. There have been numerous governmental and academic studies on the occurrences of pegmatite, variable mineralogy, and mineralization in the Wodgina pegmatite district. Work has included regional scale mapping by the Geological Survey of Western Australia (GSWA, 2001), scientific publications from Geoscience Australia, and various technical studies by the multitude of operating companies.

Exploration and development history for the property includes a variety of owners with sporadic production of multiple products over the life of the Wodgina property. Due to the complex nature of production and limited historic data available, the following represents a high-level account of production history on the property:

•Pre-1945: Various Producers: The Wodgina main load produced 85 t of beryl

•Pre-1984: Various Producers: The Wodgina main load produced 269 t of tantalum and an inferred 44 t of niobium

•Global Advanced Metals (GAM)/Talison: Mining was focused on in the Mt. Cassiterite Pit area

◦Prior to 1988: The Mt. Cassiterite pit area produced an estimated 308 t of tantalum, 193 t of tin, and 39 t of niobium

◦1988 to 1994: Wodgina main load pit ceased operation

◦Late 1990s into early 2000s: The Tinstone Pit commenced production

◦2001 to 2002: FY production of 442 t of Ta2O5 concentrate

◦2008: Mine placed in care and maintenance

◦2010 to 2011: Mining restarted

◦2012: Mine placed in care and maintenance

•Mineral Resources Ltd. operated the Mt. Cassiterite pit from April 2017 until November 2019

•MARBL was formed in late 2019 with the property immediately placed in care and maintenance after closure of the JV agreement.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 25 |

6Geological Setting, Mineralization, and Deposit

6.1Regional, Local and Property Geology

6.1.1Regional Geology

The Wodgina pegmatite deposits (including the historic Wodgina, Mount Cassiterite, and Tinstone pits) are hosted within the Paleoarchean East Strelley Greenstone Belt in the Pilbara Craton of Western Australia, located approximately 100 km S-SE of Port Hedland (Mount Cassiterite Pit at 21° 11' 25"S, 118° 40' 25"E).

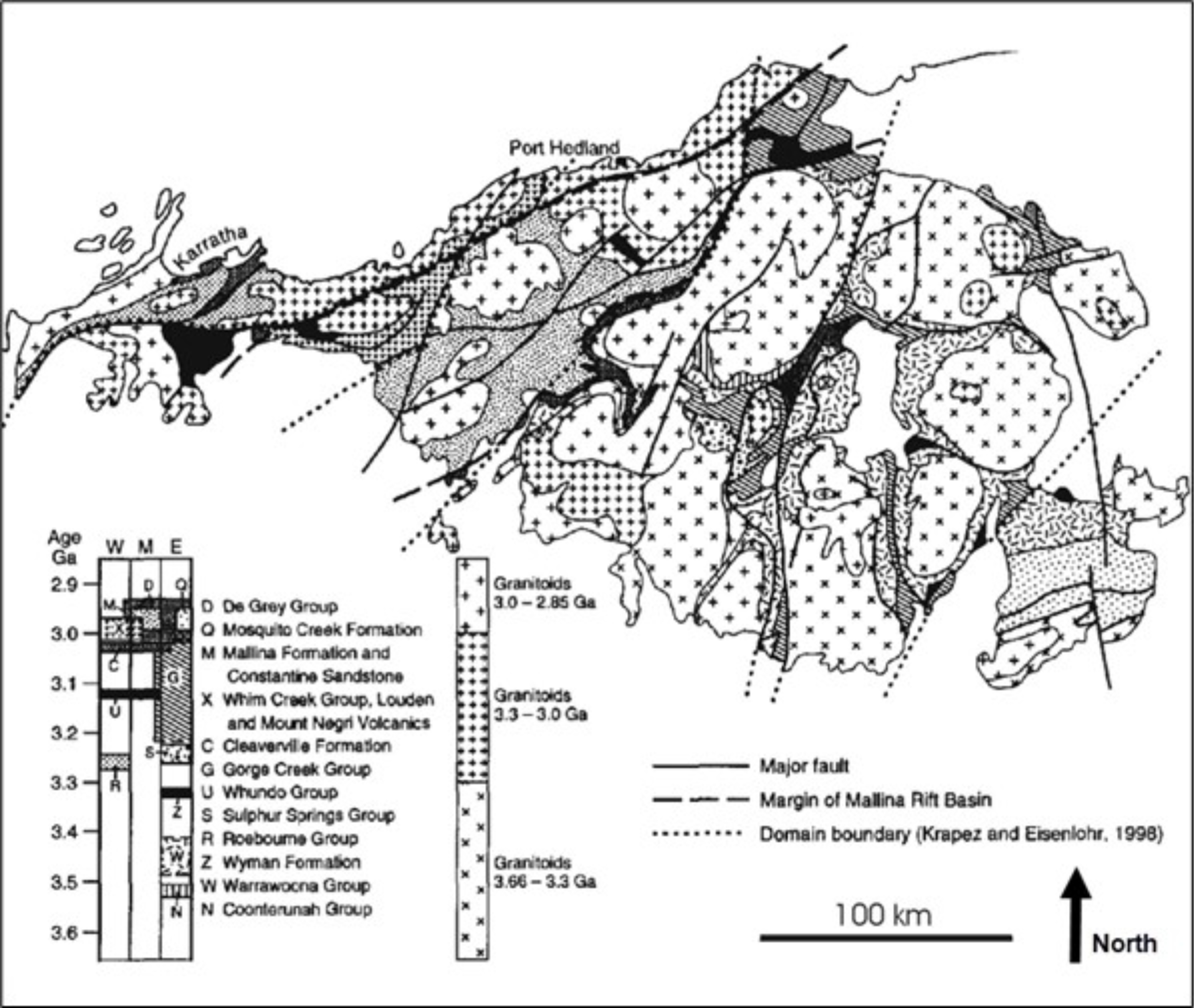

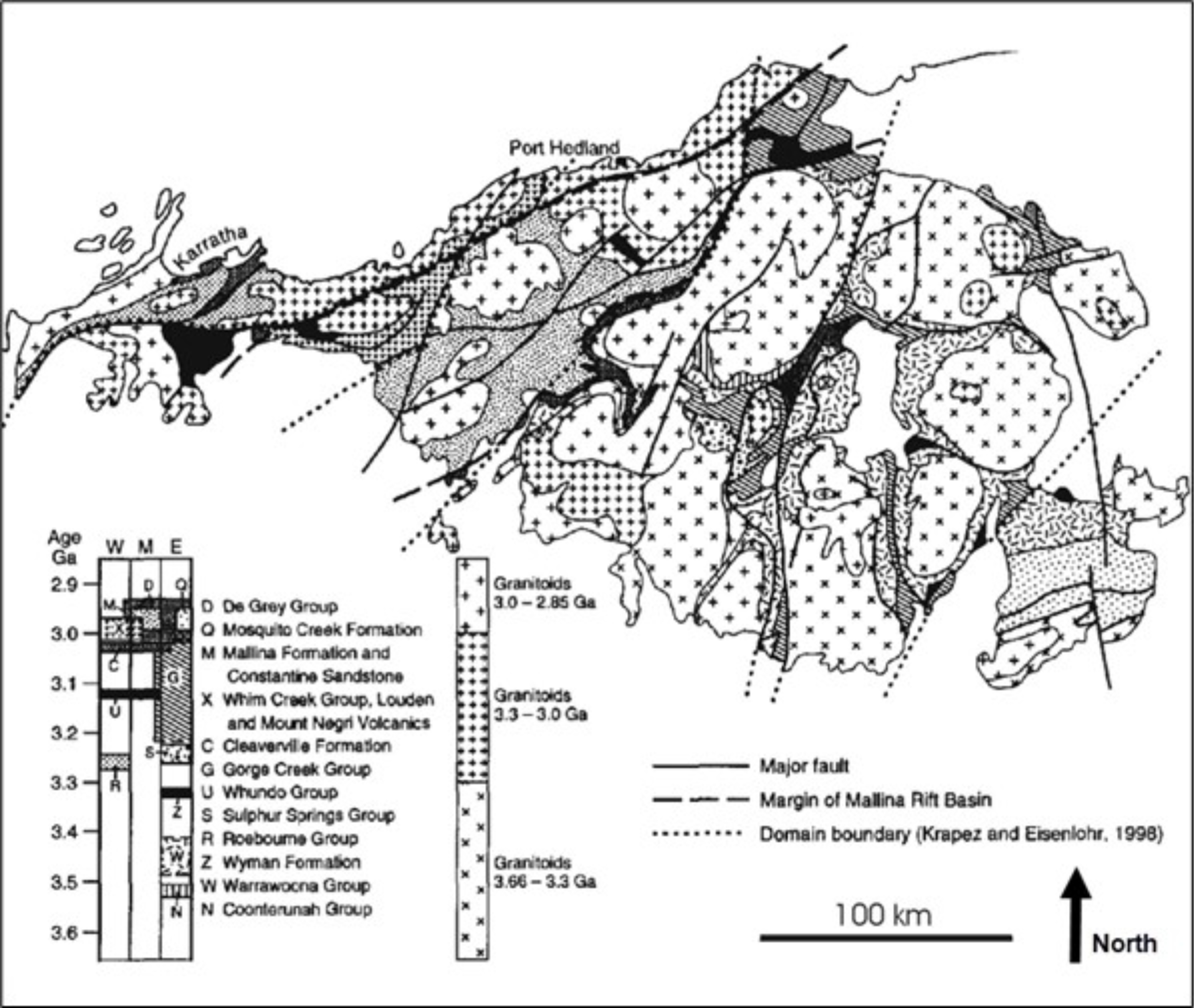

The Archean Pilbara Craton consists of large, domal, multiphase granitoid-gneiss complexes bordered by sinuous synformal to monoclinal greenstone belts (Hickman, 1983; Griffin, 1990; Barley, 1997). The greenstone belts range in age from approximately 3.56 to approximately 2.94 giga-annum (Ga), with the granitoids emplaced over a similar but slightly younger time span (e.g., Champion and Smithies, 1998). Although, the supracrustal rocks are structurally complex, the primary stratigraphic units may be correlated between greenstone belts (Hickman, 1983, 1990). The granitoid-greenstone terrane of the Pilbara Craton has been subdivided into tectonostratigraphic domains with boundaries defined by north northeast, south southwest (NNE-SSW) to northeast southwest (NE-SW) trending structural lineaments that regionally have a sinistral shear sense. The following lithotectonic units have been identified:

•East Pilbara granite-greenstone terrane

•Central Pilbara tectonic zone

•West Pilbara granite-greenstone terrane

At least seven episodes of granitic magmatism have been identified between 3.47 and 2.80 Ga. During this period, granitic magmatism became increasingly potassic and large ion lithophile element enriched, with increased compositional variability from tonalite-trondhjemite granodiorite to calc-alkaline and alkaline granite compositions due to cyclic crustal reworking and growth (Champion and Smithies, 1998). Most of the granitoid-gneiss complexes have tectonic margins, with little evidence of contact metamorphism of adjacent supracrustal sequences (Hickman, 1983). Granitic magmatism culminated with emplacement of a suite of 2.89 to 2.83 Ga granite plutons at (e.g., Blockley, 1980; Pidgeon, 1984; Bickle, et al., 1989; Smithies and Champion, 1998, 2001) and a 2.76 Ga suite of small A-type granites and stocks of tourmaline rich S-type peraluminous granites (Smithies and Champion, 1998). There is good spatial, geochemical, and geochronological evidence to link rare metal pegmatites in the Pilbara Craton with emplacement of the younger granite suite (e.g., Blockley, 1980; Kennedy, 1998; Kinny, 2000; Sweetapple, et al., 2000). Figure 6-1 shows the regional geology map.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 26 |

Source: Sweetapple, 2000

Source: Sweetapple, 2000Figure 6-1: Regional Geology Map

6.1.2Local Geology

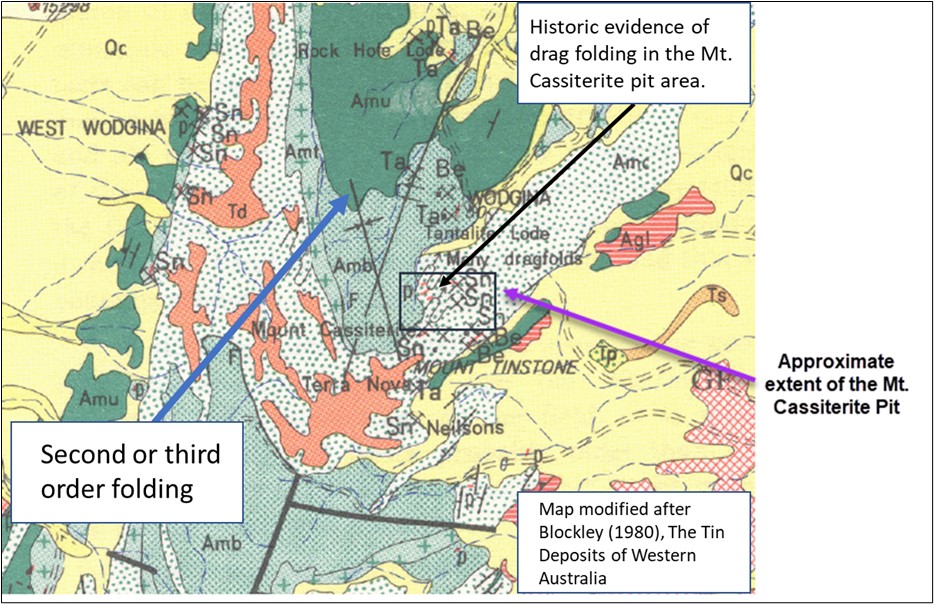

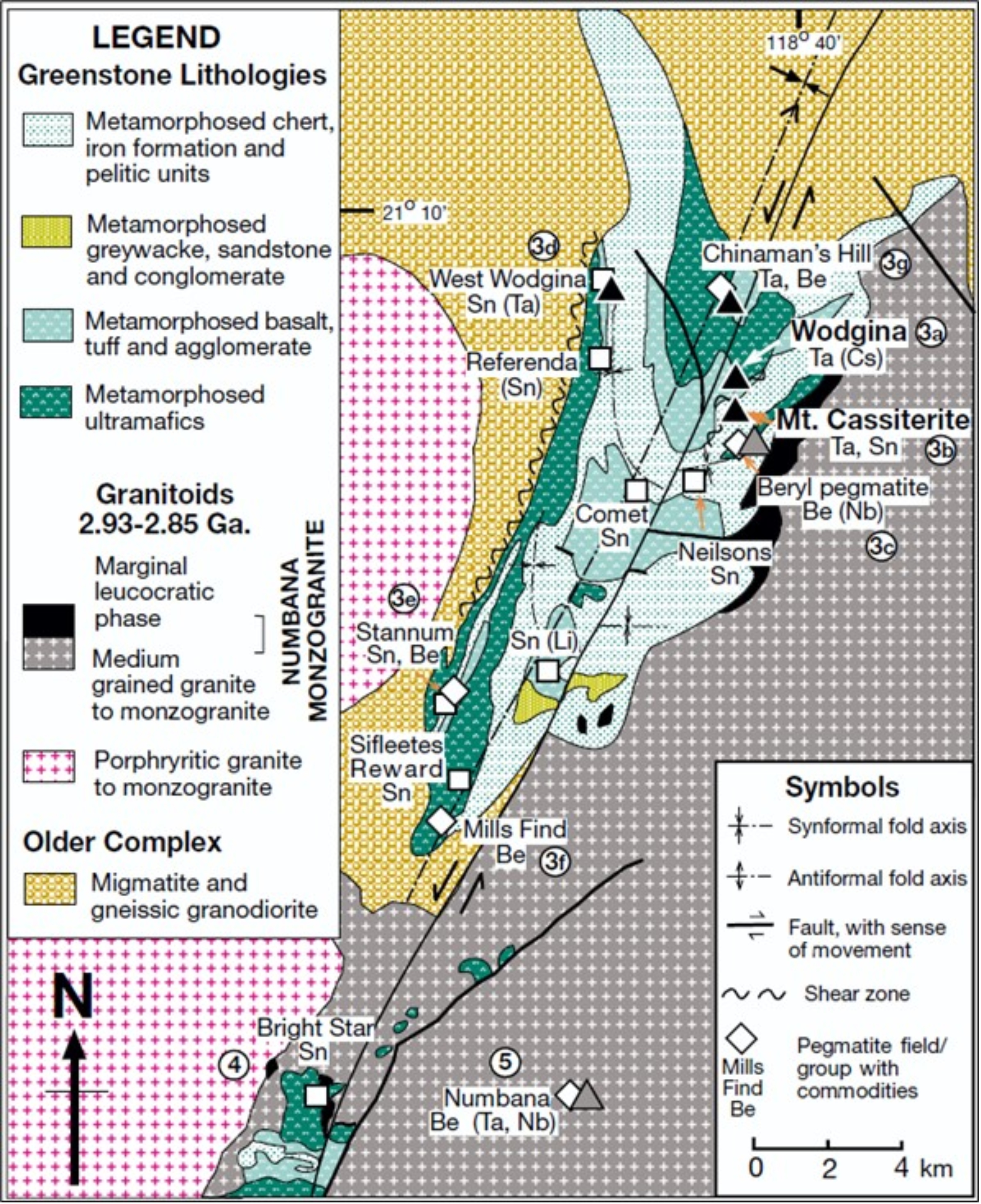

The property is located within the Wodgina Pegmatite District. This pegmatite district is entirely hosted in the eastern limb of the Wodgina greenstone belt along the southern portion of the Wodgina-Strelly lineament. This greenstone belt is a north-northeast plunging synform separating the Yule and Carlindi granitoid complexes within Central zone of the Pilbara Craton (Figure 6-1).

The Wodgina greenstone belt consists of mafic-ultramafic volcanics, sedimentary, and intrusive rocks, including ultramafic komatiites, mafic basalt, clastic sedimentary rocks, banded iron formation (BIF), and cherts. All rocks within the belt have undergone greenschist to lower amphibolite facies metamorphism at relatively low pressures (Sweetapple and Collins, 2002). A younger leucocratic granitoid of the Numbana Monzogranite is present on the eastern margins of the Wodgina greenstone belt.

Structurally, the Wodgina greenstone belt forms the core of a north-plunging synform. The Wodgina and Mt. Cassiterite deposits are located near the axis of the synform and near a left-lateral (sinistral) shear zone adjacent to the marginal leucocratic phase of the Numbana Monzogranite. It is

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 27 |

composed principally of interlayered mafic and ultramafic schists and amphibolite, with subordinate komatiite, clastic sediments, BIF and chert. The komatiitic and metasedimentary units within the Wodgina area are tentatively correlated to the Kunagunarrina and Leilira Formations respectively.

Archean volcanic activity and sedimentation was followed by the intrusion of Archean granitic batholiths with consequent deformation and metamorphism of the sequence. Late-stage granitic intrusions resulted in the emplacement of simple and complex pegmatite sills and barren quartz veins.

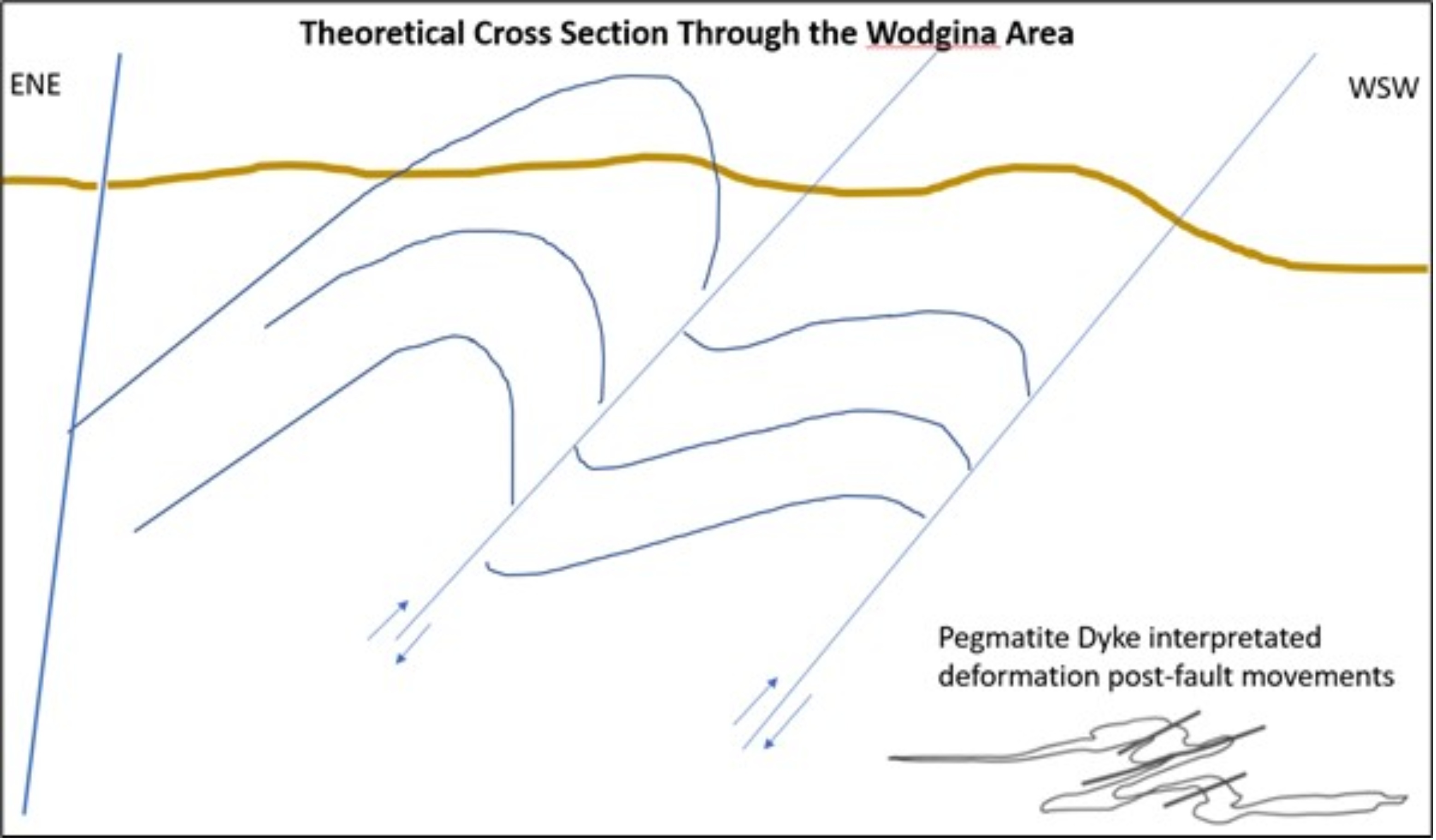

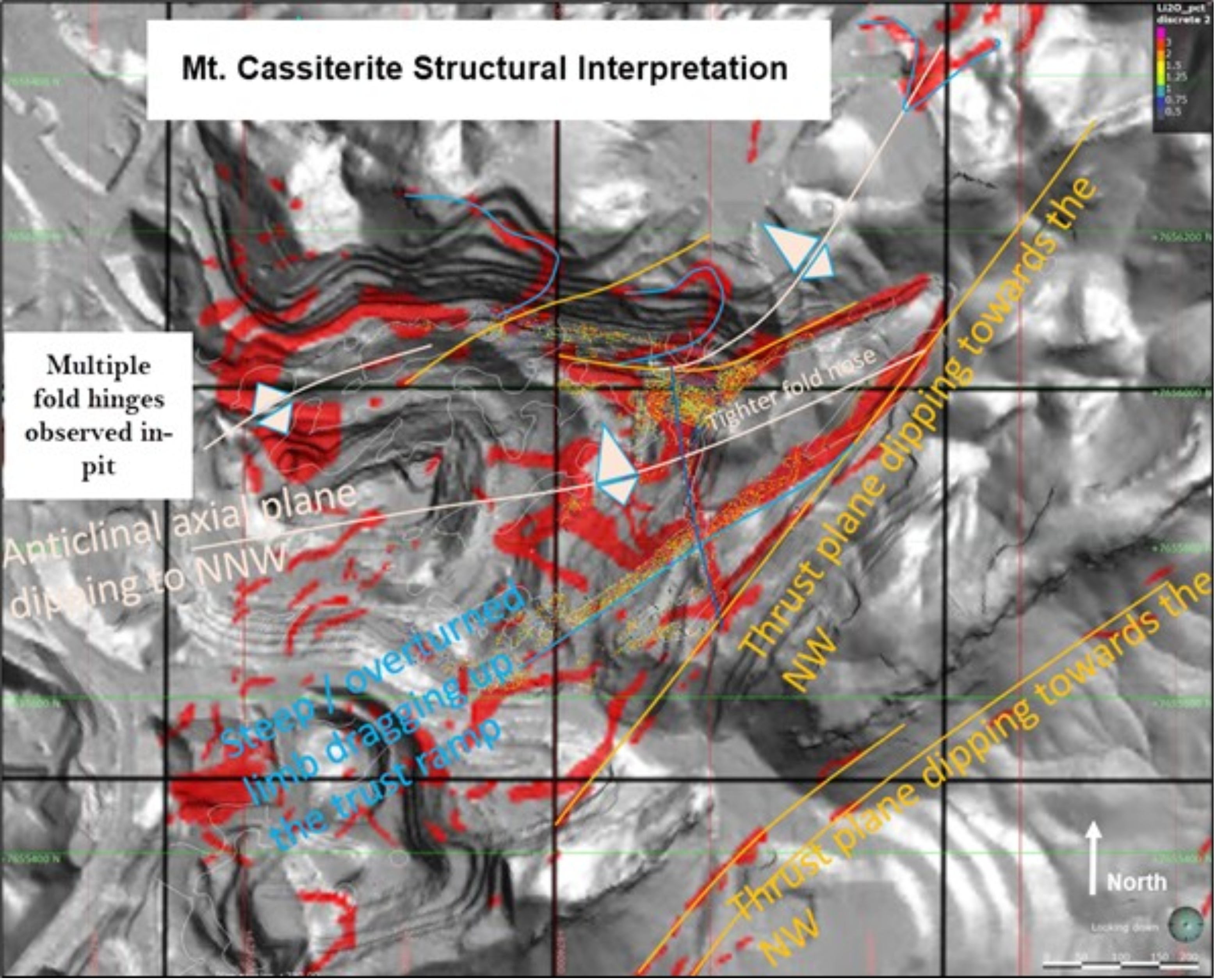

A major regional shear zone separates the two main pegmatite groups at Wodgina and Mt. Cassiterite. Both pegmatite groups have been emplaced syntectonically into fault/shear zones, with a predominantly reverse sense of movement. This emplacement has been related to a semi-concordant control of pegmatite distribution in both areas by F2 fold hinges and limbs. The Wodgina main lode pegmatite appears to be related to a major inclined fold hinge, while the pegmatites of the Mt. Cassiterite group appear to be sheets joined by a number of parasitic fold hinges.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 28 |

Source: Sweetapple and Collins, 2002

Figure 6-2: Local Geology Map of the Wodgina Pegmatite District

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 29 |

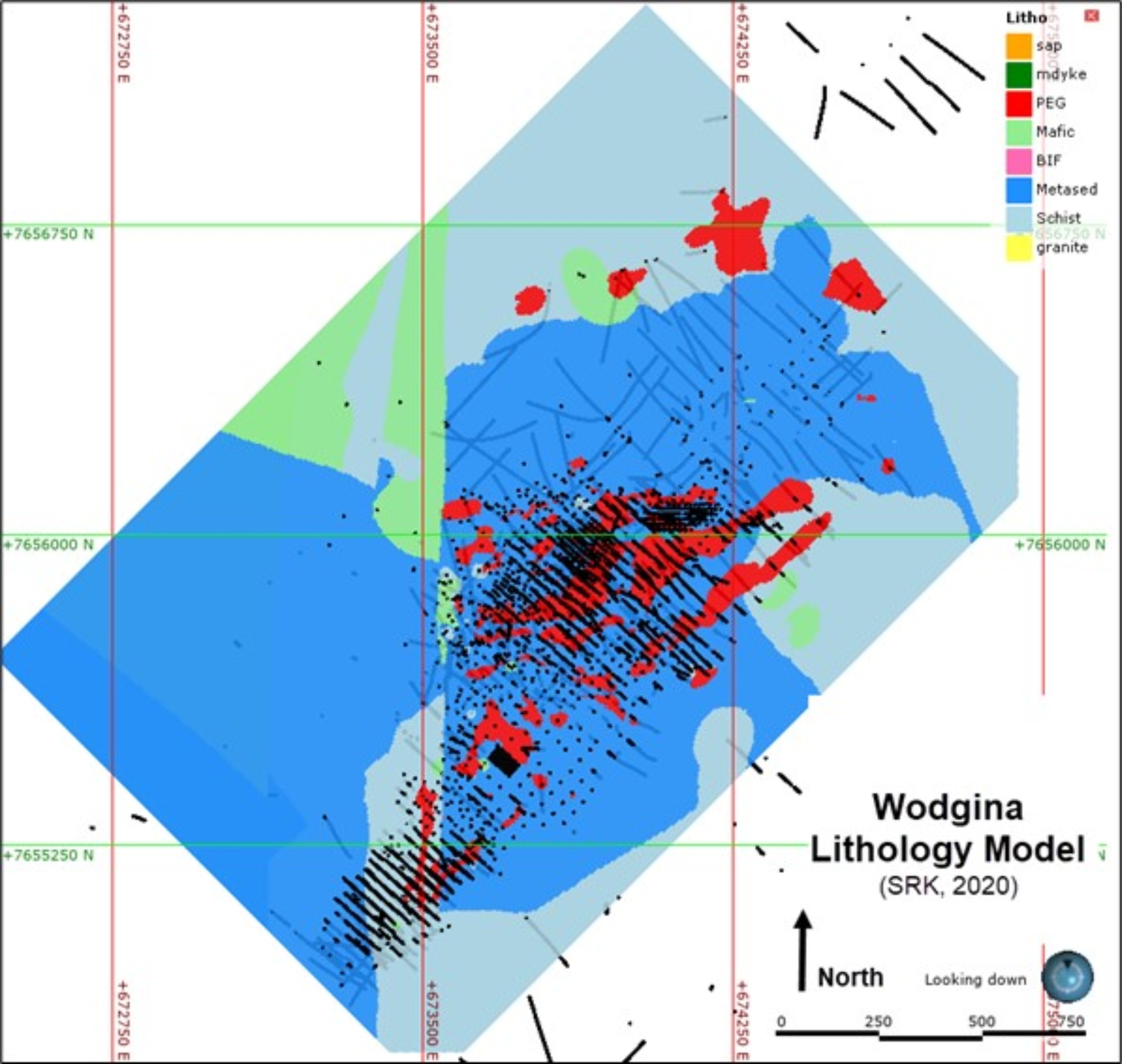

6.1.3Property Geology

The property geology has been broken into two primary areas:

•The Cassiterite area containing the Mineral Resources of the Mt. Cassiterite Pit and the North Hill area

•The historic production area of the Wodgina pit located in the northern portion of the property.

There are distinct differences in whole rock geochemistry between the two different pegmatite suites (Sweetapple and Collins, 1998) (Figure 6-2). The Wodgina pegmatite has a higher niobium: tantalum ratio than Mt. Cassiterite, which has a higher tin: tantalum ratio. These differences are reflected in the two different tantalum mineral suites in each pegmatite group. Significant differences were also noted in the gallium and beryllium contents, which were enriched and depleted respectively, in the Wodgina main lode pegmatite relative to the Mt. Cassiterite pegmatite group. The mineral assemblages in both pegmatite groups have undergone a significant degree of subsolidus recrystallisation (Sweetapple and Collins, 1998).

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 30 |

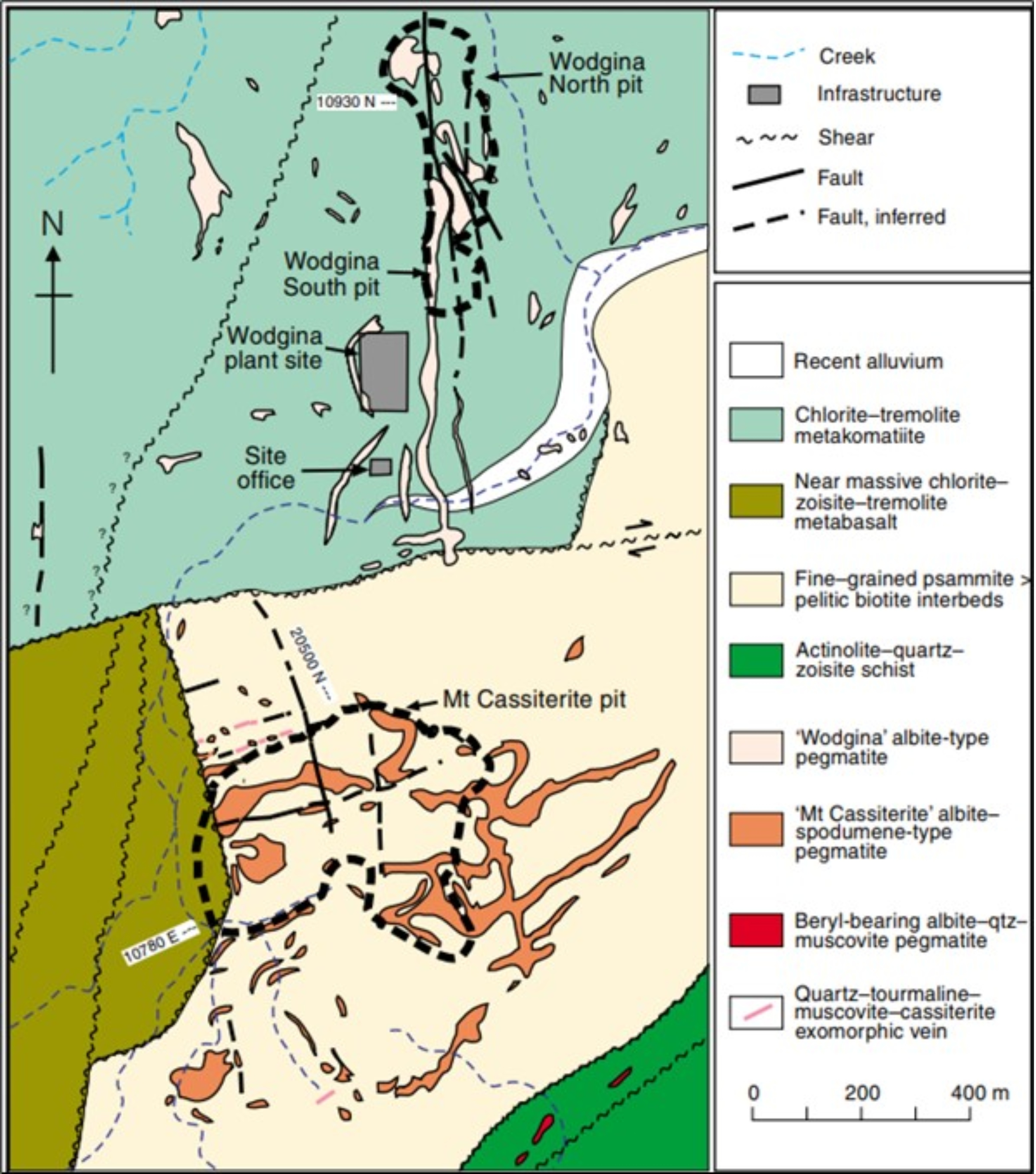

Source: Sweetapple, 2001

Figure 6-3: Wodgina Property Geology Map

Mt. Cassiterite Pegmatite Group

These pegmatites lie directly to the south of the Wodgina group and cover an area of approximately 1.1 by 0.8 km (Figure 6-4). They comprise a series of interlinked pegmatite sheets, dikes and irregular offshoot structures, and in contrast to the Wodgina group, have been emplaced within a thick formation of metasedimentary rocks, mostly composed of fine-grained psammite and thinly interbedded pelite with minor quartzite and chert (Sweetapple et al., 2001). Immediately north of the

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 31 |

Mt. Cassiterite pit, pegmatites have been intercepted from drilling hosted in amphibolite schist and generally display thicker individual pegmatite dikes with different chemistries than those observed and previously mined in the metasediments-hosted pegmatite sheets of the Mt. Cassiterite pit.

Within the Mt. Cassiterite pit, multiple sets of stacked pegmatite sheets occur, mostly 5 to 12 m thick, but ranging from 2 to 100 m and generally dipping 20 to 25°SE with localized 'roll-overs' dipping at 15 to 20°W to SW. These sheets are interconnected by near-vertical dikes that trend NW-SE and NE-SW, by irregular keel-like structures, and by thin stringers of pegmatite, all of which were emplaced at the same time. These pegmatite sheets were apparently syntectonically emplaced into a series of thrust faults that postdate at least two earlier deformation events identified by prominent cleavages and folding in the host metasedimentary rocks (Sweetapple and Collins, 2002).

Mount Cassiterite pegmatite appear to have a primary mineralogy and texture characteristic of albite-spodumene-type pegmatites, including an abundance of albite and primary spodumene with subordinate K feldspar and minor muscovite in near homogeneous sheeted bodies. The pegmatite sheets display a massive to comb-textured internal structure which Sweetapple and Collins (2002) regard as also being characteristic of albite-spodumene type pegmatites (Ginzburg and Lugovski, 1977; Cerny, 1992), with minor aplitic and K feldspar-rich layering.

These sheets are mostly unzoned, with a mineralogy dominated by megacrystic spodumene and perthitic microcline in a matrix of fine- to medium-grained quartz, albite and muscovite. Spodumene crystals are mostly aligned nearly perpendicular to the pegmatite contacts, typically exhibiting distinctive 'pull apart' structures. A weak zonation is evident as the development of finer grained border units, and occasional areas rich in microcline crystals.

Secondary assemblages, dominantly composed of fine-grained albite, variably overprint the assemblage outlined above in most areas of the pegmatite sheets. This alteration developed an accompanying pseudo-gneissic textured banding and syn-tectonic deformational textures. Cataclastic and proto-mylonitic textures are evident in places in the pegmatites. However, the micaceous minerals of the banding do not display a true schistosity, suggesting final crystallization of the pegmatite took place under hydrostatic stress conditions, after the termination of deformation association with emplacement (Sweetapple, 2000).

North Hill Pegmatite Group

These pegmatites lie directly to the north of the Mt. Cassiterite group under the area known locally as North Hill. Details on the mineralogy, chemistry, and association of these pegmatites is largely unknown but may represent a continuum of pegmatite emplacement between Mt. Cassiterite and the Wodgina Pegmatite Group to the north. This group has been identified through drilling in the North Hill area with various interpretations of the geometry and continuity over the years. Because no structural data to date has been collected in the area, the orientation is largely speculative.

The North Hill Pegmatite Group is hosted in a primary schist lithology, though logging varies greatly in the area. It is unknown whether the host lithology is complex, or the historic data is merely unreliable. This pegmatite group generally exhibits lower Li2O grades than in the Mt. Cassiterite area, along with displaying materially larger thicknesses than observed in the Mt. Cassiterite Pit. Internal pegmatite banding and mineralogy is largely unknown as evaluation and exploration activities in this Group have been conducted by reverse circulation (RC) drilling methods with analyses focused on chemistry and not mineralogy. Trace geochemistry of the North Hill Pegmatite Group varies from the

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 32 |

Mt. Cassiterite deposit located immediately to the south. It is inferred by MARBL that the primary Li mineralogy is spodumene. Although the general geochemistry of the area can be characterized by the current RC dominant drilling, deficiencies in the mineralogical characterization, metallurgical testwork, and other factors relevant to economic evaluations remain risks to the understanding of the viability of the pegmatites to support mining and processing in the North Hill area.

Wodgina Pegmatite Group

This group includes the Wodgina main lode pegmatite, plus several smaller pegmatites that are mostly subparallel to the main structure (Figure 6-3). They are characterized by an abundance of cleavelandite and/or sugary albite and are almost entirely hosted by variably foliated metakomatite. The Wodgina pit has historically exploited the Wodgina Main Lode pegmatite and associated secondary pegmatites for tantalum. The current economic focus on the property is for Li resources, whereas the Wodgina pegmatite group hosted Li as minor lepidolite and associated Li-bearing micaceous minerals.

The Wodgina main lode pegmatite is a sheeted dike that trends north-south, dips at 20 to 50° east (E), and cuts across the foliation of the host rock, which strikes north-south to NE-SW, and dips to the west. This pegmatite has a total strike length of approximately 1 km and varies from 5 to 40 m in thickness. However, most mining has been confined to the northern 500 m, where the pegmatite segments are thickest. Small offshoots of the pegmatite are subparallel to the foliation of the metakomatite host rocks.

The pegmatite postdates most of the deformation of the Wodgina greenstone belt and was apparently partially controlled by pre-existing folding and faulting. It is cut by late steeply dipping normal faults, while the northern end was disaggregated by later dip-slip faulting and late strike-slip shearing (Sweetapple et al., 2001). The northern portion of the pegmatite body has also been observed to be intruded around the hinge zone of an asymmetric fold, and its associated long limb (Sweetapple, 2000). While the pegmatite has a general easterly dip, it varies from a dike in the south, to a large bulbous mass with a saddle shape that pinches out rapidly into thin angular sheets in the north.

Although pegmatite zonation typical of highly fractionated pegmatites is not well developed in the Wodgina main lode, the zonation that is developed, takes the form of two main compositional assemblages in primary layers that subparallel contacts, as: i). layers of massive cleavelandite (a variety of albite) with rare quartz, spessartine and muscovite on both the footwall and hanging wall of the dike, and ii). a broad central unit of banded aplitic to granitic-textured medium to coarse grained albite-quartz-muscovite ±megacrystic perthitic microcline.

These assemblages are less regularly distributed on the northern end of the dike. The central bulbous section of the main dike contained a large irregular segregation of massive quartz up to 50 m wide and 60 m long. Ellis (1950) noted that the cleavelandite units appear to locally intrude the aplitic/granitic textured unit.

The marginal cleavelandite assemblage zones in the hanging wall and footwall are partially overprinted by a secondary fine-grained sugar-textured albite ±muscovite assemblage, and by lepidolite ±albite alteration of the micaceous aplitic-granitic textured unit. An intense 5 to 30 centimeter (cm) thick concentration of exomorphic mica was developed on the contacts with the wall

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 33 |

rocks (Sweetapple, 2000). Hall (1988) notes discrete units rich in beryl, spodumene and fluorite associated with these secondary overprints.

This tantalum mineralization is almost always within the massive cleavelandite units, commonly occurring in the core of radial aggregates of cleavelandite, and frequently as coarse skeletal-textured manganotantalite crystals clustered at the base of the hanging wall massive cleavelandite unit, suggesting precipitation and gravitational settling from that massive unit (Sweetapple, 2000).

The Wodgina main lode pegmatite is characterized by high-grade tantalum mineralization, and the presence of secondary lepidolite, or lithian muscovite, is consistent with it being an extremely fractionated pegmatite (Sweetapple et al., 2001). The primary cleavelandite and secondary albite units constitute approximately 78 vol.% of the pegmatite. The bulk composition of the pegmatite is more sodic and less silicic than most other rare metal pegmatites, consistent with the albite type of Cerny (1993). Other albite-enriched pegmatites close to the Wodgina main lode pegmatite are also considered to be of the albite type, as they have similar internal structure and modal mineralogy. Sweetapple and Collins (2002) suggest the low contents of rare alkali elements and volatile elements such as boron (B), Phosphorus (P), fluorine (F), and higher magnesium (Mg) and iron (Fe) values than other rare metal pegmatites are most likely to be the result of extensive ion exchange with the metakomatite wall rock. The same authors suggest it provide field evidence for the separation of a residual sodic melt enriched in lithophile elements escaping from crystallizing semi-consolidated albite-spodumene pegmatite sheets at Mount Cassiterite and appear to represent a regional zonation relationship.

6.2Mineral Deposit

The Mt. Cassiterite pegmatite group is classified as a rare element albite-spodumene type pegmatite. Spodumene (LiAlSi2O6) is the primary lithium-bearing mineral. It is massive to weakly layered pegmatite with comb-textured megacrystic microcline and spodumene with aplitic layers often displaying pseudo gneissic banding. Unlike many other Pilbara Craton pegmatite bodies, the Wodgina and Mt. Cassiterite pegmatites tend to not display internal structure such as mineralogical layering or banding. Lithium minerals are predominantly spodumene and lepidolite with secondary tin (Sn) in microlite, and manganese (Mn) in tantalite and columbite calciotantite. Other significant minerals include spessartine (Mn aluminosilicate garnet), elbaite (Na-Li alumino-boro-silicate tourmaline) and native Bi.

Geochronological work at the Wodgina deposit using various dating techniques (Rb-Sr, K-Ar, and Pb/Pb SHRIMP) provide pegmatite emplacement dates around 2,800 mega annum (Ma). This timing and other relationships suggest the likely source for the Wodgina pegmatites to be the Numbana Monzogranite.

The pegmatites at Wodgina have a semi concordant relationship to regional-scale parasitic folding (Sweetapple and Collins, 2002). Differences between the emplacement nature of the Wodgina and Mt. Cassiterite dykes appear to be controlled largely by the host rocks. The large discrete Wodgina “main lode” pegmatite is hosted in mafic-ultramafic sequence (metakomatite) compared to the smaller dike swarm at Mt. Cassiterite which is hosted within a metasedimentary (meta-arenite/psammite) sequence (Sweetapple, 2000). In addition to the main spodumene pegmatite dikes, smaller (less than 0.5 m thickness) veins and/or alternation of wall rock contain pegmatite-related

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 34 |

mineralogy of quartz-tourmaline-mica-albite-cassiterite. These secondary features often occupy parallel fractures adjacent to the main dike swarms.

At this time, individual pegmatites vary in strike length from approximately 200 m to 400 m. The thinner near surface pegmatites vary from 10 m to 30 m in thickness but vary locally from less than 2 m to up to 35 m thick. The massive basal pegmatite varies from 120 m to 200 m thick. The pegmatites intrude the mafic volcanic and meta-sedimentary host rocks of the surrounding greenstone belt.

The lithium in the Cassiterite Pit and shallower pegmatites occurs as 10 to 30 cm long grey, white spodumene crystals within medium grained pegmatites comprising primarily of quartz, feldspar, spodumene and muscovite (Figure 6-4 and Figure 6-5). Typically, the spodumene crystals are oriented orthogonal to the pegmatite contacts. Some zoning of the pegmatites parallel to the contacts is observed, with higher concentrations of spodumene occurring close to the upper contact. In the massive basal pegmatite, the spodumene is distributed within fine-grained quartz, feldspar, spodumene and muscovite matrix.

Source: MRL, 2018

Figure 6-4: Wodgina Outcropping Pegmatite Example, Visible Spodumene Crystals

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 35 |

Source: MRL, 2018

Figure 6-5: Wodgina Pegmatite Grey White Spodumene Crystals (Specimen Around 30 cm Long)

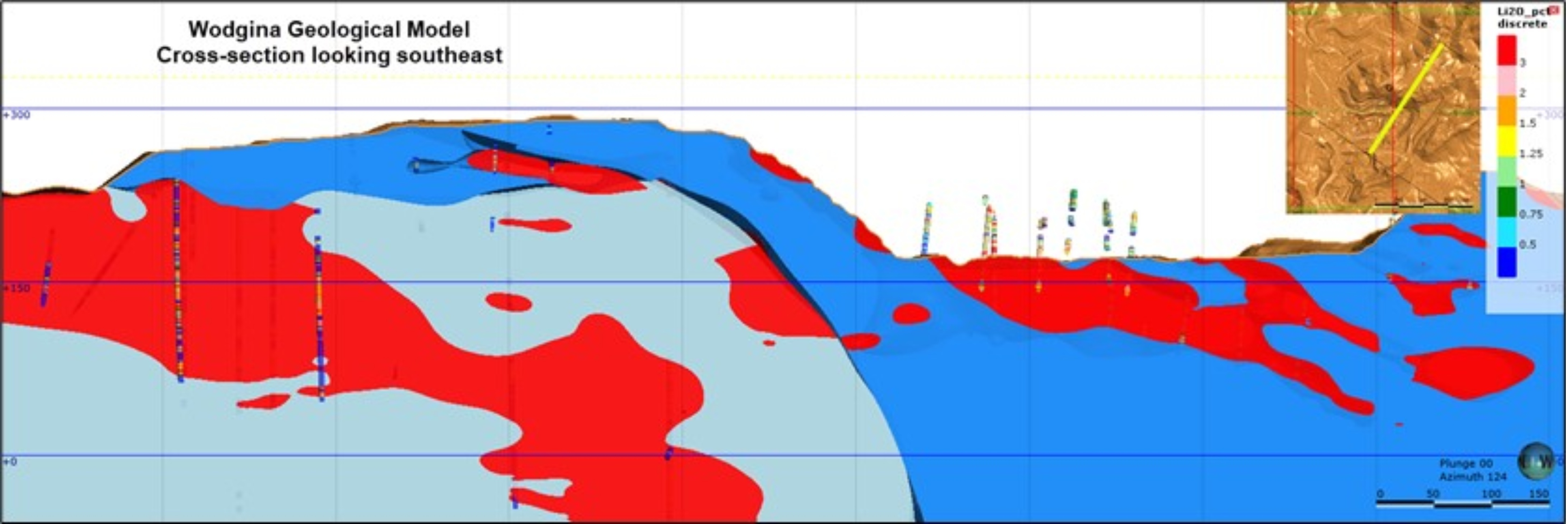

6.3Stratigraphic Column and Local Geology Cross-Section

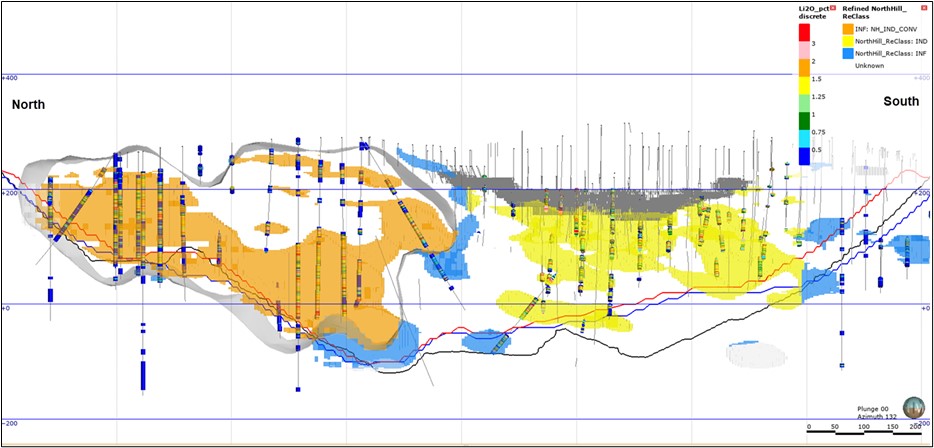

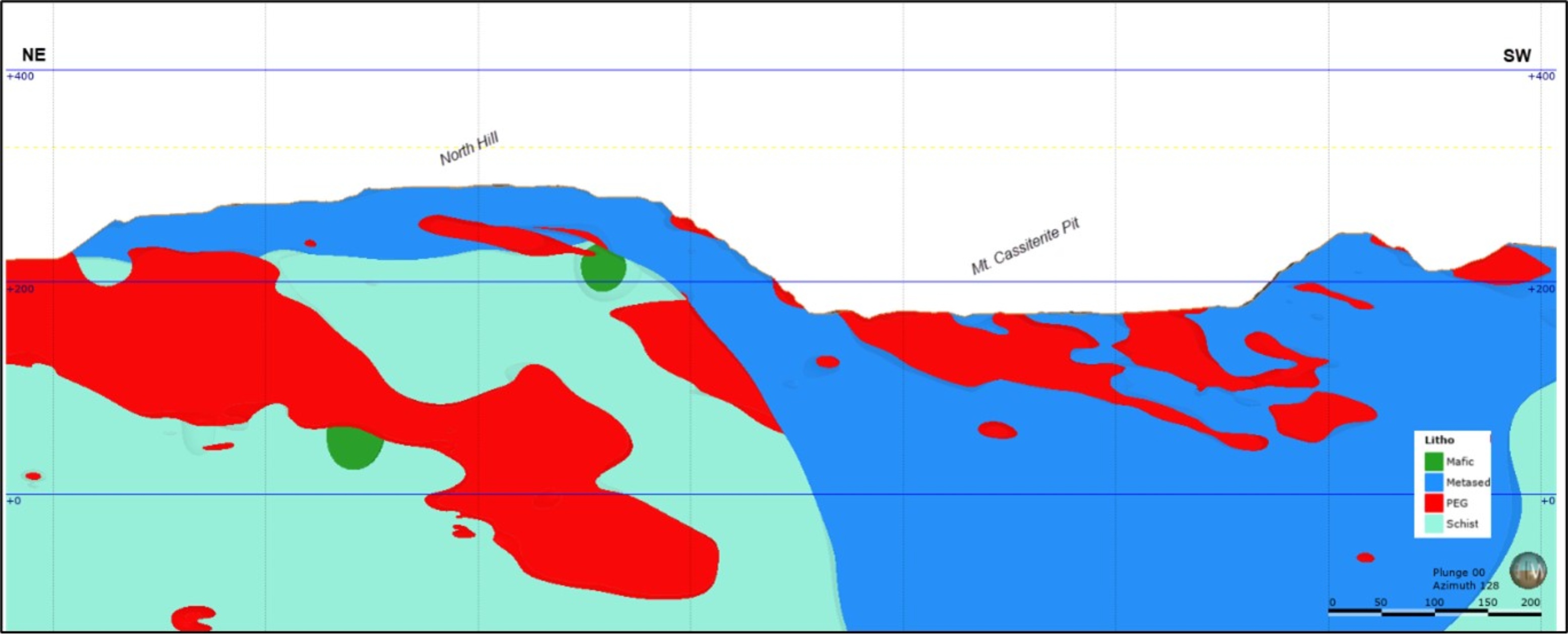

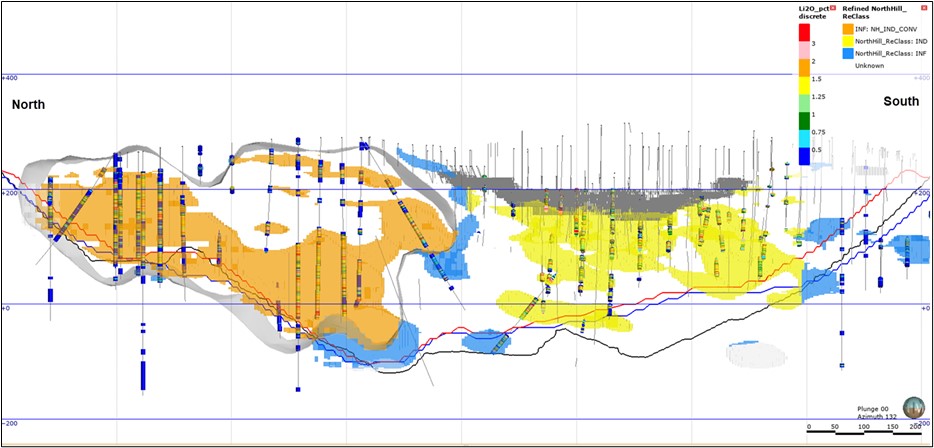

Figure 6-6 shows a generalized long-section of the North Hill - Mt. Cassiterite area containing the extents of Mineral Resources on the property. The long section shows the transition from amphibolite schist-hosted Li-pegmatites to metasedimentary-hosted Li-pegmatites in the Mt. Cassiterite Pit area.

Source: SRK, 2020

Figure 6-6: Long-Section from Northeast to Southwest across the Main Portion of the Deposit

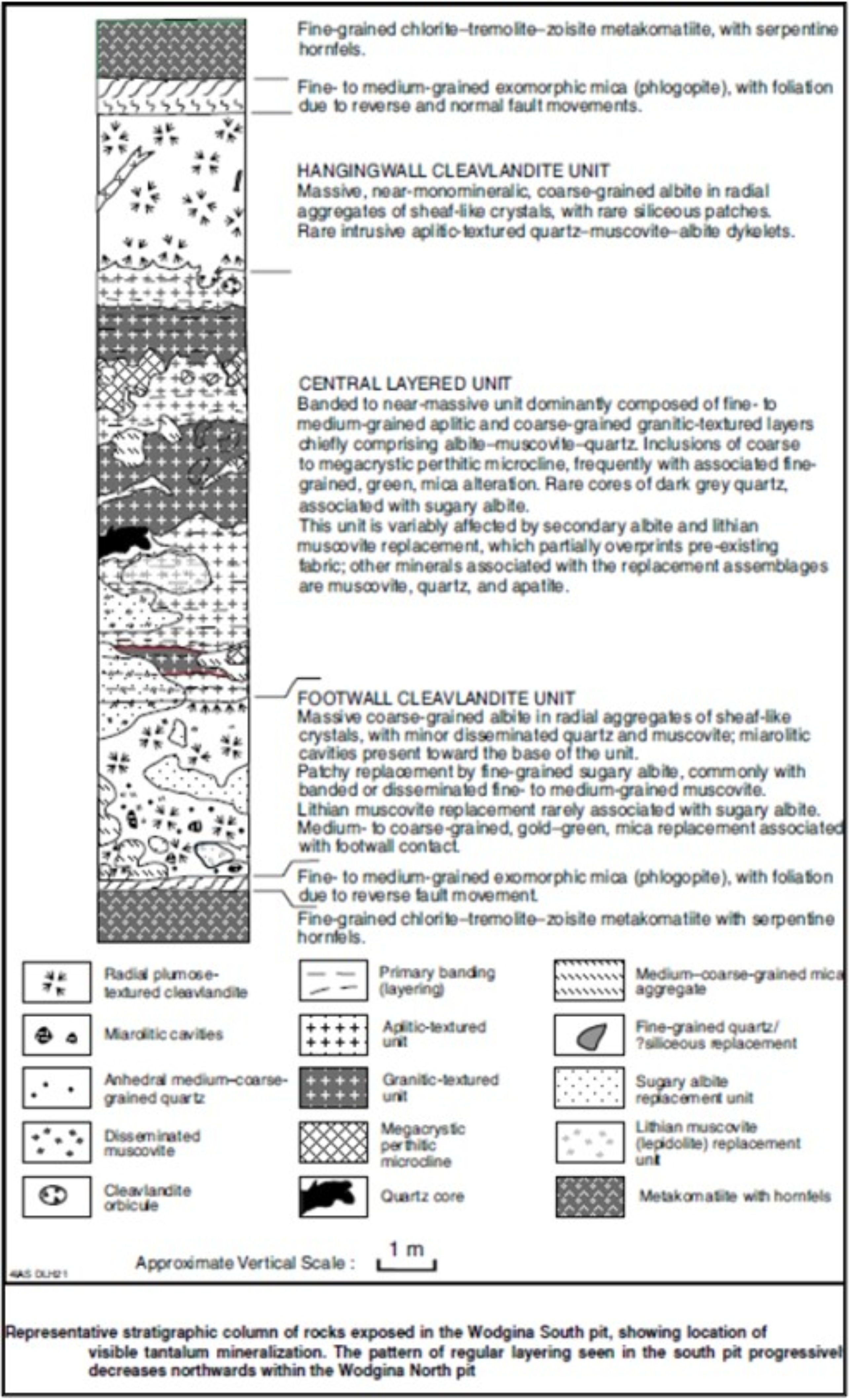

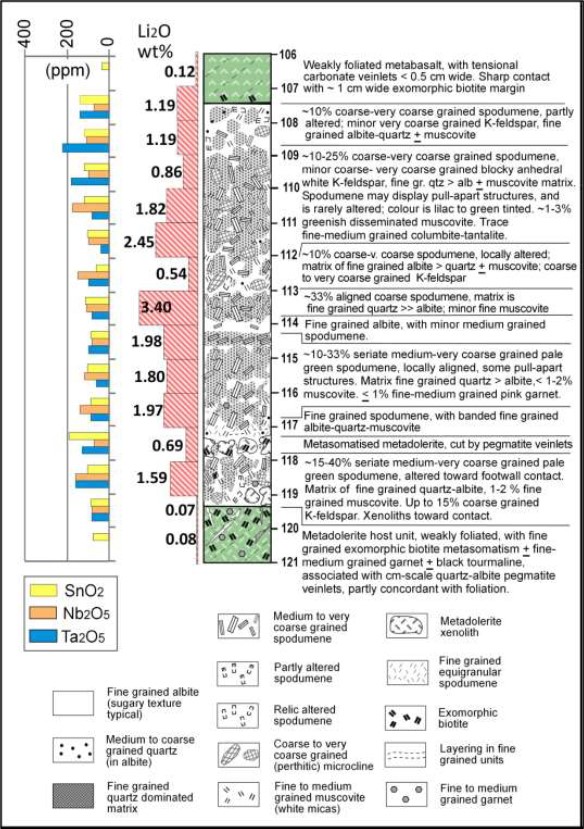

Figure 6-7 and Figure 6-8 illustrate a typical stratigraphic column through the Mt. Cassiterite pit area and an individual pegmatite dike respectively.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 36 |

Source: Sweetapple, 2001

Figure 6-7: Generalized Stratigraphic Column from the Mt. Cassiterite Pit

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 37 |

Source: Sweetapple, et al., 2017

Figure 6-8: Generalized Stratigraphic Column Through Mt. Cassiterite Pegmatite Dyke

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 38 |

7Exploration

7.1Exploration Work (Other Than Drilling)

All exploration work is currently performed via drilling. SRK is not aware of additional surveys (geochemical, geophysical, etc.) which have been performed over the Wodgina site by or on behalf of the registrant.

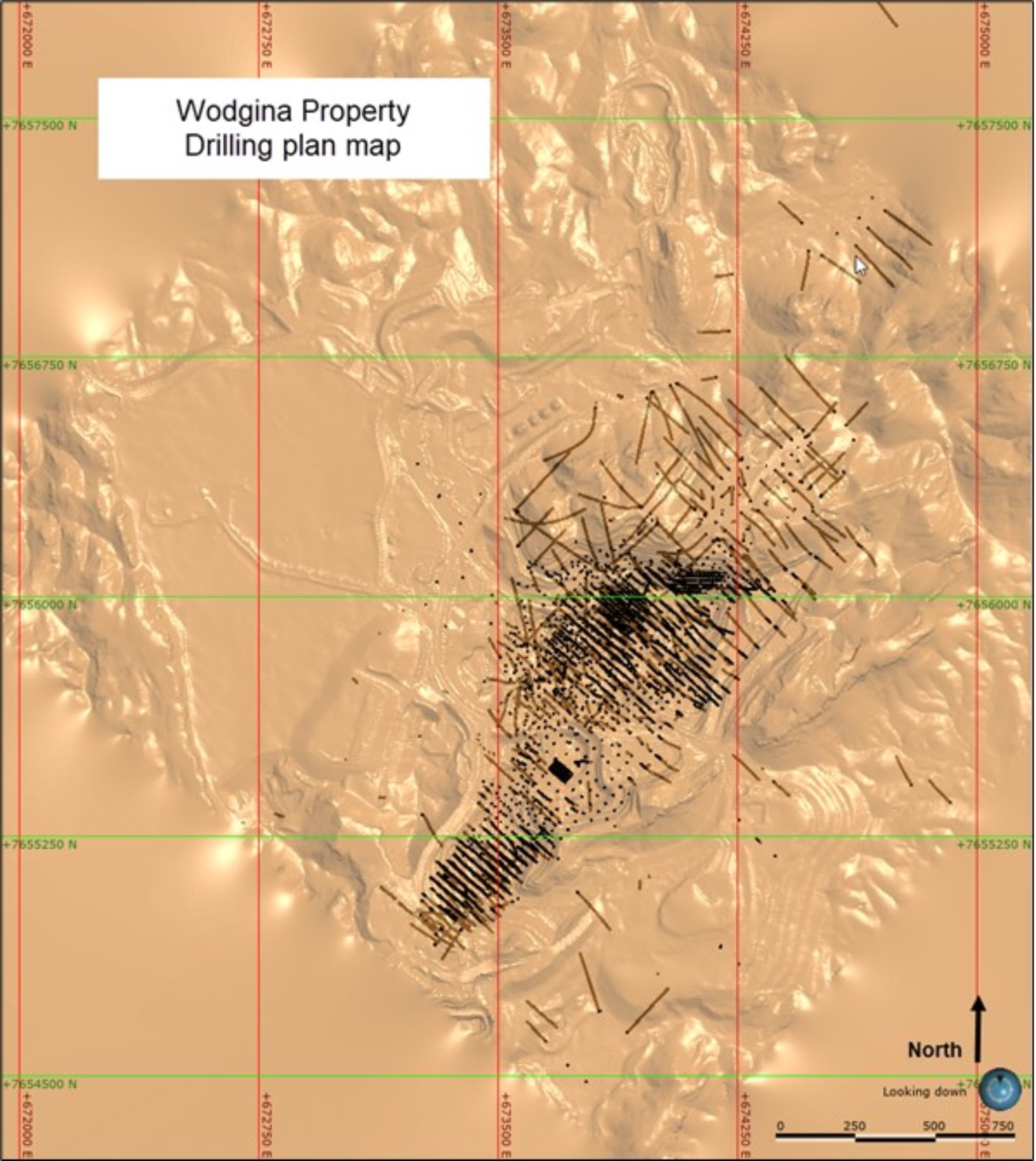

7.2Exploration Drilling

Exploration drilling which is utilized in the geological interpretation and MRE is summarized in the sub-sections below. Considering the history of exploration on the property, there are numerous drillholes pre-1990 that are not utilized as part of any Mineral Resource determination and lack detailed descriptions or documentation, which have been excluded from this report.

7.2.1Drilling Type and Extent

Drilling at the Wodgina property has historically been dominated by RC drilling methods. In addition to RC, both diamond drilling (DDH) and rotary air-blast (RAB) methods have been utilized in a limited capacity for specific purposes such as preliminary exploration, metallurgical, or geotechnical data collections.

Drilling in the Mt. Cassiterite area has been carried out by a number of drilling contractors and by a variety of different methods over the years. Drilling carried out by the Pan West JV included 3,825 m of air track: 1,145 m of RC drilling and 204 m of DDH.

Under GAM, who operated the property in the late 1990s, six development-drilling programs have been completed at the Mt. Cassiterite pit. The first, in 1996, involved a track mounted RC rig completing a 3,464 m drilling program, a resource extension program during 1998 to 99 comprised 17,586 m of RC drilling and 2,225 m of DDH, a further resource extension program in 2001 comprised 18,694 m of RC drilling, A RC infill-drilling program in Mt. Tinstone area commenced in February 2002 and totaled 5,432 m, further resource drilling was conducted in 2002/03 consisting of 12,805 m of RC drilling. As a result of this program, an infill-drilling program was carried out which targeted the East Ridge mining area, totaling 2,948 m.

Additional resource drilling, completed in March 2004, consisted of 3,866 m of RC drilling and later infill drilling for a total of 12,930 m. The 2004 drill campaign was designed to extend the resource to the south of Mt Tinstone, as well as determine the extent of the pegmatite sheets adjacent to the old Wodgina Pit, north of the Mt. Cassiterite mining area. This drilling was conducted by a track-mounted RC drill rig and consisted of 3,866 m. The drilling to the south of Mt Tinstone highlighted a significant extension of the Mt Tinstone pegmatite sheets and was subsequently infill-drilled by two drill rigs (wheel and track-mounted) for a total of 12,930 m.

Concurrent with this drilling, an infill-drilling program was also being carried out in the Mt. Cassiterite area aimed at better defining the nature of the pegmatite sheets. This drilling consisted of 8,984 m.

In 2005, further RC drilling was undertaken to determine the limits of the South Tinstone pegmatite to the south, as well as systematically infill the main Mt. Cassiterite area to achieve at least a 25 m by 25 m pattern. Selected areas within the Mt. Cassiterite area were drilled to 25 m by 12.5 m to provide data for an assessment of the effects of closer spaced drilling. This drilling included 8,458 m of

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 39 |

wheel-mounted RC drilling in Mt. Cassiterite and 2,220 m in South Tinstone. In addition to this, 1,017.5 m and 382.7 m of DDH was conducted in the Mt. Cassiterite and Tinstone areas respectively. The drilling allowed further detail to be placed on the pegmatite physical geology model. The resultant model was used as the basis of an optimization study to allow a revised pit design and schedule to be produced.

A two-staged RC drilling program was undertaken between July and October of 2006. The first stage was aimed at completing the 25 by 25 m grid-based grade control drilling, targeting the deeper portions of the resources that lay within the pit designs associated with the 2006 optimization study. The second stage involved scout resource evaluation of the known extensions to resources outside and down dip of the resources inside the pit design. A total of 7,898 m was drilled from 86 holes. The drilling allowed for the updating and refinement of the 2006 physical geology model of the deposit, as well as further spatial grade definition within the pegmatite sequence. The refinement was the basis of the 2007 MRE. The second stage exploratory RC drilling program consisted of 1,138 m drilled from five holes.

A small metallurgical and geotechnical focused DDH program was completed in 2006 in the Mt. Cassiterite and Mt Tinstone pits and totalled 1,518.7 m of HQ3 core.

In 2008, an infill RC drilling program was carried out in the Mt Tinstone and Mt. Cassiterite pits. The total program involved 1,914 m of drilling for 47 holes and was planned to target gaps in geological understanding at relatively shallow depths (less than 80 m) relevant to the pit floor level development, up until the mine was placed on care and maintenance. The program was based within the resource models of the Mt Tinstone and Mt. Cassiterite areas.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 40 |

Source: GAM, 2010

Figure 7-1: Mt. Magnet Drilling Hydro 150 Drilling RC in the Mt. Cassiterite Pit (During 2008)

August and September of 2010 saw the completion of a further RC infill drilling program, with the intent of improving the understanding of the spatial dispersion and grades of the pegmatites in the resource model between the mine grid sections 20400N to 20800N of the Mt. Cassiterite pit. The general strategy of the program is to provide an improved reconciliation of tonnes and grade for future mining in this area. In all, 27 RC holes were drilled for a total of 2,024 m.

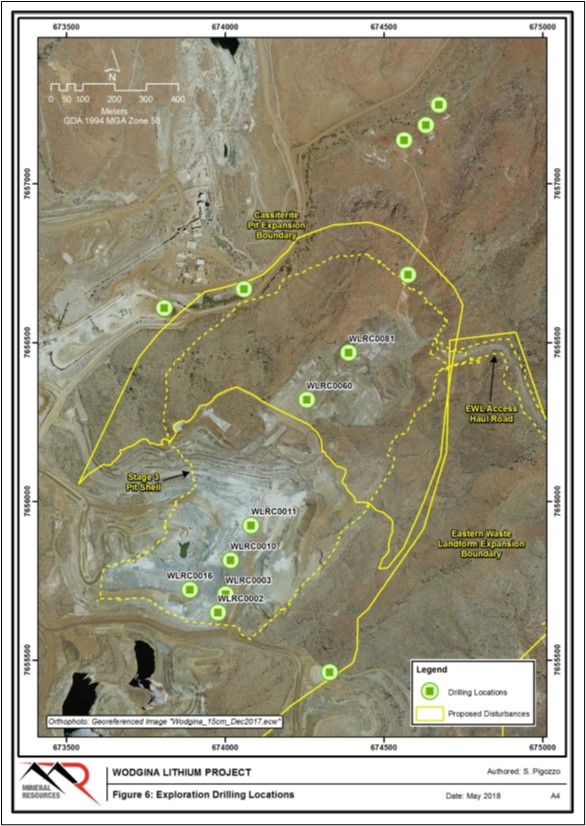

After the property was acquired by MARBL, a RC drilling program of 245 holes was conducted between September 2016 and July 2017 for a total of 61,825 m. MRL directed RC drilling was carried out using a face sampling hammer and a 142 mm diameter bit. Blast hole drilling was carried out with Atlas Copco BH rigs using a 140 mm diameter bit. No additional resource drilling has been completed on the property since 2018.

During 2018, MRL conducted a shallow drill program to assess potential resources in the tailings storage facilities (TSF). The TSF’s have been drilled on a nominal 50 m by 50 m pattern with an Open Hole Percussion Atlas Copco D65 drill rig (Figure 7-2). Hole diameter is nominally 165 mm. While this program has previously been utilized in disclosing Mineral Resources in the TSF (MRL, 2019), SRK notes that the lack of metallurgical testwork provided precludes definition of this material as a Mineral Resource herein.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 41 |

Source: Widenbar and Associates, 2018

Figure 7-2: Atlas Copco D65 Drill Rig

Table 7-1: Recent Drilling Campaigns on the Wodgina Property

| | | | | | | | | | | |

| Year | Type | Length (m) | Areas |

| 1996 | RC | 3,464 | Mt. Cassiterite |

| 1998 | RC | 17,586 | Mt. Cassiterite |

| 1998 | DDH | 2,225 | Mt. Cassiterite |

| 2002 | RC | 5,432 | Tinstone |

| 2002 | RC | 12,805 | Tinstone and Mt. Cassiterite |

| 2002 | RC | 2,948 | Mt. Cassiterite |

| 2004 | RC | 3,866 | Mt. Cassiterite |

| 2006 | RC | 7,898 | Mt. Cassiterite |

| 2008 | RC | 1,914 | Tinstone and Mt. Cassiterite |

| 2010 | RC | 2,024 | Mt. Cassiterite |

| 2016 | RC | 61,825 | Mt. Cassiterite |

Source: Widenbar, 2018

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 42 |

Collar and Downhole Survey

Historic collar locations were surveyed by a differential global positioning system (dGPS) which achieves an accuracy of ± 0.01 m. All down-hole survey data was converted to Wodgina Mine Grid and corrected for magnetic declination. The grid system is MGA Zone 51 (GDA94) for horizontal data and AHD (based on AusGeoid09) for vertical data.

For pre-2008 RC drilling programs, down-hole surveying was conducted using a single shot Eastman down-hole camera, equipped with a “high-dip‟ compass for all vertical holes. For diamond holes, survey shots were taken every 20 m and at the end of hole. The RC holes had camera shots taken at either 40 m or 50 m intervals, as well as at the end of hole. All camera shots were taken inside the 6 m stainless steel starter rod.

For the 2010 and 2012 RC drilling, all except for a few collapsed holes were gyro surveyed to compare the data. Gyro-derived data was recorded at the surface and 5 m intervals down-hole to the end of the hole. Ultimately, the gyro-surveyed data was accepted as the most-accurate of the down-hole surveys and this data was adopted into the database to project the drillhole strings.

During the 2017 and 2018 drilling program, all except for a few collapsed holes were surveyed using a north-seeking gyro survey tool. Gyro-derived data was recorded at the surface and random intervals down-hole to the end of the hole. Reflex North seeking (NS) gyros were used to survey both vertical and inclined drillholes. Ultimately, the NS gyro-surveyed data was accepted as the most-accurate of the down-hole surveys and this data was adopted into the database. Drillhole collars were surveyed by MRL Wodgina mine surveyor on a campaign basis using RTK dGPS.

7.2.2Drilling, Sampling, or Recovery Factors

Pre-2016, Li2O data on the Wodgina property was obtained from re-analysis of historic samples and rejects stored onsite. Drilling, sampling, and analyses were originally focused on tantalum resources prior to 2016.

Prior to 2008, RC chip samples were collected at 1 m intervals and split with a riffle splitter. RC samples were split with a cone splitter after 2008, to produce a sub-sample of 3 to 5 kilograms (kg) for analysis. Sieved chips from the RC drilling were logged geologically at 1 m intervals, with information recorded including lithology, color, mineralogy, grain size, texture, alteration, structure, weathering and hardness. Sample condition and recovery also were noted for each metre. Chips were collected in pre-numbered chip trays and after logging, stored in exploration sea container at Wodgina mine site.

Similar to RC chips, diamond core was logged geologically at 1 m intervals except the lithological boundaries. Lithology, color, mineralogy, grain size, texture, alteration, structure, weathering and hardness were noted, furthermore diamond core was orientated and logged for geotechnical qualities, core recovery, RQD, fractures count per m, and structures were recorded. Sampled core was photographed (dry and wet) and weighted for density calculation.

Samples have also been collected from the MRL drilling campaign conducted between July 2016 and August 2018. An RC rig-mounted cone splitter was used, with samples falling through an inverted cone splitter, splitting the sample into a 90/10 ratio. A 10% off-split is retained in a calico bag. The 90% split residue is stored on ground. All pegmatite intercepts were sampled at 1 m intervals plus 2 m of adjacent waste was sent for laboratory analysis.

| | | | | |

Wodgina_SK1300_Report_515800.040 | December 2022 |

SRK Consulting (U.S.), Inc.

| | | | | |

SEC Technical Report Summary – Wodgina | Page 43 |

Historic sample recoveries are near 100% in the pegmatite, sample loss mainly occurs in shear zones and occasionally on contacts. Most loss is recorded at the start of holes, near collars. MRL recoveries are almost all logged as 80%. There is a low probability of preferential loss of sample having an effect on the grade of pegmatites. RC recoveries are recorded as a percentage based on visual and weight estimates of the sample.

When moist or wet ground conditions were experienced in historic drilling, the cyclone was washed out between each sample and run further to ensure no inter-sample contamination. The rig had a dust collection system that involved the injection of water into the sample pipe before the sample reached the cyclone. This water injection prevented fines from being lost out of the top of the cyclone. This system was employed to minimize dust fines being released into the atmosphere in the work area and to minimize the possibility of the sample being positively biased by the loss of the lighter minerals such as quartz, feldspar, and mica, thus effectively concentrating the heavier ore minerals such as tantalite.

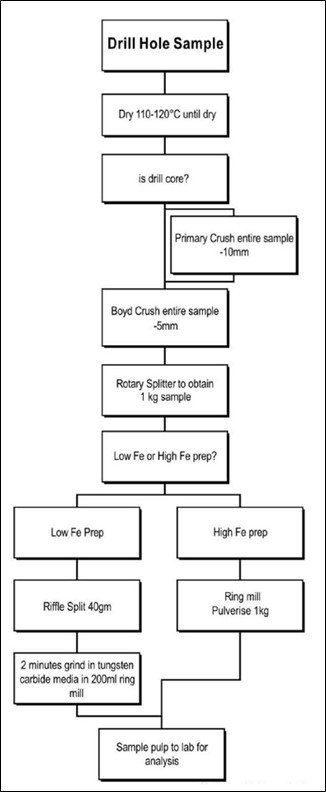

RC chips were dried at 100°C. All samples below approximately 4 kg were totally pulverized in LM5’s to nominally 85% passing a 75-micron (μm) screen. The few samples generated above 4 kg were crushed to less than 6 mm and riffle split first prior to pulverization.

Drill core samples are also collected sequentially in pre-numbered sample bags after cutting with a diamond saw. The integrity and continuity of the core string is maintained by reassembling the core in the tray. If any apparent geological discontinuities are noted within or at the end of core runs these are resolved by the logging geologist.

All HQ3 core pegmatite intercepts were quartered lengthwise using a diamond core-saw, with one quarter of the core for the pegmatite intercepts sent for XRF analysis. Selected intervals of most of the pegmatite intercepts (in the HQ3 core) were then sampled (as half-core) for metallurgical analysis.

All NQ2 core was geologically logged and split lengthwise into half core using a diamond core-saw, with half core samples sent for XRF analysis.

All diamond drill core assay samples were taken at regular 1 m intervals or at smaller intervals to conform to logged pegmatite contacts.

Commercially prepared certified reference materials (CRM) were inserted amongst the drill samples.

MRL 2018 Drill report:

A nominal 2 kg to 3 kg RC sample was collected for each metre. Samples were collected using a static cone splitter mounted below the cyclone; the material falling through the cone splitter was split in 90/10 ratio. 10% off-split was retained in a pre-numbered calico bag with the remaining residue collected in buckets and dumped on the ground in sequence adjacent to the hole.

All pegmatite intercepts were sampled at 1m intervals along with 2 m into the footwall and hangingwall of adjacent waste and delivered to the NAGROM Laboratory in Perth for analysis; samples outside the pegmatite except adjacent waste were not assayed.

After geological login of a NQ core a sample spread sheet was created with the sample intervals. 1m intervals in pegmatite zones adjusted by lithological contacts on footwall and hanging wall plus approximately 2 m of waste on each side were sampled. The core was cut in half, put in pre-

| | | | | |

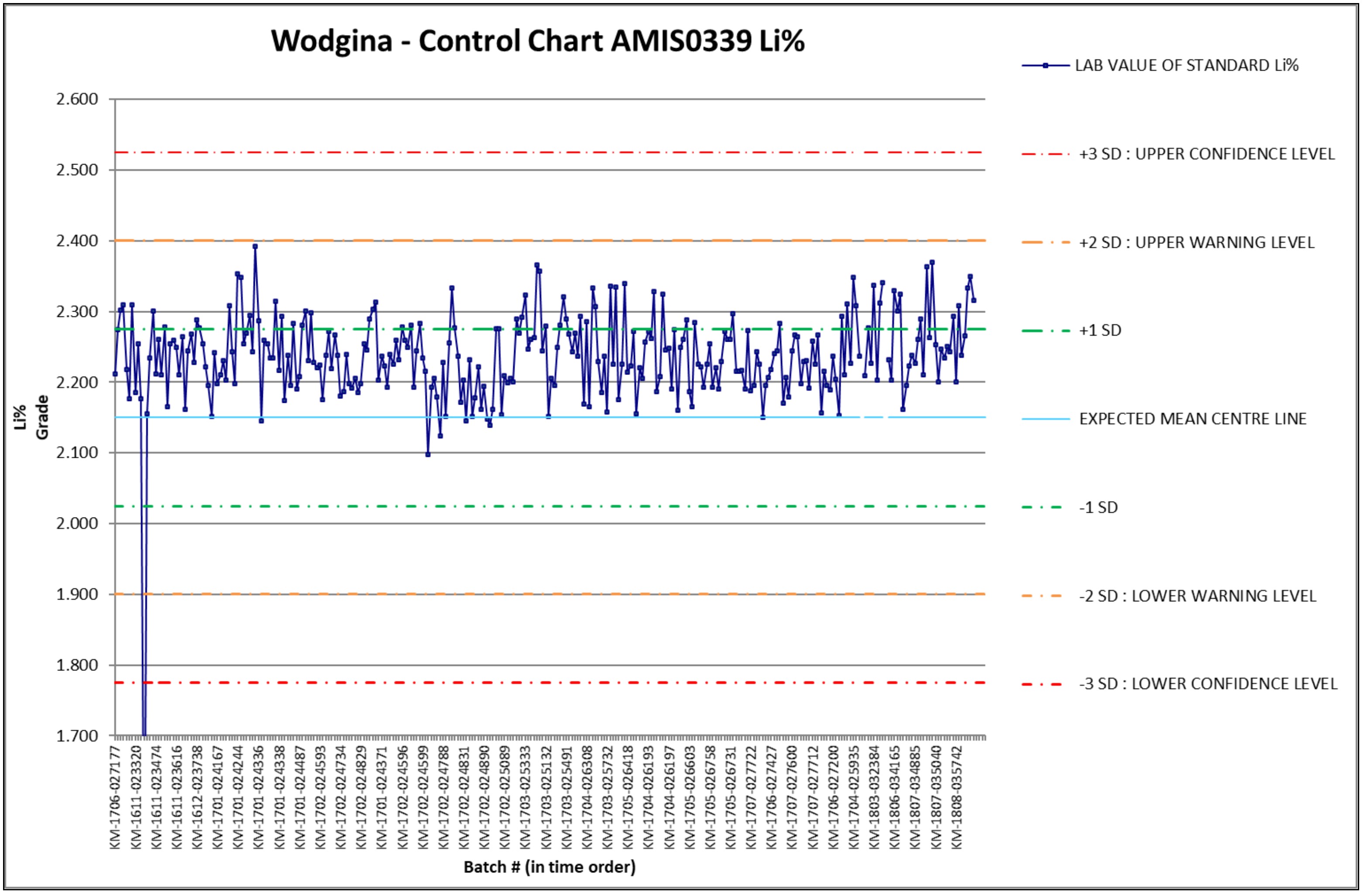

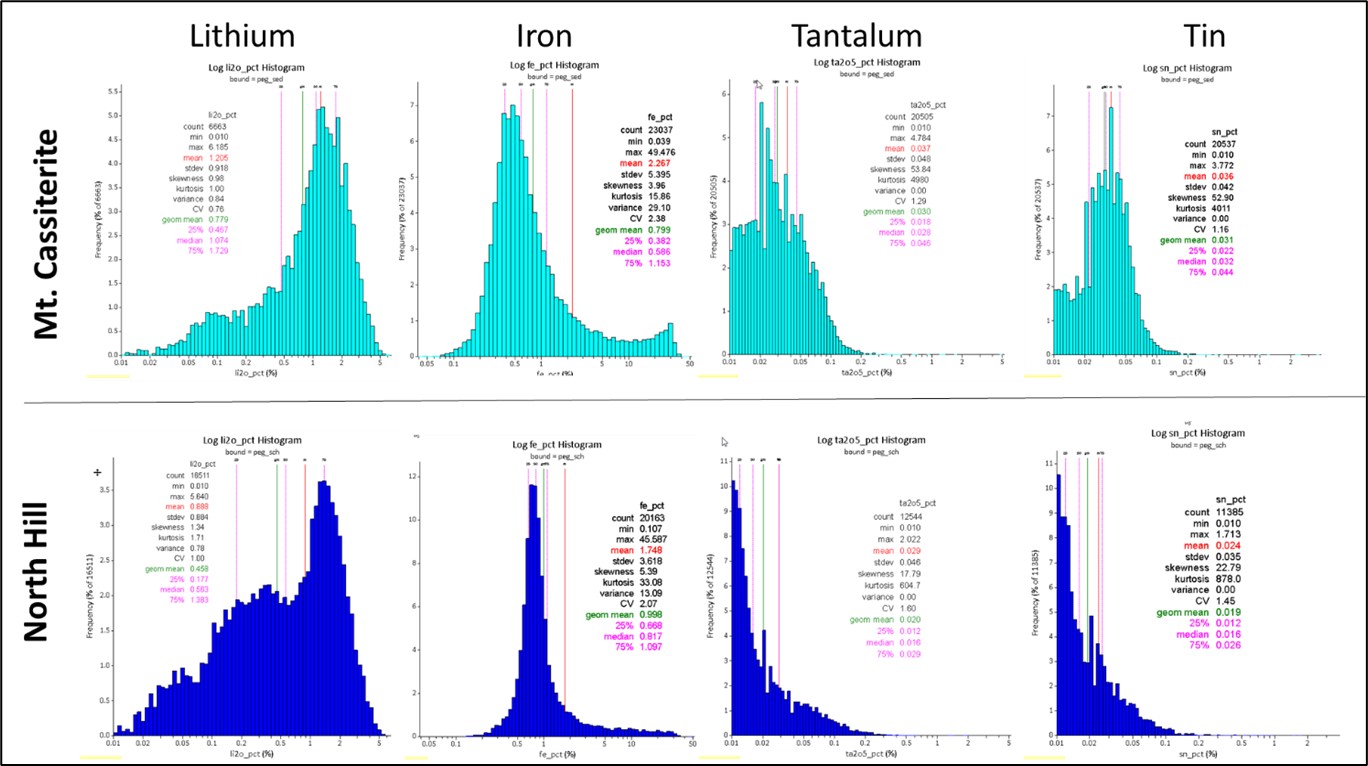

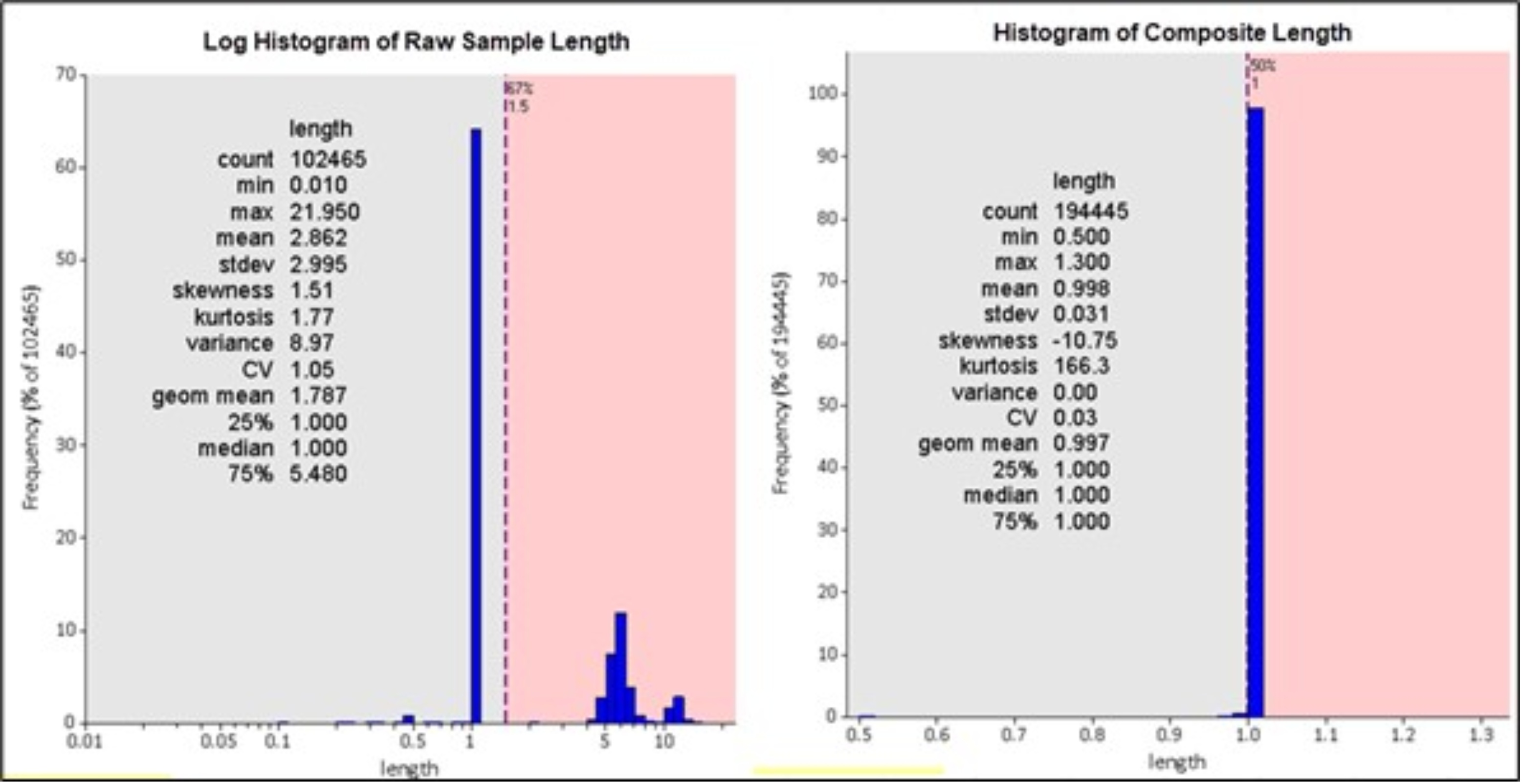

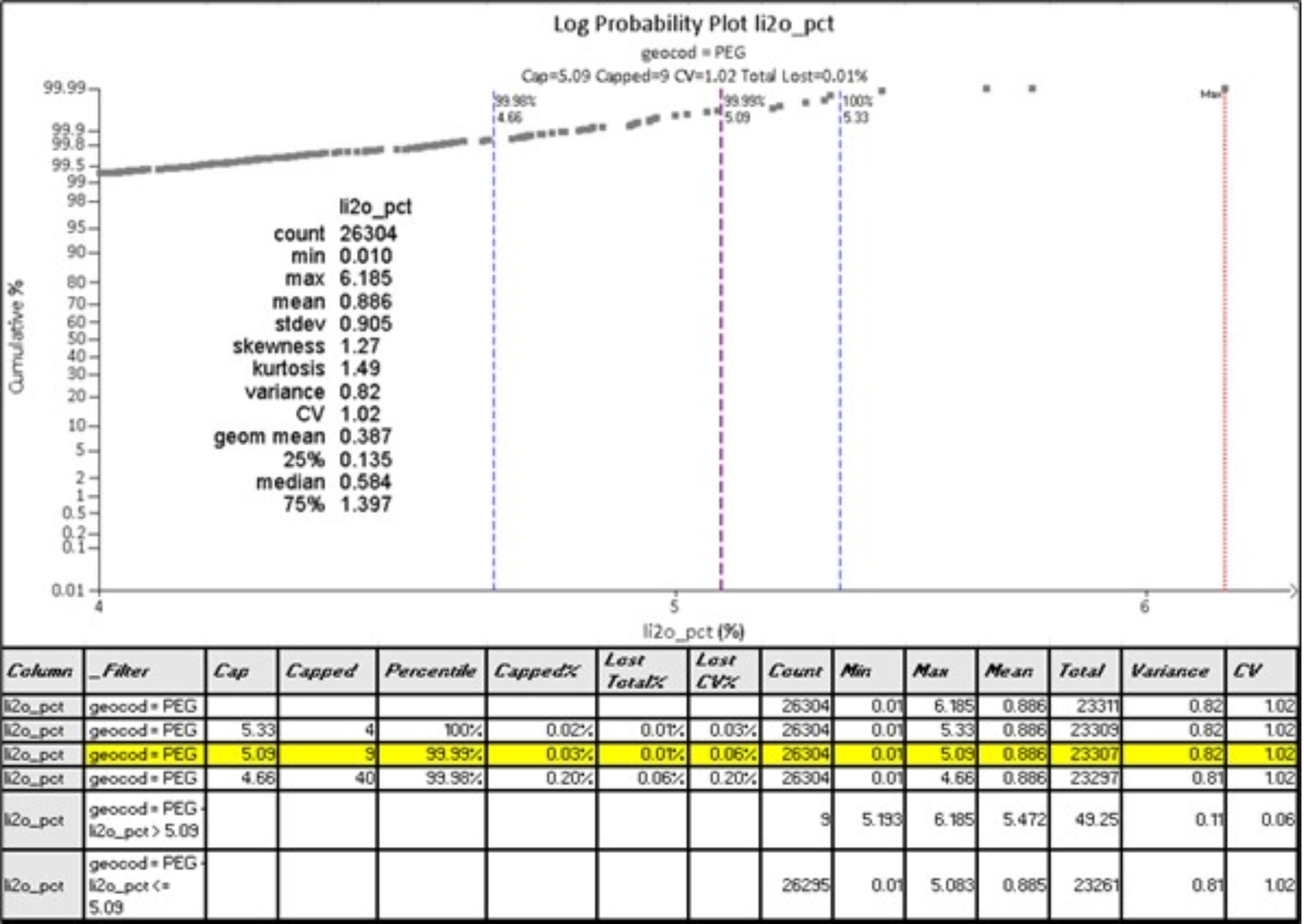

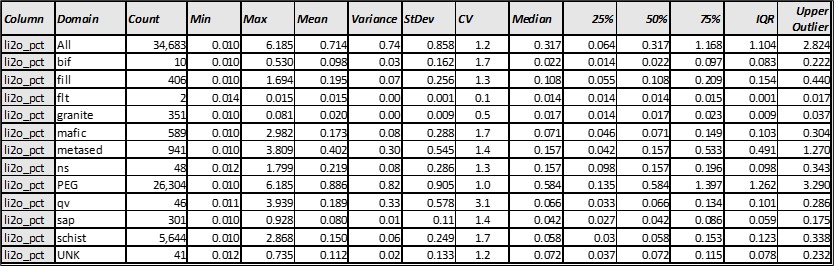

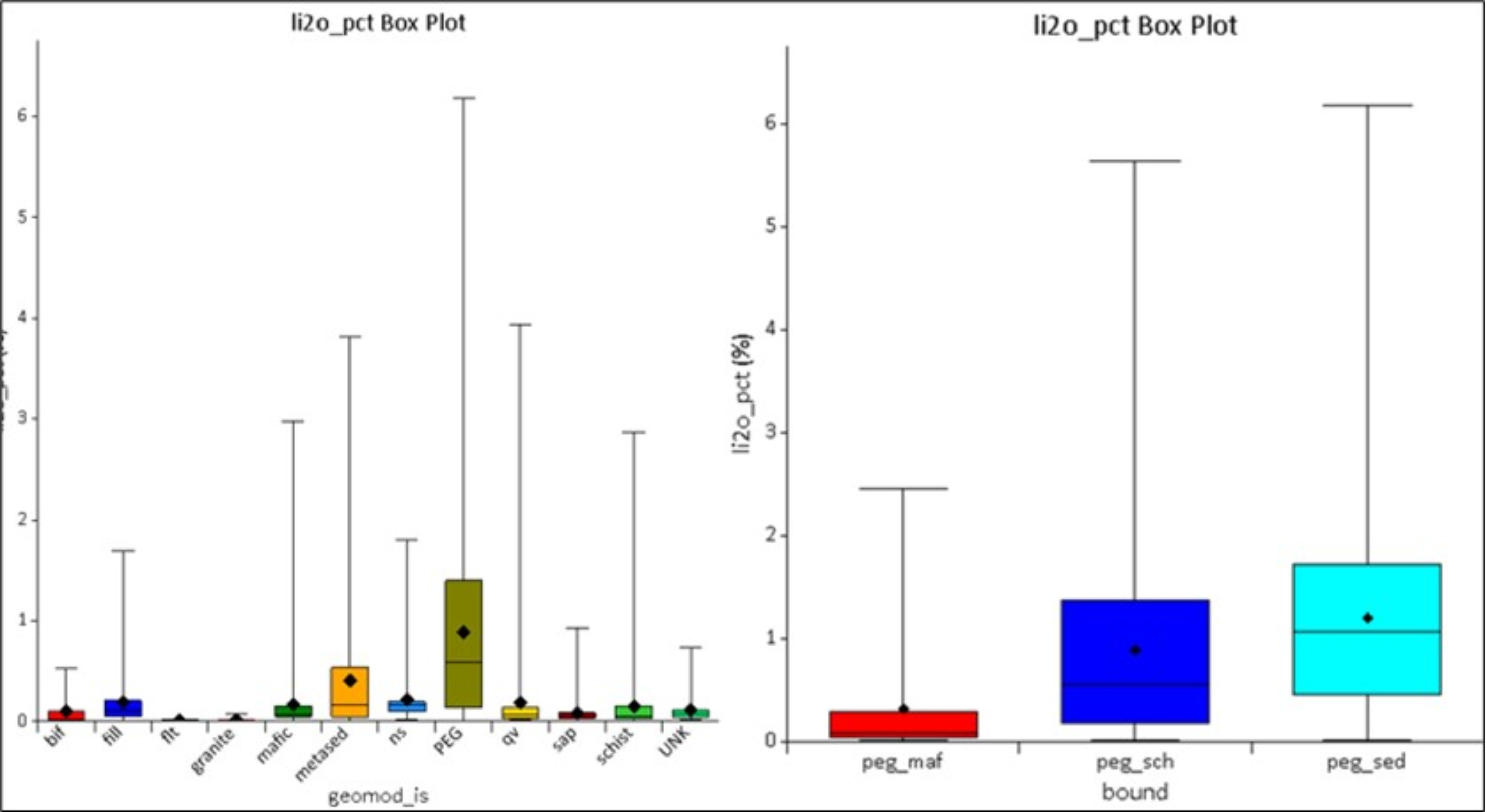

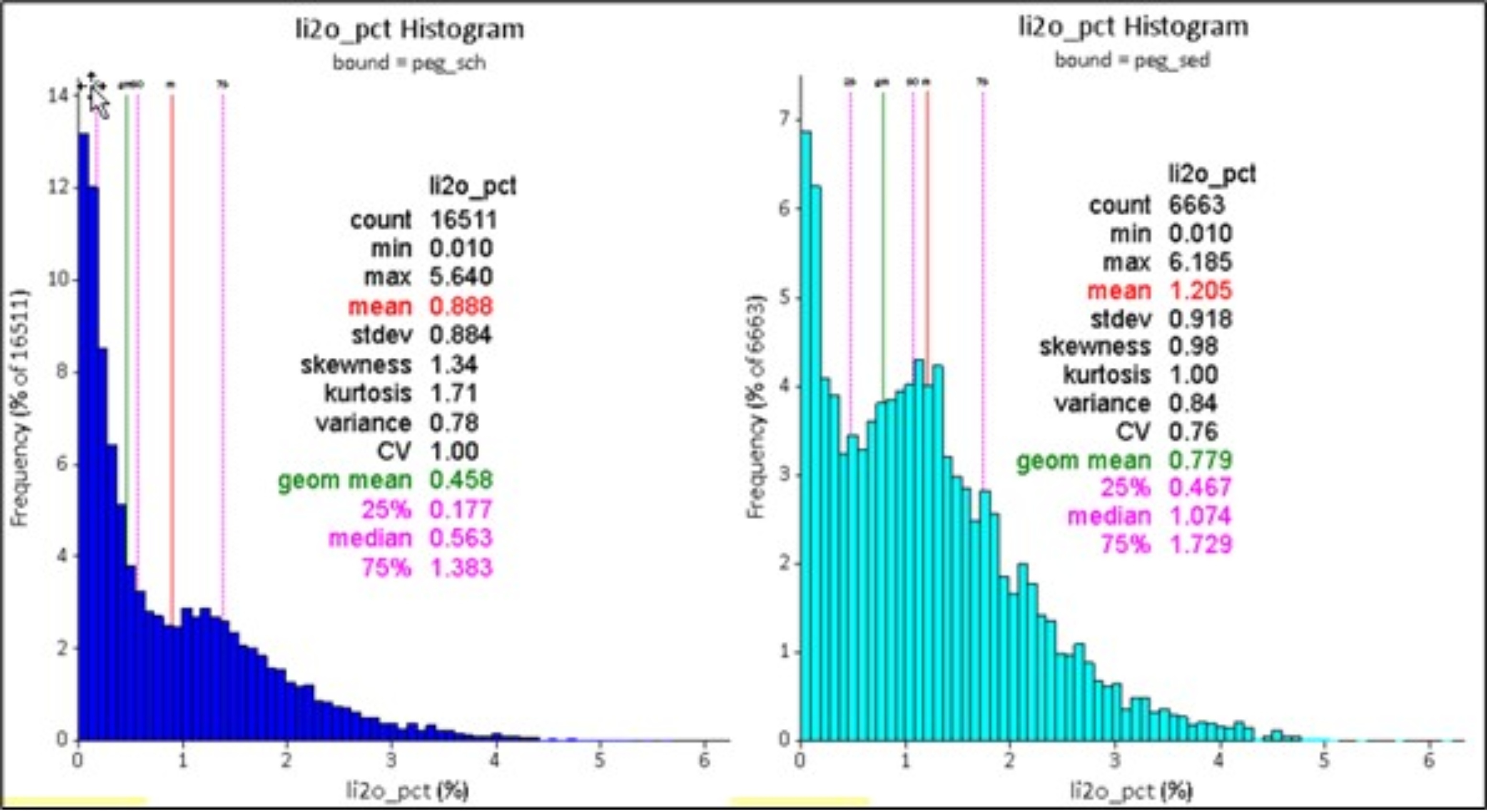

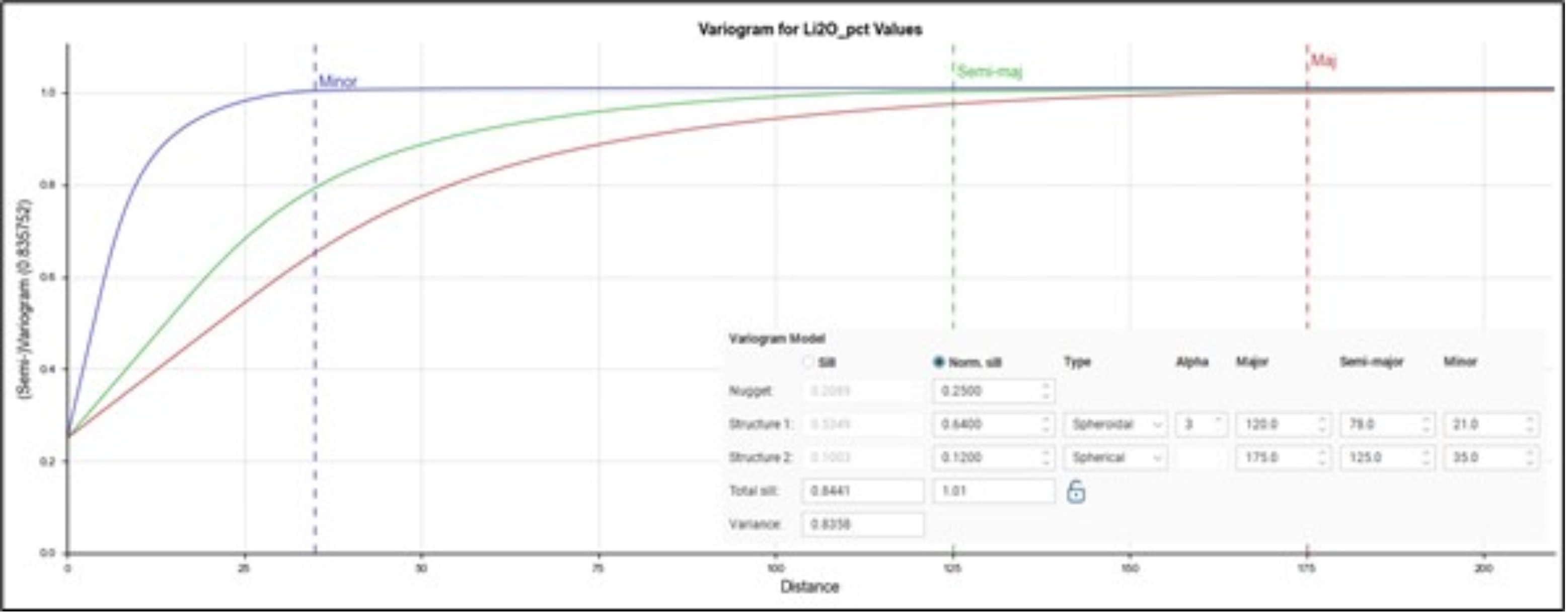

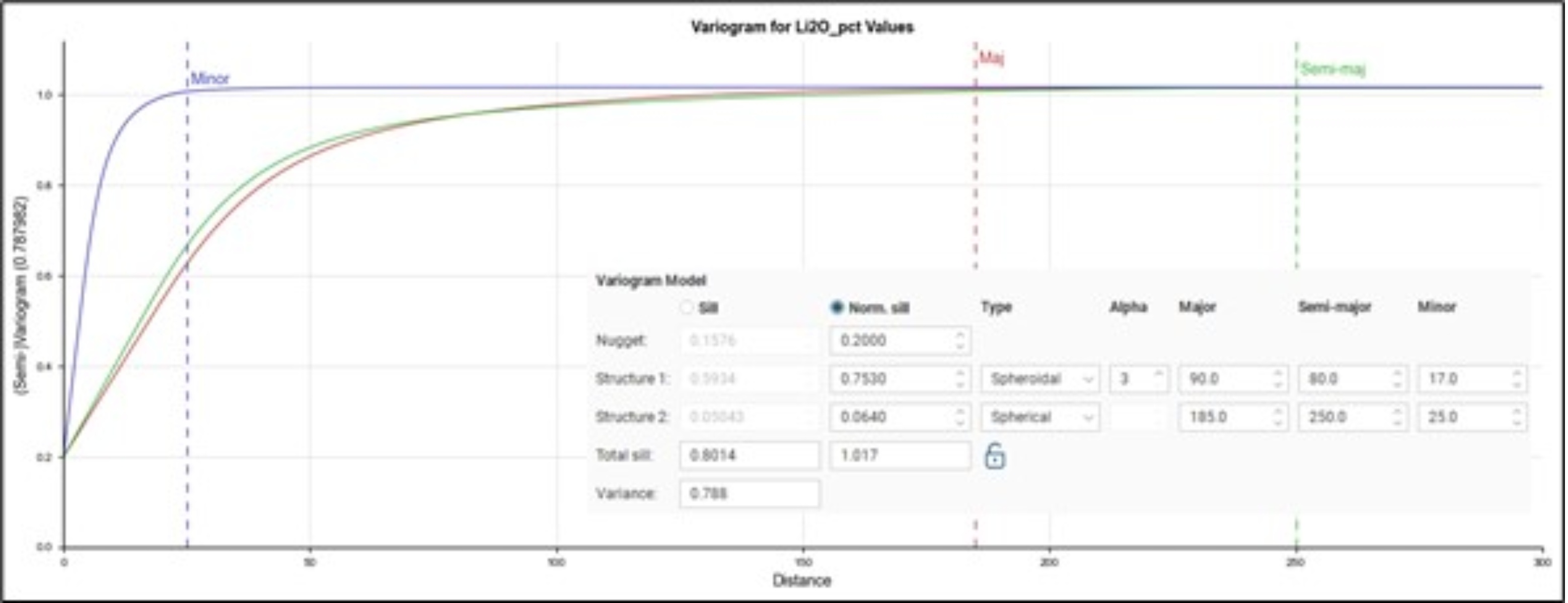

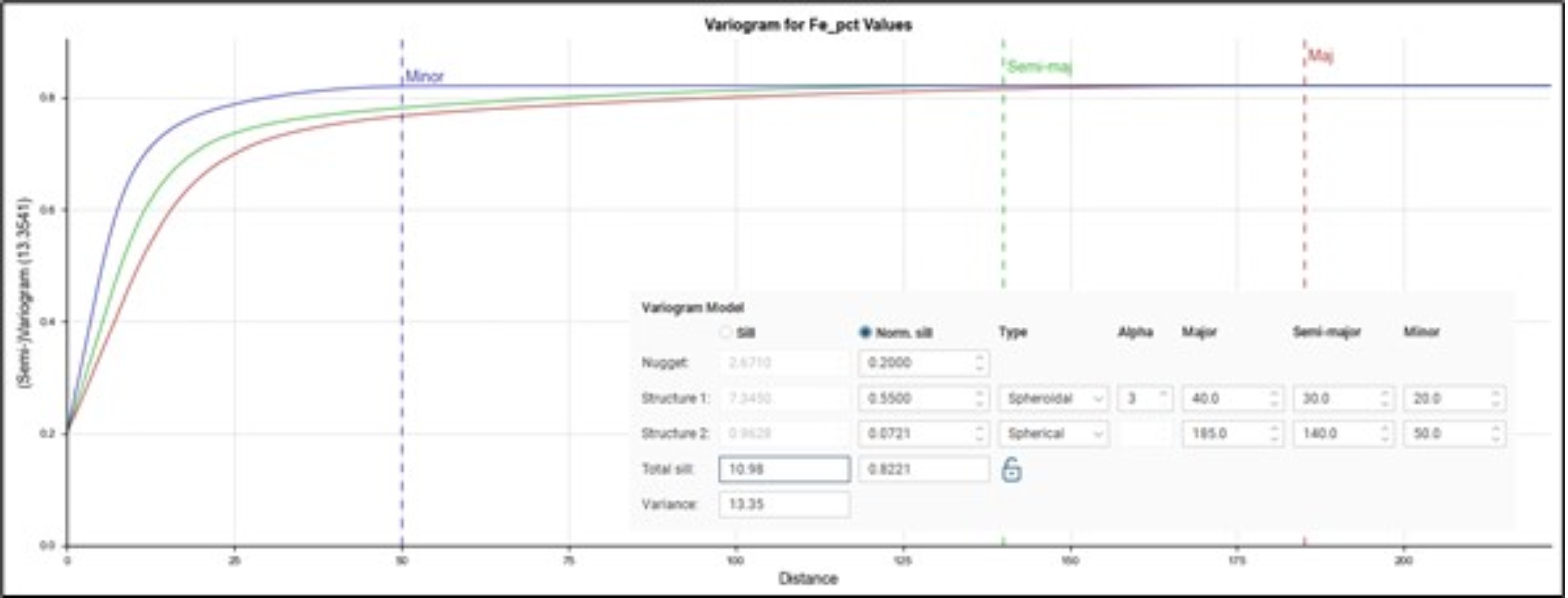

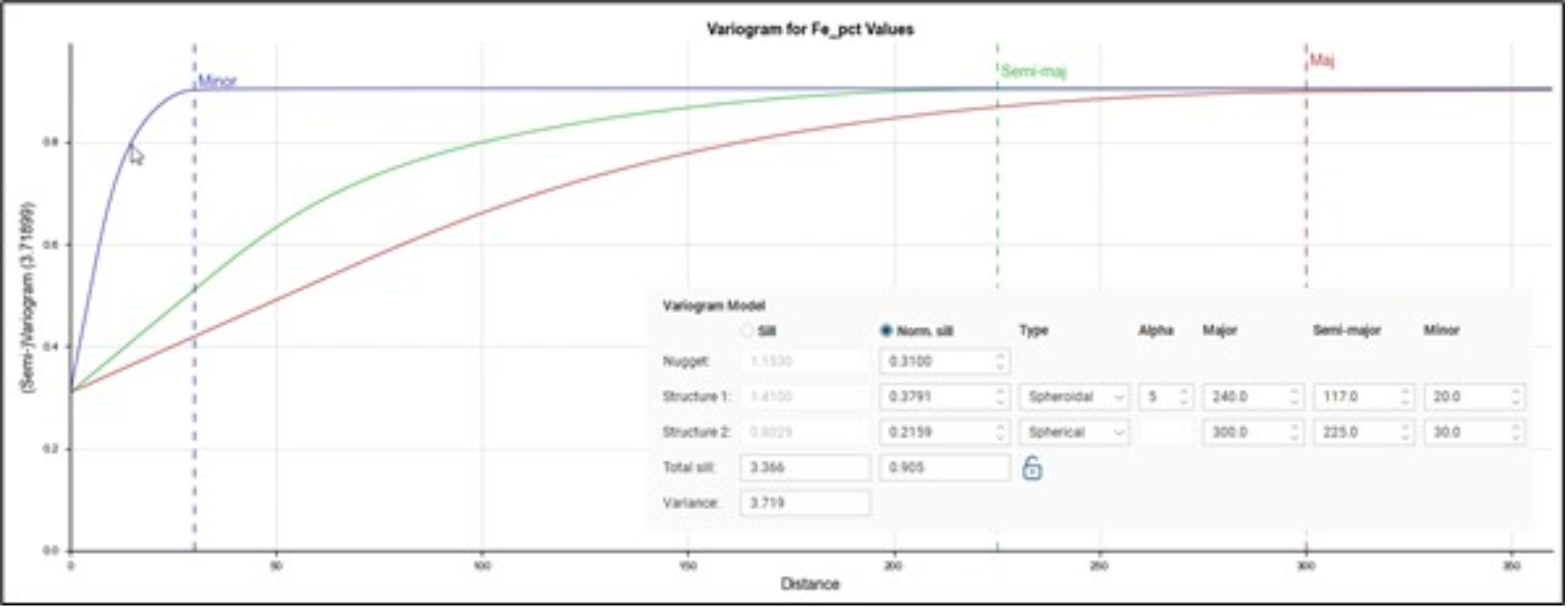

Wodgina_SK1300_Report_515800.040 | December 2022 |